Abstract

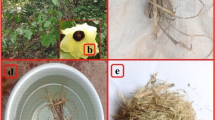

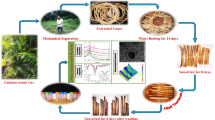

Nowadays, commercial natural fibers cannot meet the increasing industrial demand. In order to meet this demand, recommending a new natural fiber for the composites industry is very important. In this paper, Carex panicea fibers were characterized for the first time and introduced as a potential natural fiber. Physical, chemical, thermal, mechanical, and morphological properties of the Carex panicea fibers were characterized using scanning electron microscopy, Fourier transform infrared spectroscopy, thermogravimetric analysis, X-ray photoelectron spectroscopy, and X-ray diffraction analysis. Carex panicea fibers consist of 65.70% cellulose and 27.8% hemicellulose content. The density and crystallinity index of the fiber were found as 1.247 g/cm3 and 56.42%, respectively. Tensile strength and Young’s modulus of fibers were determined as 143 ± 41 MPa and 5.5 ± 1.86 GPa, respectively. Carex panicea fibers are thermally stable up to 219.4 °C. Carex panicea fibers are potential bio-degradable reinforcement material for light-weight polymeric composites with relatively enhanced mechanical properties and decomposition temperature.

Similar content being viewed by others

Data availability

Not applicable.

References

Kumar R, Sivaganesan S, Senthamaraikannan P et al (2020) Characterization of new cellulosic fiber from the bark of Acacia nilotica L. plant. J Nat Fibers. https://doi.org/10.1080/15440478.2020.1738305

Khan A, Vijay R, Singaravelu DL et al (2021) Extraction and characterization of natural fiber from Eleusine indica grass as reinforcement of sustainable fiber reinforced polymer composites. J Nat Fibers 18:1742–1750. https://doi.org/10.1080/15440478.2019.1697993

Narayanasamy P, Balasundar P, Senthil S et al (2020) Characterization of a novel natural cellulosic fiber from Calotropis gigantea fruit bunch for ecofriendly polymer composites. Int J Biol Macromol 150:793–801. https://doi.org/10.1016/j.ijbiomac.2020.02.134

Gholampour A, Ozbakkaloglu T (2020) A review of natural fiber composites: properties, modification and processing techniques, characterization, applications. J Mater Sci 55:829–892

Jiang S, Chen Y, Duan G et al (2018) Electrospun nanofiber reinforced composites: a review. Polym Chem 9:2685–2720

Linan LZ, Cidreira ACM, da Rocha CQ et al (2021) Utilization of acai berry residual biomass for extraction of lignocellulosic byproducts. J Bioresour Bioprod 6:323–337. https://doi.org/10.1016/j.jobab.2021.04.007

Fatima A, Yasir S, Khan MS et al (2021) Plant extract-loaded bacterial cellulose composite membrane for potential biomedical applications. J Bioresour Bioprod 6:26–32. https://doi.org/10.1016/j.jobab.2020.11.002

Venkatesh G, Vignesh V, Nagarajan KJ et al (2021) Extraction and characterization of agricultural discarded Sesbania aculeata stem waste as potential alternate for synthetic fibers in polymer composites. J Nat Fibers. https://doi.org/10.1080/15440478.2021.2002756

Babu NBK, Vignesh V, Nagaprasad N et al (2022) Studies on mechanical characterisation of bio-fibre reinforced polymer composites. Bio-Fiber reinforced composite materials. Springer, Singapore, pp 143–155

Vinod A, Vijay R, Singaravelu DL et al (2021) Extraction and characterization of natural fiber from stem of Cardiospermum halicababum. J Nat Fibers 18:898–908. https://doi.org/10.1080/15440478.2019.1669514

Amutha V, Senthilkumar B (2021) Physical, chemical, thermal, and surface morphological properties of the bark fiber extracted from Acacia concinna plant. J Nat Fibers 18:1661–1674. https://doi.org/10.1080/15440478.2019.1697986

Ding L, Han X, Cao L et al (2022) Characterization of natural fiber from manau rattan (Calamus manan) as a potential reinforcement for polymer-based composites. J Bioresour Bioprod 7:190–200. https://doi.org/10.1016/j.jobab.2021.11.002

