Abstract

Fermentable sugar release is a crucial step in the fermentation of lignocellulosic biomass to biofuels. The efficiency of fermentable sugar release from pretreated biomass can be improved through acquiring pre-experimental information from predictive models that function as initial screening tools during lignocellulose bioprocessing. In this study, artificial neural networks, random forest, and decision tree were used to model fermentable sugar concentration (g/L) and combined severity factor (CSF) index from a pretreated starch-based lignocellulosic biomass-cassava peels. The input parameters for all the models include soaking temperature, soaking time, autoclave duration, hydrochloric acid concentration, and percentage solid loading. A backpropagation training algorithm was adopted for the ANN models and trained on experimental data while the random forest models were trained using a binary tree–based machine learning algorithm and the decision tree models were trained using an information entropy–based learning algorithm. For the fermentable sugar concentration, the highest coefficient of determination (R2 > 0.99) was achieved with the decision tree model while the highest prediction accuracy of 82% was achieved with the ANN model (R2 > 0.82). For the CSF index, the ANN model gave both the highest coefficient of determination (R2 > 0.93) and prediction accuracy (78%). Thus, the ANN models gave better predictions of the fermentable sugar concentration and the combined severity factor index compared to the other intelligent models. The study, therefore, provides an insight into intelligent predictive modelling towards the screening of pretreatment strategies for starch-based lignocellulosic biomass valorization.

Similar content being viewed by others

References

Sivamani S, Chandrasekaran A.P, Balajii M, Shanmugaprakash M, Hosseini-Bandegharaei A, Baskar R (2018) Evaluation of the potential of cassava-based residues for biofuels production. Reviews in Environmental Science and Bio/Technology 1–18

Sivamani S, Baskar R (2015) Optimization of bioethanol production from cassava peel using statistical experimental design. Environ Prog Sustain Energy 34(2):567–574

Khawla BJ, Sameh M, Imen G, Donyes F, Dhouha G, Raoudha EG et al (2014) Potato peel as feedstock for bioethanol production: a comparison of acidic and enzymatic hydrolysis. Ind Crops Prod 52:144–149

Den W, Sharma VK, Lee M, Nadadur G, Varma RS (2018) Lignocellulosic biomass transformations via greener oxidative pretreatment processes: access to energy and value-added chemicals. Front Chem 6:141

Borisova AS, Pihlajaniemi V, Kont R, Niemelä K, Koitto T, Mikkelson A et al (2021) Effect of soluble phenolic compounds from hydrothermally pretreated wheat straw on cellulose degrading enzymes

Ziegler-Devin I, Chrusciel L, Brosse N (2021) Steam Explosion pretreatment of lignocellulosic biomass: a mini-review of theorical and experimental approaches. Frontiers in Chemistry 9

Mikulski D, Kłosowski G (2020) Microwave-assisted dilute acid pretreatment in bioethanol production from wheat and rye stillages. Biomass And Bioenergy 136:105528

Nanssou PAK, Nono YJ, Kapseu C (2016) Pretreatment of cassava stems and peelings by thermohydrolysis to enhance hydrolysis yield of cellulose in bioethanol production process. Renewable Energy 97:252–265

Mankar AR, Pandey A, Modak A, Pant K (2021) Pretreatment of lignocellulosic biomass: A review on recent advances. Biores Technol 334:125235

García-Aparicio MP, Ballesteros I, González A, Oliva JM, Ballesteros M, Negro MJ (2006) Effect of inhibitors released during steam-explosion pretreatment of barley straw on enzymatic hydrolysis. Appl Biochem Biotechnol 129(1–3):278–288

Hector RE, Bowman MJ, Skory CD, Cotta MA (2009) The Saccharomyces cerevisiae YMR315W gene encodes an NADP (H)-specific oxidoreductase regulated by the transcription factor Stb5p in response to NADPH limitation. New Biotechnol 26(3–4):171–180

Baş D, Boyacı İH (2007) Modeling and optimization II: comparison of estimation capabilities of response surface methodology with artificial neural networks in a biochemical reaction. J Food Eng 78(3):846–854

Desai KM, Survase SA, Saudagar PS, Lele S, Singhal RS (2008) Comparison of artificial neural network (ANN) and response surface methodology (RSM) in fermentation media optimization: case study of fermentative production of scleroglucan. Biochem Eng J 41(3):266–273

