Abstract

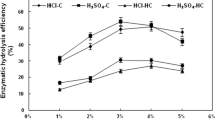

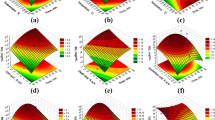

Organic substances of low biodegradability and the high moisture content of herbaceous peat inhibit its high-value utilization. In this study, the effect of pretreatment with dilute sulfuric acid on the efficiency of the anaerobic fermentation of herbaceous peat was explored. Single-factor experiments and orthogonal tests were conducted to optimize the pretreatment conditions. The milled herbaceous peat (0.43 mm) was pretreated with 5% sulfuric acid at 100°C for 120 min with a solid–liquid ratio of 1:4, and the reducing sugar yield was 13.49%. The results suggest that dilute sulfuric acid might have hydrolyzed the β-glycosidic bonds between the sugar monomers, causing the partial degradation of cellulose into reducing sugar. Compared to the fermentation of untreated herbaceous peat, the total biomethane yield increased by 29.97%, and the fermentation period decreased by 22.50%. Thus, pretreatment with dilute sulfuric acid effectively enhanced the efficiency of biomethane fermentation of herbaceous peat.

Similar content being viewed by others

References

Quik C, Palstra SWL, van Beek R, van der Velde Y, Candel JHJ, van der Linden M, Kubiak-Martens L, Swindles GT, Makaske B, Wallinga J (2022) Dating basal peat: the geochronology of peat initiation revisited. Quat Geochronol 26:101278. https://doi.org/10.1016/j.quageo.2022.101278

Kim JK, Lee HD, Kim HS, Park HY, Kim SC (2014) Combustion possibility of low rank Russian peat as a blended fuel of pulverized coal fired power plant. J Ind Eng Chem 20:1752–1760. https://doi.org/10.1016/j.jiec.2013.08.027

Stracher GB 2019 Chapter 20-Peat Fires in Ireland, in: G.B. Stracher (Ed.), Coal and peat fires: a global perspective, Elsevier, pp: 451–482. https://doi.org/10.1016/B978-0-12-849885-9.00020-2

Tyni SK, Karppinen JA, Tiainen MS, Laitinen RS (2014) Preparation and characterization of amorphous aluminosilicate polymers from ash formed in combustion of peat and wood mixtures. J Non-Cryst Solids 387:94–100. https://doi.org/10.1016/j.jnoncrysol.2013.12.032

Li Y, Zhao H, Sui X, Wang X, Ji H (2022) Studies on individual pyrolysis and co-pyrolysis of peat-biomass blends: thermal decomposition behavior, possible synergism, product characteristic evaluations and kinetics. Fuel 310:122280. https://doi.org/10.1016/j.fuel.2021.122280

Wen Y, Wang S, Mu W, Yang W, Jönsson PG (2020) Pyrolysis performance of peat moss: a simultaneous in-situ thermal analysis and bench-scale experimental study. Fuel 277:118173. https://doi.org/10.1016/j.fuel.2020.118173

Egorov RI, Taburchinov RI (2021) The numerical study of allothermal gasification of the peat by the focused light flow. Appl Therm Eng 195:117253. https://doi.org/10.1016/j.applthermaleng.2021.117253

Carlborg M, Weiland F, Ma C, Backman R, Landälv I, Wiinikka H (2017) Exposure of refractory materials during high-temperature gasification of a woody biomass and peat mixture. J Eur Ceram Soc 38:777–787. https://doi.org/10.1016/j.jeurceramsoc.2017.09.016

Kabir SB, Khalekuzzaman M, Islam MB, Hossain MR (2022) Performance optimization of organic solid waste and peat co-liquefaction mechanism for processing sustainable biocrude. Fuel Process Technol 231:107234. https://doi.org/10.1016/j.fuproc.2022.107234

Chen J, Ge J, Feng L, Zhou Y, Gan J, Li Y, Zhang Z (2020) Methane flux characteristics and its relationship with soil microbial community composition of Dajiuhu Peatland in Shennongjia. Earth Sci 45:1082–1092. https://doi.org/10.3799/dqkx.2019.289

