Abstract

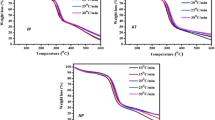

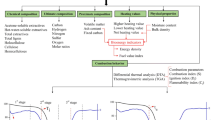

The current energy demand requires new energy sources. The use of biomass is an attractive option. In this work, the combustion thermal behaviour and kinetic of custard apple (Annona cherimola) crop remains derived from different plot fertilisation conditions (organic and inorganic) were studied. Thermogravimetry procedures were applied to seeds and wood under four heating rates (5, 10, 20 and 40 °C/min). Iso-conversional methods (Friedman, Flynn–Wall–Ozawa and Kissinger–Akahira–Sunose) were used to determine the activation energy and the frequency factor. Fuel results showed a higher high heating value for seeds (~ 24.78 MJ/mol) when compared with wood (~ 19.33 MJ/mol). Thermogravimetric profiles denoted that, while seed samples were only affected by heating ramps, pruning remains were also influenced by the type of fertiliser. Organic fertiliser was responsible for higher maximum values on the second decomposition peak for wood samples, at 20 and 40 °C/min (56.78%/min and 23.03%/min). Kinetic indexes were also notably influenced by the fertiliser nature. Organic manure reduced the average activation energy results, being more perceptible in seeds (135.51–172.32 kJ/mol) than wood (140.32–144.43 kJ/mol). Hence, it is proven that the type of fertilisation affects the thermal behaviour of custard apple residues.

Similar content being viewed by others

Abbreviations

- A:

-

Frequency factor

- DGT:

-

Derived thermogravimetric profiles

- DTGmax :

-

Maximum value reached of a DTG profile

- E a :

-

Activation energy

- FWO:

-

Ozawa-Flynn-Wall iso-conversional method

- HHV:

-

High heating value

- KAS:

-

Kissinger-Akahira-Sunose iso-conversional method

- M1:

-

Casarabonela plot

- M2:

-

Tolox plot

- R 2 :

-

Correlation coefficients

- SC:

-

Seed sample under organic fertiliser

- SM:

-

Seed sample under mineral fertiliser

- TG:

-

Thermogravimetric profiles

- TGA:

-

Thermogravimetric analysis

- WC:

-

Pruning remain sample under organic fertiliser

- WM:

-

Pruning remain sample under mineral fertiliser

- α :

-

Conversion grade

References

Mishra RK, Mohanty K (2020) Pyrolysis characteristics, fuel properties, and compositional study of Madhuca longifolia seeds over metal oxide catalysts. Biomass Convers Biorefin 10:621–637. https://doi.org/10.1007/S13399-019-00469-3

Ullah H, Lun L, Riaz L et al (2021) Physicochemical characteristics and thermal degradation behavior of dry and wet torrefied orange peel obtained by dry/wet torrefaction. Biomass Convers Biorefin. https://doi.org/10.1007/S13399-021-01777-3

Dada TK, Sheehan M, Murugavelh S, Antunes E (2021) A review on catalytic pyrolysis for high-quality bio-oil production from biomass. Biomass Convers Biorefin. https://doi.org/10.1007/S13399-021-01391-3

Cuong TT, Le HA, Khai NM et al (2021) Renewable energy from biomass surplus resource: potential of power generation from rice straw in Vietnam. Sci Rep 11. https://doi.org/10.1038/s41598-020-80678-3

Vassilev SV, Vassileva CG, Song YC et al (2017) Ash contents and ash-forming elements of biomass and their significance for solid biofuel combustion. Fuel 208:377–409

Grigiante M, Brighenti M, Maldina M (2021) A complete two-parameter kinetic model to describe the thermal pretreatment of biomasses. Biomass Convers Biorefin 11:2543–2556. https://doi.org/10.1007/S13399-020-00693-2

Pardo RNC, Rojas GMA, Florez LM (2021) Thermal analysis of the physicochemical properties of organic waste to application in the compost process. Biomass Convers Biorefin. https://doi.org/10.1007/S13399-021-01786-2

