Abstract

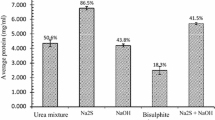

The extraction of keratin from chicken feathers is of research interest due to the beneficiation of biomass. This study investigates the impact of the keratin hydrolysate obtained using four different methods. There are two different chemical extraction methods, CH1 and CH2, and two enzymatic hydrolyses, EH1 and EH2. The investigation includes the characterization and analysis using different types of equipment for different applications. The keratin hydrolysates formed were all characterized using FTIR, TGA, SDS PAGE, and CHNS analysis, Bradford assay, and ash content. All the keratin hydrolysate from different methods showed all the amide bonds present in the keratinous structure from the FTIR, while TGA followed the three-phase trend loss of the keratinous structure. Protein concentrations obtained from CH1, CH2, EH1, and EH2 were 1.40, 1.02, 1.08, and 0.45 mg/ml respectively and their protein content was 86.56, 67.63, 78.06, and 90.00%. Their molecular weights were all in different ranges while the ash content for CH1 was 20.7, CH2 was 5.27, and EH1 was 9.19. All the results obtained were compared to the pure keratin azure and EH2 showed high protein content but low protein concentration. CH1 showed the second-highest protein content but with high impurities from the extraction method shown from the ash content.

Graphical abstract

Similar content being viewed by others

Data availability

The data used to support the findings of the study are all included in this article.

References

Abdel-Fattah AM et al (2018) Biodegradation of feather waste by keratinase produced from newly isolated Bacillus licheniformis ALW1. J Genet Eng Biotechnol 16(2):311–318. https://doi.org/10.1016/j.jgeb.2018.05.005

Alahyaribeik S, Ullah A (2020) Methods of keratin extraction from poultry feathers and their effects on antioxidant activity of extracted keratin. Int J Biol Macromol 148:449–456. https://doi.org/10.1016/j.ijbiomac.2020.01.144

Bach E, Lopes FC, Brandelli A (2015) Biodegradation of α and β-keratins by Gram-negative bacteria. Int Biodeterior Biodegradation 104:136–141. https://doi.org/10.1016/j.ibiod.2015.06.001

Bhari R et al (2018) Bioconversion of chicken feathers by Bacillus aerius NSMk2: a potential approach in poultry waste management. Bioresour Technol Rep 3(May):224–230. https://doi.org/10.1016/j.biteb.2018.07.015

Călin M et al (2017) Degradation of keratin substrates by keratinolytic fungi. Electron J Biotechnol 28:101–112. https://doi.org/10.1016/j.ejbt.2017.05.007

Dlume T (2021) Waste keratinous biomass valorization and characterization of keratinases produced by exiguobacteria species. Masters thesis, University of Fort Hare

Eremeev NL et al (2009) Enzymatic hydrolysis of keratin-containing stock for obtaining protein hydrolysates. Appl Biochem Microbiol 45(6):648–655. https://doi.org/10.1134/S0003683809060131

Fagbemi OD, Sithole B, Tesfaye T (2020) Optimization of keratin protein extraction from waste chicken feathers using hybrid pre-treatment techniques. Sustain Chem Pharm 17. https://doi.org/10.1016/j.scp.2020.100267

Fontoura R et al (2019) Characterization of a novel antioxidant peptide from feather keratin hydrolysates. New Biotechnol 49(September):71–76. https://doi.org/10.1016/j.nbt.2018.09.003

Gupta A et al (2012) Extraction of keratin protein from chicken feather, J Chem Chem Eng Available at: https://www.researchgate.net/publication/257653646

Gupta A et al (2016) Extraction and characterization of keratin from chicken feather waste biomass: a study. Available at: https://www.researchgate.net/publication/311843895.