Fritze H, Penttilä T, Mäkiranta P, Laiho R, Tuomivirta T, Forsman J, Kumpula J, Juottonen H, Peltoniemi K (2021) Exploring the mechanisms by which reindeer droppings induce fen peat methane production. Soil Biol Biochem 160:108318. https://doi.org/10.1016/j.soilbio.2021.108318

Ma L, Lu Y, Hao S (2020) Fermentation production of biomethane by superfine grinded peat. Chem Bioeng 3:21–24

Lu YN, Ma LT, Zhang TY (2021) Effect of acid/alkali pretreatment on physicochemical properties of peat. Chem Bioeng 38(12):13–18

Ghosh S, Klass DL (1979) Biomethanation of Minnesota reed sedge peat. Res Rec and Conserv 4(2):115–139. https://doi.org/10.1016/0304-3967(79)90010-6

Ma LT, Jiang QH, Zhu DC, Si WT (2015) Optimization for alkali-pretreatment condition of peat. J South Argic 46(9):1668–1672. https://doi.org/10.3969/j:issn.2095-1191.2015.09.1668

Shimizu FL, Monteiro PQ, Ghiraldi P, Melati RB, Pagnocca FC, Souza WD, Anna CS, Brienzo M (2018) Acid, alkali and peroxide pretreatments increase the cellulose accessibility and glucose yield of banana pseudostem. Ind Crop Prod 115:62–68. https://doi.org/10.1016/j.indcrop.2018.02.024

Li YM, Fan XN, Zhang HR, Ai FK, Jiao YG, Zhang QG, Zhang ZP (2022) Pretreatment of corn stover by torrefaction for improving reducing sugar and biohydrogen production. Bioresource Technol 351:126905. https://doi.org/10.1016/j.biortech.2022.126905

Zhang T, Jiang DP, Li YM, Zhang H, Zhang ZP, Jing YY, Lu CY, Zhang Y, Xia CX, Zhang QG (2022) Lignin removal, reducing sugar yield and photo-fermentative biohydrogen production capability of corn stover: effects of different pretreatments. Bioresource Technol 346:126437. https://doi.org/10.1016/j.biortech.2021.126437

van Soest PJ (1963) Use of detergents in the analysis of fibrous feeds. II. A rapid method for the determination of fiber and lignin. J Assoc Offic Agric Chem 46:829–835. https://doi.org/10.1093/jaoac/46.5.829

Madhawan A, Arora A, Das J, Sharma S, Kuila A, Sharma V (2019) Different types of thermochemical pretreatment and optimization of enzymatic hydrolysis of groundnut shell. Waste Biomass Valori 10(3):661–670. https://doi.org/10.1007/s12649-017-0083-y

Kootstra AMJ, Beeftink HH, Scott EL, Sanders JPM (2009) Comparison of dilute mineral and organic acid pretreatment for enzymatic hydrolysis of wheat straw. Biochem Eng J 46(2):126–131. https://doi.org/10.1016/j.bej.2009.04.020

Na B-I, Chang S-J, Lee KH, Lee G, Lee J-W (2016) Characterization of cell wall structure in dilute acid-pretreated biomass by confocal Raman microscopy and enzymatic hydrolysis. Biomass Bioenerg 93:33–37. https://doi.org/10.1016/j.biombioe.2016.06.026

Li C, Knierim B, Manisseri C, Arora R, Scheller HV, Auer M, Vogel KP, Simmons BA, Singh S (2010) Comparison of dilute acid and ionic liquid pretreatment of switchgrass: biomass recalcitrance, delignification and enzymatic saccharification. Bioresource Technol 101:4900–4906. https://doi.org/10.1016/j.biortech.2009.10.066

Zhang SS, Zhang K, Chen XX, Wang XJ, Zuo XM, Xue DH (2015) Research on the factors brought by furfural inhibitor during acid-pretreatment of corn stover. Sci Technol Cereals Oils Foods 4:88–92. https://doi.org/10.3969/j.issn.1007-7561.2015.04.020

Yan H, Xia S, Fu YS, Fu JQ (2017) Preliminary study on optimization of dilute sulfuric acid pretreatment of energy grass. Jiangxi Energy 4:34–37. https://doi.org/10.16056/j.1005-7676.2017.04.007

