Abstract

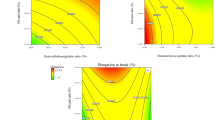

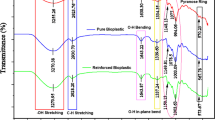

This work aimed to develop films based on pequi (Caryocar brasiliense) pulp added of gelatin and plasticizer (glycerol or sorbitol) and characterize their properties and biodegradation in different soils. The films were presented with a good appearance, easy to handle, and with a predominant yellowish color. The greater the addition of plasticizers (3.5%), the greater the elongation and the lower the tensile strength of the films. The higher the gelatin (7%) and the lower the plasticizer (1.5%) concentrations, the higher the tensile strength. Thermal analysis allowed to observe a desirable characteristic for packing films: a band between 2Ɵ = 21° for both glycerol and sorbitol films, which is present in low crystalline films, reducing the incidence of light in the products. Films were at the most 100% degraded over a period of 5 to 9 days. Thus, the films obtained are recommended to be utilized for food packaging applications.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Kumar R, Verma A, Shome A, Sinha R, Sinha S, Jha PK, Kumar R, Kumar P, Shubham DS, Sharma P, Prasad PVV (2021) Impacts of plastic pollution on ecosystem services, sustainable development goals, and need to focus on circular economy and policy interventions. Sustainability 13:9963. https://doi.org/10.3390/su13179963

Ghosh SK, Pal S, Ray S (2013) Study of microbes having potentiality for biodegradation of plastics. Environ Sci Poll Res 20:4339–4355. https://doi.org/10.1007/s11356-013-1706-x

Moshood TD, Nawanir G, Mahmud F, Mohamad F, Ahmad MH, AbdulGhani A (2022) Sustainability of biodegradable plastics: new problem or solution to solve the global plastic pollution? Cur Res Green Sustain Chem 5:100273. https://doi.org/10.1016/j.crgsc.2022.100273

Kocira A, Kozłowicz K, Panasiewicz K, Staniak M, Szpunar-Krok E, Hortyńska P (2021) Polysaccharides as edible films and coatings: characteristics and influence on fruit and vegetable quality: a review. Agronomy 11:813. https://doi.org/10.3390/agronomy11050813

Kong I, Degraeve P, Pui LP (2022) Polysaccharide-based edible films incorporated with essential oil nanoemulsions: physico-chemical, mechanical properties and its application in food preservation: a review. Foods 11:555. https://doi.org/10.3390/foods11040555

Akhter R, Masoodi FA, Wani TA, Rather SA (2019) Functional characterization of biopolymer based composite film: incorporation of natural essential oils and antimicrobial agents. Int J Biol Macromol 137:1245–1255. https://doi.org/10.1016/j.ijbiomac.2019.06.214

Ferreira ARV, Alves VD, Coelhoso IM (2016) Polysaccharide-based membranes in food packaging applications. Membranes 6:22. https://doi.org/10.3390/membranes6020022

Versino F, Lopez OV, Garcia MA, Zaritzky NE (2016) Starch-based films and food coatings: an overview. Stärke 68:1026–1037. https://doi.org/10.1002/star.201600095

Chin SS, Lyn FH, Hanani ZAN (2017) Effect of Aloe vera (Aloe barbadensis Miller) gel on the physical and functional properties of fish gelatin films as active packaging. Food Pack Shelf Life 12:128–134. https://doi.org/10.1016/j.fpsl.2017.04.008

Maraveas C (2020) Production of sustainable and biodegradable polymers from agricultural waste. Polymers 12:1127. https://doi.org/10.3390/polym12051127

Guedes AMM, Antoniassi R, de Faria-Machado AF (2017) Pequi: a Brazilian fruit with potential uses for the fat industry. Oilseeds Fats Crops Lipids 24:D507. https://doi.org/10.1051/ocl/2017040

Moreira RV, Costa MP, Castro VS, Paes CE, Mutz YS, Frasao BS, Conte-Junior CA (2019) Antimicrobial activity of pequi (Caryocar brasiliense) waste extract on goat Minas Frescal cheese presenting sodium reduction. J Dairy Sci 102:2966–2972. https://doi.org/10.3168/jds.2018-15268

Amaral LF, Moriel P, Foglio MA, Mazzola PG (2014) Caryocar brasiliense supercritical CO2 extract possesses antimicrobial and antioxidant properties useful for personal care products. BMC Compl Alt Med 14:73. https://doi.org/10.1186/1472-6882-14-73

