Abstract

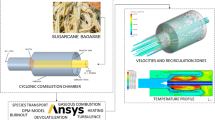

Three-dimensional computational fluid dynamics (CFD) modeling of the hydrodynamic characteristics for the various sand particle sizes (10 μm, 250 μm, 482 μm, 750 μm, 1000 μm, and the actual particle size distribution (PSD)) in a 0.1 MWth pilot-scale full-loop circulating fluidized bed combustor (CFBC) was numerically investigated with a commercial CFD code, ANSYS FLUENT. Those were clearly validated with actual CFBC operating data. As the result, the sand particle size of the actual PSD was in good agreement. In order to accurately simulate wood pellet combustion, kinetic parameters for activation energy (Ea) and pre-exponential factor (A) for wood pellet decomposition and char combustion were obtained from lab-scale TGA experiments with wood pellet sample actually used for CFBC operation. The CFD modeling on wood pellet combustion were conducted with the selected sand particle size of actual PSD with improved char combustion model using the user-defined function (UDF) reflected kinetic parameters. The CFD modeling results were carefully compared with actual CFBC operating results. Therefore, our CFD simulation results for the concentrations of gas species (N2, CO2, O2, SO2, CO, NO, and N2O) at the gas exit in the cyclone were also in good agreement with the actual CFBC operating data. The accuracy improvements were increased from 1.9 times to 2.5 times due to our improved char combustion model using the UDF.

Similar content being viewed by others

References

Dou B, Zhang H, Song Y, Zhao L, Jiang B, He M, Ruan C, Chen H, Xu Y (2019) Hydrogen production from the thermochemical conversion of biomass: issues and challenges. Sustain Energy Fuels 3:314–342

Rahib Y, Boushaki T, BrahimSarh B, Chaoufi J (2021) Combustion and pollutant emission characteristics of argan nut shell (ANS) biomass. Fuel Proce Tech 213:106665

REN21, Renewables (2020) Global Status Report. REN21 Secretariat.

The Republic of Korea’s Update of its First Nationally Determined Contribution (2020) Submission under the Paris Agreement. December 30.

Chen C, Luo Z, Yu C (2019) Release and transformation mechanisms of trace elements during biomass combustion. J Hazar Mater 380:120857

IEA. Bioenergy Countries’ Report (2018) Bioenergy policies and status of implementation. Int Energy Agen Paris.

WBA. Global Bioenergy Statistics (2019) World Bioenergy Associ. Stockholm.

Roy MM, Corscadden KW (2012) An experimental study of combustion and emissions of biomass briquettes in a domestic wood stove. Appl Energy 99:206–212

Knoef H (2005) Handbook biomass gasification, First. ed. BTG - Biomass Technology Group, Enschede.

Farid MM, Jeong HJ, Kim KH, Lee J, Kim D, Hwang J (2017) Numerical investigation of particle transport hydrodynamics and coal combustion in an industrial-scale circulating fluidized bed combustor: Effects of coal feeder positions and coal feeding rates. Fuel 192:187–200

Hwang IS, Jeong HJ, Hwang J (2019) Numerical simulation of a dense flow cyclone using the kinetic theory of granular flow in a dense discrete phase model. Powd Tech 356:129–138

Hwang IS, Sohn J, Lee UD, Hwang J (2021) CFD-DEM simulation of air-blown gasification of biomass in a bubbling fluidized bed gasifier: Effects of equivalence ratio and fluidization number. Energy 219:119533

We Y, Liu D, Hu J, Ma J, Chen X (2021) Comparative study of two fluid model and dense discrete phase model for simulations of gas–solid hydrodynamics in circulating fluidized beds. Particuology 55:108–117

Adamczyk WP, Myohanen K, Hartge E, Ritvanen J, Klimanek A, Hyppanen T (2018) Generation of data sets for semi-empirical models of circu-lated fluidized bed boilers using hybrid Euler-Lagrange technique. Energy 143:219–240

Andrew MJ, Orourke PJ (1996) The multiphase particle-in-cell (MP-PIC) method for dense particulate flows. Int J Multi Flow 22:379–402

Hashemisohi A, Wang L, Shahbazi A (2019) Dense discrete phase model coupled with kinetic theory of granular flow to improve predictions of bub-bling fluidized bed hydrodynamics. KONA Powd Part J 36:215–223

Adamczyk WP, Kozołub P, We˛cel G, Klimanek A, Białecki RA, Czakiert T (2014) Modeling oxy-fuel combustion in a 3D circulating fluidized bed using the hybrid Euler-Lagrange approach. Appl Therm Eng 71:266–275

Klimanek A, Adamczyk W, Katelbach-Woz´niak A, We˛cel G, Szle˛k A (2015) Towards a hybrid Eulerian-Lagrangian CFD modeling of coal gasification in a circulating fluidized bed reactor. Fuel 152:131–137

Adamczyk WP, Wecel G, Klajny M, Kozołub P, Klimanek A, Białecki RA (2014) Modeling of particle transport and combustion phenomena in a large-scale circulating fluidized bed boiler using a hybrid Euler-Lagrange approach. Particuology 16:29–40