Jamshaid H, Mishra R, Basra S et al (2020) Lignocellulosic natural fiber reinforced bisphenol F epoxy based bio-composites: characterization of mechanical electrical performance. J Nat Fibers 19:3317–3332. https://doi.org/10.1080/15440478.2020.1843586

Bijlwan PP, Prasad L, Sharma A (2021) Recent advancement in the fabrication and characterization of natural fiber reinforced composite: a review. In: Materials Today: Proceedings. Elsevier, pp 1718–1722

Vignesh V, Balaji AN, Mohamed Rabi BR et al (2021) Cellulosic fiber based hybrid composites: a comparative investigation into their structurally influencing mechanical properties. Constr Build Mater 271:121587. https://doi.org/10.1016/j.conbuildmat.2020.121587

Gaba EW, Asimeng BO, Kaufmann EE et al (2021) Mechanical and structural characterization of pineapple leaf fiber. Fibers 9:51. https://doi.org/10.3390/fib9080051

Kian LK, Saba N, Jawaid M, Fouad H (2020) Characterization of microcrystalline cellulose extracted from olive fiber. Int J Biol Macromol 156:347–353. https://doi.org/10.1016/j.ijbiomac.2020.04.015

Alvarez V, Rodriguez E, Vázquez A (2006) Thermal degradation and decomposition of jute/vinylester composites. J Therm Anal Calorim 85:383–389

Keshk S, Suwinarti W, Sameshima K (2006) Physicochemical characterization of different treatment sequences on kenaf bast fiber. Carbohydr Polym 65:202–206. https://doi.org/10.1016/j.carbpol.2006.01.005

Sawpan MA, Pickering KL, Fernyhough A (2011) Effect of various chemical treatments on the fibre structure and tensile properties of industrial hemp fibres. Compos Part A Appl Sci Manuf 42:888–895. https://doi.org/10.1016/j.compositesa.2011.03.008

Xu Y, Adekunle K, Ramamoorthy SK et al (2020) Methacrylated lignosulfonate as compatibilizer for flax fiber reinforced biocomposites with soybean-derived polyester matrix. Compos Commun 22:100536. https://doi.org/10.1016/J.COCO.2020.100536

Jagadeesh P, Puttegowda M, Mavinkere Rangappa S, Siengchin S (2021) A review on extraction, chemical treatment, characterization of natural fibers and its composites for potential applications. Polym Compos 42:6239–6264. https://doi.org/10.1002/PC.26312

Dawit JB, Regassa Y, Lemu HG (2021) Property characterization of acacia tortilis for natural fiber reinforced polymer composite. Mater Today Proc 44:1718–1722. https://doi.org/10.1016/j.rinma.2019.100054

Vijay R, Manoharan S, Arjun S et al (2020) Characterization of silane-treated and untreated natural fibers from stem of Leucas aspera. J Nat Fibers. https://doi.org/10.1080/15440478.2019.1710651

Kılınç AÇ, Köktaş S, Seki Y et al (2018) Extraction and investigation of lightweight and porous natural fiber from Conium maculatum as a potential reinforcement for composite materials in transportation. Compos Part B Eng 140:1–8. https://doi.org/10.1016/j.compositesb.2017.11.059

Ahmed J, Balaji MA, Saravanakumar SS, Senthamaraikannan P (2021) A comprehensive physical, chemical and morphological characterization of novel cellulosic fiber extracted from the stem of Elettaria cardamomum plant. J Nat Fibers 18:1460–1471. https://doi.org/10.1080/15440478.2019.1691121

Rajeshkumar G, Devnani GL, Maran JP et al (2021) Characterization of novel natural cellulosic fibers from purple bauhinia for potential reinforcement in polymer composites. Cellulose 28:5373–5385. https://doi.org/10.1007/s10570-021-03919-2

Gedik G (2021) Extraction of new natural cellulosic fiber from Trachelospermum jasminoides (star jasmine) and its characterization for textile and composite uses. Cellulose 28:6899–6915. https://doi.org/10.1007/s10570-021-03952-1

Sumihartati A, Wardiningsih W, Al Kautsar N et al (2021) Natural cellulosic fiber from Cordyline australis leaves for textile application: extraction and characterization. Res J Text Appar. https://doi.org/10.1108/RJTA-04-2021-0049

Eyupoglu S, Merdan N (2021) Physicochemical properties of new plant based fiber from lavender stem. J Nat Fibers: 1–11. https://doi.org/10.1080/15440478.2021.1982816

