Abstract

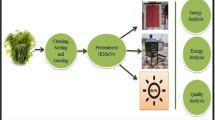

Cardamom, also known as the “Queen of Spices,” is the world’s oldest recognized spice with a high market value for its dried final product. In this work, the drying kinetics of small cardamom (cv. Njallani) has been studied using a solar and a heat pump dryer. Before drying, the produce was pre-treated in sodium carbonate (Na2CO3) at 1%, 2%, and 3%. The treated small cardamom samples are dried as a single and double layer at 40, 45, and 50 °C. The maximum temperature observed inside the solar dryer is 80 °C, resulting in a faster drying rate than the heat pump dryer but poor quality and greenness ((a*) − 0.8 to − 3.25) even after being pre-treated with Na2CO3. The heat pump dryer showed a constant and falling rate drying period at all the temperatures, with the highest drying rate at 50 °C. It required at least 12 h to dry the cardamom samples from 455.5 to 10.2% moisture content as a single layer. The temperature and the bed thickness have the maximum influence on the water activity of dried cardamom (0.54–0.64). A higher greenness value and essential oil percentage are obtained from the small cardamom dried in the heat pump dryer at 45 °C.The COP and SMER are found best at 50 °C. Four different models are used to predict the moisture ratio curve of the dried cardamom, with the quadratic model having the highest R2 value.

Similar content being viewed by others

Data availability

All data are available upon request.

Abbreviations

- %:

-

Percentage

- > :

-

Greater than

- a*:

-

Greenness-redness

- AC:

-

Alternating current

- ANOVA:

-

Analysis of variance

- a w :

-

Water activity

- b*:

-

Bluish-yellowness

- COP:

-

Coefficient of performance

- cv. :

-

Cultivar

- E b :

-

Power consumption by blower

- E c :

-

Power consumption by compressor and blower

- EO:

-

Essential oil

- g:

-

Gram

- h:

-

Hour

- ha:

-

Hectare

- hp:

-

Horse power

- HPD:

-

Heat pump dryer

- IS:

-

Indian standard

- kg:

-

Kilogram

- kJ:

-

Kilojoule

- kW:

-

Kilowatt

- L*:

-

Darkness-lightness

- LDPE:

-

Low-density polyethylene

- LPG:

-

Liquid petroleum gas

- M:

-

Instantaneous moisture content at any time

- m2 :

-

Meter square

- MATLAB:

-

Matrix laboratory

- Me :

-

Equilibrium moisture content

- min:

-

Minutes

- Mm:

-

Millimeter

- Mo :

-

Initial moisture content

- MR:

-

Moisture ratio

- Na2CO3 :

-

Sodium carbonate

- °C:

-

Degree Celsius

- R :

-

Drying rate

- R 2 :

-

Coefficient of determination

- R22 (CHCIF2):

-

Difluoromonochloro methane

- rpm:

-

Revolution per minute

- SMER:

-

Specific moisture extraction rate

- TR:

-

Tonnes of refrigeration

- USD:

-

United States dollar

- V :

-

Voltage

- V EO :

-

The volume of essential oil

- Ver.:

-

Version

- w.b.:

-

Wet basis

- W m :

-

Weight of water evaporated

- W s :

-

Mass of sample (g)

- α:

-

Alpha

- ± :

-

Plus or minus

- Q c :

-

Condenser heating capacity (kW)

- P c :

-

Compression power consumption (kW)

References

Aktaş M, Ceylan I, Yilmaz S (2009) Determination of drying characteristics of apples in a heat pump and solar dryer. Desalination 239:266–275

Aktaş M, Taşeri L, Şevik S, Gülcü M, UysalSeçkin G, Dolgun EC (2019) Heat pump drying of grape pomace: performance and product quality analysis. Drying Technol 37(14):1766–1779. https://doi.org/10.1080/07373937.2018.1536983

Arun KR, Kunal G, Srinivas M, Sujith Kumar CS, Mohanraj M, Jayaraj S (2020) Drying of untreated Musa nendra and Momordica charantia in a forced convection solar cabinet dryer with thermal storage. Energy 192:116697

Ashokkumar K, Murugan M, Dhanya MK, Warkentin TD (2020) Botany, traditional uses, phytochemistry and biological activities of cardamom [Elettaria cardamomum (L.) Maton]–A critical review. J Ethnopharmacol 246:112244

Balakrishnan M, Raghavan GSV, Sreenarayanan VV, Viswanathan R (2011) Batch drying kinetics of cardamom in a two-dimensional spouted bed. Drying Technol 29:1283–1290