Santos SA, Vilela C, Camacho JF et al (2016) Profiling of lipophilic and phenolic phytochemicals of four cultivars from cherimoya (Annona cherimola mill.). Food Chem 211:845–852. https://doi.org/10.1016/J.FOODCHEM.2016.05.123

Jamkhande PG, Ajgunde BR, Jadge DR (2017) Annona cherimola mill. (custard apple): a review on its plant profile, nutritional values, traditional claims and ethnomedicinal properties. Orient Pharm Exp Med 17:189–201

Jagtap UB, Bapat VA (2018) Custard apple— Annona squamosa L. Exotic Fruits:163–167. https://doi.org/10.1016/B978-0-12-803138-4.00019-8

García-Salas P, Verardo V, Gori A et al (2016) Determination of lipid composition of the two principal cherimoya cultivars grown in Andalusian region. LWT Food Sci Technol 65:390–397. https://doi.org/10.1016/J.LWT.2015.08.004

Mengqi Z, Shi A, Ajmal M et al (2021) Comprehensive review on agricultural waste utilization and high-temperature fermentation and composting. Biomass Convers Biorefin. https://doi.org/10.1007/S13399-021-01438-5

Haile A, Gelebo GG, Tesfaye T et al (2021) Pulp and paper mill wastes: utilizations and prospects for high value-added biomaterials. Bioresources and Bioprocessing 8. https://doi.org/10.1186/S40643-021-00385-3

García-Carmona M, Márquez-San Emeterio L, Reyes-Martín MP et al (2020) Changes in nutrient contents in peel, pulp, and seed of cherimoya (Annona cherimola mill.) in relation to organic mulching on the Andalusian tropical coast (Spain). Sci Hortic 263(109120). https://doi.org/10.1016/j.scienta.2019.109120

Benítez E, Viera W, Garrido P et al (2020) Current research on Andean fruit crop diseases. Agricultural, Forestry and Bioindustry Biotechnology and Biodiscovery 387–401. https://doi.org/10.1007/978-3-030-51358-0_19

Durán-Zuazo VH, Tarifa DF, García-Tejero IF et al (2019) Water use and leaf nutrient status for terraced cherimoya trees in a subtropical mediterranean environment. Horticulturae 5:46. https://doi.org/10.3390/HORTICULTURAE5020046

Zhang X, Davidson EA, Mauzerall DL et al (2015) Managing nitrogen for sustainable development. Nature 528:51–59

Rahman KMA, Zhang D (2018) Effects of fertilizer broadcasting on the excessive use of inorganic fertilizers and environmental sustainability. Sustainability 10:759. https://doi.org/10.3390/su10030759

Dahunsi SO, Oranusi S, Efeovbokhan VE et al (2021) Crop performance and soil fertility improvement using organic fertilizer produced from valorization of Carica papaya fruit peel. Sci Rep 11. https://doi.org/10.1038/s41598-021-84206-9

Paniagua S, Escudero L, Escapa C et al (2016) Effect of waste organic amendments on Populus sp biomass production and thermal characteristics. Renew Energy 94:166–174. https://doi.org/10.1016/j.renene.2016.03.019

Paniagua S, Zanfaño L, Calvo LF (2020) Influence of the fertilizer type in the agronomic and energetic behaviour of the residues coming from oleander, cypress and quinoa. Fuel 272:117711. https://doi.org/10.1016/J.FUEL.2020.117711

Paniagua Bermejo S, Prado-Guerra A, García Pérez AI, Calvo Prieto LF (2020) Study of quinoa plant residues as a way to produce energy through thermogravimetric analysis and indexes estimation. Renew Energy 146. https://doi.org/10.1016/j.renene.2019.08.056

Paniagua S, Reyes S, Lima F et al (2021) Combustion of avocado crop residues: effect of crop variety and nature of nutrients. Fuel 291. https://doi.org/10.1016/j.fuel.2020.119660

FAO (2014) Word reference base for soil resources. International soil classification system for naming soils and creating legends for soil map, Rome

Astudillo ÁRM, Cueva BC, Valarezo PSA (2004) Genetic diversity and geographic distribution of Annona cherimola in, Southern Ecuador

AENOR (2018) UNE-EN ISO 18135:2018. Solid biofuels - Sampling

Friedman HL (1964) Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci Polym Symp:6:183