Belouadah Z, Toubal LM, Belhaneche-Bensemra N, Ati A (2021) Characterization of ligno-cellulosic fiber extracted from Atriplex halimus L. plant. Int J Biol Macromol 168:806–815. https://doi.org/10.1016/j.ijbiomac.2020.11.142

Senthamaraikannan P, Kathiresan M (2018) Characterization of raw and alkali treated new natural cellulosic fiber from Coccinia grandis.L. Carbohydr Polym 186:332–343. https://doi.org/10.1016/j.carbpol.2018.01.072

Belouadah Z, Ati A, Rokbi M (2015) Characterization of new natural cellulosic fiber from Lygeum spartum L. Carbohydr Polym 134:429–437. https://doi.org/10.1016/j.carbpol.2015.08.024

Chakravarthy KS, Madhu SM, Naga Raju JS, Shariff MdJ (2020) Characterization of novel natural cellulosic fiber extracted from the stem of Cissus vitiginea plant. Int J Biol Macromol 161:1358–1370. https://doi.org/10.1016/j.ijbiomac.2020.07.230

Arul Marcel Moshi A, Ravindran D, Sundara Bharathi SR et al (2020) Characterization of natural cellulosic fiber extracted from Grewia damine flowering plant’s stem. Int J Biol Macromol 164:1246–1255. https://doi.org/10.1016/j.ijbiomac.2020.07.225

Dalmis R, Kilic GB, Seki Y et al (2020) Characterization of a novel natural cellulosic fiber extracted from the stem of Chrysanthemum morifolium. Cellulose 27:8621–8634. https://doi.org/10.1007/s10570-020-03385-2

Vijay R, James Dhilip JD, Gowtham S et al (2022) Characterization of natural cellulose fiber from the barks of Vachellia farnesiana. J Nat Fibers 19:1343–1352. https://doi.org/10.1080/15440478.2020.1764457

KılınÇ AÇ, Köktaş S, Atagür M, Seydibeyoglu MÖ (2018) Effect of extraction methods on the properties of Althea officinalis L. fibers. J Nat Fibers 15:325–336. https://doi.org/10.1080/15440478.2017.1325813

Moussaoui N, Rokbi M, Osmani H et al (2021) Extraction and characterization of fiber treatment Inula viscosa fibers as potential polymer composite reinforcement. J Polym Environ 29:3779–3793. https://doi.org/10.1007/s10924-021-02147-w

Raju JSN, Depoures MV, Kumaran P (2021) Comprehensive characterization of raw and alkali (NaOH) treated natural fibers from Symphirema involucratum stem. Int J Biol Macromol 186:886–896. https://doi.org/10.1016/j.ijbiomac.2021.07.061

Mylsamy K, Rajendran I (2010) Investigation on physio-chemical and mechanical properties of raw and alkali-treated Agave americana fiber. J Reinf Plast Compos 29:2925–2935. https://doi.org/10.1177/0731684410362817

Kumar AM, Parameshwaran R, Kumar PS et al (2017) Effects of abaca fiber reinforcement on the dynamic mechanical behavior of vinyl ester composites. Mater Test 59:555–562. https://doi.org/10.3139/120.111044

Bhuvaneshwaran M, Subramani SP, Palaniappan SK et al (2021) Natural cellulosic fiber from Coccinia indica stem for polymer composites: extraction and characterization. J Nat Fibers 18:644–652. https://doi.org/10.1080/15440478.2019.1642826

Mylsamy B, Palaniappan SK, Subramani SP et al (2020) Innovative characterization and mechanical properties of natural cellulosic Coccinia indica fiber and its composites. Mater Test 62:61–67. https://doi.org/10.3139/120.111451

Mylsamy B, Palaniappan SK, Pavayee Subramani S et al (2019) Impact of nanoclay on mechanical and structural properties of treated Coccinia indica fibre reinforced epoxy composites. J Mater Res Technol 8:6021–6028. https://doi.org/10.1016/j.jmrt.2019.09.076

Aruchamy K, Pavayee Subramani S, Palaniappan SK et al (2020) Study on mechanical characteristics of woven cotton/bamboo hybrid reinforced composite laminates. J Mater Res Technol 9:718–726. https://doi.org/10.1016/j.jmrt.2019.11.013

