Abstract

Bamboo, the fastest-growing plant, has several unique characteristics that make it appropriate for diverse applications. It is low-cost, high-tensile, lightweight, flexible, durable, and capable of proliferating even in ineffectual areas (e.g., incline). This review discusses the unique properties of bamboo for making charcoal and biochar for diverse applications. To produce bamboo charcoal and biochar, this study reports on the pyrolysis process for the thermal degradation of organic materials in an oxygen-depleted atmosphere under a specific temperature. This is an alternative method for turning waste biomass into products with additional value, such as biochar. Due to various advantages, bamboo charcoal is preferred over regular charcoal as it has four times the absorption rate and ten times more surface area reported. According to the reports, the charcoal yield ranges from 24.60 to 74.27%. Bamboo chopsticks were the most useful source for producing charcoal, with a high yield of 74.27% at 300 °C in nitrogen, but the thorny bamboo species have a tremendous amount of minimal charcoal, i.e., 24.60%. The reported biochar from bamboo yield ranges from 32 to 80%. The most extensive biochar production is produced by the bamboo D. giganteus, which yields 80% biochar at 300 °C. Dry bamboo stalks at 400 °C produced 32% biochar. One of the sections highlights biochar as a sustainable solution for plastic trash management produced during the COVID-19 pandemic. Another section is dedicated to the knowledge enhancement about the broad application spectrum of the charcoal and biochar. The last section highlights the conclusions, future perspectives, and recommendations on the charcoal and biochar derived from bamboo.

Graphical Abstract

Similar content being viewed by others

1 Introduction

The world’s fastest-growing plant, bamboo, may expand by at least 60 cm daily. Bamboos belong to the grass family and have a columnar shape as opposed to a tapering one. The bamboos have enormous social, economic, and cultural ramifications globally, especially in East and South Asia. They are mainly used as raw materials and as a root of food and building materials. The bamboos have good bending strength and are flexible. The bamboo plant may reach a height of 40 m while still withstanding wind force Yuming Y et al. [1]. Bamboo is cheaper, lighter, flexible, stronger, and adaptable than steel. Because bamboo offers many advantages over other building materials, it must be used widely in construction. Due to its superior physical and mechanical properties, bamboo is often used in place of wood. Contrasting to wood, which requires almost 20 years reaching maturity, it does so in 3–4 years. It can breed in unproductive regions (like on an eroding hillside), and because its root system keeps growing even after harvest, it can produce new shoots. Most soil types support bamboo growth except alkaline soils, deserts, marsh, plains, hilly regions, and mountainous regions. According to some research, bamboo grows at a rate of 30 to 60 cm per day, reaches a height of around 36 m over the growth season, and yields more biomass than other lignocellulose crops.

Scientists, engineers, and architects are working to create various building components that use bamboo as their primary building material. Bamboo is an environmentally friendly building material that offers several advantages, such as sustainability, the potential to be recycled or used again, and environmental accessibility, as researched by Xia and other members in 2016. The world’s fastest-growing trees, bamboo has a special rhizome-dependent growth strategy [2]. Bamboo has more silica, charcoal, and alkaline extractives than wood. Its compressive strength is more important than wood and brick, and its tensile strength is notable compared to steel. However, bamboo is a plant that contains a lot of fibrovascular bundles. Due to their use as a supply of food, building materials, and adaptable raw materials, South Asia, Southeast Asia, and East Asia are significant regions both economically and culturally.

Further, biochar and charcoal are precisely two essential and non-similar materials. The International Biochar Initiative describes biochar as “a compacted material produced by the thermochemical reduction of biomass in an oxygen-limited environment” wherein charcoal is defined as “a dark or black porous carbon primed from vegetable or animal materials where the air is excluded”. The primary source material for making biochar is biomass like plant residues, agricultural waste, wood chips, etc. In contrast, the main source of charcoal is wood-based biomass, which may be divided into four categories: common charcoal (made of wood, peat, coconut husk, and petroleum). Although pyrolysis, heat conversion processes of organic matter like organic wastes into carbon in the lack of oxygen, is used to create biochar and charcoal. But the contemporary pyrolysis technique uses the heat generated by gas combustion to promote pyrolysis and produces biochar [3].

Both biochar and charcoal are forms of black carbon that are amorphous (without a definite shape) and have many pores and grooves. Because it is more porous and has a larger surface area than charcoal, a few ounces of biochar can have an interior surface area the equivalent of a football field. This surface and porosity area aid biochar in enhancing the structure of the soil and housing helpful bacteria, resulting in healthy soil. Charcoal has less porosity than biochar because of its low manufacturing temperatures. In addition, this temperature produces some less stable forms of carbon, which breaks down in the soil more quickly than biochar. As a good insulator, charcoal also has low electric and thermal conductivity. The chemical properties of charcoal and biochar vary. The amount of macronutrients (such as phosphorus) and micronutrients (such as zinc) in biochar may vary depending on the source of the feedstock [4]. Although it typically has an alkaline pH, it can range from 4.6 to 9.3 based on the source material's temperature and the manufacturing temperature. Because of its negative charge, it aids in boosting soil's exchange capacity, improving nutrient availability for plants. Charcoal typically has less than 1% moisture; charcoal loses heating performance at higher moisture levels. Activated charcoal has a pH range of 9 to 11, making it more alkaline than biochar. This aids in its ability to absorb organic material from water [5, 6].

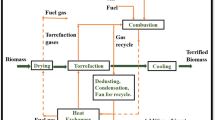

Due to its inexpensive cost, bamboo is a perfect starting material for synthesizing biochar and activated carbon, high biomass yield and significantly accelerated growth rate. Further, to improve their properties, biochar and charcoal can be activated. Furthermore, bamboo charcoal has garnered much attention due to its excellent adsorption properties, huge surface area, and highly porous structure. For various reasons, a bamboo is a superior option to other wood planks. Bamboo is superior to wood in all ways, including strength, environmental friendliness, water resistance, cost, soil protection, and contribution to air quality. Due to its superior physical and mechanical characteristics, bamboo is a substitute for wood. It has multifold benefits. Proliferates and do not bound to follow the stringent rules for growing, harvesting, propagating and cutting. Bamboos can tolerate a wide range of temperatures (− 28–38 °C), efficient in its water and soil usage and needs no fertilizers or pesticides. Bamboo is an excellent absorber of carbon dioxide and releases a large amount of oxygen (approximately 30%) back into the atmosphere, thus, can cure global warming. High strength bamboo grows quickly and can be collected for usage for charcoal in just three to six years, making it far more desirable than wood, which takes a lot longer to grow. In addition, bamboo charcoal has four times the absorption rate of conventional charcoal and ten times more surface area. Bamboo charcoal’s porous structure offers microscopic holes that efficiently absorb odors, moisture, and airborne pollutants like formaldehyde, ammonia, and benzene and also act as a Carbon dioxide absorbent [7, 8]. These benefits were the driving force behind several uses for this material, including blood purification, electromagnetic-wave absorbers, and water purifiers. These benefits are influenced by the activation and carbonization procedures used to make bamboo charcoal. Green bamboo wood is roasted to a constant temperature to create activated charcoal when charcoal is exposed to oxygen by using the pyrolysis method, as illustrated in Fig. 1. The biomass' cellulose, hemicellulose, lignin, volatile matter, and fixed carbon content substantially impact the biochar’s characteristics and shape.

In view of the above unique and essential aspects of bamboo, charcoal, and biochar importance, this review focuses on the potentiality of bamboo for its uniqueness in making charcoal and biochar for multiple uses. Bamboo as a source for making biochar via pyrolysis is another focus of this investigation. The significant scientific advancements in bamboo charcoal and biochar from bamboo are highlighted critically. This will give the updated version of the present times in the scientific community to understand and develop more interest in the potentiality of bamboo for making charcoal or biochar, depending upon the requirement and applications. The review also highlights the practical concept of using activated bamboo charcoal and biochar in many potential applications and for many valuable purposes. The experimental results displayed excellent performance when analyzed. Another section is dedicated to the knowledge enhancement about the utilization spectrum of the activated charcoal and biochar derived from bamboo. The last section highlights the conclusions, future perspectives, and recommendations on the charcoal and biochar derived from bamboo as a unique natural source full of versatile characteristics.

A diagram of the process flow of producing charcoal and biochar from bamboo for versatile applications is illustrated in the Fig. 2.