Flynn JH, Wall LA (1966) A quick, direct method for the determination of activation energy from thermogravimetric data. J Polym Sci B Polym Lett 4:323–328. https://doi.org/10.1002/POL.1966.110040504

Ozawa T (1965) A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn 38:1881–1886. https://doi.org/10.1246/BCSJ.38.1881

Doyle CD (1965) Series approximations to the equation of thermogravimetric data. Nature 207(4994):290–291. https://doi.org/10.1038/207290a0

Kissinger HE (1956) Variation of peak temperature with heating rate in differential thermal analysis. J Res Natl Bur Stand (4):57, 217

Kissinger HE (1957) Reaction kinetics in differential thermal analysis. Anal Chem 29:1702–1706

Coats AW, Redfern JP (1964) Kinetic parameters from thermogravimetric data. Nature 201:68–69

Yuan X, He T, Cao H, Yuan Q (2017) Cattle manure pyrolysis process: kinetic and thermodynamic analysis with isoconversional methods. Renew Energy 107:489–496. https://doi.org/10.1016/j.renene.2017.02.026

Yaras A, Demirel B, Akkurt F, Arslanoglu H (2021) Thermal conversion behavior of paper mill sludge: characterization, kinetic, and thermodynamic analyses. Biomass Convers Biorefin. https://doi.org/10.1007/S13399-020-01232-9

Elnajjar E, Al-Zuhair S, Hasan S et al (2020) Morphology characterization and chemical composition of United Arab Emirates date seeds and their potential for energy production. Energy 213. https://doi.org/10.1016/J.ENERGY.2020.118810

Schroeder P, do Nascimento BP, Romeiro GA et al (2017) Chemical and physical analysis of the liquid fractions from soursop seed cake obtained using slow pyrolysis conditions. J Anal Appl Pyrolysis 124:161–174. https://doi.org/10.1016/j.jaap.2017.02.010

Su CH, Nguyen HC, Pham UK et al (2018) Biodiesel production from a novel nonedible feedstock, Soursop (Annona muricata L.) seed oil, Energies (Basel), p 11. https://doi.org/10.3390/EN11102562

Janković B, Manić N, Dodevski V et al (2020) Kinetic study of oxy-combustion of plane tree (Platanus orientalis) seeds (PTS) in O2/Ar atmosphere. J Therm Anal Calorim 142:953–976. https://doi.org/10.1007/S10973-019-09154-Z/TABLES/4

Picchi G, Lombardini C, Pari L, Spinelli R (2018) Physical and chemical characteristics of renewable fuel obtained from pruning residues. J Clean Prod 171:457–463. https://doi.org/10.1016/J.JCLEPRO.2017.10.025

Kethobile E, Ketlogetswe C, Gandure J (2020) Characterisation of the non-oil Jatropha biomass material for use as a source of solid fuel. Biomass Convers Biorefin 10:1251–1267. https://doi.org/10.1007/S13399-019-00511-4

Mu L, Wang R, Zhai Z et al (2021) Evaluation of thermokinetics methodology, parameters, and coke characterization of co-pyrolysis of bituminous coal with herbaceous and agricultural biomass. Biomass Convers Biorefin. https://doi.org/10.1007/S13399-021-01502-0

Dorokhov VV, Kuznetsov GV, Yu K, Vershinina PAS (2021) Relative energy efficiency indicators calculated for high-moisture waste-based fuel blends using multiple-criteria decision-making. Energy 234. https://doi.org/10.1016/j.energy.2021.121257

Vicente ED, Vicente AM, Evtyugina M et al (2019) Emissions from residential pellet combustion of an invasive acacia species. Renew Energy 140:319–329. https://doi.org/10.1016/J.RENENE.2019.03.057

Khan SR, Zeeshan M, Ahmed A, Saeed S (2021) Comparison of synthetic and low-cost natural zeolite for bio-oil focused pyrolysis of raw and pretreated biomass. J Clean Prod 313. https://doi.org/10.1016/J.JCLEPRO.2021.127760

Coimbra RN, Paniagua S, Escapa C et al (2016) Thermal valorization of pulp mill sludge by co-processing with coal. Waste Biomass Valorization 7:995–1006