Sethuraman B, Subramani SP, Palaniappan SK et al (2020) Experimental investigation on dynamic mechanical and thermal characteristics of Coccinia indica fiber reinforced polyester composites. J Eng Fiber Fabr 15:1–6. https://doi.org/10.1177/1558925020905831

Chinnasamy V, Subramani SP, Palaniappan SK et al (2020) Characterization on thermal properties of glass fiber and kevlar fiber with modified epoxy hybrid composites. J Mater Res Technol 9:3158–3167. https://doi.org/10.1016/j.jmrt.2020.01.061

Mylsamy B, Chinnasamy V, Palaniappan SK et al (2020) Effect of surface treatment on the tribological properties of Coccinia indica cellulosic fiber reinforced polymer composites. J Mater Res Technol 9:16423–16434. https://doi.org/10.1016/j.jmrt.2020.11.100

Aruchamy K, Subramani SP, Palaniappan SK et al (2022) Effect of blend ratio on the thermal comfort characteristics of cotton/bamboo blended fabrics. J Nat Fibers 19:105–114. https://doi.org/10.1080/15440478.2020.1731903

Nagappan S, Subramani SP, Palaniappan SK, Mylsamy B (2021) Impact of alkali treatment and fiber length on mechanical properties of new agro waste Lagenaria siceraria fiber reinforced epoxy composites. J Nat Fibers. https://doi.org/10.1080/15440478.2021.1932681

Rieley JO (1967) The ecology of carex flacca schreb and carex panicea L. Dissertation, Durham University

Vermeer JG (1983) Berendse F (1983) The relationship between nutrient availability, shoot biomass and species richness in grassland and wetland communities. Vegetatio 532(53):121–126. https://doi.org/10.1007/BF00043032

Keskin OY, Dalmis R, Balci Kilic G et al (2020) Extraction and characterization of cellulosic fiber from Centaurea solstitialis for composites. Cellulose 27:9963–9974

Ahvenainen P, Kontro I, Svedström K (2016) Comparison of sample crystallinity determination methods by X-ray diffraction for challenging cellulose I materials. Cellulose 23:1073–1086. https://doi.org/10.1007/s10570-016-0881-6

Sreenivas HT, Krishnamurthy N, Arpitha GR (2020) A comprehensive review on light weight kenaf fiber for automobiles. Int J Light Mater Manuf 3:328–337

Shyam Kumar R, Balasundar P, Al-Dhabi NA et al (2021) A new natural cellulosic pigeon pea (Cajanus cajan) pod fiber characterization for bio-degradable polymeric composites. J Nat Fibers 18:1285–1295. https://doi.org/10.1080/15440478.2019.1689887

Gapsari F, Purnowidodo A, Hidayatullah S, Suteja S (2021) Characterization of Timoho Fiber as a reinforcement in green composite. J Mater Res Technol 13:1305–1315. https://doi.org/10.1016/j.jmrt.2021.05.049

Senthamaraikannan P, Sanjay MR, Bhat KS et al (2019) Characterization of natural cellulosic fiber from bark of Albizia amara. J Nat Fibers 16:1124–1131. https://doi.org/10.1080/15440478.2018.1453432

Hyness NRJ, Vignesh NJ, Senthamaraikannan P et al (2018) Characterization of new natural cellulosic fiber from Heteropogon contortus plant. J Nat Fibers 15:146–153. https://doi.org/10.1080/15440478.2017.1321516

Manimaran P, Saravanan SP, Sanjay MR et al (2020) New lignocellulosic Aristida adscensionis fibers as novel reinforcement for composite materials: extraction, characterization and weibull distribution analysis. J Polym Environ 28:803–811. https://doi.org/10.1007/s10924-019-01640-7

Subramanian SG, Rajkumar R, Ramkumar T (2021) Characterization of natural cellulosic fiber from Cereus hildmannianus. J Nat Fibers 18:343–354. https://doi.org/10.1080/15440478.2019.1623744

Ramkumar R, Saravanan P (2021) Characterization of the cellulose fibers extracted from the bark of Piliostigma racemosa. J Nat Fibers. https://doi.org/10.1080/15440478.2021.1875356

Maepa CE, Jayaramudu J, Okonkwo JO et al (2015) Extraction and characterization of natural cellulose fibers from maize tassel. Int J Polym Anal Charact 20:99–109. https://doi.org/10.1080/1023666X.2014.961118

