Abstract

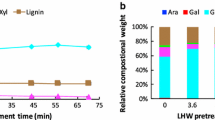

Initial material characteristics were one of the decisive factors affecting the hydrothermal pretreatment of woody biomass with a dense structure. In this study, the effect of initial material particle size on poplar hydrothermal pretreatment and enzymatic hydrolysis was evaluated. The enzymatic hydrolysis yield and the accessibility of the enzymatic reaction were significantly increased with an initial material with an average particle size of initial material (D50) < 500 μm, because of the different pretreatment effects of initial material. SEM and compositional analysis indicated that the reduction of the initial particle size facilitated hydrothermal pretreatment with better depolymerization effects. The bulk density of D50 < 500 μm increased by 28.87%, and the SSA increased by 68.51% compared with 2000–2500 μm. In contrast, the water holding capacity decreased by 59.40%. In addition, there was almost no free water in D50 < 500 μm and had weak mechanical properties, which was more conducive to the stirring of the hydrothermal pretreatment. Compared with the particle size of initial material being less than 100 μm, the D50 of initial material between 100 and 2500 μm was more energy saving and economically feasible. The particle size of poplar powder in this study could reduce pretreatment intensity and energy consumption and improve pretreatment energy efficiency significantly. This study was meaningful in identifying the size effects and exploring the optimal properties of initial material for poplar on hydrothermal pretreatment.

Graphical abstract

Similar content being viewed by others

References

Biswas S, Sharma DK (2021) A review on the co-processing of biomass with other fuels sources. Int J Green Energy 18(1):1–19

Bhatia SK, Jagtap SS, Bedekar AA, Bhatia RK, Patel AK, Pant D, Rajesh Banu J, Rao CV, Kim Y, Yang Y (2020) Recent developments in pretreatment technologies on lignocellulosic biomass: effect of key parameters, technological improvements, and challenges. Biores Technol 300:122724

Rajendran K, Drielak E, Sudarshan Varma V, Muthusamy S, Kumar G (2018) Updates on the pretreatment of lignocellulosic feedstocks for bioenergy production–a review. Biomass Conversion and Biorefinery 8(2):471–483

Kim SM, Dien BS, Singh V (2016) Promise of combined hydrothermal/chemical and mechanical refining for pretreatment of woody and herbaceous biomass. Biotechnol Biofuels 9(1):97

Pu Y, Hu F, Huang F, Davison BH, Ragauskas AJ (2013) Assessing the molecular structure basis for biomass recalcitrance during dilute acid and hydrothermal pretreatments. Biotechnol Biofuels 6(1):15

Meng X, Wells TJ, Sun Q, Huang F, Ragauskas A, O.R.T.U. Oak Ridge National Lab. ORNL, (2015) Insights into the effect of dilute acid, hot water or alkaline pretreatment on the cellulose accessible surface area and the overall porosity of Populus. Green chemistry : an international journal and green chemistry resource : GC 17(8):4239–4246

Das NPK, Padhi JD, Mohanty MK, Sahoo G (2021) A comprehensive review of characterization, pretreatment and its applications on different lignocellulosic biomass for bioethanol production. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-021-01294-3

Chai L, Liu M, Yan X, Cheng X, Zhang T, Si M, Min X, Shi Y (2018) Elucidating the interactive impacts of substrate-related properties on lignocellulosic biomass digestibility: a sequential analysis. ACS Sustainable Chemistry & Engineering 6(5):6783–6791

Rezania S, Oryani B, Cho J, Talaiekhozani A, Sabbagh F, Hashemi B, Rupani PF, Mohammadi AA (2020) Different pretreatment technologies of lignocellulosic biomass for bioethanol production: an overview. Energy 199:117457

Ji G, Xiao W, Gao C, Cao Y, Zhang Y, Han L (2018) Mechanical fragmentation of wheat and rice straw at different scales: energy requirement in relation to microstructure properties and enzymatic hydrolysis. Energy Convers Manage 171:38–47

Oyedeji O, Gitman P, Qu J, Webb E, O.R.T.U. Oak Ridge National Lab. ORNL, (2020) Understanding the impact of lignocellulosic biomass variability on the size reduction process: a review. ACS sustainable chemistry & engineering 8(6):2327–2343