2 Brief on pyrolysis method

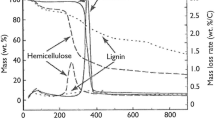

The term “pyrolysis” refers to the non-oxygen thermal breakdown of organic molecules at a temperature around 250 and 900 °C. Using contemporary biomass pyrolysis techniques to produce biofuels , biochar , syngas and other valuable goods , this could be a huge step toward enabling worldwide carbon capture [9, 10]. Producing biochar from agricultural waste is a practical solution for handling these massive amounts of garbage and lowering greenhouse gas emissions from burning. Obtainable by the pyrolysis of diverse biomass and biodegradable waste, biochar is a fine-grained charcoal-like product with a high amount of organic carbon and low degradation susceptibility [11]. Biochar has more significant catalytic activity, surface area, permeability, and physico- chemical stability than other biomass materials, Yaashikaa et al. [12]. Char and bio-oil are the products that are solid and liquid, while carbon dioxide, carbon monoxide, hydrogen, and syngas are the gaseous products (C1-C2 hydrocarbons). Various reactor designs manufacture biochar, including bubbling fluidized beds and kilns [13,14,15]. The kind and nature of the biomass used determine biochar yield during the pyrolysis process. The most significant variables affecting chars’ yields, pore volumes, and surface areas are temperature and holding time. Low-temperature biochar production causes combustible aliphatic volatile materials to become trapped in the pores rather than escaping the structure. The volatiles in such a low-temperature biochar works as fuel when heated, enabling the combustion of the biochar. However, all the volatiles evaporate when biochar is produced at higher temperatures (for instance, > 500 °C), leaving only a carbon skeleton [16]. Because it contains no volatiles and only pores, biochar produced at high temperatures is way ahead more combustible than biochar produced at lower temperatures. Excellent fire resistance is another benefit of the high-temperature biochar’s robust C–C covalent bonds. High pyrolysis temperatures (> 500 ℃) yield biochar with high fire resistance properties due to the development of strong C–C covalent bonds and the absence of volatile matters. Figure 3 depicts the pyrolysis process’ mechanism [17]. Depending upon the reaction temperature, temperature, residence duration, and pressure, pyrolysis can be distributed into fast and slow pyrolysis processes [18,19,20].

The figure illustrates the mechanism of pyrolysis (adapted from Yaashikaa et al. [12])

3 Environmental benefits of biochar and charcoal

A carbon-rich substance called biochar is created by pyrolyzing organic waste. The feedstock types and pyrolysis conditions affect how productive biochar is. Pyrolysis conditions, gasification, and carbonization were used to create biochar for soil remediation. As a result, biochar has become a value-added product that supports the bioeconomy by reducing CO2 emissions and global warming in the environment, reducing nutrient leaching losses, sequestering carbon from the atmosphere into the soil, raising agricultural production, and reducing the bioavailability of environmental contaminants [21, 22]. Biochar soil has been advocated as a potential large scale solution to offset global greenhouse gas emissions [23, 24]. Therefore, biochar is affordable and environmentally beneficial, contrary to polymer and cementitious materials. Identifying sources of contaminated wood in waste stream feedstocks is crucial before large-scale application of biochar or wood ash to soil is considered [25]. In recent years, carbonaceous materials such as activated carbons and char products (biochar) from thermochemical processing (slow/fast pyrolysis and gasification) of biomass for biofuel production purposes have received considerable interests as a waste-derived soil/sediment amendment for in situ stabilization of inorganic and organic contaminants [26, 27].

Different biomasses can be used for making biochar, and the biomass feedstocks for biochar can be broadly classified into (1) wood, (2) grasses and straw, (3) husks and shells, (4) manures and sludges, and (5) other industrial wastes such as papermill waste. Figure 4 shows the environmental benefits of biochar, which in turn improves its profitable functionality. The combination of the large surface area, charged groups, and functional group elaborate the potential to absorb heavy metallic elements and other contaminants, mainly organic ones. It discusses the wide range of characteristics and beneficial properties with broad spectrum of reactivty for overall chemical and microbial stability [28, 29].

Activated carbon is a key component of the filter material used to clean exhaust gases utilized in treating wastewater and drinking water. Activated carbon is a popular adsorbent with a huge surface area, a consistent microporous structure, and radiation stability Mahanim et al. [30]. Numerous uses of this substance exist, such as in treating electromagnetic radiation and blood. Furthermore, these advantages depend on bamboo charcoal's activation and carbonization processes. Bamboo charcoals have four times the voids, three times the nutrient levels, and nearly double the adsorption efficiency of wood charcoal. The majority of bamboo charcoal’s applications include adsorbent material, an anode for dye-sensitive solar panels, a water purifier, an electromagnetic wave insulator for communication systems, a blood purifier, and many more, driven by the effectiveness of its absorption properties. Bamboo charcoal’s carbonization and activation processes chiefly determine its uses. These actions might impact adsorption, surface area, and porosity. For carbon capture, inexpensive activated carbons made from biomass that have a high capacity for CO2 adsorption are appealing. It was discovered that bamboo makes a good precursor for making activated carbon [31,32,33]. Another carbon-rich compound identified as biochar is created whenever feedstock, such as wood, leaves are baked in a sealed vessel with little to no available air. About 70% of biochar is made up of carbon. The remaining components include various substances such as oxygen, hydrogen, and nitrogen Shareef et al. [34]. Biochar is a by-product of the pyrolysis process converting biomass into valuable products such as chemicals and energy [35, 36]. An inexpensive, renewable, and environmentally friendly adsorbent is bamboo biochar. Numerous advantageous effects of biochar are reported in the agricultural sector. Biochar increases soil fertility by loading up the soil on the ground. Recent research has shown that turning biomass into biochar generates renewable energy and reduces the number of pollutants, especially carbon dioxide (CO2) [37].

Biochar, has received potential interest as a cost-efficient and environmentfriendly sorbent material to remediate metal contamination recently [38]. It has a unique microporous structure, has recently attracted much attention. These provide the porous carbonaceous structure of activated carbon and other qualities like quick growth, higher productivity, and small production circles [39]. Bamboo charcoal has four fold times the pores, three times the ions, and four times the adsorption rate of wood charcoal. Bamboo charcoal has a surface area of 300 m2 g−1, which is ten times that of wood charcoal and is significantly larger than MWCNT (200 m2 g−1). The majority of applications for this activated charcoal are studied on its proper absorption qualities, including the purification of water [40], as an anode in dye-sensitive solar cells [41], as an electromagnetic wave absorbing material in communication devices, and in the purification of the blood, among other applications.

Thus, bamboo charcoal is preferred over regular charcoal as it has four times the absorption rate of conventional charcoal and ten times more surface area. Bamboo charcoal is a powerful adsorbent due to its natural adsorption properties and large surface area. Numerous pollutants and other dangerous compounds can be captured and stored in its millions of pores. By trapping odour and pollution particles as air or water passes through its pores, charcoal purifies the air or water in its immediate vicinity. Therefore, bamboo charcoal is substantially more effective than standard charcoal due to its greater porosity.

4 The uniqueness of bamboo for obtaining charcoal and biochar

4.1 Bamboo-derived charcoal

Bamboo charcoal has been utilized in ample ways since 1486 AD because of its exceptional qualities [42, 43]. By heating bamboo stems in an argon environment, [44] investigated and published a simple and customizable method for producing fluorescent carbon nanostructures. Bamboo can be carbonized by annealing it in an argon atmosphere, forming a graphitic cluster in the amorphous carbon matrix. The band gap of the nanostructured carbon produced after 500 °C annealing is 2.8 eV. However, the optical band-gap of bamboo charcoal (BC), when annealed at 600 °C (BC-600) is discovered to be 3.3 eV. The XRD investigation confirmed the generation of graphite nano-structure submerged in the amorphous carbon matrix. At ambient temperature, bamboo charcoal exhibits photo-luminescence (PL), mimicking the luminescence of its crystalline counterparts. The specimens of synthetic charcoal were discovered to contain two optical centers. Two photo-luminescence spectra were shown to be excitation wavelength-independent when stimulated with UV light. One of them has distinct, robust spectroscopy in the range of green light, and the other is in the region of yellow light. Predominant transitions are responsible for the PL emission of the carbon nano-crystallites, as shown in Fig. 5. External sp2 packed band gap produced each of the PL spectra. The -C-O, -COOH, and -NH2 compounds that are physically connected to the sp2 carbon backbone change the band gap energy of the graphene sheets. Activated charcoal nano-structures with PL characteristics were created to generate excitation wavelength-neutral bio-based detectors that could recognize and/or track UV light.