Das A, Sharangi AB (2018) Postharvest technology and value addition of spices. In: Sharangi A (ed) Indian Spices. Springer, Cham, Switzerland, pp 249–76

Dash S, Choudhury S, Dash KK (2022) Energy and exergy analyses of solar drying of black cardamom (Amomum subulatom Roxburgh) using indirect type flat plate collector solar dryer. J Food Process Eng 45(4):e14001. https://doi.org/10.1111/jfpe.14001

Dash S, Dash KK, Choudhury S (2021) Evaluation of energy efficiency and moisture diffusivity for convective drying of large cardamom. In: IOP conference series: Materials science and engineering, vol 102. IOP Publishing, Bristol, England. https://doi.org/10.1088/1757-899X/1020/1/012016

Hamzaa R, Osman N (2012) Using of coffee and cardamom mixture to ameliorate oxidative stress induced in γ-irradiated rats. Biochem Ana Biochem 1:113–119

Hii CL, Law CL, Suzannah S (2012) Drying kinetics of the individual layer of cocoa beans during heat pump drying. J Food Eng 108:276–282

Ilangantileke SG, Karunaratne C, Senanyake M (1993) Effects of chemical pretreatment and drying temperatures on the commercial quality of cardamom (Elettaria cardamomum). J Food Qual 16:451–470

Jeevarathinam G, Pandiselvam R, Pandiarajan T, Preetha P, Balakrishnan M, Thirupathi V, Anjineyulu K (2021) Infrared assisted hot air dryer for turmeric slices: effect on drying kinetics and quality parameters. LWT-Food Sci Technol 144:111258

Jeevarathinam G, Pandiselvam R, Pandiarajan T, Preetha, P, Krishnakumar T, Balakrishnan M, Thirupathi V, Ganapathy S, Amirtham D (2021) Design, development, and drying kinetics of infrared assisted hot air dryer for turmeric slices. J Food Process Eng 45(6):e13876. https://doi.org/10.1111/jfpe.13876

Kuan M, Shakir Y, Mohanraj M, Belyayev Y, Jayaraj S, Kaltayev A (2019) Numerical simulation of a heat pump assisted solar dryer for continental climates. J Renew Energy 143:214–225

Lakshmi DVN, Muthukumar P, Layek A, Nayak PK (2018) Drying kinetics and quality analysis of black turmeric (Curcuma caesia) drying in a mixed mode forced convection solar dryer integrated with thermal energy storage. Renew Energy 120:23–34

Lopez A, Iguaz A, Esnoz A, Virseda P (2000) Thin layer drying behaviour of vegetable wastes from wholesale market. Drying Technol 18:995–1006

Mandal S, Tanna HR, Nath A, Singh RK, Kumar A (2018) Development of low-cost portable biomass fired dryer for cardamom drying in hilly areas. J Environ Biol 39(6):1021–1026

Mathew KM, Ranjanan R, Rithin VC, Bhat SK, Remashree AB (2022) Genetic resources of small cardamom. In: Priyadarshan P, Jain SM (eds) Cash Crops, Springer, Cham. Switzerland, pp. 559–608. https://doi.org/10.1007/978-3-030-74926-2_15

Mishra S, Sahu JK, Sanwal N, Sharma N (2021) Hot air convective drying of small cardamom (Elettaria cardamomum Maton): evaluation of drying, color, and aroma kinetics. J Food Process Eng 44(4):e13649

Mohammadi I, Tabatabaekoloor R, Motevali A (2019) Effect of air recirculation and heat pump on mass transfer and energy parameters in drying of kiwifruit slices. Energy 170:149–158. https://doi.org/10.1016/j.energy.2018.12.099

Mohanraj M (2014) Performance of a solar-ambient hybrid source heat pump drier for copra drying under hot-humid weather conditions. Energy Sustain Dev 23:165–169

Mohanraj M, Chandrasekar P, Sreenarayanan VV (2008) Performance of a heat pump drier for copra drying. Proc Inst Mech Eng Part A J Power Energy 222:283–287

Mohanraj M, Belyayev Y, Jayaraj S, Kaltayev A (2018) Research and developments on solar assisted compression heat pump systems - a comprehensive review (Part A: modelling and modifications). Renew Sustain Energy Rev 83:90–123

Mohanraj M, Belyayev Y, Jayaraj S, Kaltayev A (2018) Research and developments on solar assisted compression heat pump systems - a comprehensive review (Part-B: applications). Renew Sustain Energy Rev 83:124–155

