Abstract

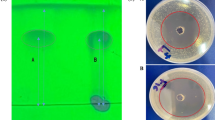

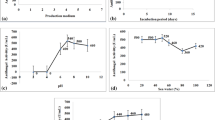

Cyclosporin A (CyA) is a neutral cyclic polypeptide as an immunosuppressive drug that usually was produced from the culture medium of Tolypocladium inflatum. In this study, screening of six environmental components (dairy sludge (%), molasses (%), glucose (g/mL), malt extract (%), TES (mL), and ammonium sulfate (%)) and five culture parameters (temperature (°C), pH, time (h), shaking (rpm), and inoculation (mL)) of CyA production based on Plackett–Burman experimental design was performed. The most important factors affecting fermentation including carbon source (dairy sludge, glucose), nitrogen source (malt extract, ammonium sulfate), and trace elements solution (TES) were optimized using central composite rotatable design (CCRD). Based on the results obtained from the statistical design, the culture medium with combinations of 46.47% of carbon source, 9.56% of nitrogen source, and 1.49 mL of mineral matter was selected as optimal conditions. The treatments of ultrasound (US), high hydrostatic pressure (HHP), and pulsed electric field (PEF) were applied to the culture medium on the 1st, 5th, and 10nth days of fermentation. Scanning electron microscopy (SEM) images related to treatment were prepared to evaluate the morphology of the fungus, and the bioassay method was used to compare the amount of CyA production in terms of clear zone creation of each plate. The amount of CyA in the optimal was measured by high performance liquid chromatography (212 ppm) and US stress on the 10th day of fermentation (334 ppm), respectively, which indicates a twofold increase in the production of CyA. The results show the optimized culture medium containing dairy sludge waste with US treatment can have a suitable efficiency for the production of CyA.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included within the article.

References

Lichtiger S, Present DH, Kornbluth A, Gelernt I, Bauer J, Galler G et al (1994) Cyclosporine in severe ulcerative colitis refractory to steroid therapy. N Engl J Med 330:1841–1845

Wenger R (1983) Method for the total synthesis of cyclosporins, novel cyclosporins and novel intermediates and methods for their production. Google Patents

Anjum T, Azam A, Irum W (2012) Production of cyclosporine A by submerged fermentation from a local isolate of Penicillium fellutanum. Indian J Pharm Sci 74:372

Price DA, Eng H, Farley KA, Goetz GH, Huang Y, Jiao Z et al (2017) Comparative pharmacokinetic profile of cyclosporine (CsA) with a decapeptide and a linear analogue. Org Biomol Chem 15:2501–2506

Khan T (2017) Cyclosporin a production from Tolilpocladium infatum. Gen Med (Los Angeles) 5:294. https://doi.org/10.4172/2327-5146.1000294

Rao HY, Kamalraj S, Jayabaskaran C (2020) Fascinating fungal endophytes associated with medicinal plants: recent advances and beneficial applications. Microb Endophytes 263–89

Franke EK, Luban J (1996) Inhibition of HIV-1 replication by cyclosporine A or related compounds correlates with the ability to disrupt the Gag–cyclophilin A interaction. Virology 222:279–282

Moussaïf M, Jacques P, Schaarwächter P, Budzikiewicz H, Thonart P (1997) Cyclosporin C is the main antifungal compound produced by Acremonium luzulae. Appl Environ Microbiol 63:1739–1743

Nakajima H, Hamasaki T, Nishimura K, Kondo T, Kimura Y, Udagawa S-i et al (1988) Isolation of 2-acetylamino-3-hydroxy-4-methyloct-6-enoic acid, a derivative of the “C9-amino acid” residue of cyclosporins, produced by the fungus Neocosmospora vasinfecta EF Smith. Agric Biol Chem 52:1621–3

Azam A, Anjum T, Irum W (2012) Trichoderma harzianum: a new fungal source for the production of cyclosporin. Bangladesh J Pharmacol 7:33–5

Irum W, Anjum T (2012) Production enhancement of Cyclosporin ‘A’by Aspergillus terreus through mutation. Afr J Biotech 11:1736–1743

