Abstract

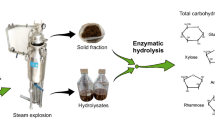

Semi-solid wastes from the beverage industry, like agave bagasse or brewery spent grains, were partly turned to the liquid phase by employing hydrothermal carbonization (HTC) or steam explosion (SE). The methane release in anaerobic batch assays of those extracts reached 316–362 mL g−1 of chemical oxygen demand for the SE pretreatment and 162–173 mL g−1 COD for HTC employed as a pretreatment. However, the yield of chemical oxygen demand in the extracts depends on both the pretreatment as well as the substrate. HTC applied to agave bagasse yielded 0.281 g of COD per gram of biomass, which is more than twice the amount from SE. In contrast, SE is more than 3 times effective than HTC using brewery spent grains as substrate with a yield of 0.582 g COD g−1. The combination of both process conversion efficiencies led to an available energy recovery of up to 0.4 for SE of spent grains and up to 0.1 for HTC of agave bagasse in relation to the energy content of substrate. For the latter, the slow and incomplete bioconversion of substrates obtained by HTC must be overcome. This holistic approach to sustainable management of large quantities of agro-industrial wastes turns an on-site environmental challenge into the availability of in-house renewable energy.

Similar content being viewed by others

References

Awasthi MK, Sarsaiya S, Patel A, Juneja A, Singh RP, Yan B, Awasthi SK, Jain A, Liu T, Duan Y, Pandey A, Zhang Z, Taherzadeh MJ (2020) Refining biomass residues for sustainable energy and bio-products: an assessment of technology, its importance, and strategic applications in circular bio-economy. Renew Sustain Energy Rev 127:109876. https://doi.org/10.1016/j.rser.2020.109876

Reshmy R, Balakumaran PA, Divakar K, Philip E, Madhavan A, Pugazhendhi A, Sindhu R (2022) Microbial valorization of lignin: prospects and challenges. Bioresour Technol 344:126240. https://doi.org/10.1016/j.biortech.2021.126240

Rachwał K, Waśko A, Gustaw K, Polak-Berecka M (2020) Utilization of brewery wastes in food industry. PeerJ 8:e9427. https://doi.org/10.7717/peerj.9427

Wahlström R, Rommi K, Willberg-Keyriläinen P, Ercili-Cura D, Holopainen-Mantila U, Hiltunen J, Kuutti L (2017) High yield protein extraction from Brewer’s spent grain with novel carboxylate salt-urea aqueous deep eutectic solvents. ChemistrySelect 2:9355–9363. https://doi.org/10.1002/slct.201701492

Zhou Z, Liu D, Zhao X (2021) Conversion of lignocellulose to biofuels and chemicals via sugar platform: an updated review on chemistry and mechanisms of acid hydrolysis of lignocellulose. Renew Sustain Energy Rev 146:111169. https://doi.org/10.1016/j.rser.2021.111169

Menon V, Rao M (2012) Trends in bioconversion of lignocellulose: biofuels, platform chemicals & biorefinery concept. Prog Energy Combust Sci 38:522–550. https://doi.org/10.1016/j.pecs.2012.02.002

Wainaina S, Lukitawesa AMK, Taherzadeh MJ (2019) Bioengineering of anaerobic digestion for volatile fatty acids, hydrogen or methane production: a critical review. Bioengineered 10:437–458. https://doi.org/10.1080/21655979.2019.1673937

Fernández-Dacosta C, Posada JA, Kleerebezem R, Cuellar MC, Ramirez A (2015) Microbial community-based polyhydroxyalkanoates (PHAs) production from wastewater: techno-economic analysis and ex-ante environmental assessment. Bioresour Technol 185:368–377. https://doi.org/10.1016/j.biortech.2015.03.025

Velebil J, Malalák J, Bradna J (2016) Mass and energetic yields of hydrochar from brewer’s spent grain. Agron Res 14:614–623

Cedeno M (1995) Tequila Production. Crit Rev Biotechnol 15:1–11. https://doi.org/10.3109/07388559509150529