Silva CAA, Fonseca GG (2016) Brazilian savannah fruits: characteristics, properties, and potential applications. Food Sci Biotechnol 25:1225–1232. https://doi.org/10.1007/s10068-016-0195-3

da Silva AO, Cortez-Vega WR, Prentice C, Fonseca GG (2020) Development and characterization of biopolymer films based on bocaiuva (Acromonia aculeata) flour. Int J Biol Macromol 15:1157–1168. https://doi.org/10.1016/j.ijbiomac.2019.11.083

AOAC (2000) Association of Official Analytical Chemists, Official methods of analysis, 17th edn. Washington, AOAC

de Andrade CS, Fonseca GG, Innocentini-Mei LH, Fakhouri FM (2017) Development and characterization of multilayer films based on polyhydroxyalkanoates and hydrocolloids. J Appl Polym Sci 134:44458(1/8)-44458(8/8). https://doi.org/10.1002/app.44458

Scudeler CGS, Costa TL, Velasco JI, Fakhouri FM, Fonseca GG (2021) Nile tilapia (Oreochromis niloticus) waste protein-based films. Int J Biobased Plast 3:85–97. https://doi.org/10.1080/24759651.2021.1878600

ASTM (2000) American Society for Testing and Material, ASTM E96–00: Standard test method for water vapor transmission of materials. ASTM, Philadelphia

ASTM (1998) Manual on test sieving methods: guidelines for establishing sieve analysis procedures. American Society for Testing and Materials, West Conshohocken, PA, America

Maraveas C, Bayer IS, Bartzanas T (2021) Recent advances in antioxidant polymers: from sustainable and natural monomers to synthesis and applications. Polymers 13:2465. https://doi.org/10.3390/polym13152465

Díaz O, Ferreiro T, Rodríguez-Otero JL, Cobos Á (2019) Characterization of chickpea (Cicer arietinum L.) flour films: effects of pH and plasticizer concentration. Int J Mol Sci 20:1246. https://doi.org/10.3390/ijms20051246

Al-Hassan AA, Norziah MH (2012) Starch-gelatin edible films: water vapor permeability and mechanical properties as affected by plasticizers. Food Hydrocoll 26:108–117. https://doi.org/10.1016/j.foodhyd.2011.04.015

Farias MG, Fakhouri FM, Carvalho CWP, Ascheri JLR (2012) Physicochemical characterization of edible starch films with Barbados cherry (Malphigia emarginata D.C.). Quím Nova 35:546–552. https://doi.org/10.1590/S0100-40422012000300020

Davoodi MN, Milani JM, Farahmandfar R (2021) Preparation and characterization of a novel biodegradable film based on sulfated polysaccharide extracted from seaweed Ulva intestinalis. Food Sci Nutr 9:4108–4116. https://doi.org/10.1002/fsn3.2370

Muscat D, Tobin MJ, Guo Q, Adhikari B (2014) Understanding the distribution of natural wax in starch-wax films using synchroton-based FTIR (S-FTIR). Carbohydr Polym 102:125–135. https://doi.org/10.1016/j.carbpol.2013.11.004

Müller CMO, Yamashita F, Laurindo JB (2008) Evaluation of the effects of glycerol and sorbitol concentration and water activity on the water barrier properties of cassava starch films through a solubility approach. Carbohydr Polym 72:82–87. https://doi.org/10.1016/j.carbpol.2007.07.026

Yousuf B, Sun Y, Wu S (2021) Lipid and lipid-containing composite edible coatings and films. Food Rev Int 1–24. https://doi.org/10.1080/87559129.2021.1876084

Villalobos R, Chanona J, Hernández P, Gutiérrez G, Chiralt A (2005) Gloss and transparency of hydroxypropyl methylcellulose films containing surfactants as affected by their microstructure. Food Hydrocoll 19:53–61. https://doi.org/10.1016/j.foodhyd.2004.04.014

Diéguez MCV, Pelissari FP, Sobral PA, Menegalli FC (2015) Effect of process conditions on the production of nanocomposite films based on amaranth flour and montmorillonite. LWT - Food Sci Technol 61:70–79. https://doi.org/10.1016/j.lwt.2014.11.017

Martelli MR, Barros TT, de Moura MR, Mattoso LHC, Assis OBG (2012) Effect of chitosan nanoparticles and pectin content on mechanical properties and water vapor permeability of banana puree films. J Food Sci 78:N98–N104. https://doi.org/10.1111/j.1750-3841.2012.03006

Silva RS, Santos BMM, Fonseca GG, Prentice CP, Cortez-Vega WR (2020) Analysis of hybrid sorubim protein films incorporated with glycerol and clove essential oil for packaging applications. J Polym Environ 28:421–432. https://doi.org/10.1007/s10924-019-01608-7

Laycock B, Nikolic M, Colwell JM, Gauthier E, Halley P, Bottle S, George G (2017) Lifetime prediction of biodegradable polymers. Progr Polym Sci 71:144–189. https://doi.org/10.1016/j.progpolymsci.2017.02.004