Seki Y, Köktaş S, Kilinc AC, Dalmis R (2019) Green alternative treatment for cellulosic fibers: ionic liquid modification of Abelmoschus esculentus fibers with methyl-tri-n-butyl ammonium methyl sulphate. Mater Res Express 6:8. https://doi.org/10.1088/2053-1591/AB2015

Seki Y, Kılınç AÇ, Dalmis R et al (2018) Surface modification of new cellulose fiber extracted from Conium maculatum plant: a comparative study. Cellulose 25:3267–3280. https://doi.org/10.1007/S10570-018-1797-0

Uma Maheswari C, Obi Reddy K, Muzenda E et al (2012) Extraction and characterization of cellulose microfibrils from agricultural residue - Cocos nucifera L. Biomass Bioenerg 46:555–563. https://doi.org/10.1016/j.biombioe.2012.06.039

Obi Reddy K, Guduri BR, Rajulu AV (2009) Structural characterization and tensile properties of Borassus fruit fibers. J Appl Polym Sci 114:603–611. https://doi.org/10.1002/app.30584

Mwaikambo LY, Ansell MP (2002) Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J Appl Polym Sci 84:2222–2234. https://doi.org/10.1002/app.10460

Sreenivasan VS, Somasundaram S, Ravindran D et al (2011) Microstructural, physico-chemical and mechanical characterisation of Sansevieria cylindrica fibres - an exploratory investigation. Mater Des 32:453–461. https://doi.org/10.1016/j.matdes.2010.06.004

Jonoobi M, Harun J, Shakeri A et al (2009) Chemical composition, crystallinity, and thermal degradation of bleached and unbleached kenaf bast (Hibiscus cannabinus) pulp and nanofibers. BioResources 4:626–639. https://doi.org/10.15376/biores.4.2.626-639

Sgriccia N, Hawley MC, Misra M (2008) Characterization of natural fiber surfaces and natural fiber composites. Compos Part A Appl Sci Manuf 39:1632–1637. https://doi.org/10.1016/j.compositesa.2008.07.007

Dalmis R, Köktaş S, Seki Y, Kılınç AÇ (2020) Characterization of a new natural cellulose based fiber from Hierochloe odarata. Cellulose 27:127–139. https://doi.org/10.1007/s10570-019-02779-1

Fackler K, Stevanic JS, Ters T et al (2011) FT-IR imaging microscopy to localise and characterise simultaneous and selective white-rot decay within spruce wood cells. Holzforschung 65:411–420. https://doi.org/10.1515/HF.2011.048

De Rosa IM, Kenny JM, Puglia D et al (2010) Morphological, thermal and mechanical characterization of okra (Abelmoschus esculentus) fibres as potential reinforcement in polymer composites. Compos Sci Technol 70:116–122. https://doi.org/10.1016/j.compscitech.2009.09.013

De Rosa IM, Kenny JM, Maniruzzaman M et al (2011) Effect of chemical treatments on the mechanical and thermal behaviour of okra (Abelmoschus esculentus) fibres. Compos Sci Technol 71:246–254. https://doi.org/10.1016/j.compscitech.2010.11.023

Alemdar A, Sain M (2008) Isolation and characterization of nanofibers from agricultural residues - wheat straw and soy hulls. Bioresour Technol 99:1664–1671. https://doi.org/10.1016/j.biortech.2007.04.029

Xu F, Yu J, Tesso T et al (2013) Qualitative and quantitative analysis of lignocellulosic biomass using infrared techniques: a mini-review. Appl Energy 104:801–809

Oh SY, Dong IY, Shin Y et al (2005) Crystalline structure analysis of cellulose treated with sodium hydroxide and carbon dioxide by means of X-ray diffraction and FTIR spectroscopy. Carbohydr Res 340:2376–2391. https://doi.org/10.1016/j.carres.2005.08.007

Porras A, Maranon A, Ashcroft IA (2015) Characterization of a novel natural cellulose fabric from Manicaria saccifera palm as possible reinforcement of composite materials. Compos Part B Eng 74:66–73. https://doi.org/10.1016/j.compositesb.2014.12.033

Saha P, Manna S, Chowdhury SR et al (2010) Enhancement of tensile strength of lignocellulosic jute fibers by alkali-steam treatment. Bioresour Technol 101:3182–3187. https://doi.org/10.1016/j.biortech.2009.12.010