Ismaiel A (2017) Production of the immunosuppressant cyclosporin A by a new soil isolate, Aspergillusfumigatus, in submerged culture. Appl Microbiol Biotechnol 101(8):3305

Tanseer S, Anjum T (2011) Modification of c and n sources for enhanced production of cyclosporin’a’by Aspergillus Terreus. Braz J Microbiol 42:1374–1383

Hodge KT, Krasnoff SB, Humber RA (1996) Tolypocladium inflatum is the anamorph of Cordyceps subsessilis. Mycologia 88:715–719

Corrales M, Toepfl S, Butz P, Knorr D, Tauscher B (2008) Extraction of anthocyanins from grape by-products assisted by ultrasonics, high hydrostatic pressure or pulsed electric fields: a comparison. Innov Food Sci Emerg Technol 9:85–91

Sun Y, Zhang M, Fang Z (2020) Efficient physical extraction of active constituents from edible fungi and their potential bioactivities: a review. Trends Food Sci Technol 105:468–482

Martínez J, Schottroff F, Haas K, Fauster T, Sajfrtová M, Álvarez I et al (2020) Evaluation of pulsed electric fields technology for the improvement of subsequent carotenoid extraction from dried Rhodotorula glutinis yeast. Food Chem 323:126824

Martín-Belloso O, Sobrino-López A (2011) Combination of pulsed electric fields with other preservation techniques. Food Bioprocess Technol 4:954–968

Awad T, Moharram H, Shaltout O, Asker D, Youssef M (2012) Applications of ultrasound in analysis, processing and quality control of food: a review. Food Res Int 48:410–427

Leong T, Ashokkumar M, Kentish S (2011) The fundamentals of power ultrasound—a review. Acoust Aust 39:54–63

Survase SA, Kagliwal LD, Annapure US, Singhal RS (2011) Cyclosporin A—a review on fermentative production, downstream processing and pharmacological applications. Biotechnol Adv 29:418–435

Sun L, Liu L, Yang L, Wang Y, Dabbour M, Mintah BK et al (2021) Effects of low-intensity ultrasound on the biomass and metabolite of Ganoderma lucidum in liquid fermentation. J Food Process Eng 44:e13601

Murthy MR, Mohan E, Sadhukhan A (1999) Cyclosporin-a production by Tolypocladium inflatum using solid state fermentation. Process Biochem 34:269–280

Singh AK, Singh G, Gautam D, Bedi MK (2013) Optimization of dairy sludge for growth of Rhizobium cells. BioMed Res Int 2013:845264. https://doi.org/10.1155/2013/845264

Porwal H, Mane A, Velhal S (2015) Biodegradation of dairy effluent by using microbial isolates obtained from activated sludge. Water Resources and Industry 9:1–15

Shi W, Healy MG, Ashekuzzaman S, Daly K, Leahy JJ, Fenton O (2021) Dairy processing sludge and co-products: a review of present and future re-use pathways in agriculture. J Clean Prod 314:128035

Falah F, Vasiee A, Alizadeh Behbahani B, Tabatabaee Yazdi F, Mortazavi SA (2021) Optimization of gamma-aminobutyric acid production by Lactobacillus brevis PML1 in dairy sludge-based culture medium through response surface methodology. Food Sci Nutr 9:3317–3326

Ismaiel AA (2010) El-Sayed E-SA, Mahmoud AA Some optimal culture conditions for production of cyclosporin a by Fusarium roseum. Braz J Microbiol 41:1112–23

Balaraman K, Mathew N (2006) Optimization of media composition for the production of cyclosporin A by Tolypocladium species. Indian J Med Res 123:525

Survase SA, Annapure US, Singhal RS (2009) Statistical optimization of cyclosporin A production on a semi-synthetic medium using Tolypocladium inflatum MTCC 557. Global J Biotechnol Biochem 4:184–192

Lee M-J, Lee H-N, Han K-B, Kim E-S (2008) Spore inoculum optimization to maximize cyclosporin a production in Tolypocladium niveum. J Microbiol Biotechnol 18:913–917