Bychkov A, Podgorbunskikh E, Bychkova E, Lomovsky O (2019) Current achievements in the mechanically pretreated conversion of plant biomass. Biotechnol Bioeng 116(5):1231–1244

DeMartini JD, Foston M, Meng X, Jung S, Kumar R, Ragauskas AJ, Wyman CE (2015) How chip size impacts steam pretreatment effectiveness for biological conversion of poplar wood into fermentable sugars. Biotechnol Biofuels 8(1):209

Liu Y, Wang J, Wolcott MP (2017) Size effects on acid bisulfite pretreatment efficiency: multiple product yields in spent liquor and enzymatic digestibility of pretreated solids. ACS Sustainable Chemistry & Engineering 5(6):5418–5423

Athmanathan A, Trupia S (2016) Examining the role of particle size on ammonia-based bioprocessing of maize stover. Biotechnol Prog 32(1):134–140

Simangunsong E, Ziegler-Devin I, Chrusciel L, Girods P, Wistara NJ, Brosse N (2020) Steam explosion of beech wood: effect of the particle size on the xylans recovery. Waste and Biomass Valorization 11(2):625–633

Sitotaw YW, Habtu NG, Gerven TV (2022) Intensification of low concentration alkaline pretreatment with planetary ball milling for efficient enzymatic saccharification of enset fiber (Ensete ventricosum). Biomass Conver Biorefin. https://doi.org/10.1007/s13399-021-02185-3

Sluiter JB, Ruiz RO, Scarlata CJ, Sluiter AD, Templeton DW (2010) Compositional analysis of lignocellulosic feedstocks 1 Review and description of methods. J Agric Food Chem. 58(16):9043–53

Ji G, Gao C, Xiao W, Han L (2016) Mechanical fragmentation of corncob at different plant scales: impact and mechanism on microstructure features and enzymatic hydrolysis. Biores Technol 205:159–165

Ding H, Yu W, Boiarkina I, Depree N, Young BR (2019) Effects of morphology on the dispersibility of instant whole milk powder. J Food Eng 276:109841

Cui X, Zhu C, Hu M, Wang R, Liu H (2021) Permeability of porous media in coral reefs. Bull Eng Geol Env 80(6):5111–5126

Lu M, Li J, Han L, Xiao W (2019) An aggregated understanding of cellulase adsorption and hydrolysis for ball-milled cellulose. Biores Technol 273:1–7

Jiang J, Wang J, Zhang X, Wolcott M (2017) Microstructure change in wood cell wall fracture from mechanical pretreatment and its influence on enzymatic hydrolysis. Ind Crops Prod 97:498–508

Li J, Zhang H, Lu M, Han L (2019) Comparison and intrinsic correlation analysis based on composition, microstructure and enzymatic hydrolysis of corn stover after different types of pretreatments. Biores Technol 293:122016

Zhang H, Han L, Dong H (2021) An insight to pretreatment, enzyme adsorption and enzymatic hydrolysis of lignocellulosic biomass: experimental and modeling studies. Renew Sustain Energy Rev 140:110758

Liu M, Wang L, Si M, Wang Z, Zhang T, Cheng X, Min X, Chai L, Shi Y (2019) New insight into enzymatic hydrolysis of the rice straw and poplar: an in-depth statistical analysis on the multiscale recalcitrance. BioEnergy Research 12(1):21–33

Buzała K, Przybysz P, Rosicka-Kaczmarek J, Kalinowska H (2015) Production of glucose-rich enzymatic hydrolysates from cellulosic pulps. Cellulose 22(1):663–674

Kumar R, Hu F, Sannigrahi P, Jung S, Ragauskas AJ, Wyman CE (2013) Carbohydrate derived-pseudo-lignin can retard cellulose biological conversion. Biotechnol Bioeng 110(3):737–753

Mariano APB, Unpaprom Y, Ramaraj R (2020) Hydrothermal pretreatment and acid hydrolysis of coconut pulp residue for fermentable sugar production. Food Bioprod Process 122:31–40