Liñán-Montes A, Parra-Arciniega SM, Garza-González MT, García-Reyes RB, Soto-Regalado E, Cerino- Córdova FJ (2014) Characterization and thermal analysis of agave bagasse and malt spent grain. J Therm Anal Calorim 115:751–758. https://doi.org/10.1007/s10973-013-3321-y

van Lier JB, van der Zee FP, Frijters CT, Ersahin ME (2015) Celebrating 40 years anaerobic sludge bed reactors for industrial wastewater treatment. Rev Environ Sci Biotechnology 14:681–702. https://doi.org/10.1007/s11157-015-9375-5

Weber B, Stadlbauer EA (2017) Sustainable paths for managing solid and liquid waste from distilleries and breweries. J Cleaner Prod 149:38–48. https://doi.org/10.1016/j.jclepro.2017.02.054

Mussatto SI, Dragone G, Roberto IC (2006) Brewers’ spent grain: generation, characteristics and potential 5 applications. J Cereal Sci 43:1–14. https://doi.org/10.1016/j.jcs.2005.06.001

Crespo MR, González DR, Rodríguez R, Rendón LA, del Real JI, Torres JP (2013) Evaluation of agave bagasse compost as a component of substrates to produce seedlings of blue agave. Revista Mexicana de Ciencias Agrícolas 4:1161–1173

Libra JA, Ro KS, Kamann C, Funke A, Berge ND, Neubauer Y, Titirici MM, Fühner C, Bens O, Kern J, Emmerich KH (2011) Hydrothermal carbonization of biomass residuals: a comparative review of the chemistry, processes and applications of wet and dry pyrolysis. Biofuels 2:71–106. https://doi.org/10.4155/bfs.10.81

Titirici MM, Thomas A, Antonietti M (2007) Back in the black: hydrothermal carbonization of plant material as an efficient chemical process to treat the CO2 problem? New J Chem 31:787–789. https://doi.org/10.1039/B616045J

Aida TM, Sato Y, Watanabe M, Tajima K, Nonaka T, Hattori H, Arai K (2007) Dehydration of D-glucose in high temperature water at pressures up to 80 MPa. J Supercritical Fluids 40:381–388. https://doi.org/10.1016/j.supflu.2006.07.027

Antal MJ, Mok WSL, Richards GN (1990) Mechanism of formation of 5-(hydroxymethyl)-2-furaldehyde from d-fructose and sucrose. Carbohydrate Res 199:91–109. https://doi.org/10.1016/0008-6215(90)84096-D

Poerschmann J, Weiner B, Wedwitschka H, Baskyr I, Koehler R, Kopinke FD (2014) Characterization of biocoals and dissolved organic matter phases obtained upon hydrothermal carbonization of brewer’s spent grain. Bioresour Technol 164:162–169. https://doi.org/10.1016/j.biortech.2014.04.052

Heilmann SM, Lindsey R, Jader MJ, Sadowsky S, FJ, von Keitz MG, Valentas KJ, (2011) Hydrothermal carbonization of distiller’s grains. Biomass Bioenerg 35:2526–2533. https://doi.org/10.1016/j.biombioe.2011.02.022

Ramos LP (2003) The chemistry involved in the steam treatment of lignocellulosic materials. Quim Nova 26:863–871. https://doi.org/10.1590/S0100-40422003000600015

Negro MJ, Manzanares P, Oliva JM, Ballesteros I, Ballesteros M (2003) Changes in various physical/chemical parameters of Pinus pinaster wood after steam explosion treatment. Biomass Bioenerg 25:301–308. https://doi.org/10.1016/S0961-9534(03)00017-5

Hongzhang C, Liying L (2007) Unpolluted fractionation of wheat straw by steam explosion and ethanol extraction. Bioresour Technol 98:666–676. https://doi.org/10.1016/j.biortech.2006.02.029

Yang B, Wyman CE (2008) Pretreatment: the key to unlocking low-cost cellulosic ethanol. Biofuels Bioprod Bioref 2:26–40. https://doi.org/10.1002/bbb.49

Galbe M, Zacchi G (2012) Pretreatment: the key to efficient utilization of lignocellulosic materials. Biomass Bioenergy 46:70–78. https://doi.org/10.1016/j.biombioe.2012.03.026

Arreola-Vargas J, Flores-Larios A, González-Álvarez V, Corona-González RI, Méndez-Acosta HO (2016) Single and two-stage anaerobic digestion for hydrogen and methane production from acid and enzymatic hydrolysates of Agave tequilana bagasse. Int J Hydrogen Energy 41:897–904. https://doi.org/10.1016/j.ijhydene.2015.11.016