600 °C carbonized bamboo microstructural analysis (BC-600). (A) Secondary electron microscopy (SEM) micrograph and (B) Bright field TEM micrograph (figure adapted from [44] under Creative Common Attribution License 4.0)

In a study published in 2014, Huang and other colleagues experimentally tested the capacity of Moso bamboo (Phyllostachys edulis) derived porous charcoal to absorb carbon dioxide. To understand the adsorption characteristics, the basic features of porous activated bamboo charcoal involve charcoal yield, pH level, ash estimation, surface area of BET, pore volume, and powder size were calculated. The porous bamboo charcoal was produced and ground in powders at varying temperatures. In the experiment, 1.854% carbon dioxide was absorbed for 120 h using charcoal carbonized at various temperatures. The findings showed that charcoal production decreased as carbonization temperature and pH level were elevated.

At normal room temperature and atmospheric pressure, Moso bamboo-based porous charcoal gives good power for the adsorption of CO2 than commercially available activated carbon. The pore volumes were also 8.6–10.7 cm3/g for carbonization temperatures between 600 and 1000 °C. Additionally, the BET surface area and iodine adsorption value were maximum in the carbonized bamboo at this temperature. According to the results, the best adsorption capacity was found in bamboo charcoal carbonized at 1000 °C and significantly reducing the CO2 concentration to 0.836 percent. Figure 6 shows the method representation’s flow chart for producing Moso bamboo-based porous charcoal.

Systematic representation of the method for producing Moso bamboo-based porous charcoal (adapted from [45])

Acid rain, algae blooms, sulfur dioxide (SO2), and sulfur powder (SP) regularly float in the air, leading to sickness. In additional research by Kaur et al. [46], the production and use of bamboo charcoal as an adsorbent to remove sulfur from polluted water and effectively absorb smells, humidity, and sulfur from sulfur solutions was reported. Due to its incredible porousness, bamboo charcoal enables the absorption of substances containing sulfur. Bamboo charcoal was produced in two directions: by pyrolyzing it with tin foil. The moisture content in this example is 40.80%, the weight reduction (%) of the bamboo charcoal is 69.61%, and the pure sodium sulphate adsorption parameters are found to be 2.63 g/125 g for a swirling time of 60 min and 0.88 g/125 g for a stirring time of 120 min. In another process, the bamboo pieces are pyrolyzed at 600 °C, and the solvent is then purified. In this, the moisture content was 15.87%, the weight loss was 93.88%, and the optimal sodium sulphate adsorption condition was 0.88 g/125 g for a stirring time of 120 min. The absolute adsorption condition was 2.63 g/125 g.

The XRD analysis of charcoal then showed there are two distinct peaks at 44° and 25°, correspondingly associated with (001) and (002) reflections and supporting the high degree of graphitization. The FTIR spectroscopy of activated charcoal carbonized at various times can determine the breakdown temperature of the hemicellulose, cellulose, and lignin present in bamboo. Bamboo charcoal was exposed to two chemicals (sodium per-sulfate and sodium sulphate powder) to ascertain the ideal adsorption conditions and the material's intrinsic change. Bamboos hemicelluloses are broken down, and large numbers of cellulose and hemicellulose hydroxyl groups from cellulose and hemicellulose are dislocated when bamboo is pyrolyzed using aluminum foil, which causes water to escape. Additionally, the net architecture of lignin collapses when pyrolyzed in a muffle furnace at 600 °C. More aryl group positions are then substituted based on the band's disappearance, which originates in the skeletal vibration and alteration in the intensity values of a trio-band. According to the experiment results, bamboo can be an absorber for extracting sulfur from contaminated water.

In a study by Liu and his coworkers’, 2009, bamboo was microwave-induced activated to generate activated carbon, with combination of phosphoric acid as the activating agent. Since it had an acidic surface and was largely microporous, the activated carbon was discovered to be superb for adsorption of organic pollutants. The impacts of many variables like radiation period, the proportion of phosphoric acid to carbon when activated, etc., have been examined. The increase in these factors promoted the generation of the pore structure of activated carbon. To achieve a high surface area and a carbon yield of 48%, the ideal activation parameters were found to be: microwave power of 350 W, with a radiation time of 20 min, and a phosphoric acid/carbon ratio of 1:1. The surface chemical characteristics were analyzed by different methods including FTIR spectra, XPS spectra, point of zero charges measurement, and acid–base titration. The pH measurement and acid–base titration showed that there were several acidic groups present on the carbon surface. While the XPS spectrum displays the changes in the relative amounts of different elements and carbon species, the FTIR spectra qualitatively characterize the surface groups. Both conventional thermal and microwave-prepared activated carbons showed similar surface chemistry characteristics. But in comparison with the traditional heat method, the microwave-induced activation method has been shown to have a larger carbon yield and a faster activation rate.

Considering the issues with water scarcity that many nations are experiencing, activated carbon may become a necessary product for contemporary culture. In this context, in an experimental work performed by [39] the creation of these materials utilizing bamboo as the raw material was proposed. To offer the best-activated carbons that could be utilized to treat polluted water, they evaluated the effectiveness of their application in this situation. The bamboo was collected and underwent simultaneous physical and chemical activations to become activated carbon, which was then given the name H3 PO4/H2O activated carbon. The yield, ash content, surface area, apparent density, thermogravimetric analysis, MB and iodine indices, pH and point of zero charge analysis, Boehm titration method, and SEM were used to describe the obtained material. The H3 PO4/H2O activated carbon yielded 39.00 percent, an SBET of 1196.30 m2.g−1. The activated carbon was used as an adsorbent for eliminating the (2, 4-D), (MTZ), and (FRD) pesticides. The adsorption capacities for these three are found to be 274.70 mg. g−1 (2, 4-D), 756.47 mg. g−1(MTZ), 868.98 mg.g−1 (FRD). The studies indicate that H3PO4/H2O activated carbon was used in several pesticide-contaminated water bodies, mostly in quantities over the legally authorized limits.

In another research by [47], activated charcoal was made from bamboo. This study used bamboo as a raw material source to illustrate the high-quality and undeniably affordable activated charcoal production. They utilized synchronous direct physical–chemical at 500 °C for 1 h to test its adsorption capacity for methylene blue (MB) dye. The generated activated carbon exhibited a relatively high surface area value of 1354.42 m2.g1. The Langmuir and Freundlich isotherms systems were used to understand the adsorption process better. At room temperature, batch adsorption dynamics and equilibrium tests were conducted to determine the impact of the MB dye on the produced activated charcoal. The Langmuir isotherm described the adsorption performance, whose utmost adsorption capacity was 374.75 mg.g−1. In comparison to SBET values reported in the study, the activated charcoal showed a significantly enhanced SBET. This study’s findings suggested using activated charcoal made from bamboo in water treatment tainted with MB dye, preferably at quantities more significant than those permitted by law.

Another intriguing study by Xia et al. [48] advocated microwave heating for converting bamboo into a large surface area of activated carbon. Various chemical activators were used to determine the best activating agent. Some are KOH, K2CO3, and Na2CO3, NaOH. KOH was the one to generate the carbon with the larger surface area and porosity among the tested activating agents, with a significant amount of that carbon being microporous. The optimal KOH/C ratio of 4 was determined to be where the total area and pore volume started to decrease. According to the SEM result, the pore structure was highly developed of activated carbon. FTIR was used to confirm that several functional groups were present on the activated carbon's surface [48].

In another experimental work reported by [49], activated carbon derived from bamboo was prepared by chemical activation, and K2CO3 acted as an activator. The experiment results demonstrated that under ideal conditions, the specific surface area, ash content, and volume resistivity of activated carbon could be reached an exceptionally high level of results. The ideal working conditions adopted were an activation temperature of 900 °C for 2 h and an impregnation ratio of 1. The premise surface was estimated by using BET surface area analysis. The structural variations among various activated carbons were investigated using SEM analysis. The structural characteristics of the activated carbon produced at varying temperatures were examined using XRD analysis. The effects of annealing temperature, time, and impregnation ratio on the total area of generated activated carbon were systematically examined, and encouraging results were obtained.

Activated carbon was created by PH Huang et al. [50] using raw, prickly bamboo (4–5 years old). The basic adsorption properties comprising wood fuel, pH value, particle density, the amount of heavy metals, BET surface area, and iodide number were analyzed to evaluate the absorption and capture capacities of activated carbon. The impact of the activation condition was discussed on the removal of heavy metals from groundwater. Experimental findings indicate that when the initiation temperature is exceeded, the yield value of bamboo charcoal decreases, and the pH level rises. These four activation temperatures- 600, 700, 800, and 900 °C were used in this study to discuss variations in the thorny bamboo's ability to produce charcoal. The maximum average charcoal output, or 24.63%, was attained at the reaction temperature of 600 °C. The generation of charcoal dropped as the activating temperature increased to around 600–900 °C. As well as having a high adsorptive capacity, the activated carbon produced at 800 °C displayed the highest specific surface area value and iodine sorption value [51].