Muller J, Heindl A (2006) Drying of medicinal plants. In: Bogers RJ, Craker LE, Lange D (eds) Medicinal and Aromatic Plants. Springer, Berlin/Heidelberg, Germany, pp 237–252

Nair SK (2006) The problems of production and marketing in the cardamom industry with particular reference to Kerala. University of Calicut, India

Olivero-Verbel J, González-Cervera T, Guette-Fernandez T, Jaramillo-Colorado B, Stashenko, (2010) Chemical composition and antioxidant activity of essential oils isolated from Colombian plants Braz. J Pharmacogn 20:568–574

Ozdemir M, Devres YO (1999) The thin layer drying characteristics of hazelnuts during roasting. J Food Eng 42:225–233

Panchariya PC, Popovic D, Sharma AL (2002) Thin-layer modeling of black tea drying process. J Food Eng 52:349–357

Parthasarathy VA, Prasath D (2012) Cardamom. Manual - Indian Institute of Spices Research, India

Ponkham K, Meeso N, Soponronnarit S, Siriamornpun S (2012) Modeling of combined far-infrared radiation and air drying of a ring shaped-pineapple with/without shrinkage. Food Bioprod Process 90:155–164

Rajkumar S, Muthupandi M, Sabeer MM, Arungokul M, Karuppuchamy S (2015) Electrical dryer for small cardamom by revolving type drying chamber aimed at effective dry. Int J Mod Trends Eng Sci 2(3):1–4

Savan E, Küçükbay FZ (2013) Essential oil composition of Elettaria cardamomum Maton. J Appl Biol Sci 7(3):42–45

Seveda MS, Jhajharia D (2012) Design and performance evaluation of solar dryer for drying of large cardamom (Amommumsubulatum). J Renew Sustain Energy 4(6):63129 (2–11)

Shreelavaniya R, Kamaraj S, Subramanian S, Pangayarselvi R, Murali S, Bharani A (2021) Experimental investigations on drying kinetics, modeling and quality analysis of small cardamom (Elettaria cardamomum) dried in solar-biomass hybrid dryer. Sol Energy 227:635–644

Tajudin NH, Tasirin SM, Ang WL, Rosli MI, Lim LC (2019) Comparison of drying kinetics and product quality from convective heat pump and solar drying of Roselle calyx. Food Bioprod Process 118:40–49. https://doi.org/10.1016/j.fbp.2019.08.012

Thomas M, Menon PP (2022) Forecasting of small cardamom price using sarima model. J Res ANGRAU 50(4):116–123. https://doi.org/10.58537/jorangrau.2022.50.4.12

Triwahyudi S, Suratmo B, Nelwan LO, Wulandani D (2015) The effect of temperature and relative humidity on the characteristics of thin layer drying of local cardamom (Amomum cardamomum Wild). Indian J Sci Res Technol 3(1):12–21

Vadiraj BA (2004) New concepts in cardamom drying. Spice India 17(3):27–28

Vijayan AK, Kumar Pradip, Remashree, (2018) Small cardamom production technology and future prospects. Int J Agric 16(10):6943–6948

Wang J, Li Y, Lu Q, Hu Q, Liu P, Yang Y, Li G, Xie H, Tnag H (2021) Drying temperature affects essential oil yield and composition of black cardamom (Amomum tsao-ko). J Ind Crops Prod 168:113580

Winarsi H, Sasongko ND, Purwanto A, Nuraeni I (2014) Effect of cardamom leaves extract as antidiabetic, weight lost and hypocholesterolemic to alloxan-induced Sprague Dawley diabetic rats. Int Food Res J 21:2253–2261

Acknowledgements

The authors are thankful to ICAR-AICRP on PHET, Ludhiana, India for the financial support of this work.

Funding

This work received financial support from the ICAR-AICRP on PHET, Ludhiana, India.

Author information

Authors and Affiliations

Contributions

Jikky Jayakumar—conceptualization, methodology, investigation; G. Jeevarathinam—conceptualization, methodology, investigation, I.P. Sudagar—methodology, investigation; V. Arun Prasath—methodology, investigation, writing original draft; Punit Singh—methodology, investigation, writing original draft; S. Dinesh Kumar—investigation, resources, original draft, review and editing; R. Pandiselvam—conceptualization, investigation, resources, original draft, review and editing.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

All authors agreed on the publication of this research work.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jayakumar, J., Jeevarathinam, G., Sudagar, I.P. et al. Performance analysis of solar and heat pump dryer of small cardamom (Elettaria Cardamomum Maton) using energy analysis, drying kinetics, and quality. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04177-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04177-x