Shinde SD, X. Meng R. Kumar, AJ. Ragauskas, and O.R.T.N. Oak Ridge National Lab. Ornl (2018) Recent advances in understanding the pseudo-lignin formation in a lignocellulosic biorefinery. 2(1):2192-225

Kumar V, Yadav SK, Kumar J, Ahluwalia V (2020) A critical review on current strategies and trends employed for removal of inhibitors and toxic materials generated during biomass pretreatment. Biores Technol 299:122633

Wu J, Elliston A, Le Gall G, Colquhoun IJ, Collins SRA, Wood IP, Dicks J, Roberts IN, Waldron KW (2018) Optimising conditions for bioethanol production from rice husk and rice straw: effects of pre-treatment on liquor composition and fermentation inhibitors. Biotechnol Biofuels 11(62):1–13

Sivagurunathan P, Kumar G, Mudhoo A, Rene ER, Saratale GD, Kobayashi T, Xu K, Kim S, Kim D (2017) Fermentative hydrogen production using lignocellulose biomass: an overview of pre-treatment methods, inhibitor effects and detoxification experiences. Renew Sustain Energy Rev 77:28–42

Mittal A, Pilath HM, Johnson DK (2020) Direct conversion of biomass carbohydrates to platform chemicals: 5-Hydroxymethylfurfural (HMF) and furfural. Energy Fuels 34(3):3284–3293

Wojtusik M, Villar JC, Zurita M, Ladero M, Garcia-Ochoa F (2017) Study of the enzymatic activity inhibition on the saccharification of acid pretreated corn stover. Biomass Bioenerg 98:1–7

Karamchandani A, Yi H, Puri VM (2015) Fundamental mechanical properties of ground switchgrass for quality assessment of pellets. Powder Technol 283:48–56

Sui W, Chen H (2015) Study on loading coefficient in steam explosion process of corn stalk. Biores Technol 179:534–542

Lisowski A, Matkowski P, Dąbrowska M, Piątek M, Świętochowski A, Klonowski J, Mieszkalski L, Reshetiuk V (2020) Particle size distribution and physicochemical properties of pellets made of straw, hay, and their blends. Waste and Biomass Valorization 11(1):63–75

Zhang Y, Wang L, Chen H (2017) Correlations of medium physical properties and process performance in solid-state fermentation. Chem Eng Sci 165:65–73

Liu H, Chen X, Ji G, Yu H, Gao C, Han L, Xiao W (2019) Mechanochemical deconstruction of lignocellulosic cell wall polymers with ball-milling. Biores Technol 286:121364

Zhang H, Chen L, Li J, Lu M, Han L (2017) Quantitative characterization of enzyme adsorption and hydrolytic performance for ultrafine grinding pretreated corn stover. Biores Technol 234:23–32

Liu Z, Chen H (2015) Biomass–water interaction and its correlations with enzymatic hydrolysis of steam-exploded corn stover. ACS Sustainable Chemistry & Engineering 4(3):1274–1285

Lu M, He D, Li J, Han L, Xiao W (2021) Rheological characterization of ball-milled corn stover with different fragmentation scales at high-solids loading. Ind Crops Prod 167:113517

Thomsen ST, Weiss ND, Zhang H, Felby C (2021) Water retention value predicts biomass recalcitrance for pretreated biomass: biomass water interactions vary based on pretreatment chemistry and reflect composition. Cellulose 28(16):317–330

Ji P, Jin J, Chen X, Wang C, Wang H (2016) Characterization of water state and distribution in fibre materials by low-field nuclear magnetic resonance. RSC Adv 6(14):11492–12115

Arif Yılmaz V, Faik Koca A (2020) Quality, sensorial and textural properties of einkorn and durum bulgur produced with several methods. International Journal of Gastronomy and Food Science 22:100263

Batista G, Souza RBA, Pratto B, dos Santos Rocha MSR, Cruz AJG (2019) Effect of severity factor on the hydrothermal pretreatment of sugarcane straw - ScienceDirect. Bioresource Technology 275:321–327