Balsora HK, Kartik S, Rainey TJ et al (2021) Kinetic modelling for thermal decomposition of agricultural residues at different heating rates. Biomass Convers Biorefin. https://doi.org/10.1007/S13399-021-01382-4

Pal DB, Tiwari AK, Srivastava N et al (2021a) Thermal studies of biomass obtained from the seeds of Syzygium cumini and Cassia fistula L. and peel of Cassia fistula L. fruit. Biomass Convers Biorefin. https://doi.org/10.1007/S13399-021-01492-Z

Shrigiri BM (2021) Combustion characteristics of sugar apple seed (Annona squamosa) oil methyl ester and its blends on compression ignition engine. International Journal of Ambient Energy. https://doi.org/10.1080/01430750.2021.1888801

Rami Reddy S, Murali G, Ahamad Shaik A et al (2021) Experimental evaluation of diesel engine powered with waste mango seed biodiesel at different injection timings and EGR rates. Fuel 285. https://doi.org/10.1016/J.FUEL.2020.119047

Asokan MA, Senthur Prabu S, Kamesh S, Khan W (2018) Performance, combustion and emission characteristics of diesel engine fuelled with papaya and watermelon seed oil bio-diesel/diesel blends. Energy 145:238–245. https://doi.org/10.1016/J.ENERGY.2017.12.140

Kougioumtzis MA, Kanaveli IP, Karampinis E et al (2021) Combustion of olive tree pruning pellets versus sunflower husk pellets at industrial boiler. Monitoring of emissions and combustion efficiency. Renew Energy 171:516–525. https://doi.org/10.1016/J.RENENE.2021.02.118

Duranay ND, Akkuş G (2021) Solid fuel production with torrefaction from vineyard pruning waste. Biomass Convers Biorefin 11:2335–2346. https://doi.org/10.1007/S13399-019-00496-0

Ozyuguran A, Akturk A, Yaman S (2018) Optimal use of condensed parameters of ultimate analysis to predict the calorific value of biomass. Fuel 214:640–646. https://doi.org/10.1016/J.FUEL.2017.10.082

Zhai J, Burke IT, Mayes WM, Stewart DI (2021) New insights into biomass combustion ash categorisation: a phylogenetic analysis. Fuel 287:119469. https://doi.org/10.1016/J.FUEL.2020.119469

Nudri NA, Bachmann RT, Ghani WAWAK et al (2020) Characterization of oil palm trunk biocoal and its suitability for solid fuel applications. Biomass Convers Biorefin 10:45–55. https://doi.org/10.1007/S13399-019-00419-Z

Mishra RK, Mohanty K (2018a) Characterization of non-edible lignocellulosic biomass in terms of their candidacy towards alternative renewable fuels. Biomass Convers Biorefin 8:799–812. https://doi.org/10.1007/S13399-018-0332-8

Castells B, Amez I, Medic L et al (2021) Study of lignocellulosic biomass ignition properties estimation from thermogravimetric analysis. https://doi.org/10.1016/j.jlp.2021.104425

Du J, Zhong B, Subbiah V et al (2021) Lc-esi-qtof-ms/ms profiling and antioxidant activity of phenolics from custard apple fruit and by-products. Separations 8. https://doi.org/10.3390/SEPARATIONS8050062

Ahmad MS, Mehmood MA, Al Ayed OS et al (2017) Kinetic analyses and pyrolytic behavior of Para grass (Urochloa mutica) for its bioenergy potential. Bioresour Technol 224:708–713. https://doi.org/10.1016/J.BIORTECH.2016.10.090

Boubacar Laougé Z, Merdun H (2020) Pyrolysis and combustion kinetics of Sida cordifolia L. using thermogravimetric analysis. Bioresour Technol 299:122602. https://doi.org/10.1016/j.biortech.2019.122602

Paniagua S, Prado-Guerra A, García AI, Calvo LF (2019) Bioenergy derived from an organically fertilized poplar plot: overall TGA and index estimation study for combustion, gasification, and pyrolysis processes. Biomass Convers Biorefin 1–12. https://doi.org/10.1007/s13399-019-00392-7