In 2014, Lin and team members [52] observed the characteristics of bamboo charcoal produced from 4 to 6-year-old Moso bamboo (Phyllostachys pubescens) grown in Jhu Shan, Taiwan. A three-stage carbonization and activation process was employed. The software programme FactSage for thermochemistry was used to simulate an approach based on the principles of thermodynamics. This model represents the chemical reactions of the carbonization process, which involves several solid and component gas phases. The very first stage of activated carbon was used to read the BC, the second version of activation was used to activate it, and the final session was used to refine it. Following an explanation of measured variations in the pH values of the BC using the gas products chemistry, a potential limit pH value for the charcoal was subsequently introduced.

We can quicken the technology innovation of generalized activated carbon for various bio-resources following a unique chemical reaction mechanism and a multi-stage process. This study provides basic information on design concepts and bio-resources combustion like bamboo and wood. Using BET, the FTIR was also used to determine the element's structure, pH value, component contents, and surface area. Reiterating the significance of process optimization, the measured maximum BET-specific surface area of refined bamboo charcoal obtained during the three-stage procedure outlined above was over 2000 times that of the samples created at 4000 °C at the start of carbonization process.

Isa et al. [53] performed a work in which they produced bamboo charcoal from a variety, Gigantochloa Albociliata (Buluh Madu), in a controlled atmosphere for one hour at 500 °C (lab-prepared). The material’s dispersibility and adsorption behavior were then used to describe it. They adopted two methods to prepare bamboo charcoal, one was lab prepared, and another one was the commercial method. From Malaysian Buluh Madu, bamboo charcoal has been produced using mechanical kiln and furnace carbonization techniques. To test the samples’ stability and dispersibility, pulverized charcoal from bamboo was produced in ethyl alcohol and purified water. The outcomes demonstrated that the solution in ethyl alcohol was significantly more stable than DI water. As the bamboo charcoal particles began to agglomerate in the mechanical kiln process, the SEM images demonstrate that they were more extensive than those produced in the lab furnace. The samples functional groups are visible in the FTIR spectrum and are consistent with earlier published findings. Both samples exhibit comparable adsorption characteristics, with a similar peak being formed and an increase in adsorption. In conclusion, the laboratory-produced sample was comparable to the bamboo charcoal prepared for sale.

Table 1 summarizes the properties of charcoals obtained from various bamboo species. The bamboo species and the manner of production influence the charcoal yield %. As a result, several bamboo species like Bambusa vulgaris, Gigantochloa Albociliata, Moso bamboo (Phyllostachys edulis), etc., yield a good variety of charcoal.

A graph of the charcoal yield percentage from various bamboo sources is depicted in Fig. 7. The charcoal yield ranges from 24.60 to 74.27%. According to the result, bamboo from used chopsticks was the most effective source of charcoal, with a high yield of 74.27% at 300 °C in a nitrogen atmosphere [30]. It is because the chopstick’s bamboo waste has a significant amount of lignin, producing a high charcoal production. The outcome displays that the thorny bamboo species produce a tremendous amount of minimal charcoal, i.e., 24.60% [45].

4.2 Bamboo- derived biochar

As reported below, few researchers and scientists have used bamboo as a unique source for developing biochar.

In 2014, Laidy E. and his colleagues [56] regulated the slow pyrolysis of the Bamboo D. giganteus Munro. They calculated the end product yield as a factor in the final reactor temperature. The procedure proceeded at a heating of 10 °C/min and temperatures ranging from 300 to 600 °C in a bed reactor of fixed type. Physical–chemical analysis was utilized to describe the bamboo biomass and the biochar to look into the primary alterations brought on by the pyrolysis process on the properties of biochar. To confirm the primary characteristics and uses of this product, the physical and chemical parameters of the biochar of bamboo generated at pyrolysis temperature 500 °C were further characterized. Due to an increasing rate of thermal breakdown, char yield falls as temperature rises. At 300 °C, a maximum biochar output of 80% was achieved. The biochar’s characterization revealed a significant carbon content. The biochar produced through slow pyrolysis is comparable to most wood biochar heating values, making it suitable for energy in gasification. The high porosity and carbon concentration is the reason that makes it applicable to be used as activated carbon after being physically or chemically activated.

S.S. Sahoo et al. [57] exhibited a work concentrating on the effects of the different temperatures of pyrolysis on the physicochemical qualities of biochars. Bamboo and pigeon pea stem were used as agricultural waste materials and were pyrolyzed at varying temperatures (400 to 600 °C) [57]. Bamboo and pigeon pea stem biomass are slowly pyrolyzed to create biochar at the beginning of the process. Afterwards, biochar was cooled to ambient temperature while being kept in a nitrogen environment [58]. After the cooling, the biochar sample were assembled, thoroughly cleaned with water, and dehydrated for 12 h at 105 °C [59, 60]. The biochars made from pigeon pea stalks are mentioned as PPS400, PPS500, and PPS600 to specify the activated carbon produced at 400, 500, and 600 °C.

The biochar generated from the bamboo biomass was designated by the letters BB400, BB500, and BB600. As indicated in Fig. 8, the biochars were analyzed to determine how the pyrolysis operations affected their structural, chemical, and functional properties. Biochar production was determined to be between 32.20 and 21.70% and rapidly reduced as pyrolysis temperature increased to 600 °C from 400 °C. It has been discovered that the produced biochar has potential uses as an adsorbent to swap out commercially activated char [61]. As a result, bamboo’s higher lignin content and lower volatile matter levels than pigeon pea stalk biomass show that bamboo produced more biochar.

Viglaová et al. [62] researched the agriculture bamboo residue from greenway golden bamboo (Phyllostachys viridiglaucescens) when producing bamboo-based biochar (BC-A) and a composite of bamboo biochar and montmorillonite (BC-D). Bamboo was cleaned multiple times to eliminate contaminants before being crushed, cut, and used. Bamboo biomass was used as the feedstock and was pyrolyzed at 460 °C. Nitrogen was utilized as the flush gas to guarantee an atmosphere devoid of oxygen and consistent heating conditions. The biochar product was crushed and sieved after pyrolysis. The material was dried in the oven after being rinsed with DI water numerous times. The bamboo feedstock obtained using the processes above was used to create the bamboo-biochar composite with montmorillonite (BC-D). Clay substance MK10 powder was mixed with DI water to create a suspension, which was then sonicated using a sonicator. A suspension of produced bamboo feedstock (10 g) and MK10 was fluxed in, and the mixture was stirred for two hours. After being separated from the mixture, the feedstock was dried. The pre-treated, dimensioned bio material was pyrolyzed. The sample of biochar was squeezed, pressed, and sieved through the mesh to the particle size following pyrolysis. This sorbent was preserved after being repeatedly cleaned with DI water. After finding an appropriate, readily available, and reasonably priced biomass-bamboo, a biochar/montmorillonite composite was created. Physical, chemical, and structural characterization techniques were used to describe this material. The results show that the bamboo-based composite performed significantly better than unmodified biochar, indicating that it can be employed effectively in cleaning dirty wastewater or industrial effluents [62].

The impacts of carbonizing bamboo charcoal at different temperatures on tomato (Solanum lycopersicum L.) plant development and nutrient status were examined by [63]. In sand medium with 0, 1, and 3% of biochar added that had been produced in the temperatures ranging from 300 to 600 °C. Shoots of the tomato variety “Micro-Tom” were produced and cultivated. The fruit picked at the ripening stage was examined for color, structure, dissolvable solids content, glucose, acidity, and ascorbic acid. Plant development was also observed. Results revealed that adding 3% or 1% of an amendment to biochar produced at 300 °C or pyrolyzed at 450 °C enhanced plant growth index, as seen in Fig. 9. In the growing media, the elevated levels of Mg, NO3, P and Ca in the growing media were linked to better plant growth and superior quality of fruit. According to our findings, biochar use can be optimized by focusing on its development conditions and application, which impart positive effects on soil amendment and fruit quality. Thus, biochar might have helped the fruit's nutritional value to improve. The impact on the physiology of ripening (hormonal regulation) should also be taken into account. According to this study, the medium with biochar added and pyrolyzed at 300 °C had the most significant mean concentrations of NO3-N, P, Ca, and Mg. The plant growth and quality were enhanced since these values are well in the ranges advised for fruit production. This could explain the better fruit quality, higher plant growth, and the possible practical application of bamboo biochar as a soil amendment. Biochar can considerably enhance crop growth and soil quality when used as a soil amendment.