Hernandez-Guzman A, Navarro-Gutiérrez IM, Meléndez-Hernández PA, Beltrán J, Hernández-Escoto H (2020) Enhancement of alkaline-oxidative delignification of wheat straw by semi-batch operation in a stirred tank reactor. Biores Technol 312:123589

Nishinari K, Fang Y (2018) Perception and measurement of food texture: solid foods. J Texture Stud 49(2):160–201

Kasunmala IGG, Navaratne SB, Wickramasinghe I (2020) Effect of process modifications and binding materials on textural properties of rice noodles. International J of Gastronomy and Food Sci 21:100217

Vega-Gálvez A, Zura-Bravo L, Lemus-Mondaca R, Martinez-Monzó J, Quispe-Fuentes I, Puente L, Di Scala K (2015) Influence of drying temperature on dietary fibre rehydration properties texture and microstructure of Cape gooseberry (Physalis peruviana L). J Food Sci Technol 52(4):2304–2311

Xu J, Bock JE, Stone D (2020) Quality and textural analysis of noodles enriched with apple pomace. J Food Process Preserv 44(8):1–8

Rezaei H, Lim CJ, Lau A, Sokhansanj S (2016) Size, shape and flow characterization of ground wood chip and ground wood pellet particles. Powder Technol 301:737–746

Yang, Y. M. Zhang, J. Zhao, and D. Wang (2022) Effects of particle size on biomass pretreatment and hydrolysis performances in bioethanol conversion. Biomass Conversion and Biorefinery

Licari A, Monlau F, Solhy A, Buche P, Barakat A (2016) Comparison of various milling modes combined to the enzymatic hydrolysis of lignocellulosic biomass for bioenergy production: Glucose yield and energy efficiency. Energy 102:335–342

Gu BJ, Wang J, Wolcott MP, Ganjyal GM (2018) Increased sugar yield from pre-milled Douglas-fir forest residuals with lower energy consumption by using planetary ball milling. Bioresource Technology: Biomass, Bioenergy, Biowastes, Conversion Technologies, Biotransformations, Production Technologies 251(1):93–98

Nanda S, Mohammad J, Reddy SN, Kozinski JA, Dalai AK (2014) Pathways of lignocellulosic biomass conversion to renewable fuels. Biomass Conversion and Biorefinery 4(2):157–191

Shahabazuddin M, Banuvalli BK, Mulik N, Pande A, Bokade V, Mudliar SN (2021) Comparative studies of the influence of particle size on various pretreatments of rice husk by assessment of chemical and structural components and wastewater characteristics of liquid fraction. Biomass Conver Biorefin. https://doi.org/10.1007/s13399-021-01565-z

Borrega M, Pihlajaniemi V, Liiti T, Wikstrm L, Tamminen T (2021) Evaluation of chemical additives in hydrothermal pre-treatment of wood for the integrated production of monosugars and hydrolysis lignins for PLA-based biocomposites. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-021-01365-5

Funding

This study was financially supported by the National Key R&D Program of China (Grant 2019YFB1503800) and the Transformational Technologies for Clean Energy and Demonstration (Strategic Priority Research Program of the Chinese Academy of Sciences, Grant No. XDA 21060300).

Author information

Authors and Affiliations

Contributions

All the authors contributed to the study conception and design.

Minglu Li: methodology, data collection, and analysis, writing.

Lan Wang: funding acquisition, investigation, project administration, supervision, writing — review and editing.

Hongzhang Chen: conceptualization, investigation, supervision, funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• The particle size of initial material was the key factor in hydrothermal pretreatment.

• The reduction in particle size relieved the compactness of initial material.

• The enzymatic hydrolysis yield increased 31% when D50 < 500 μm.

• The D50 > 100 μm had an advantage in energy requirements and energy efficiency.

• D50 < 500 μm could reduce pretreatment intensity at the same enzymatic hydrolysis yield.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, M., Wang, L. & Chen, H. Evaluation of initial material particle size on the hydrothermal pretreatment of poplar powder. Biomass Conv. Bioref. 14, 11265–11277 (2024). https://doi.org/10.1007/s13399-022-03165-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03165-x