Kannan N, Kalaichelvan P (2007) Production of immunosuppressant drug cyclosporin A from Tolypocladium inflatum in presence of L-valine. Allelopath J 19:549–553

Margaritis A, Chahal PS (1989) Development of a fructose based medium for biosynthesis of cyclosporin-A by Beauveria nivea. Biotech Lett 11:765–768

Survase SA, Bacigalupi C, Annapure US, Singhal RS (2009) Use of coconut coir fibers as an inert solid support for production of cyclosporin A. Biotechnol Bioprocess Eng 14:769–774

Survase SA, Shaligram NS, Pansuriya RC, Annapure US, Singhal RS (2009) A novel medium for the enhanced production of cyclosporin A by Tolypocladium inflatum MTCC 557 using solid state fermentation. J Microbiol Biotechnol 19:462–467

Sobrino-Lopez A, Martin-Belloso O (2006) Enhancing inactivation of Staphylococcus aureus in skim milk by combining high-intensity pulsed electric fields and nisin. J Food Prot 69:345–353

Ulug SK, Jahandideh F, Wu J (2021) Novel technologies for the production of bioactive peptides. Trends Food Sci Technol 108:27–39

Dellarosa N, Frontuto D, Laghi L, Dalla Rosa M, Lyng JG (2017) The impact of pulsed electric fields and ultrasound on water distribution and loss in mushrooms stalks. Food Chem 236:94–100

Ben Ammar J, Lanoisellé JL, Lebovka N, Van Hecke E, Vorobiev E (2011) Impact of a pulsed electric field on damage of plant tissues: effects of cell size and tissue electrical conductivity. J Food Sci 76:E90–E97

Galván-D’Alessandro L, Carciochi RA (2018) Fermentation assisted by pulsed electric field and ultrasound: A review. Fermentation 4(1):1

Martínez JM, Delso C, Álvarez I, Raso J (2020) Pulsed electric field-assisted extraction of valuable compounds from microorganisms. Compr Rev Food Sci Food Saf 19:530–552

Toepfl S, Mathys A, Heinz V, Knorr D (2006) Potential of high hydrostatic pressure and pulsed electric fields for energy efficient and environmentally friendly food processing. Food Rev Intl 22:405–423

Naderi N, House JD, Pouliot Y, Doyen A (2017) Effects of high hydrostatic pressure processing on hen egg compounds and egg products. Compr Rev Food Sci Food Saf 16:707–720

Amanor-Atiemoh R, Zhou C, Abdullaleef Taiye M, Sarpong F, Wahia H, Amoa-Owusu A et al (2020) Effect of ultrasound-ethanol pretreatment on drying kinetics, quality parameters, functional group, and amino acid profile of apple slices using pulsed vacuum drying. J Food Process Eng 43:e13347

Chikari F, Han J, Wang Y, Ao W (2020) Synergized subcritical-ultrasound-assisted aqueous two-phase extraction, purification, and characterization of Lentinus edodes polysaccharides. Process Biochem 95:297–306

Dabbour M, He R, Mintah B, Xiang J, Ma H (2019) Changes in functionalities, conformational characteristics and antioxidative capacities of sunflower protein by controlled enzymolysis and ultrasonication action. Ultrason Sonochem 58:104625

Dahroud BD, Mokarram RR, Khiabani MS, Hamishehkar H, Bialvaei AZ, Yousefi M et al (2016) Low intensity ultrasound increases the fermentation efficiency of Lactobacillus casei subsp. casei ATTC 39392. Int J Biol Macromolecules 86:462–7

Dai C, Xiong F, He R, Zhang W, Ma H (2017) Effects of low-intensity ultrasound on the growth, cell membrane permeability and ethanol tolerance of Saccharomyces cerevisiae. Ultrason Sonochem 36:191–197

Liu R, Li W, Sun L-Y, Liu C-Z (2012) Improving root growth and cichoric acid derivatives production in hairy root culture of Echinacea purpurea by ultrasound treatment. Biochem Eng J 60:62–66