(Adapted from [63]

Representation process of bamboo biochar effect on the growth of plant and quality of fruit tomato (Solanum lycopersicum L.)

Ye. and other team members, 2015 reported a work examining the biochar production from the shotshell of (Dendrocalamus latiflorus Munro) bamboo. The D. latiflorus Munro bamboo shoot shell (BSS) was obtained, cleaned, dried, and pulverized by a grinder and sieved to BSS particles. Biochar can be used to improve the density, alkalinity, water retention, and durability of ions of heavy metals in soils. The dried BSS particles were uploaded in the pyrolysis process and heated to the appropriate pyrolysis temperatures of 300, 350, 400, 450, and 500 C under a flow of pure N2. The biochar made from BSS (BSSBC) in the furnace was spontaneously cooling to room temperature. BSSBC were taken out of the furnace for analysis after cooling. The biochar produced at each temperature was represented by BC300, BC350, BC400, BC450, and BC500, respectively. The data show that at 300 °C, the maximum yield was 48%, and when the temperature rose, the yield falls from 48 to 33%. The results show that BSS can be pyrolyzed to create a soil ameliorant.

Many bamboo species like Dendrocalamus giganteus, Dendro. latiflorus Munro, dry bamboo stalks, Phyllostachys virdiglaucesons etc. have been used for making biochar. Table 2 summarizes the biochar yield obtained by different bamboo species and their application.

The biochar created by the different bamboo species has a significant positive impact on the soil and ecosystem. Figure 10 shows the biochar production of various bamboo species. The reported biochar yield ranges from 32 to 80%. The most extensive biochar production is produced by the bamboo D. giganteus, which yields 80% biochar at 300 °C, because of the high carbon content in the bamboo [56]. Dry bamboo stalks at 400 °C produced 32% biochar, the lowest yield of all the bamboo species under study, due to the stalks' relatively low lignin concentration [57].

4.3 Comparison of biochar from bamboo vs. other sources

The following is the comparison between biochar from bamboo and different biochar in terms of performance, production, and advantages.

4.3.1 In terms of production

Sahoo et al., 2021 reported a study analysis on the creation and evaluation of the biochar made from bamboo and pigeon pea stalks by slow pyrolysis. Due to the bamboo’s higher lignin content and lower volatile matter, its charcoal biomass yields (32.20–27.00%) were higher than those from pigeon pea stalks (29.80–21.70%) in the same pyrolysis temperature. The mole fraction of carbon content in biochar was substantially higher than that in biomass, ranging from 81.85 to 85.68%. For both biochars derived biomass, the char with the largest carbon mass fraction was discovered at pyrolysis of 600 °C. Application areas benefited from the resulting biochars’ excellent ash recovery. The study also found that 600 °C was the most efficient pyrolysis temperature in terms of high mass fractions of carbon, fixed carbon surface area, and total pore volume for both biomass materials. It is also assured that the composition of biomass and pyrolysis temperature significantly impacted the biochar yield and its physicochemical, morphological, and characterization.

4.3.2 In terms of performance

A study by [66], reported a comparison study of physico-chemical characteristic of biochar pyrolyzed from two species ( moso bamboo and rice husk) under two different pyrolysis temperatures (200–800 °C) as shown in Fig. 11. The results showed that as the temperature increased, the production dropped for both bamboo biochar (BC) and rice husk biochar (RHC). In contrast, the amounts of fixed carbon and carbon elements, high heating value, and pH increase for both BC and RHC. The BC had a high heating value, higher fixed carbon concentration and carbon element at the same pyrolysis temperature, and lower ash content than RHC, indicating BC was more potential material for high-quality fuel and carbon sequestration. According to the data, rice husk biochar is less effective than biochar made from moso bamboo.

Representation of biomass pyrolysis experiment (adapted from [66])

Adsorption post-combustion capture technology is gaining popularity due to rising carbon dioxide (CO2) emissions. More consideration is given to inexpensive adsorbents with outstanding performance. One of the most important tactics to reduce the effects of anthropogenic CO2 emissions on the climate is carbon capture and storage (CCS). Due to the reusable nature of adsorbents, low capital investment, and simple automatic operation, adsorption technology is acknowledged as a potential CO2 capture method available to small and medium size CO2 emitter [67, 68]. Systematic studies on carbon dioxide capture technology, depending on the coal-fired power plants, have been undertaken to promote and apply adsorbents. Y. Ji et al. [69] and N. Susarla et al. [70], however, concentrated on MEA integration with chemical absorbents. For instance, with a capital cost of US$1357 kW1, evaluated the financial and technical performance of a post-combustion capture technology based on MEA incorporated with a 650-MW tar power plant. However, due to the energy cost and impact on the environment of MEA during solvent regeneration, adsorption carbon capture is much more economical for its low investment cost. As a result, BBC-KOH, a revolutionary KOH activation biomass-derived activated carbon, is produced. KOH is added to the activation system to maximise the morphology of inexpensive bamboo charcoal and hence raise its CO2 capacity. Overall, it describes a novel strategy for lowering industrial CO2 emissions and provides an example of an alternate adsorbent for the treatment of industrial exhaust gases T. Chen et al. [71, 72].

Bamboo sawdust is constantly carbonized at a high temperature after being compressed to a very high density. The test's raw material is bamboo charcoal. The activation process of biochar made from bamboo is depicted in Fig. 12. It is ground, sieved, and dried in an oven to make black powder. KOH and BBC, a dried charcoal powder, are physically combined in a 1:1 ratio. The combination powder is placed in the horizontal tube's furnace center after being loaded into a quartz tube. Tube furnace is heated from room temperature to 700 °C while nitrogen is introduced. K-element-containing compounds are removed from activated bamboo charcoal using sufficient deionized water and HCl until the filtrate's pH is neutral, after which the sample is dried. In this work, the sample is referred to as BBC-KOH. A technical, economic analysis to investigate potential advantages in a practical context, a photo voltaic coal-fired power station coupled with a heat swing adsorption mechanism is used. Results displayed the outcome that BBC-KOH has a remarkable ability for adsorption. Additionally, it is found that for a combined cycle of natural gas, a system based on the physical adsorbent, specifically activated carbon, is comparatively more favorable compared to MEA in terms of cost-effectivity and efficiency.

Schematic diagram for activation of bamboo-derived biochar (adapted from Y. Ji et al. [69])

4.3.3 In terms of advantages

It is possible to create biochar, a carbon-rich, fine-grained residue, using either traditional methods (such as covering burnt biomass with soil and letting it smoulder) or cutting-edge contemporary biomass gasification/pyrolysis technologies. At the same time, gasification and pyrolysis of such biomass would transform it into biochar, which, when applied to soil, would store this CO in the soil and improve soil fertility, combustion, and breakdown of tree biomass and agricultural leftovers emit enormous amounts of carbon dioxide. Bamboo forests are growing in size while tropical and subtropical forest coverage is declining. When compared to other types of wood and alternative items, using bamboo for biochar products has various advantages Laidy E. et al. [56] and [73] listed below:

-

High economic value, easy management, and high biomass production

-

Unlike trees, which can be harvested every 20 to 50 years, bamboo can be picked each year for 3–5 years.

-

Bamboo may be picked yearly and regenerated without needing to be replanted.

-

Bamboo produces 30% more oxygen than trees and aids in lowering carbon dioxide levels, contributing to global warming. Some bamboo replenishes fresh air by capturing up to 12 tonnes of carbon dioxide per hectare.

-

The amount of carbon stored into the soil for thousands of years can be increased by using bamboo biochar. Additionally, it lowers methane and nitrogen emissions and aids in soil water retention.

