Abstract

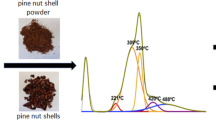

The nutshell waste streams (pine nut shells (PNS), walnut shells (WNS), and almond shells (ANS)) were effectively converted into biocarbon materials employing slow pyrolysis in a fixed bed horizontal reactor at 500 and 900 °C with a 10 °C min−1 heating rate and 60 min holding time. The acquired biocarbon materials were then characterized to understand the influence of pyrolysis temperature on their ash content, elemental composition, thermal stability, graphitic content, functionality, surface morphology, and electrical conductivity. The obtained results established that the pyrolysis temperature has a leading impact on the yield and physicochemical properties of biocarbon. Increasing the pyrolysis temperature of PNS, WNS, and ANS from 500 to 900 °C, respectively, decreases the biocarbon yields from 32, 28, and 28 wt.% to 28, 24, and 25 wt.%. Furthermore, the increasing pyrolysis temperature increases the carbon content and purity of PNS, WNS, and ANS biocarbon due to the elimination of oxygen. Thus, the electrical conductivity of PNS, WNS, and ANS biocarbon acquired at 900 °C was significantly higher than 500 °C. Overall, it can be surmised that biocarbon prepared at a higher temperature is preferable for material applications due to its greater characteristics.

Similar content being viewed by others

References

Chen N, Pilla S (2021) A comprehensive review on transforming lignocellulosic materials into bio carbon and its utilization for composites applications. Composites Part C: Open Access 100225. https://doi.org/10.1016/j.jcomc.2021.100225

Saini S, Chand P, Joshi A (2021) Biomass derived carbon for supercapacitor applications: review. J. Energy Storage 39:102646. https://doi.org/10.1016/j.est.2021.102646

Senanu S, Solheim A (2021) Biocarbon in the aluminium industry: a review. Light Met.:649–656. https://doi.org/10.1007/978-3-030-65396-5_87

Fahmy TY, Fahmy Y, Mobarak F, El-Sakhawy M, Abou-Zeid RE (2020) Biomass pyrolysis: past, present, and future. Environ. Dev. Sustainability 22(1):17–32. https://doi.org/10.1007/s10668-018-0200-5

Fahmy Y, Fahmy TYA, Mobarak F, El-Sakhawy M, Fadl MH (2017) Agricultural residues (wastes) for manufacture of paper, board, and miscellaneous products: background overview and future prospects. Int. J. Chem. Tech. Res. 10(2):424–448. https://doi.org/10.5539/ibr.v10n8p31

Fahmy Y, Mobarak F, Schweers W (1982) Pyrolysis of agricultural residues. Part II. Yield and chemical composition of tars and oils produced from cotton stalks, and assessment of lignin structure. Cellul. Chem. Technol.(Romania) 16(4)

Fahmy Y, Mobarak F, Schweers W (1982) Production of phenols and charcoal from bagasse by a rapid continuous pyrolysis process. Wood Sci. Technol. 16(1):59–66. https://doi.org/10.1007/BF00351374

Fahmy Y (1982) Pyrolysis of agricultural residues. Part I. Prospects of lignocellulose pyrolysis for producing chemicals and energy sources. Cellul. Chem. Technol. 16(3):347–355

Chatterjee S, Saito T (2015) Lignin-derived advanced carbon materials. ChemSusChem 8:3941–3958. https://doi.org/10.1002/cssc.201500692

Hou Z-Q, Luo M-Y, Yang Y-T, Zhou J-C, Liu L-C, Cai J-J (2021) Algae-based carbons: design, preparation and recent advances in their use in energy storage, catalysis and adsorption. New Carbon Mater. 36:278–303. https://doi.org/10.1016/S1872-5805(21)60020-3

Li N, He M, Lu X, Yan B, Duan X, Chen G, Wang S (2022) Municipal solid waste derived biochars for wastewater treatment: production, properties and applications. Resour. Conserv. Recycl. 177:106003. https://doi.org/10.1016/j.resconrec.2021.106003

Chang BP, Rodriguez-Uribe A, Mohanty AK, Misra M (2021) A comprehensive review of renewable and sustainable biosourced carbon through pyrolysis in biocomposites uses: current development and future opportunity. Renew. Sust. Energ. Rev. 152:111666. https://doi.org/10.1016/j.rser.2021.111666

Quosai P, Anstey A, Mohanty AK, Misra M (2018) Characterization of bio carbon generated by high-and low-temperature pyrolysis of soy hulls and coffee chaff: for polymer composite applications. R. Soc. Open Sci. 5:171970. https://doi.org/10.1098/rsos.171970