Zhang J, Shao S, Bao J (2016) Long term storage of dilute acid pretreated corn stover feedstock and ethanol fermentability evaluation. Bioresource Tech 201:355–359. https://doi.org/10.1016/j.biortech.2015.11.024

Ji W, Shen Z, Wen Y (2015) Hydrolysis of whet straw by dilute sulfuric acid in a continuous mode. Chem Eng J 260:20–27. https://doi.org/10.1016/j.cej.2014.08.089

Gao FQ, Jing YY, De Y, Wan QH, Liu YH, Ta N (2020) Effects of dilute sulfuric acid pretreatment on chemical composition and characterization structure of hybrid (Pennisetum Pennisetum americanum × P purpureum) lignocellulose. Sci Agric Si 53(21):4516–4526. https://doi.org/10.3864/j.issn.0578-1752.2020.21.019

Bujang N, Rodhi MNM, Musa M, Subari F, Idris N, Makhtar NSM, Hamid KHK (2013) Effect of dilute sulfuric acid hydrolysis of coconut dregs on chemical thermal properties. Procedia Eng 68:372–378. https://doi.org/10.1016/j.proeng.2013.12.194

Kim SB, Lee SJ, Jang EJ, Han SO, Park C, Kim SW (2012) Sugar recovery from rice straw by dilute acid pretreatment. J Ind Eng Chem 18:183–187. https://doi.org/10.1016/j.jiec.2011.11.016

Wen J-L, Sun S-N, Yuan T-Q, Xu F, Sun R-C (2013) Fractionation of bamboo culms by autohydrolysis, organosolv delignification and extended delignification: understanding the fundamental chemistry of the lignin during the integrated process. Bioresource Technol 150:278–286. https://doi.org/10.1016/j.biortech.2013.10.015

Ma LT, Lu YN, Hao SW (2020) Fermentation production of biomethane by superfine grinded peat. Chem Bioeng 37(1):21–24. https://doi.org/10.3969/j.issn.1672-5425.2020.01.004

Hao SW, Ma LT, Wang YX, Li J (2021) Enhanced methane production from peat with rare earth compounds. J Chin Soc Rare Earths 39(2):294–301. https://doi.org/10.11785/S1000-4343.20210212

Song ZL, Yang GH, Liu XF, Yan ZY, Yuan YX, Liao YZ (2014) Comparison of seven chemical pretreatments of corn straw for improving methane yield by anaerobic digestion. PLoS ONE 9(4):e93801. https://doi.org/10.1371/journal.pone.0101617

Jiao J, Wang JL, Zheng Y, Wang G, Guo CJ, Peng ZL, Zhou J (2014) Effects of chemical pretreatment on biogas production by anaerobic fermentation of sugarcane leaves. Chin J Trop Crops 35(4):779–783. https://doi.org/10.3969/j.issn.1000-2561.2014.04.027

Lu YN, Ma LT, Li J (2020) Effects of sulfuric acid pretreatment and liquid acids precipitation on the structure of fulvic acid extracted from peat. Spectrosc Lett 54(2):89–98. https://doi.org/10.1080/00387010.2020.1854306

Ma LT, Lu YN, Wang YX (2020) Effects of methane fermentation on spectral properties of fulvic acid extracted from peat through liquid acid precipitation. J Chem 2:1–10. https://doi.org/10.1155/2020/5084508

Funding

This work is financially supported by the National Natural Science Foundation of China (21766025) and The Ministry of Education’s “Chunhui Plan” cooperative research project (2018042).

Author information

Authors and Affiliations

Contributions

Investigations, the collection and analysis of data, and editing were conducted by Ying Wang. Conceptualization, resources, methodology, the formal analysis, and editing were conducted by Litong Ma. Analyzing data and writing the original draft were performed by Yuchen Bai. Analyzing, writing/reviewing, and editing were conducted by Jun Li, and writing/reviewing and editing were performed by Yanan Lu.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Ma, L., Bai, Y. et al. Increased biomethane production from herbaceous peat through pretreatment with dilute sulfuric acid. Biomass Conv. Bioref. 14, 11145–11153 (2024). https://doi.org/10.1007/s13399-022-03052-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03052-5