5 Biochar as a sustainable solution for plastic wastes management produced during COVID-19 pandemic

The global production of disinfectant debris has significantly increased due to COVID-19, with the hospital, clinics, and other healthcare facilities producing most of this trash. Personal protection equipment (PPE) and packaging materials have been widely used, but frequently handled improperly, resulting in a significant amount of plastic waste. Both practical applications and environmental protection were considered while discussing the upcycling of plastic trash into biochar, which may be confirmed as a promising material for energy storage and environmental protection [74,75,76]. Additionally, the creative upcycling of plastic waste into biochar is advantageous to reduce the pervasive plastic pollution, avoid negative effects on people and the environment caused by direct and indirect micro-/nano-plastic transmission routes, and simultaneously achieve sustainable plastic waste management for value-added products. This implies that plastic trash could be utilised as a useful resource in an innovative and environmentally friendly way [77, 78]. The plastics frequently used during COVID era include testing kits, facemasks, shields, disposable gloves, disposable syringes, discarded gowns, and surgical drapes. Most of these parts are made of plastics like nylon, polystyrene (PS), polyethylene terephthalate (PET), polyethylene terephthalate (PET), and polypropylene (PP) [79, 80].The COVID-19 medical wastes might be risky and contagious because coronavirus strains can stay alive in plastic products for up to 72 h, depending on the material. This makes managing medical waste more challenging, especially in developing countries [81, 82]. Therefore, sustainable plastic waste disposal techniques have received much attention, including upcycling, burning, and biochar manufacturing [83, 84, 85]. It is acknowledged that upcycling plastics to create chemicals, fuels, and numerous other value-added goods is a big step in reducing their risky consequences. Upcycling trash management chains was emphasized by [18,19,20, 86], Li et al. [87], and You et al. [88]. Upcycling encourages the reuse of plastics; however, the intricacy, heterogeneity, and variety of plastics, a lack of facilities for reuse, subpar technology, and a small market for upcycled goods all contribute to a poor rate of transformation [89]. The era of COVID adversely affected every part of world and every work sector, which mainly affected industry sector .The industries which fulfill necessitites of food food and other necessities safely to customers is is being impacted more and more as the coronavirus pandemic spreads and its humanitarian impact grows. Due to the pandemic, consumers and businesses now recognise the hygiene benefits that plastic packaging can provide, which seem to exceed worries about recycling and environmental plastic waste leaks [90,91,92].

Similarly, incineration is the managed burning of waste with a significant reduction in waste weight (e.g., by 90%) to produce energy, ash, and flue gas in the presence of oxygen. However, burning plastic-based materials like polyvinyl chloride has several hazardous chlorinated chemicals and polyaromatic hydrocarbons [61, 93]. Also, it produces microplastics, which could risk human health and the environment if not properly controlled and monitored.

However, producing biochar from plastic trash via pyrolysis can be an effective and sustainable option for simultaneously managing plastic waste and mitigating environmental issues. During pyrolysis, complex hydrocarbon compounds of the wastes can break down into simpler molecules, and products that are comparatively necessary, such as gases, liquids, and solid char, are created. Only H2, CH4, C2H2, C2H4, C2H6, C3H6, C3H8, and C4H4 are detected in the gases produced during the normal pyrolysis of medical waste [69, 94, 95]. Figure 13 shows a schematic representation of COVID-19 waste creation and degradation processes. Inorganic compounds called “char” are carbon-rich materials found in plastic garbage. Condensable gases and solid char are produced due to the pyrolysis process's initial breakdown of garbage.

The figure displays the COVID-19 waste creation and degradation processes (adapted from Selvakumar D. et al., 2021 [96])

Additionally, the gases would go through a secondary breakdown, evolving into liquids, char, and non-condensable gases (CH4, CO2, CO, and H2). The char, a solid by-product of waste breakdown, has carbon sequestration (CO2 trapping) qualities [69, 97]. Like coal feedstock, char has a high heating value of 34 MJ/kg.

Additionally, it can be used as fuel during the pyrolysis process Zeng et al. [98]. Due to its high carbon content, char has characteristics that are similar to those of activated carbon. They have great adsorption qualities that can be utilized to create activated carbon since char is a product obtained from waste plastic. It can be a less expensive alternative to activated charcoal [99].

Recycled PET plastic bottles were transformed into designed biochar for CO2 post-combustion capture, according to a study by Yuan et al. [79] and Wang et al. [18] successfully tackling two significant environmental issues at once: plastics pollution and climate change. From a life-cycle perspective, this perspective was also acknowledged as a closed carbon loop, which help reach carbon neutrality by year 2050 and sustainable plastic management. The characteristics and environmental usages of biochar made by co-pyrolyzing biomass and plastic were investigated by Rathnayake et al. [100]. Thus, a very sustainable method of reducing the global production of plastic trash could be to produce biochar. Pyrolysis offers a practical method for recycling COVID-19 era plastics and other pollutants, with the benefit of energy recovery and its ease in producing char, fuels, and gases [101, 102].

This section thoroughly covered the plastic items used, the various types and quantities of plastic trash produced by the COVID -19 epidemic, and viable remedies for these plastic wastes. Both practical applications and environmental protection were considered while discussing the conversion of plastic trash into biochar, which may be confirmed as a promising material for energy storage and environmental protection [103].

6 Potential applications of bamboo-derived charcoal and biochar

The bamboo-derived charcoal and biochar have tremendous applications in various sectors, as depicted below-.

6.1 Potential applications of activated charcoal

Bamboo is a valuable material for making activated charcoal. Bamboo charcoal can be used in treating wastewater, farming, soil improvement, and environmental protection for energy-related uses as depicted in Fig. 14. In addition, it can be used as a substrate for the production of hydrogen, added to fermenting and composting processes, used as a catalytic in pyrolysis for tar reduction, utilized in gas, pelletized as fuel, and more. Numerous studies have been published on the manufacturing, characterization, and potential uses and applications of activated charcoal from various feedstocks. Due to its many benefits, bamboo-activated charcoal is preserving its significance in the modern day [44]. The commercial, agricultural, and environmental sectors use bamboo-activated charcoal the most.

-

In dye-sensitized solar cell electrodes

Mesoporous carbon, a carbon-based substance like bamboo charcoal, can be used as the electrode in Dye Sensitized Solar Cells (DSSC). The resistance of carbonized bamboo charcoal, which is heated to temperatures between 700 and 900 °C, makes it ideal for use as an electrode [104]. The biochar most exceptional result in DSSC, which is 5.4%, is due to the porous activated carbon encased in nano-crystalline TiO2, which raises the absorptive capacity and the electron generation on exposure to light. Using bamboo charcoal to create DSSC is still in its early stages. Thus, additional advancements must be made.

-

As a cleansing of water-absorbent

Several businesses produce volatile compounds, polluting the environment and threatening human health. Activated carbon is an excellent adsorbent which has been used extensively for the removal of various pollutants [105]. Dye pollution of the environment is becoming increasingly well-known as an issue. An significant environmental concern is dye removal from wastewaters. Advanced oxidation processes biological treatment, ion exchange, and adsorption are a few of the methods used to treat dye wastewater. Due to its low cost, high adsorption capacity, and environmental friendliness, adsorption has been shown to be an efficient method for dye removal. In order to remove colour from wastewaters, porous materials, in particular activated carbon (AC), have frequently been utilised as adsorbents [106, 107]. Global concern has grown over microplastics contamination and their interactions with heavy metal ions. In all aquatic habitats, heavy metal ions must be absorbed [108, 109]. Hydrocarbon molecules like O2, N2, sulfur, halogen, and others are among the frequent substances. Typically, pollutants were removed from sewage or waste gas using adsorbents. According to R. Wang et al. [40, 110], the carbonization temperature affects the sorption of bamboo charcoal. The pore size and adsorption rate both increased as the temperature rose. Bamboo carbon is activated and affects how things are absorbed into the water. Compared with charcoal activated with CO2, which mainly relies on the activation temperature. With the development of acidic functional groups but no change to the pore structure, bamboo activated with HNO3 showed a greater surface area. The research also discovered that charcoal powered by NH3 did not generate a satisfactory yield, although the membrane pore size increases with temperature. However, the HNO3 activation mechanism has many more functional groups and is more capable of adsorbing water vapour in low humidity settings.

-

As an electromagnetic waves absorber

Porous structure of carbon functionalization as a absorber of electromagnetic waves (adapted from Hongtao [111])

Electromagnetic (EM) interference issues have significantly increased due to the intensive work toward gigahertz (Ghz) electronic systems and telecommunication gadgets. According to J.M. Thomassin et al. [110], electromagnetic waves are electromagnetic signals conducted or radiated by electrical circuits while operating. These signals can interfere with the operation of nearby equipment and result in radioactive harm to living things.

As a result, there is a critical requirement for creating EM absorptive materials with low density, better thermal stability, higher adsorption capabilities, comprehensive electromagnetic implementation, and a more affordable solution. Bamboo charcoal can be an acceptable replacement based on the requirements because it has comparable high conductivity and surface area with high adsorption properties, as shown in Fig. 15.