Kozolub P, Klimanek A, Bialecki RA, Adamczyk WP (2017) Numerical simulation of a dense solid particle flow inside a cyclone separator using the hybrid Euler-Lagrange approach. Particuology 31:170–180

Schneiderbauer S, Haider MF, Hauzenberger F, Pirker S (2016) A Lagrangian-Eulerian hybrid model for the simulation of industrial-scale gas-solid cyclones. Powd Tech 304:229–240

Adamczyk WP, Kozołub P, Klimanek A, Białecki RA, Andrzejczyk M, Klajny M (2015) Numerical simulations of the industrial circulating fluidized bed boiler under air-and oxy-fuel combustion. Appl Therm Eng 87:127–136

Yoon SH, Beak GU, Moon JH, Jo SH, Park SJ, Kim JY, Seo MW, Yoon SJ, Yoon SM, Lee JG, Kim JS, Mun TY (2021) Air-staging effect for NOx reduction in circulating fluidized bed combustion of domestic unused biomass. Korean Chem Eng Res 59:127–137

Gidaspow D, Bezburuah R, Ding J (1992) Hydrodynamics of circulating fluidized beds, kinetic theory approach, Proceedings of the 7th Engineering Foundation Conference on Fluidization, Gold Coast In Australia 75–82.

Lun CKK, Savage SB, Jeffrey DJ, Chepurniy N (1984) Kinetic theories for granular flow: inelastic particles in couette flow and slightly inelastic particles in a general flow field. J Fluid Mech 140:223–256

Schaeffer D (1987) Instability in the evolution equations describing incompressible granular flow. J Differ Equ 66:19–55

Gidaspow D (1994) Multiphase flow and fluidization: continuum and kinetic theory descriptions. Academic Press

Wen CY, Yu YH (1996) MechanicCs of fluidization. Chem Eng Prog Symp 162:100–111

Ergun S (1952) Fluid flow through packed columns. Chem Eng Prog 48:89–94

Qiu X, Wang Y, Zhou Z, Duan Y, Duan L (2022) Particulate matter formation mechanism during pressurized air-and oxy-coal combustion in a 10kWth fluidized bed. Fuel Proc Tech 225:107064

Luan YT, Chyou YP, Wang T (2013) Numerical analysis of gasification performance via finite-rate model in a cross-type two-stage gasifier. Int J Heat Mass Transfer 57:558–566

ANSYS FLUENT 2019R3 (2019) Theory Guide book, Canonsburg, U.S.: ANSYS Inc.

Bhatia SK, Perlmutter DD (1980) A random pore model for fluid–solid reactions. I. Isothermal, kinetic control. AIChE J 26:379–386

Laurendeau NM (1978) Heterogeneous kinetics of coal char gasification and combustion. Progr Energy Combust Sci 4:221–270

Youngquist GR (1970) Diffusion and flow of gases in porous solids: flow through porous media. American Chemical Society Publications, Washington (DC)

El-Rub ZA (2008) Biomass char as an in-situ catalyst for tar removal in gasification systems Ph.D. Thesis. Department of Thermal Engineering: Twente University.

Holtmeyer ML, Kumfer BM, Axelbaum RL (2012) Effects of biomass particle size during co-firing under air-fired and oxyfuel conditions. Appl Energy 93:606–613

Cussler EL (2009) Diffusion, 3rd edn. Cambridge University Press, New York

Smith IW (1982) The combustion rates of coal chars: a review. Proc Combust Inst 19:1045–1065

Watanabe H, Otaka M (2006) Numerical simulation of coal gasification in entrained flow coal gasifier. Fuel 85:1935–1943

Jeong HJ, Seo DK, Hwang J (2014) CFD modeling for coal size effect on coal gasification in a two-stage commercial entrained-bed gasifier with an improved char gasification model. App Energy 123:29–36

Zhong W, Xie J, Shao Y, Liu X, Jin B (2015) Three-dimensional modeling of olive cake combustion in CFB. Appl Ther Eng 88:322–333

Anantharaman A, Issangya A, Karri SBR, Findlay J, Hrenya CM, Cocco RA, Chewa JW (2017) Annulus flow behavior of Geldart group B particles in a pilot-scale CFB riser. Powd Tech 305:816–828

Yang YB, Sharifi VN, Swithenbank J, Ma L, Darvell LI, Jones JM, Pourkashanian M, Williams A (2008) Combustion of a sigle particle of biomass. Energy Fuels 22:306–316

Yang S, Wang S, Wang H (2020) Numerical study of biomass gasification in a 0.3 MWth full-loop circulating fluidized bed gasifier. Energy Conver Manag 223:113439

Nikolopoulos A, Nikolopoulos N, Charitos A, Grammelis P, Kakaras E, Bidwe AR, Varela G (2013) High-resolution 3-D full-loop simulation of a CFB carbonator cold model. Chem Eng Sci 90:137–150

Wang S, Luo K, Hu C, Fan J (2017) CFD-DEM study of the effect of cyclone arrangements on the gas-solid flow dynamics in the full-loop circulating fluidized bed. Chem Eng Sci 172:199–215

Goo JH, Seo MW, Kim SD, Song BH (2010) Effects of temperature and particle size on minimum fluidization and transport velocities in a dual fluidized bed. In: Proceedings of the 20th inter confer fluidized bed combustion. 305–310.