Sarikanat M, Seki Y, Sever K, Durmuşkahya C (2014) Determination of properties of Althaea officinalis L. (Marshmallow) fibres as a potential plant fibre in polymeric composite materials. Compos Part B Eng 57:180–186. https://doi.org/10.1016/j.compositesb.2013.09.041

Belaadi A, Amroune S, Seki Y et al (2022) Extraction and characterization of a new lignocellulosic fiber from Yucca treculeana L. leaf as potential reinforcement for industrial biocomposites. J Nat Fibers: 1–16. https://doi.org/10.1080/15440478.2022.2054895

Köktaş S, Keskin ÖY, Dalmiş R et al (2022) Extraction and characterization of natural cellulosic fiber from Taraxacum Sect. Ruderalia. J Nat Fibers. https://doi.org/10.1080/15440478.2022.2064389

Albayrak D, Seki Y, Balcı Kılıç G et al (2022) Exploration of alternative cellulosic natural fiber from the stem of Malva slyvestris. J Nat Fibers. https://doi.org/10.1080/15440478.2022.2073498

Kale RD, Getachew Alemayehu T, Gorade VG (2020) Extraction and characterization of lignocellulosic fibers from Girardinia bullosa (Steudel) Wedd. (Ethiopian Kusha Plant). J Nat Fibers 17:906–920. https://doi.org/10.1080/15440478.2018.1539940

Ridzuan MJM, Abdul Majid MS, Afendi M et al (2016) Characterisation of natural cellulosic fibre from Pennisetum purpureum stem as potential reinforcement of polymer composites. Mater Des 89:839–847. https://doi.org/10.1016/j.matdes.2015.10.052

Saravanakumar SS, Kumaravel A, Nagarajan T et al (2013) Characterization of a novel natural cellulosic fiber from Prosopis juliflora bark. Carbohydr Polym 92:1928–1933. https://doi.org/10.1016/j.carbpol.2012.11.064

Moniruzzaman M, Mahmood H, Yusup S, Akil HM (2017) Exploring ionic liquid assisted pretreatment of lignocellulosic biomass for fabrication of green composite. J Japan Inst Energy 96:376–379. https://doi.org/10.3775/jie.96.376

Baskaran PG, Kathiresan M, Senthamaraikannan P, Saravanakumar SS (2018) Characterization of new natural cellulosic fiber from the bark of Dichrostachys cinerea. J Nat Fibers 15:62–68. https://doi.org/10.1080/15440478.2017.1304314

Yao F, Wu Q, Lei Y et al (2008) Thermal decomposition kinetics of natural fibers: Activation energy with dynamic thermogravimetric analysis. Polym Degrad Stab 93:90–98. https://doi.org/10.1016/j.polymdegradstab.2007.10.012

Balasundar P, Narayanasamy P, Senthamaraikannan P et al (2018) Extraction and characterization of new natural cellulosic Chloris barbata fiber. J Nat Fibers 15:436–444. https://doi.org/10.1080/15440478.2017.1349015

Kathirselvam M, Kumaravel A, Arthanarieswaran VP, Saravanakumar SS (2019) Isolation and characterization of cellulose fibers from Thespesia populnea barks: a study on physicochemical and structural properties. Int J Biol Macromol 129:396–406. https://doi.org/10.1016/j.ijbiomac.2019.02.044

Poletto M, Ornaghi J H L, Zattera AJ (2015) Thermal decomposition of natural fibers: kinetics and degradation mechanisms. In: Reactions and mechanisms in thermal analysis of materials, 1st edn. Wiley, New Jersey, pp 515–545

Fu P, Hu S, Xiang J et al (2012) Study on the gas evolution and char structural change during pyrolysis of cotton stalk. J Anal Appl Pyrolysis 97:130–136. https://doi.org/10.1016/j.jaap.2012.05.012

Khan A, Vijay R, Singaravelu DL et al (2022) Extraction and characterization of natural fibers from Citrullus lanatus climber. J Nat Fibers 19:621–629. https://doi.org/10.1080/15440478.2020.1758281

Vijay R, Manoharan S, Arjun S et al (2021) Characterization of silane-treated and untreated natural fibers from stem of Leucas aspera. J Nat Fibers 18:1957–1973. https://doi.org/10.1080/15440478.2019.1710651

Raja K, Prabu B, Ganeshan P et al (2021) Characterization studies of natural cellulosic fibers extracted from Shwetark stem. J Nat Fibers 18:1934–1945. https://doi.org/10.1080/15440478.2019.1710650