Shen Y (2018) Rice husk-derived activated carbons for adsorption of phenolic compounds in water. Global Challenges 2:1800043. https://doi.org/10.1002/gch2.201800043

Kalinke C, Mangrich AS, Marcolino-Junior LH, Bergamini MF (2016) Biochar prepared from castor oil cake at different temperatures: a voltammetric study applied for Pb2+, Cd2+ and Cu2+ ions preconcentration. J. Hazard. Mater. 318:526–532. https://doi.org/10.1016/j.jhazmat.2016.07.041

Jung K-W, Hwang M-J, Ahn K-H, Ok Y-S (2015) Kinetic study on phosphate removal from aqueous solution by biochar derived from peanut shell as renewable adsorptive media. Int. J. Environ. Sci. Technol. 12:3363–3372. https://doi.org/10.1007/s13762-015-0766-5

Sharashkin L and Gold M, Pine nuts: species, products, markets, and potential for US production, in Northern Nut Growers Association 95th Annual Report Proceeding for the 95th annual meeting, Columbia, Missouri (2004).

Service USDoAUFA Tree nuts: world markets and trade. (2021).

Qin L, Hou Z, Zhang S, Zhang W, Jiang E (2020) Supercapacitive charge storage properties of porous carbons derived from pine nut shells. J. Electroanal. Chem. 866:114140. https://doi.org/10.1016/j.jelechem.2020.114140

Qiu Z, Chen J, Tang J, Zhang Q (2018) A study of cadmium remediation and mechanisms: improvements in the stability of walnut shell-derived biochar. Sci. Total Environ. 636:80–84. https://doi.org/10.1016/j.scitotenv.2018.04.215

Klasson KT, Uchimiya M, Lima IM (2015) Characterization of narrow micropores in almond shell biochars by nitrogen, carbon dioxide, and hydrogen adsorption. Ind. Crops Prod. 67:33–40. https://doi.org/10.1016/j.indcrop.2015.01.010

Mukome FN, Six J, Parikh SJ (2013) The effects of walnut shell and wood feedstock biochar amendments on greenhouse gas emissions from a fertile soil. Geoderma 200:90–98. https://doi.org/10.1016/j.geoderma.2013.02.004

Nunes RM, Costa D, Ortiz N (2017) The use of eucalyptus activated bio carbon for water treatment-adsorption processes. Am. J. Anal. Chem. 8:515. https://doi.org/10.4236/ajac.2017.88037

Wang G, Dai Y, Yang H, Xiong Q, Wang K, Zhou J, Li Y, Wang S (2020) A review of recent advances in biomass pyrolysis. Energy & Fuels 34:15557–15578. https://doi.org/10.1021/acs.energyfuels.0c03107

Tripathi M, Sahu JN, Ganesan P (2016) Effect of process parameters on production of biochar from biomass waste through pyrolysis: a review. Renew. Sust. Energ. Rev. 55:467–481. https://doi.org/10.1016/j.rser.2015.10.122

Chen X, Che Q, Li S, Liu Z, Yang H, Chen Y, Wang X, Shao J, Chen H (2019) Recent developments in lignocellulosic biomass catalytic fast pyrolysis: strategies for the optimization of bio-oil quality and yield. Fuel Process. Technol. 196:106180. https://doi.org/10.1016/j.fuproc.2019.106180

Mishra RK, Misra M, Mohanty AK (2022) Value-added bio-carbon production through the slow pyrolysis of waste bio-oil: fundamental studies on their structure–property–processing co-relation. ACS Omega 7(2):1612–1627. https://doi.org/10.1021/acsomega.1c01743

Ábrego J, Plaza D, Luño F, Atienza-Martínez M, Gea G (2018) Pyrolysis of cashew nutshells: characterization of products and energy balance. Energy 158:72–80. https://doi.org/10.1016/j.energy.2018.06.011

Bhatnagar A, Barthen R, Tolvanen H, Konttinen J (2021) Bio-oil stability through stepwise pyrolysis of groundnut shells: role of chemical composition, alkali and alkaline earth metals, and storage conditions. J. Anal. Appl. Pyrolysis 157:105219. https://doi.org/10.1016/j.jaap.2021.105219

Doshi P, Srivastava G, Pathak G, Dikshit M (2014) Physicochemical and thermal characterization of nonedible oilseed residual waste as sustainable solid biofuel. Waste Manage. 34:1836–1846. https://doi.org/10.1016/j.wasman.2013.12.018