6.2 Applications of the biochar

Biochar is an adaptable bio-product used in the industrial, agricultural, and energy industries. According to numerous researches, biochar is helpful for soil emendation and purification [4]. Additionally, the biochar can disable heavy metals, including Cu, Pb, Zn, and Cd, through various mechanisms, such as raising soil pH. A value-added product that supports the economy, biochar has made significant advancements. In addition to reducing emissions of greenhouse gases and global warming, biochar has also helped to increase agricultural output, absorb carbon from the environment into the soil, and decrease the bioavailability of environmental pollutants. Exploration and utilization of bio-resources are implied by the term “bio-economy,” which also refers to the utilization of biotechnology to produce valuable bio-products. Producing biochar can therefore improve soil quality and provide prospects for additional income.

-

Release of nutrients from biochar

Numerous studies demonstrate biochar improves nutrient availability, making it an excellent candidate for use as a slow release of fertilizer in the soil. The desorption properties of biochar are the only factors that affect when nutrients are released from it. The pyrolysis temperature, feedstock type, and biochar application are the only factors impacting biochar desorption characteristics [112]. To achieve the anticipated effects on nutrient delivery, it is assumed that many biochar types can be utilized differently to deliver different soil minerals in the same soil [113, 114].

-

Enhances the soil properties

The environment is strongly impacted by biochar’s presence in the soil’s uppermost layer, including depth, porosity, altered texture, structure, and consistency. This is due to the pore size distribution, surface energy, packings, particle sizes, and bulk density change. However, it alters the soil’s properties, directly impacting how well the plant grows [115, 116]. It modifies the soil’s physical makeup, increasing its specific surface area, which unquestionably improves the soil's aeration and structure [117]. Mycorrhiza fungi are stimulated by biochar in their activity. The mycorrhiza fungi’s ability to live in biochar and the soil quality is improved. It increases the soil’s ability to exchange cations and anions, enhancing soil characteristics and raising the pH and total P and N levels while lowering any possible levels of aluminum. The soil’s moisture is increased, nutrients loss and soil degradation are decreased, and drought is lessened by biochar. This results in substantial potential for the adsorption of hazardous compounds since the biochar surface comprises a range of reactive chemical groups, such as acetone, diols, and carboxylic. In heavy metal-polluted soils, the dangerous elements include leads, cadmium, nickel, and copper. Acidic soils often include manganese and aluminum. Due to some biochar granules, the soil becomes substantially more porous. These particles also promote circulation through the waste disposal site and improve oxygen diffusion within the landfill cover, which may cause severe microbial degradation [118, 119]. Using biochar in soil has several advantages, as shown in Fig. 16. Biochar boosts the bio-physical characteristics of the soil, such as its capacity to store water and retain nutrients, while promoting plant growth.

-

Gas remediation

Biochar is particularly effective in removing hazardous gas constituents. H2S from biogas is successfully removed by biochar made from pig manure, camphor, rice hulls, bamboo, sludge, and hardwood chips Lehmann and others, 2006 [120].

-

Biochar and greenhouse gases

The main contributors to climate change are the rise in global warming and greenhouse gas emission, while carbon dioxide (CO2) emissions account for more than 77% of these changes [121]. Comparing the release of carbon (IV) oxide from soil respiration to that from burning fossil fuels, the difference is around ten times greater [122]. To moderate climate change, it is also crucial to reduce carbon dioxide pollutants in agricultural soil. Biochar is utilised to lower nitrous oxide (N2O) and CH4 emissions while increasing soil carbon sequestration. Recent research suggests that charcoal could lessen soil releases of methane and nitrous oxide, two greenhouse gases (GHGs) incredibly influential in global warming and are in charge of global warming. An illustration of this can be seen in the fact that chicken litter made from green waste, biosolids, and paper mill waste lowers N2O emissions from an acidic Ferro sol, despite the claims of specific researchers. These demonstrate that different biochar forms have various effects on soil GHGs emissions. The soil's water content, the feedstocks used to produce biochar, and the material’s heat temperature is pyrolyzed all impact the material’s ability to lower greenhouse gas emissions. Biochar has a large surface area and provides suitable nitrous oxide and nitrogen adsorption sites, which decrease the spread of these pollutants from the land ecology. The removal of nutrients and GHGs from constructed wetlands (CWs) was determined using biochar and various COD/N ratios, according to Guo and co-workers [123]. By including biochar in the CWs, the elimination of COD, + NH—N4 and TN might be improved. As illustrated in Fig. 17, biochar could increase CH4 generation while reducing N2O and CO2 fluxes.

Fig. 17 The effect of biochar on the greenhouse effect (adapted from F. [123]

-

Removal of organic pollutant

Introducing biochar to soil is essential for removing organic pollutants, especially fungicides, herbicides, pesticides, and insecticides. The primary methods for removing organic pollutants are physisorption and chemisorption (electrophilic interaction). There are further methods, such as bio-degradation. The biochar interaction with organic pollutants is influenced by pH, the temperature of pyrolysis, bio-feedstock, and pollutant ratios [124]. Because the biochar produced at higher pyrolysis temperatures has more surface area and microporosity, which makes it ideal for removing nonpolar organic contaminants, it is not produced at lower temperatures. At higher pyrolysis temperatures (above 500 °C), removing O- and H-containing functional groups upon biochar is associated with increased aromaticity, low polarity, and acidity. However, biochar produced at the lower temperatures than 500 °C may have more functional groups that contain O and H, making it more naturally attracted to hydrophilic organic molecules. Hydrophobic interactions quicken as functional groups containing the O- start to decline [29]. Utilizing biochar has decreased the accessibility of organic soil contaminants and their uptake by microbial life and plants, as shown in Fig. 18. The figure illustrates how biochar removes organic pollutants from waste water.

Biochar application of removal of organic toxic pollutants from wastewater (adapted from [125])

-

Plastic waste management

Due to COVID-19, the amount of disinfectant waste produced worldwide has considerably increased, with hospitals, pharmacies, and other health clinics producing the majority of this waste. Personal protective equipment (PPE) and plastic wrapping materials have been widely used to stop the spread of COVID-19, resulting in massive amounts of plastic waste and other medical waste. These include test kits, facemasks, shields, throw-away gloves, syringes, surgical drapes, and gowns. An efficient and long-lasting method for managing plastic waste and reducing environmental problems simultaneously is the pyrolysis of plastic waste to produce biochar [87, 88]. This adversely effect the marine life also, from the poles to the equator, from shorelines, estuaries, and the sea surface to the depths of the ocean, man-made waste has ruined marine environments. The four material kinds that are most frequently discovered in marine debris are glass, metal, paper, and plastic [126]. It is clear from the published literature that plastic items constantly rank among the most numerically abundant types of marine debris on a global basis. Chemical pollutants like metals or medicines can be adsorbently taken up by microplastics, where they can then go up the food chain [127,128,129]. Complex hydrocarbon compounds found in wastes may be reduced to simpler molecules during the pyrolysis process, which also produces relatively essential byproducts such as gas, liquids, and solid char [86].

7 Conclusion, future prospective and recommendations

This review’s primary purpose is to comprehensively summarize the potential of various bamboo species for producing charcoal and biochar. The essential scientific developments in bamboo biochar and charcoal in recent years are critically highlighted. A separate section about the charcoal and biochar has been focused upon. Several bamboo species like Bambusa vulgaris, Gigantochloa Albociliata, Moso bamboo (Phyllostachys edulis), Dendrocalamus giganteus, Bamboo Dendro. catiflorus Munro, Dry bamboo stalks, Phyllostachys virdiglaucesons etc., were used by various researchers for developing bamboo charcoal and biochar. As per the reports and data analysis, bamboo chopsticks are the most efficient source for making charcoal, yielding a high of 74.27% at 300 °C in nitrogen atmosphere, where in the bamboo D. giganteus, generated 80% biochar at 300 °C.

The argon, nitrogen, or inert environment has been created during the charcoal or biochar preparation process from bamboo. The broad application spectrum of charcoal and biochar has been highlighted in a separate section. The charcoal is a promising adsorbent that can be used as an electromagnetic wave absorber, play a role in dye-sensitized solar cells as electrodes, and water purification as an absorbent. Biochar is reported to be helpful for the release of nutrients, gas remediation, effect on soil properties, biochar and greenhouse gasses and removal of organic pollutants. The COVID-19 era’s medical and plastic wastes was decomposed through pyrolysis, producing fuels and char. Thus, bamboo, a lignocellulosic material, has evolved and changed into several forms, such as charcoal and biochar, for various environmental benefits. This in-depth analysis of bamboo's distinctive ability to yield charcoal and biochar is fundamental. The research's findings imply that charcoal and biochar will soon hold a significant position in the urban, green building, and gardening industries and help increase the nation's economic aspects. Thus, it is enforced to enhance the property of the developed charcoal and biochar from bamboo as an unique natural gift source. Researchers, producers, and potential adopters have all expressed interest in using charcoal and biochar in these areas since they may offer many advantages and opportunities. Due to its multifunctional properties, we propose that the tailored biochar technique has to continue to be developed in other domains. The procedure of making activated charcoal from raw bamboo is altered, which has many positive effects on the future modification and preference of activated charcoal. Some recommendations may include the following:

-

It is advised to grow more bamboos to assist the environment and the economy.