Purwadi R, Brandberg T, Taherzadeh MJ (2007) A possible industrial solution to ferment lignocellulosic hydrolyzate to ethanol: continuous cultivation with flocculating yeast. Int J Mol Sci 8:920–932. https://doi.org/10.3390/i8090920

Wirth B, Mumme J (2013) Anaerobic digestion of waste water from hydrothermal carbonization of corn silage. Appl Bioenergy (discontinued) 1:1–10. https://doi.org/10.2478/apbi-2013-0001

Luz CF, Cordiner S, Manni A, Mulone V, Rocco V (2018) Biochar characteristics and early applications in anaerobic digestion—a review. J Environ Chem Eng 6:2892–2909. https://doi.org/10.1016/j.jece.2018.04.015

Aragón-Briceño CI, Ross AB, Camargo-Valero MA (2021) Mass and energy integration study of hydrothermal carbonization with anaerobic digestion of sewage sludge. Renew Energy 167:473–483. https://doi.org/10.1016/j.renene.2020.11.103

Marin-Batista JD, Villamil JA, Qaramaleki SV, Coronella CJ, Mohedano AF, de la Rubia MA (2020) Energy valorization of cow manure by hydrothermal carbonization and anaerobic digestion. Renew Energy 160:623–623. https://doi.org/10.1016/j.renene.2020.07.003

van Soest PJ, Wine RH (1967) Use of detergents in the analysis of fibrous feeds. IV. Determination of plant cell-wall constituents. J Assoc Official Anal Chem 50:50–55. https://doi.org/10.1093/jaoac/50.1.50

Stökle K, Kruse A (2019) Extraction of sugars from forced chicory roots. Biomass Conv Bioref 9:699–708. https://doi.org/10.1007/s13399-019-00374-9

DuBois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356. https://doi.org/10.1021/ac60111a017

Buitrón G, Schoeb ME, Moreno-Andrade I, Moreno J (2005) Evaluation of two control strategies for a sequencing batch reactor degrading high concentration peaks of 4-chlorophenol. Water Res 39:1015–1024. https://doi.org/10.1016/j.watres.2004.12.023

Weber B, Stadlbauer EA, Eichenauer S, Koch C, Albert K, Kramer M, Steffens D (2013) Nature of carbonaceous materials from biomass by hydrothermal carbonization and low temperature conversion. J Biobased Mat Bioenergy 7:367–375. https://doi.org/10.1166/jbmb.2013.1358

van Haandel AC, Lettinga G (1994) Anaerobic sewage treatment: a practical guide for regions with a hot climate. J Wiley and Sons Ltd, Chichester

Bougrier C, Dognin D, Laroche C, Gonzalez V, Benali-Raclot D, Cacho-Rivero JA (2018) Anaerobic digestion of brewery spent grains: trace elements addition requirement. Bioresour Technol 247:1193–1196. https://doi.org/10.1016/j.biortech.2017.08.211

Ortiz I, Torreiro Y, Molina G, Maroño M, Sánchez JM (2019) A feasible application of circular economy: spent grain energy recovery in the beer industry. Waste Biomass Valorization 10:3809–3819. https://doi.org/10.1007/s12649-019-00677-y

Cholico-González D, Lara NO, Sánchez-Miranda AS, Morales-Estrella R, Escudero-García R, León-Patiño C (2021) Efficient metallization of magnetite concentrate by reduction with agave bagasse as a source of reducing agents. Int J Miner Metall Mater 28:603–611. https://doi.org/10.1007/s12613-020-2079-z

Figueira CE, Moreira PF, Guidici R (2015) Thermogravimetric analysis of the gasification of microalgae Chlorella vulgaris. Bioresour Technol 198:717–724. https://doi.org/10.1016/j.biortech.2015.09.059

Santillán-Urquiza E, Arteaga-Cardona F, Hernandez-Herman E, Pacheco-García PF, González-Rodríguez R, Coffer JL, Mendoza-Alvarez ME, Vélez-Ruiz JF, Méndez-Rojas MA (2015) Inulin as a novel biocompatible coating: evaluation of surface affinities toward CaHPO4, α-Fe2O3, ZnO, CaHPO4@ZnO and α-Fe2O3@ZnO nanoparticles. J Colloid Interface Sci 460:339–348. https://doi.org/10.1016/j.jcis.2015.08.057

de Diego-Díaz B, Durán A, Álvarez-García MR, Fernández-Rodríguez J (2019) New trends in physicochemical characterization of solid lignocellulosic waste in anaerobic digestion. Fuel 245:240–246. https://doi.org/10.1016/j.fuel.2019.02.051