Nawaz A, Mishra RK, Sabbarwal S, Kumar P (2021) Studies of physicochemical characterization and pyrolysis behavior of low-value waste biomass using thermogravimetric analyzer: evaluation of kinetic and thermodynamic parameters. Bioresour. Technol. Rep. 16:100858. https://doi.org/10.1016/j.biteb.2021.100858

Pang YX, Foo DC, Yan Y et al (2021) Analysis of environmental impacts and energy derivation potential of biomass pyrolysis via Piper diagram. J. Anal. Appl. Pyrolysis 154:104995. https://doi.org/10.1016/j.jaap.2020.104995

Chiou B-S, Valenzuela-Medina D, Bilbao-Sainz C et al (2015) Torrefaction of pomaces and nut shells. Bioresour. Technol. 177:58–65. https://doi.org/10.1016/j.biortech.2014.11.071

Socrates G (2004) Infrared and Raman characteristic group frequencies: tables and charts. John Wiley & Sons

Queirós CS, Cardoso S, Lourenço A et al (2020) Characterization of walnut, almond, and pine nut shells regarding chemical composition and extract composition. Biomass Convers. Biorefin. 10:175–188. https://doi.org/10.1007/s13399-019-00424-2

Paris O, Zollfrank C, Zickler GA (2005) Decomposition and carbonisation of wood biopolymers-a microstructural study of softwood pyrolysis. Carbon 43:53–66. https://doi.org/10.1016/j.carbon.2004.08.034

Klasson KT, Uchimiya M, Lima IM (2014) Uncovering surface area and micropores in almond shell biochars by rainwater wash. Chemosphere 111:129–134. https://doi.org/10.1016/j.chemosphere.2014.03.065

Suliman W, Harsh JB, Abu-Lail NI, Fortuna A-M, Dallmeyer I, Garcia-Perez M (2016) Influence of feedstock source and pyrolysis temperature on biochar bulk and surface properties. Biomass and Bioenergy 84:37–48. https://doi.org/10.1016/j.biombioe.2015.11.010

Açıkalın K (2011) Thermogravimetric analysis of walnut shell as pyrolysis feedstock. J. Therm. Anal. Calorim. 105:145–150. https://doi.org/10.1007/s10973-010-1267-x

Arnold S, Rodriguez-Uribe A, Misra M, Mohanty AK (2018) Slow pyrolysis of bio-oil and studies on chemical and physical properties of the resulting new bio-carbon. J. Cleaner Prod. 172:2748–2758. https://doi.org/10.1016/j.jclepro.2017.11.137

Tripathi N, Uribe AR, Weldekidan H, Misra M, Mohanty AK (2022) Upcycling of waste jute biomass to advanced bio carbon materials: the effect of pyrolysis temperature on their physicochemical and electrical properties. Mater. Adv. 3(24):9071–9082. https://doi.org/10.1039/d2ma00678b

Snowdon MR, Mohanty AK, Misra M (2014) A study of carbonized lignin as an alternative to carbon black. ACS Sustainable Chem. Eng. 2(5):1257–1263. https://doi.org/10.1021/sc500086v

Data availability

The datasets generated during and analyzed for the study are available from the corresponding author upon reasonable request.

Funding

The authors are thankful for the financial support from the following to carry out this research: (i) The Natural Sciences and Engineering Research Council of Canada (NSERC), Collaborative Research and Development Grants (CRD) Project Nos. 401637 and 401730 with the partner industries Prism Farms Limited and Competitive Green Technologies, Leamington, Ontario, Canada; (ii) the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA)- Ontario Agri-Food Research Initiative (Project No. 055217); (iii) the Ontario Agri-Food Innovation Alliance – Bioeconomy for Industrial Uses Research Program (Project Nos. 030332 and 030578); (iii) the NSERC, Canada Research Chair (CRC) Program Project No. 460788 and the NSERC Discovery Grants Project No. 401716.

Author information

Authors and Affiliations

Contributions

KA and MS: conceptualization, methodology, formal analysis, investigation, writing—original draft preparation, and writing—review and editing. SV, RM, and GC: methodology and writing—review and editing. AKM and MM: project conceptualization, methodology, administration, resources, funding acquisition, and supervision. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Ethical approval

Not Applicable

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Agweh, K., Snowdon, M.R., Mishra, R.K. et al. Production and characterization of waste nutshells derived biocarbon through slow pyrolysis: an investigation on the effects of pyrolysis temperature. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-03851-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-03851-4