Li S, Xu M, Jia L, Tan L, Lu Q (2016) Influence of operating parameters on N2O emission in O2 /CO2 combustion with high oxygen concentration in circulating fluidized bed. Appl Energy 173:197–209

Li S, Li W, Xu M, Wang X, Li H, Lu Q (2015) The experimental study on nitrogen oxides and SO2 emission for oxy-fuel circulation fluidized bed combustion with high oxygen concentration. Fuel 146:81–87

Gu J, Zhong W, Yu A (2019) Three-dimensional simulation of oxy-fuel combustion in a circulating fluidized bed. Powder Tech 351:16–27

Gui Y, Liu X, Zhong W (2020) Simulations of coal combustion in a pressurized supercritical CO2 circulating fluidized bed. Energy Fuels 34:4977–4992

Konga L, Zhanga C, Zhu J (2014) Evaluation of the effect of wall boundary conditions on numerical simulations of circulating fluidized beds. Particuol 13:114–123

Upadhyay M, Park JH (2015) CFD simulation via conventional two-fluid model of a circulating fluidized bed riser: influence of models and model parameters on hydrodynamic behavior. Powder Tech 272:260–268

Murugan PC, Sekhar SJ (2017) Species eTransport CFD model for the gasification ofrice husk (Oryza Sativa) using downdraft gasifier. Comput Electron Agric 1390:33–40

Snider DM, Clark SM, O’Rourke PJ (2011) EulerianeLagrangian method for threedimensional thermal reacting flow with application to coal gasifiers. Chem Eng Sci 66:1285–1295

Xie J, Zhong W, Jin B, Shao Y, Liu H (2014) Three-dimensional Eulerian−Eulerian modeling of gaseous pollutant emissions from circulating fluidized-bed combustors. Energy Fuels 28:5523–5533

Zhou W, Zhao CS, Duan LB, Qu CR, Chen XP (2011) Two-dimensional computational fluid dynamics simulation of coal combustion in a circulating fluidized bed combustor. Chem Eng J 166:306–314

Westbrook CK, Dryer FL (1981) Simplified reaction mechanisms for the oxidation of hydrocarbon fuels in flames. Combust Sci Tech 27:31–43

Ma J, Zitney SE (2012) Computational fluid dynamic modeling of entrained-flow gasifiers with improved physical and chemical sub-models. Energy Fuel 26:7195–7219

Jess A (1996) Mechanisms and kinetics of thermal reactions of aromatic hydrocarbons from pyrolysis of solid fuels. Fuel 75:1441–1448

Bustamante F, Enick RM, Killmeyer RP, Howard BH, Rothenberger KS, Cugini AV, Morreale BD, Ciocco MV (2005) Uncatalyzed and wall-catalyzed forward water-gas shift reaction kinetics. AIChE J 51:1440–1454

Yan LB, Cao Y, Li XZ, He BS, Grace JR (2016) Simulation of biomass-steam gasification in fluidized bed reactors: model setup, comparisons and preliminary predictions. Bioresour Tech 254:97–106

Desroches-Ducarne E, Dolignier JC, Marty E, Martin G, Delfosse L (1998) Modelling of gaseous pollutants emissions in circulating fluidized bed combustion of municipal refuse. Fuel 77:1399–1410

Kilpinen P, Kallio S, Konttinen J, Barisic V (2002) Char-nitrogen oxidation under fluidised bed combustion conditions: single particle studies. Fuel 81:2349–2362

Funding

This work was supported by the Technology Innovation Program (Project No.:20005788, Development of pollutant reduction combustion technology for multi-fuels custom) funded by the Ministry of Trade, Industry & Energy in Korea.

Author information

Authors and Affiliations

Contributions

Sang Shin Park, Ji-Hong Moon, Tae-Young Mun, Sang-Hee Yoon, Geon-Uk Baek, Sungho Jo: Conceptualization; Sang Shin Park, Ji-Hong Moon, Tae-Young Mun: methodology; Sang Shin Park, Ji-Hong Moon, Tae-Young Mun, Sang-Hee Yoon, Geon-Uk Baek, Sung-Jin Park, Sang-Jun Yoon, Jae-Goo Lee, Ho Won Ra, Sung-Min Yoon: formal analysis and investigation; Sang Shin Park, Ji-Hong Moon, Tae-Young Mun: writing—original draft preparation; Sang Shin Park, Tae-Young Mun: writing review and editing; Tae-Young Mun: funding acquisition; Sang Shin Park: resources and software; Tae-Young Mun: project administration and Supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Park, S.S., Moon, JH., Yoon, SH. et al. Accuracy improvement of CFD modeling of a hydraulics with wood pellet combustion operating in a full-loop circulating fluidized bed combustor (CFBC). Biomass Conv. Bioref. 14, 7807–7833 (2024). https://doi.org/10.1007/s13399-022-03108-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03108-6