Chum HL, Johnson DK, Black SK, Overend RP (1990) Pretreatment-catalyst effects and the combined severity parameter. Appl Biochem Biotechnol 24:1–14. https://doi.org/10.1007/BF02920229

Ruiz HA, Galbe M, Garrote G, Ramirez-Gutierrez DM, Ximenes E, Sun SN, Lachos-Perez D, Rodríguez-Jasso RM, Sun RC, Yang B, Ladisch MR (2021) Severity factor kinetic model as a strategic parameter of hydrothermal processing (steam explosion and liquid hot water) for biomass fractionation under biorefinery concept. Bioresour Technol 342:125961. https://doi.org/10.1016/j.biortech.2021.125961

Wu Q, Yu S, Hao N, Wells T, Meng X, Li M, Pu Y, Liu S, Ragauskas AJ (2017) Characterization of products from hydrothermal carbonization of pine. Bioresour Technol 244:78–83. https://doi.org/10.1016/j.biortech.2017.07.138

Kreuger E, Nges IA, Björnsson L (2011) Ensiling of crops for biogas production: effects on methane yield and total solids determination. Biotechnol Biofuels 4:44. https://doi.org/10.1186/1754-6834-4-44

Teixeira Franco R, Coarit H, Bayard R, Buffière P (2019) An improved procedure to assess the organic biodegradability and the biomethane potential of organic wastes for anaerobic digestion. Waste Manag Res 37:746–754. https://doi.org/10.1177/0734242X19851201

Duran-Cruz V, Hernández S, Ortíz I (2021) Evaluation of steam explosion pretreatment and enzymatic hydrolysis conditions for agave bagasse in biomethane production. Bioenerg Res 14:1328–1337. https://doi.org/10.1007/s12155-021-10245-9

Kruse A, Dadoux F, Grandl R, Wüst D (2012) Hydrothermal carbonization: 2. Kinetics of draff conversion. Chem Ing Tech 84:509–513. https://doi.org/10.1002/cite.201100168

Balasundaram G, Banu R, Varjani S, Kazmi AA, Tyagi VK (2022) Recalcitrant compounds formation, their toxicity, and mitigation: key issues in biomass pretreatment and anaerobic digestion. Chemosphere 291:132930. https://doi.org/10.1016/j.chemosphere.2021.132930

Monlau F, Sambusiti C, Barakat A, Quéméneur M, Trably E, Steyer JP, Carrère H (2014) Do furanic and phenolic compounds of lignocellulosic and algae biomass hydrolyzate inhibit anaerobic mixed cultures? A comprehensive review. Biotechnol Adv 32:934–951. https://doi.org/10.1016/j.biotechadv.2014.04.007

Caroca E, Serrano A, Borja R, Jiménez A, Carvajal A, Braga AF, Fermoso FG (2021) Influence of phenols and furans released during thermal pretreatment of olive mill solid waste on its anaerobic digestion. Waste Manag 120:202–208. https://doi.org/10.1016/j.wasman.2020.11.027

Martín C, Wu G, Wang Z, Stagge S, Jönsson LJ (2018) Formation of microbial inhibitors in steam-explosion pretreatment of softwood impregnated with sulfuric acid and sulfur dioxide. Bioresour Technol 262:242–250. https://doi.org/10.1016/j.biortech.2018.04.074

Cao Z, Hülsemann B, Wüst D, Ill L, Oechsner H, Kruse A (2020) Valorization of maize silage digestate from two-stage anaerobic digestion by hydrothermal carbonization. Energy Conv Manag 222:113218. https://doi.org/10.1016/j.enconman.2020.113218

Lu Z, Hegemann W (1998) Anaerobic toxicity and biodegradation of formaldehyde in batch cultures. Wat Res 32:209–215. https://doi.org/10.1016/S0043-1354(97)00181-4