Sher F, Iqbal SZ, Liu H et al (2020) Thermal and kinetic analysis of diverse biomass fuels under different reaction environment: a way forward to renewable energy sources. Energy Convers Manag 203. https://doi.org/10.1016/J.ENCONMAN.2019.112266

Liu L, Pang Y, Lv D et al (2021) Thermal and kinetic analyzing of pyrolysis and combustion of self-heating biomass particles. Process Saf Environ Prot 151:39–50. https://doi.org/10.1016/J.PSEP.2021.05.011

Pérez A, Martín-Lara MA, Gálvez-Pérez A et al (2018) Kinetic analysis of pyrolysis and combustion of the olive tree pruning by chemical fractionation. Bioresour Technol 249:557–566. https://doi.org/10.1016/J.BIORTECH.2017.10.045

Altantzis AI, Kallistridis NC, Stavropoulos G, Zabaniotou A (2021) Apparent pyrolysis kinetics and index-based assessment of pretreated peach seeds. Processes (9):905. https://doi.org/10.3390/PR9060905

Pal DB, Srivastava N, Pal SL et al (2021b) Lignocellulosic composition based thermal kinetic study of Mangiferaindica Lam, Artocarpus Heterophyllus lam and Syzygium Jambolana seeds. Bioresour Technol 341. https://doi.org/10.1016/J.BIORTECH.2021.125891

Luo L, Guo X, Zhang Z et al (2020) Insight into pyrolysis kinetics of Lignocellulosic biomass: Isoconversional kinetic analysis by the modified Friedman method. Energy and Fuels 34:4874–4881

Burnham AK, Dinh LN (2007) A comparison of isoconversional and model-fitting approaches to kinetic parameter estimation and application predictions. J Therm Anal Calorim 89:479–490. https://doi.org/10.1007/S10973-006-8486-1

Al-Salem SM (2019) 9 - kinetic studies related to polymer degradation and stability. In: Al-Salem SM (ed) Plastics to energy. William Andrew Publishing, pp 233–268

Berčič G (2017) The universality of Friedman’s isoconversional analysis results in a model-less prediction of thermodegradation profiles. Thermochim Acta 650:1–7. https://doi.org/10.1016/J.TCA.2017.01.011

Wang C, Jin L, Wang Y et al (2022) Thermogravimetric investigation on co-combustion characteristics and kinetics of antibiotic filter residue and vegetal biomass. J Therm Anal Calorim 147:925–938. https://doi.org/10.1007/S10973-020-10280-2

Mohd Safaai NS, Pang S (2021) Pyrolysis kinetics of chemically treated and torrefied radiata pine identified through thermogravimetric analysis. Renew Energy 175:200–213. https://doi.org/10.1016/J.RENENE.2021.04.117

Garcia-Maraver A, Perez-Jimenez JA, Serrano-Bernardo F, Zamorano M (2015) Determination and comparison of combustion kinetics parameters ofagricultural biomass from olive trees. Renew Energy 83:897–904. https://doi.org/10.1016/J.RENENE.2015.05.049

Kaur R, Gera P, Jha MK, Bhaskar T (2018) Pyrolysis kinetics and thermodynamic parameters of castor (Ricinus communis) residue using thermogravimetric analysis. Bioresour Technol 250:422–428. https://doi.org/10.1016/j.biortech.2017.11.077

Khasraw D, Spooner S, Hage H et al (2021) Devolatilisation characteristics of coal and biomass with respect to temperature and heating rate for HIsarna alternative ironmaking process. Fuel 284. https://doi.org/10.1016/J.FUEL.2020.119101

Misse SE, Brillard A, Brilhac JF, et al (2018) Thermogravimetric analyses and kinetic modeling of three Cameroonian biomass. J Therm Anal Calorim 132:1979–1994. https://doi.org/10.1007/S10973-018-7108-Z

Shen DK, Gu S, Jin B, Fang MX (2011) Thermal degradation mechanisms of wood under inert and oxidative environments using DAEM methods. Bioresour Technol 102:2047–2052. https://doi.org/10.1016/J.BIORTECH.2010.09.081