Baidurah S, Takada S, Shimizu K, Ishida Y, Yamane T, Ohtani H (2013) Evaluation of biodegradation behavior of poly(butylene succinate-co-butylene adipate) with lowered crystallinity by thermally assisted hydrolysis and methylation-gas chromatography. J Anal Appl Pyrol 103:73–77. https://doi.org/10.1016/j.jaap.2012.08.011

Baidurah S, Murugan P, Sen KY, Furuyama Y, Nonome M, Sudesh K, Ishida Y (2019) Evaluation of soil burial biodegradation behavior of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) on the basis of change in copolymer composition monitored by thermally assisted hydrolysis and methylation-gas chromatography. J Anal Appl Pyrol 137:146–150. https://doi.org/10.1016/j.jaap.2018.11.020

Siracusa V (2019) Microbial degradation of synthetic biopolymers waste. Polymers 11:1066. https://doi.org/10.3390/polym11061066

Maiti S, Ray D, Mitra D (2012) Role of crosslinker on the biodegradation behavior of starch/polyvinylalcohol blend films. J Polym Environ 20:749–759. https://doi.org/10.1007/s10924-012-0433-6

Epelde L, Burges A, Mijangos I, Garbisu C (2014) Microbial properties and attributes of ecological relevance for soil quality monitoring during a chemical stabilization field study. Appl Soil Ecol 75:1–12. https://doi.org/10.1016/j.apsoil.2013.10.003

Heijboer A, ten Berge HFM, de Ruiter PC, Jørgensen HB, Kowalchuk GA, Bloem J (2016) Plant biomass, soil microbial community structure and nitrogen cycling under different organic amendment regimes; a 15N tracer-based approach. Appl Soil Ecol 107:251–260. https://doi.org/10.1016/j.apsoil.2016.06.009

Li L, Xu M, Eyakub Ali M, Zhang W, Duan Y, Li D (2018) Factors affecting soil microbial biomass and functional diversity with the application of organic amendments in three contrasting cropland soils during a field experiment. PLoS ONE 13:e0203812. https://doi.org/10.1371/journal.pone.0203812

Boonsuk P, Sukolrat A, Kaewtatip K, Chantarak S, Kelarakis A, Chaibundit C (2020) Modified cassava starch/poly(vinyl alcohol) blend films plasticized by glycerol: structure and properties. J Appl Polym Sci (1–13),48848. https://doi.org/10.1002/app.48848

Siddiqua S, Mamun AA (2020) An inclusive review on recent status of plastic biodegradation. Int J Advanced Res 8:42–54. https://doi.org/10.21474/IJAR01/11463

Xiong H, Tang S, Tang H, Zou P (2008) The structure and properties of a starch-based biodegradable film. Carbohydr Polym 71:263–268. https://doi.org/10.1016/j.carbpol.2007.05.035

Torres FG, Troncoso OP, Torres C, Díaz DA, Amaya E (2011) Biodegradability and mechanical properties of starch films from Andean crops. Int J Biol Macromol 48:603–606. https://doi.org/10.1016/j.ijbiomac.2011.01.026

Jaramillo CM, Gutiérrez TJ, Goyanes S, Bernal C, Famá L (2016) Biodegradability and plasticizing effect of yerba mate extract on cassava starch edible films. Carbohydr Polym 151:150–159. https://doi.org/10.1016/j.carbpol.2016.05.025

Yarwood SA (2021) Microbial ecology. In: Principles and applications of soil microbiology (3rd Ed.). Gentry TJ, Fuhrmann JJ, Zuberer DA (editors). Microb Ecol (Chapter 10), 239–267. https://doi.org/10.1016/B978-0-12-820202-9.00010-1

Funding

The authors gratefully thank the Brazilian research funding agencies CNPq, CAPES, and FUNDECT for the financial support.

Author information

Authors and Affiliations

Contributions

AOS: investigation, formal analysis, writing—original draft; FMF: methodology, investigation, formal analysis; GGF: conceptualization, validation, formal analysis, investigation, writing—original draft, review and editing, supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Films were developed with pequi pulp added of gelatin and plasticizer.

• Films with 7.0% gelatin and 1.5% plasticizer had higher tensile strength.

• The different types of soil interfered in the decomposition of the polymers.

• Films were at the most 100% degraded over a period of 5 to 9 days.

• Thermal analysis indicated desirable characteristic for food packing films.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

da Silva, A.O., Fakhoury, F.M. & Fonseca, G.G. Development of highly biodegradable and sustainable films based on pequi pulp. Biomass Conv. Bioref. 14, 10161–10176 (2024). https://doi.org/10.1007/s13399-022-03047-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03047-2