Oliveira SVWB, Moraes EM, Adorno MAT, Varesche MBA, Foresti E, Zaiat M (2004) Formaldehyde degradation in an anaerobic packed-bed bioreactor. Wat Res 38:1685–1694. https://doi.org/10.1016/j.watres.2004.01.01

Wikandari R, Sanjaya AP, Millati R, Karimi K, Taherzadeh M J (2019) Fermentation inhibitors in ethanol and biogas processes and strategies to counteract their effects. In: Pandey A, Larroche C, Dussap CG, Gnansounou E, Khanal SK, Ricke S Eds. Biofuels: alternative feedstocks and conversion processes for the production of liquid and gaseous biofuels. Academic Press pp. 461–499. https://doi.org/10.1016/B978-0-12-816856-1.00020-8

Titirici MM, Antonietti M, Baccile N (2008) Hydrothermal carbon from biomass: a comparison of the local structure from poly- to monosaccharides and pentoses/hexoses. Green Chem 10:1204–1212. https://doi.org/10.1039/B807009A

Ischia G, Fiori L, Gao L, Goldfarb JL (2021) Valorizing municipal solid waste via integrating hydrothermal carbonization and downstream extraction for biofuel production. J Cleaner Prod 289:125781. https://doi.org/10.1016/j.jclepro.2021.125781

Bär RM, Voigt T (2019) Analysis and prediction methods for energy efficiency and media demand in the beverage industry. Food Eng Rev 11:200–217. https://doi.org/10.1007/s12393-019-09195-y

Funke A, Ziegler F (2011) Heat of reaction measurements for hydrothermal carbonization of biomass. Bioresour Technol 102:7595–7598. https://doi.org/10.1016/j.biortech.2011.05.016

Heller M (2017) Food product environmental footprint literature summary: Beer. State of Oregon, Department of Environmental Quality. https://www.oregon.gov/deq/FilterDocs/PEF-FoodTransportation-FullReport. Accessed 22 June 2021

Martínez JM, Baltierra-Trejo E, Taboada-Gonázlez P, Aguilar-Virgen Q, Marquez-Benavides L (2020) Life cycle environmental impacts and energy demand of craft mezcal in Mexico. Sustainability 12:8242. https://doi.org/10.3390/su12198242

CRT – Consejo Regulador del Tequila 2021. Sustainability strategy for the agave-tequila chain (Actions, Results & Perspectives). https://www.origin-gi.com/images/stories/PDFs/English/Event/20_april_2021-origin_spirits_and_sustainability/Tequila-Sprits_GIs_sustainability_20-04-2021.pdf. Accessed 22 june 2021

Weber B, Sandoval-Moctezuma AC, Estrada-Maya A, Martínez-Cienfuegos IG, Durán-García MD (2020) Agave bagasse response to steam explosion and anaerobic treatment. Biomass Convers Biorefin 10:1279–1289. https://doi.org/10.1007/s13399-020-00619-y

Tellez-Echeverri I, Weber B. (2020) Comparativa de la producción de biogás de diversos sustratos en pruebas de lote y en un digestor de operación continua. XIV Latin American Workshop and Symposium on Anaerobic Digestion 11–13 of November 2020

Mendez-Acosta HO, Gonzalez-Alvarez V (2014) Methane production from tequila vinasses. In. Torres L, Bandala ER (eds) Energy and environment nowadays. Ed. Nova Publishers, New York, pp 165–188

Esslinger HM, Narziss L (2003) Beer. Ullmann’s Encyclopedia of industrial chemistry, vol 4, 6th edn. Wiley-VCH, Weinheim, pp 657–699

López-López A, Davila-Vazquez G, León-Becerril E, Villegas-García E, GallardoValdez J (2010) Tequila Viansses: generation and full scale treatment processes. Rev Environ Sci Biotechnol 9:109–116. https://doi.org/10.1007/s11157-010-9204-9

Funding

This research was conducted with the support of Fondo Sectorial CONACyT-Sener, Cemie-Bio Project: 247006 “Biocombustibles Gaseosos.”

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Weber, B., Ayala-Mercado, I.D. & Stadlbauer, E.A. Steam explosion versus hydrothermal carbonization: evaluation of applicability for pretreatment of semi-solid waste from beverage industries to facilitate on-site biogas production. Biomass Conv. Bioref. 14, 7659–7671 (2024). https://doi.org/10.1007/s13399-022-02983-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02983-3