Fan M (2010) Characterization and performance of elementary hemp fibres: factors influencing tensile strength. BioResources 5:2307–2322. https://doi.org/10.15376/biores.5.4.2307-2322

Seki Y, Kılınç AÇ, Dalmış R, Köktaş S (2019) Characterization of flax, jute, and sisal fibers after sodium perborate modification. AATCC J Res 6:25–31. https://doi.org/10.14504/ajr.6.6.4

Karimi S, Tahir PM, Karimi A et al (2014) Kenaf bast cellulosic fibers hierarchy: a comprehensive approach from micro to nano. Carbohydr Polym 101:878–885. https://doi.org/10.1016/j.carbpol.2013.09.106

Liu Y, Hu H (2008) X-ray diffraction study of bamboo fibers treated with NaOH. Fibers Polym 9:735–739. https://doi.org/10.1007/s12221-008-0115-0

Sunny T, Pickering KL, Lim SH (2020) Alkali treatment of hemp fibres for the production of aligned hemp fibre mats for composite reinforcement. Cellulose 27:2569–2582. https://doi.org/10.1007/s10570-019-02939-3

Chiang CL, Yang JM (2015) Flame retardance and thermal stability of polymer/graphene nanosheet oxide composites. In: Fillers and Reinforcements for Advanced Nanocomposites. Woodhead Publishing, pp 253–272

Pandey R, Sinha MK, Dubey A (2018) Cellulosic fibers from Lotus (Nelumbo nucifera) peduncle. J Nat Fibers 17:298–309. https://doi.org/10.1080/15440478.2018.1492486

Seki Y, Sarikanat M, Sever K, Durmuşkahya C (2013) Extraction and properties of Ferula communis (chakshir) fibers as novel reinforcement for composites materials. Compos Part B Eng 44:517–523. https://doi.org/10.1016/j.compositesb.2012.03.013

Tran LQN, Yuan XW, Bhattacharyya D, et al (2015) Fiber-matrix interfacial adhesion in natural fiber composites. In: International Journal of Modern Physics B. World Scientific Publishing Company

Mat Taib R, Ariawan D, Mohd Ishak ZA (2016) Surface characterization of alkali treated kenaf fibers by XPS and AFM. Key Eng Mater 94:29–33. https://doi.org/10.4028/www.scientific.net/KEM.694.29

Seki Y, Sever K, Erden S et al (2012) Characterization of Luffa cylindrica fibers and the effect of water aging on the mechanical properties of its composite with polyester. J Appl Polym Sci 123:2330–2337. https://doi.org/10.1002/app.34744

Maache M, Bezazi A, Amroune S et al (2017) Characterization of a novel natural cellulosic fiber from Juncus effusus L. Carbohydr Polym 171:163–172. https://doi.org/10.1016/j.carbpol.2017.04.096

Alves Fidelis ME, Pereira TVC, Gomes ODFM et al (2013) The effect of fiber morphology on the tensile strength of natural fibers. J Mater Res Technol 2:149–157. https://doi.org/10.1016/j.jmrt.2013.02.003

Amroune S, Bezazi A, Belaadi A et al (2015) Tensile mechanical properties and surface chemical sensitivity of technical fibres from date palm fruit branches (Phoenix dactylifera L.). Compos Part A Appl Sci Manuf 71:95–106. https://doi.org/10.1016/j.compositesa.2014.12.011

Sanjay MR, Madhu P, Jawaid M et al (2018) Characterization and properties of natural fiber polymer composites: a comprehensive review. J Clean Prod 172:566–581

Author information

Authors and Affiliations

Contributions

Ozgur Yasin Keskin: conceptualization, methodology, validation, investigation, writing — original draft, writing — review and editing, and visualization; Serhan Koktas: investigation and writing — review and editing; Yasemin Seki: conceptualization, methodology, validation, investigation, writing — original draft, and writing — review and editing; Ramazan Dalmis: investigation and writing — review and editing; Gonca Balci Kilic: investigation and writing — review and editing; Didem Albayrak: investigation and writing — review and editing.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Keskin, O.Y., Koktas, S., Seki, Y. et al. Natural cellulosic fiber from Carex panicea stem for polymer composites: extraction and characterization. Biomass Conv. Bioref. (2022). https://doi.org/10.1007/s13399-022-03458-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-022-03458-1