Idris A et al (2013) Dissolution of feather keratin in ionic liquids. Green Chem 15(2):525–534. https://doi.org/10.1039/c2gc36556a

Khumalo M, Sithole B, Ramjugernath D (2019) Possible beneficiation of waste chicken feathers via conversion into biomedical applications precipitation and valorisation of lignin obtained from South African Kraft Mill Black Liquor View project modelling of small molecules and amorphous polymers View project. Article Int J Chem Sci. https://doi.org/10.21767/0972-768X.1000298

Khumalo M, Sithole B, Tesfaye T (2020) Valorisation of waste chicken feathers: optimisation of keratin extraction from waste chicken feathers by sodium bisulphite, sodium dodecyl sulphate and urea. J Environ Manage 262(March):110329. https://doi.org/10.1016/j.jenvman.2020.110329

Khumalo M, Sithole B, Tesfaye T (2020) Valorisation of waste chicken feathers: optimisation of keratin extraction from waste chicken feathers by sodium bisulphite, sodium dodecyl sulphate and urea. J Environ Manage 262(February):110329. https://doi.org/10.1016/j.jenvman.2020.110329

Mariotti F, Tomé D, Mirand P (2019) Converting nitrogen into protein – beyond 6. 25 and Jones ’ Factors To cite this version : HAL Id : hal-02105858. Crit Rev Food Sci Nutr 48(2):1–21

Medronho B, Fonseca AC (2019) Brief overview on bio-based adhesives and sealants. (October). https://doi.org/10.3390/polym11101685.

Nuutinen M (2017) Title of thesis feather characterization and processing. Available at: www.aalto.fi.

Saha S et al (2019) Keratin as a biopolymer, (January), pp. 163–185. https://doi.org/10.1007/978-3-030-02901-2_6.

Sharma S et al (2017) Characterization of keratin microparticles from feather biomass with potent antioxidant and anticancer activities. Int J Biol Macromol 104:189–196. https://doi.org/10.1016/j.ijbiomac.2017.06.015

Tesfaye T et al (2017) Valorisation of chicken feathers: characterisation of physical properties and morphological structure. J Clean Prod 149:349–365. https://doi.org/10.1016/j.jclepro.2017.02.112

Tesfaye T et al (2018a) Valorisation of chicken feathers: characterisation of thermal, mechanical and electrical properties. Sustain Chem Pharm 9. https://doi.org/10.1016/j.scp.2018.05.003

Tesfaye T et al (2018) Valorisation of chicken feathers: characterisation of thermal, mechanical and electrical properties. Sustain Chem Pharm 9:27–34. https://doi.org/10.1016/j.scp.2018.05.003

Wang YX, Cao XJ (2012) Extracting keratin from chicken feathers by using a hydrophobic ionic liquid. Process Biochem 47(5):896–899. https://doi.org/10.1016/j.procbio.2012.02.013

Zoccola M, Aluigi A, Tonin C (2009) Characterisation of keratin biomass from butchery and wool industry wastes. J Mol Struct 938(1–3):35–40. https://doi.org/10.1016/j.molstruc.2009.08.036

Acknowledgements

The authors thank the Biorefinery Industrial Development Facility-Council of Scientific and Industrial Research (BIDF-CSIR) for the laboratory facility, Technology Innovation Agency (TIA) for the funding, University of KwaZulu Natal (UKZN), and University of Fort Hare.

Funding

Lizzy Kekana reports financial support was provided by University of KwaZulu-Natal. Bruce Sithole reports a relationship with The Council Of Scientific And Industrial Research that includes: equity or stocks, funding grants, and non-financial support.

Author information

Authors and Affiliations

Contributions

I am responsible for the study, conception and design. Material were supplied by M. Khumalo, O. Fagbemi, O. Mnguni and T. Dlume. All data collection and analysis were performed by L. Kekana. The first draft and the final version of the manuscript were written by L. Kekana and all authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing financial interests

The authors declare the following financial interests/personal relationships which may be considered as potential competing interests.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Novelty Statement

The main objective of this article is to compare the different keratin hydrolysates produced from different extraction methods. Most authors focus on the extraction methods and optimization but not the detailed characteristics of the keratin hydrolysate obtained for a specific application.

The quality and quantity of the keratin hydrolysate are dependent on the method used. Comparing the different hydrolysates helps with determining which method to use to obtain a specific hydrolysate with the quality and quantity required for the application in the study.

This research has not been done before where the same characterizations techniques are used on different keratin hydrolysate from different methods, then comparing their qualities and quantities. The applications of the keratin hydrolysates are all dependent on the quality of the hydrolysate obtained which is dependent on the method used, this is the reason why this research is important.

Rights and permissions

About this article

Cite this article

Kekana, L.M., Sithole, B.B., Govinden, R. et al. Keratinous hydrolysate profiling: comparison of the differences obtained from different extraction methods. Biomass Conv. Bioref. 14, 6749–6757 (2024). https://doi.org/10.1007/s13399-022-02965-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02965-5