Olatunji O, Akinlabi S, Madushele N (2020) Application of artificial intelligence in the prediction of thermal properties of biomass. Springer, Valorization of Biomass to Value-Added Commodities, pp 59–91

da Silva Bispo VD, Scheid CM, Calçada LA, da Cruz Meleiro LA (2017) Development of an ANN-based soft-sensor to estimate the apparent viscosity of water-based drilling fluids. J Pet Sci Eng 150:69–73

Obafemi O, Stephen A, Ajayi O, Nkosinathi M (2019) A survey of artificial neural network-based prediction models for thermal properties of biomass. Procedia Manuf 33:184–191

Moodley P, Rorke DC, Kana EBG (2019) Development of artificial neural network tools for predicting sugar yields from inorganic salt-based pretreatment of lignocellulosic biomass. Biores Technol 273:682–686

Mascaro J, Asner GP, Knapp DE, Kennedy-Bowdoin T, Martin RE, Anderson C et al (2014) A tale of two “forests”: random forest machine learning aids tropical forest carbon mapping. PLoS ONE 9(1):e85993

Adebayo, R.A.; Moyo, M.; Gueguim-Kana, E.B.;Nsahlai, I.V (2020) The use of artificial neural networks for modelling rumen fill. Canadian Journal of Animal Science ja

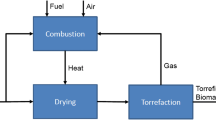

Aruwajoye GS, Faloye FD, Kana EG (2017) Soaking assisted thermal pretreatment of cassava peels wastes for fermentable sugar production: process modelling and optimization. Energy Convers Manage 150:558–566

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31(3):426–428

Lee J-W, Jeffries TW (2011) Efficiencies of acid catalysts in the hydrolysis of lignocellulosic biomass over a range of combined severity factors. Biores Technol 102(10):5884–5890

Patil-Shinde V, Kulkarni T, Kulkarni R, Chavan PD, Sharma T, Sharma BK et al (2014) Artificial intelligence-based modeling of high ash coal gasification in a pilot plant scale fluidized bed gasifier. Ind Eng Chem Res 53(49):18678–18689

Song Y-Y, Ying L (2015) Decision tree methods: applications for classification and prediction. Shanghai Arch Psychiatry 27(2):130

Elmaz F, Yücel Ö, Mutlu AY (2020) Machine learning based approach for predicting of higher heating values of solid fuels using proximity and ultimate analysis. Int J Adv Eng Pure Sci 32(2):145–151

Nwosu-Obieogu K, Dzarma GW, Ugwuodo C, Chiemenem L (2022) Environmental sustenance via melon seed peel conversion to fermentable sugars using soft computing models. Clean Eng Technol 7:100452

Nwosu-Obieogu K, Aguele F.O, Agu C.M, Onyekwulu C.S, Akatobi K.N (2021) Optimisation of the hydrolysis of melon seed (Citrullus lanatus) husk with hydrochloric acid using response surface methodology. Indian chemical engineer 1–10

Kana EG, Oloke J, Lateef A, Adesiyan M (2012) Modeling and optimization of biogas production on saw dust and other co-substrates using artificial neural network and genetic algorithm. Renew Energy 46:276–281

Vani S, Sukumaran RK, Savithri S (2015) Prediction of sugar yields during hydrolysis of lignocellulosic biomass using artificial neural network modeling. Biores Technol 188:128–135

Galvão RM, Santana TS, Fontes CH, Sales EA (2013) Modeling of biomass production of Haematococcus pluvialis. Appl Math 4(8A):50

Author information

Authors and Affiliations

Contributions

Conceptualization: G.S.A. and E.G.K. Methodology: G.S.A., F.D.F., and E.G.K. Data curation: G.S.A. Modelling and validation: G.S.A. Resources: A.K., A.K.S., and E.G.K. Writing—original draft preparation: G.S.A. Writing—review and editing: G.S.A., A.K., F.D.F., A.K.S., and E.G.K. Supervision: A.K., A.K.S., and E.G.K.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interest.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aruwajoye, G.S., Faloye, F.D., Kassim, A. et al. Intelligent modelling of fermentable sugar concentration and combined severity factor (CSF) index from pretreated starch-based lignocellulosic biomass. Biomass Conv. Bioref. (2022). https://doi.org/10.1007/s13399-022-03013-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-022-03013-y