-

The activated charcoal and biochar surface area needs to be increased so that the pores become more prominent and have more extraordinary adsorption properties, which makes it useful for various biological applications.

-

To improve the adsorption property of the activated charcoal, a more laser-sharp focus should be made on numerous aspects such as temperature, precursor, and activation methods.

Data availability

All research data mentioned in the manuscript are appropriately cited and linked to the data.

References

Yuming Y, Jian ZH (1991) Prospect for bamboo based products as replacement for wood in Yunan . In : Proceedings of 4th international bamboo workshop , Thailand 273–277

Yang D, Li H, Xiong Z, Mimendi L, Lorenzo R, Corbi I, Corbi O, Hong C (2020) Mechanical properties of laminated Bamboo under off-axis compression. Compos A Appl Sci Manuf 138:106042

Qiao Y, Zhang S, Quan C, Gao N, Johnston C, Wu C (2020) One-pot synthesis of digestate-derived biochar for carbon dioxide capture. Fuel 279:118525

Bruun S, Clauson-Kaas S, Bobuľská L, Thomsen IK (2014) Carbon dioxide emissions from biochar in soil: role of clay, microorganisms and carbonates. Eur J Soil Sci 65(1):52–59

Igalavithana AD, Lee SE, Lee YH, Tsang DCW, Rinklebe J, Kwon EE, Ok YS (2017) Heavy metal immobilization and microbial community abundance by vegetable waste and pine cone biochar of agricultural soils. Chemosphere 174:593–603

Akdeniz N (2019) A systematic review of biochar use in animal waste composting. Waste Manag 88:291–300

Gupta T, Ghosh R (2015) Rotating bed adsorber system for carbon dioxide capture from flue gas. Int J Greenhouse Gas Control 32:172–188

Jiang L, Gonzalez-Diaz A, Ling-Chin J, Roskilly AP, Smallbone AJ (2019) Post-combustion CO2 capture from a natural gas combined cycle power plant using activated carbon adsorption. Appl Energy 245:1–15

Lee JW, Hawkins B, Kidder MK, Evans BR, Buchanan AC, Day D (2016) Characterization of biochars produced from peanut hulls and pine wood with different pyrolysis conditions. Bioresources and Bioprocessing 3(1):1–10

Osayi I, Iyuke S, Ogbeide SE (2014) Biocrude production through pyrolysis of used tyres. J Catal 2014:1–9

Ephraim A, Pozzobon V, Lebonnois D, Peregrina C, Sharrock P, Nzihou A (2020) Pyrolysis of wood and PVC mixtures : thermal behaviour and kinetic modelling. Bioref, Biomass Conv. https://doi.org/10.1007/s13399-020-00952-2

Yaashikaa PR, Kumar P, Senthil Varjani, Sunita Saravanan, A. (2020). A critical review on the biochar production techniques, characterization, stability and applications for circular bioeconomy. Biotechnology Reports 28:e00570. https://doi.org/10.1016/j.btre.2020.e00570

Gradus RHJM, Nillesen PHL, Dijkgraaf E, van Koppen RJ (2017) A cost-effectiveness analysis for incineration or recycling of Dutch household plastic waste. Ecol Econ 135:22–28. https://doi.org/10.1016/j.ecolecon.2016.12.021

Hernandez-Mena LE, Pécoraa AAB, Beraldob AL (2014) Slow pyrolysis of bamboo biomass: analysis of biochar properties. Chem Eng 37:115–120. https://doi.org/10.3303/CET1437020

Vigneshwaran Shanmugam SN, Sreenivasan Rhoda Afriyie Mensah, Michael Försth, Gabriel Sas, Mikael S. Hedenqvist, Rasoul Esmaeely Neisiany, Yongming Tu, Oisik Das, A review on combustion and mechanical behaviour of pyrolysis biochar,Materials Today Communications, Volume 31,2022,103629,ISSN 2352–4928

Wei J, Tu C, Yuan G, Liu Y, Bi D, Xiao L, Lu J, Theng BK, Wang H, Zhang L, Zhang X (2019) Assessing the effect of pyrolysis temperature on the molecular properties and copper sorption capacity of a halophyte biochar. Environ Pollut 251:56–65

Bai M, Wilske B, Buegger F, Esperschütz J, Kammann CI, Eckhardt C, Koestler M, Kraft P, Bach M, Frede HG, Breuer L (2013) Degradation kinetics of biochar from pyrolysis and hydrothermal carbonization in temperate soils. Plant Soil 372(1):375–387

Wang J, Yuan X, Deng S, Zeng X, Yu Z, Li S, Li K (2020a) Waste polyethylene terephthalate (PET) plastics-derived activated carbon for CO2 capture: a route to a closed carbon loop. Green Chem 22(20):6836–6845. https://doi.org/10.1039/d0gc01613f

Wang L, Ok YS, Tsang DC, Alessi DS, Rinklebe J, Wang H, Mašek O, Hou R, O’Connor D, Hou D (2020) New trends in biochar pyrolysis and modification strategies: feedstock, pyrolysis conditions, sustainability concerns and implications for soil amendment. Soil Use Manag 36(3):358–386

Wang J, Yuan X, Deng S, Zeng X, Zhi Yu (2020b) Shuangjun Li Kaixiang Li Waste polyethylene terephthalate (PET) plastics-derived activated carbon for CO2 capture: a route to a closed carbon loop. Green Chem 22:6836–6845

Babalola Aisosa Oni, Olubukola Oziegbe, Obembe O.Olawole (2019) Significance of biochar application to the environment and economy. Ann Agric Sci 64:(2)

Plaza MG, Rubiera F, Pevida C (2017) Evaluating the feasibility of a TSA process based on steam stripping in combination with structured carbon adsorbents to capture CO2 from a coal power plant. Energy Fuels 31:9760–9775

Lucchini P, Quilliam RS, Deluca TH, Vamerali T, Jones DL (2014) Does biochar application alter heavy metal dynamics in agricultural soil? Agr Ecosyst Environ 184:149–157. https://doi.org/10.1016/j.agee.2013.11.018

Balahmar N, Al-Jumialy AS, Mokaya R (2017) Biomass to porous carbon in one step: directly activated biomass for high performance CO2 storage. J Mater Chem A 5:12330–12339

Lucchini P, Quilliam RS, Deluca TH, Vamerali T, Jones DL (2014) Increased bioavailability of metals in two contrasting agricultural soils treated with waste wood-derived biochar and ash. Environ Sci Pollut Res 21:3230–3240. https://doi.org/10.1007/s11356-013-2272-y

Uchimiya M, Klasson KT (2011) Screening biochars for heavy metal retention in soil: role of oxygen functional groups. J Hazard Mater 190:432–441. https://doi.org/10.1016/j.jhazmat.2011.03.063

Zhang YLZ, Maroto-Valer MM, Andresen JM, Schobert HH (2003) Comparison of high-unburned-carbon fly ashes from different combustor types and their steam activated products. Energy & Fuels 17:369–377

Buss W, Kammann C, Koyro HW (2012) Biochar reduces copper toxicity in Chenopodium quinoa willd: in a sandy soil. Journal of Environmental Quility 41:1157–1165. https://doi.org/10.2134/jeq2011.0022

Spokas KA (2010) Review of the stability of biochar in soils: predictability of O: C molar ratios. Carbon Manage 1:289–303

Mahanim SMA, Asma IW, Rafidah J, Puad E, Shaharuddin H (2011) Production of activated carbon from industrial bamboo wastes. J Trop Forest Sci 23:417–424

Wei H, Deng S, Hu B, Chen Z, Wang B, Huang J, Yu G (2012) Granular bamboo-derived activated carbon for high CO2 adsorption: the dominant role of narrow micropores. Chemsuschem 5:2354–2360

Li K, Leigh W, Feron P, Yu H, Tade M (2016) Systematic study of aqueous monoethanolamine (MEA)-based CO2 capture process: techno-economic assessment of the MEA process and its improvements. Appl Energy 165:648–659