Nyakuma BB, Wong SL, Oladokun O et al (2020) Review of the fuel properties, characterisation techniques, and pre-treatment technologies for oil palm empty fruit bunches. Biomass Convers Biorefin. https://doi.org/10.1007/S13399-020-01133-X

Mishra RK, Mohanty K (2018b) Pyrolysis kinetics and thermal behavior of waste sawdust biomass using thermogravimetric analysis. Bioresour Technol 251:63–74. https://doi.org/10.1016/J.BIORTECH.2017.12.029

Saveliev R, Chudnovsky B, Korytnyi E et al (2007) Prediction of performance and pollutant emission from bituminous and sub-bituminous coals in utility boilers. Proc ASME Power Conf:437–446. https://doi.org/10.1115/POWER2007-22065

Zhao S, Pu W, Sun B et al (2019) Comparative evaluation on the thermal behaviors and kinetics of combustion of heavy crude oil and its SARA fractions. Fuel 239:117–125. https://doi.org/10.1016/J.FUEL.2018.11.014

Wang X, Hu M, Hu W et al (2016) Thermogravimetric kinetic study of agricultural residue biomass pyrolysis based on combined kinetics. Bioresour Technol 219:510–520. https://doi.org/10.1016/J.BIORTECH.2016.07.136

Wang B, Li Y, Zhou J et al (2021) Thermogravimetric and kinetic analysis of high-temperature thermal conversion of pine wood sawdust under CO2/Ar. Energies 14:5328. https://doi.org/10.3390/EN14175328

Özsin G, Pütün AE (2017) Kinetics and evolved gas analysis for pyrolysis of food processing wastes using TGA/MS/FT-IR. Waste Manag 64:315–326. https://doi.org/10.1016/J.WASMAN.2017.03.020

Gu X, Liu C, Jiang X et al (2014) Thermal behavior and kinetics of the pyrolysis of the raw/steam exploded poplar wood sawdust. J Anal Appl Pyrolysis 106:177–186. https://doi.org/10.1016/J.JAAP.2014.01.018

Florentino-Madiedo L, Vega MF, Díaz-Faes E, Barriocanal C (2021) Evaluation of synergy during co-pyrolysis of torrefied sawdust, coal and paraffin. A kinetic and thermodynamic study. Fuel 292. https://doi.org/10.1016/J.FUEL.2021.120305

Montiano MG, Díaz-Faes E, Barriocanal C (2016) Kinetics of co-pyrolysis of sawdust, coal and tar. Bioresour Technol 205:222–229. https://doi.org/10.1016/J.BIORTECH.2016.01.033

Konwar K, Nath HP, Bhuyan N et al (2019) Effect of biomass addition on the devolatilization kinetics, mechanisms and thermodynamics of a northeast Indian low rank sub-bituminous coal. Fuel 256:115926. https://doi.org/10.1016/J.FUEL.2019.115926

Paniagua S, Otero M, Coimbra RNR et al (2015) Simultaneous thermogravimetric and mass spectrometric monitoring of the pyrolysis, gasification and combustion of rice straw. J Therm Anal Calorim 121:603–611. https://doi.org/10.1007/s10973-015-4632-y

Funding

The authors thank the University of León and the University of Málaga for allowing the use of their facilities and resources to carry out this work. The Spanish Ministry of Science and Innovation is gratefully acknowledged for the Juan de la Cierva-Formation contract of Dr. Sergio Paniagua (FJC2020-043479-I).

Author information

Authors and Affiliations

Contributions

Alba Prado-Guerra: Conceptualisation, Investigation, Methodology, Writing—review and editing. Luis F. Calvo: Conceptualisation, Investigation, Supervision, Project administration. Sergio Reyes: Resources, Investigation, Visualisation. Francisco Lima: Resources, Investigation, Methodology. Sergio Paniagua: Conceptualisation, Investigation, Methodology, Supervision, Review and editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Prado-Guerra, A., Calvo, L.F., Reyes, S. et al. Custard apple crop residues combustion: an overall study of their energy behaviour under different fertilisation conditions. Biomass Conv. Bioref. 14, 10459–10473 (2024). https://doi.org/10.1007/s13399-022-03046-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03046-3