Tizazu BZ, Roy K, Moholkar VS (2018) Mechanistic investigations in ultrasound-assisted xylitol fermentation. Ultrason Sonochem 48:321–328

Wang T-Y, Wilson EK, Machtaler S, Willmann KJ (2013) Ultrasound and microbubble guided drug delivery: mechanistic understanding and clinical implications. Curr Pharma Biotechnol 14:743–52

Ojha KS, Mason TJ, O’Donnell CP, Kerry JP, Tiwari BK (2017) Ultrasound technology for food fermentation applications. Ultrason Sonochem 34:410–417

Delalande A, Kotopoulis S, Postema M, Midoux P, Pichon C (2013) Sonoporation: mechanistic insights and ongoing challenges for gene transfer. Gene 525:191–199

Pitt WG, Ross SA (2003) Ultrasound increases the rate of bacterial cell growth. Biotechnol Prog 19:1038–1044

Sulaiman AZ, Ajit A, Yunus RM, Chisti Y (2011) Ultrasound-assisted fermentation enhances bioethanol productivity. Biochem Eng J 54:141–150

Nitayavardhana S, Shrestha P, Rasmussen ML, Lamsal BP, van Leeuwen JH, Khanal SK (2010) Ultrasound improved ethanol fermentation from cassava chips in cassava-based ethanol plants. Biores Technol 101:2741–2747

Schläfer O, Sievers M, Klotzbücher H, Onyeche TI (2000) Improvement of biological activity by low energy ultrasound assisted bioreactors. Ultrasonics 38:711–716

Lanchun S, Bochu W, Zhiming L, Chuanren D, Chuanyun D, Sakanishi A (2003) The research into the influence of low-intensity ultrasonic on the growth of S cerevisiaes. Colloids Surfaces B: Biointerfaces 30:43–9

Jiang B, Pan J, Xie R, Qin J, He R, Ma H (2015) Screening of strains used for producing rapeseed peptide and degradation of glucosinolates by solid-state fermentation. Sci Technol Food Ind 36:164–168

Huang G, Tang Y, Sun L, Xing H, Ma H, He R (2017) Ultrasonic irradiation of low intensity with a mode of sweeping frequency enhances the membrane permeability and cell growth rate of Candida tropicalis. Ultrason Sonochem 37:518–528

Nyborg WL (2000) Biological effects of ultrasound: development of safety guidelines: Part I: personal histories. Ultrasound Med Biol 26:911–964

Zhang Z, Xiong F, Wang Y, Dai C, Xing Z, Dabbour M et al (2019) Fermentation of Saccharomyces cerevisiae in a one liter flask coupled with an external circulation ultrasonic irradiation slot: Influence of ultrasonic mode and frequency on the bacterial growth and metabolism yield. Ultrason Sonochem 54:39–47

Sainz Herrán N, Casas López JL, Sánchez Pérez JA, Chisti Y (2008) Effects of ultrasound on culture of Aspergillus terreus. J Chem Technol Biotechnol 83:593–600

Funding

This work was supported by funds from the Ferdowsi University of Mashhad (Grant # 3/53741) and the Iran National Science Foundation (Grant #99028947).

Author information

Authors and Affiliations

Contributions

Fereshteh Falah: conceptualization, experimental tests, and writing-original draft. Seyed Ali Mortazavi: review and editing and formal analysis. Abolghasem Danesh: resources administration, review, and editing the manuscript. Farideh Tabatabaee Yazdi: validation and writing and editing the manuscript. Mohammad Ramezani: data curation and editing. All authors read and approved the manuscript.

Corresponding authors

Ethics declarations

Ethical approval

This article does not contain any studies with human participants performed by any of the authors.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Falah, F., Mortazavi, S.A., Danesh, A. et al. Production of cyclosporin A by Tolypocladium inflatum using dairy waste medium: optimization and investigation of the effect of ultrasound, high hydrostatic pressure, and pulsed electric field treatments on the morphology of fungus. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-03899-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-03899-2