Abstract

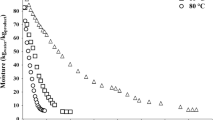

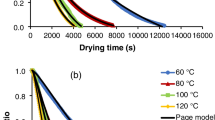

In the present work, infrared drying (IRD) technique was used to process kinnow mandarin peels at different temperatures and to check its influence on quality characteristics. The drying behavior of peels was mapped using the semi-empirical models. The moisture, water activity, total phenol content (TPC), total flavonoid content (TFC), DPPH radical scavenging activity, total carotenoids, and color attributes of fresh and dried peels were explored. The analyzed data revealed that with a rise in the drying temperature (50 to 70°C), drying time of peels decreased, and the page model was observed to fit appropriately to the drying data with the maximum R2 values (0.99995–1) and the minimum RMSE (0.140 × 10−3 to 0.571 × 10−3), and χ2 (0.002 × 10−4 to 0.103 ×10−4). Arrhenius equation was employed to obtain the activation energy of 34.45 kJ/mol. IRD temperature exhibited a significant effect (p<0.05) on the TPC, TFC, and total carotenoid content. The percent retention of phenols and flavonoids in kinnow peels varied from 83 to 93% and 70 to 81%, respectively. DPPH radical scavenging activity significantly increased up to 25% with increasing IRD temperature. IRD of peels at 60°C led to the retention of most of the total phenols, and enhancement of antioxidants and color characters (L* & b*). Furthermore, 10% incorporation of kinnow peel dietary fiber resulted in good overall acceptability score (8.00) of muffins. The present findings help to better understand the IRD of kinnow peels and map the drying behavior to maintain quality characters.

Graphical abstract

Similar content being viewed by others

Abbreviations

- a*:

-

Redness

- b*:

-

Yellowness

- Db:

-

Dry basis

- DPPH:

-

2, 2-diphenyl-1-picrylhydrazyl

- IRD:

-

Infrared drying

- L*:

-

Lightness

- MR:

-

Moisture ratio

- RMSE:

-

Root mean square error

- TFC:

-

Total flavonoid content

- TPC:

-

Total phenol content

- χ 2 :

-

Chi-square

References

FAOSTAT (2022) Food and agriculture data. In: Food Agric. Organ. https://www.fao.org/faostat/en/#data/QC. Accessed 21 Feb 2022

Matthaus B, & Ozcan MM (2012) Chemical evaluation of citrus seeds, an agro-industrial waste, as a new potential source of vegetable oils. grasas y aceites 63:313–320. 10.3989/gya.118411

Rafiq S, Sofi SA, Kumar H et al (2022) Physicochemical, antioxidant, and polyphenolic attributes of microencapsulated freeze-dried kinnow peel extract powder using maltodextrin as wall material. J Food Process Preserv 46:e16177. https://doi.org/10.1111/jfpp.16177

Russo C, Maugeri A, Lombardo GE et al (2021) The second life of citrus fruit waste: a valuable source of bioactive compounds. Molecules 26:5991. https://doi.org/10.3390/molecules26195991

Almasi S, Najafi G, Ghobadian B, Ebadi MT (2021) Waste to fuel: biodiesel production from bitter orange (Citrus aurantium) seed as a novel bio-based energy resource. Biomass Convers Biorefinery. https://doi.org/10.1007/S13399-021-01635-2

Leporini M, Tundis R, Sicari V, Loizzo M (2021) Citrus species: modern functional food and nutraceutical-based product ingredient. Ital. J Food Sci 33:63–107. https://doi.org/10.15586/ijfs.v33i2.2009

İnan Ö, Ozcan MM, Aljuhaimi F (2018) Effect of location and Citrus species on total phenolic, antioxidant, and radical scavenging activities of some Citrus seed and oils. J Food Process Preserv 42:E13555. https://doi.org/10.1111/jfpp.13555

Suri S, Singh A, Nema PK (2021) Recent advances in valorization of citrus fruits processing waste: a way forward towards environmental sustainability. Food Sci Biotechnol 30:1601–1626. https://doi.org/10.1007/S10068-021-00984-Y

Duman E, Soltanbeigi A, Ozcan MM (2016) Chemical compositions of essential oil of some Citrus spp. (Sour, Lemon, Kumquat, Mandarin and Orange) peels. J Med Spice Plants 21:153–159

Dhurve P, Tarafdar A, Arora VK (2021) Vibro-fluidized bed drying of pumpkin seeds: assessment of mathematical and artificial neural network models for drying kinetics. J Food Qual 2021:1–12. https://doi.org/10.1155/2021/7739732

Chou S, Chua K (2001) New hybrid drying technologies for heat sensitive foodstuffs. Trends Food Sci Technol 12:359–369. https://doi.org/10.1016/S0924-2244(01)00102-9

Adak N, Heybeli N, Ertekin C (2017) Infrared drying of strawberry. Food Chem 219:109–116. https://doi.org/10.1016/j.foodchem.2016.09.103

Nowak D, Lewicki P (2004) Infrared drying of apple slices. Innov Food Sci Emerg Technol 5:353–360. https://doi.org/10.1016/j.ifset.2004.03.003

Babar OA, Tarafdar A, Malakar S et al (2020) Design and performance evaluation of a passive flat plate collector solar dryer for agricultural products. J Food Process Eng 43:e13484. https://doi.org/10.1111/jfpe.13484

Sehrawat R, Nema P, Kaur B (2018) Quality evaluation and drying characteristics of mango cubes dried using low-pressure superheated steam, vacuum and hot air drying methods. LWT - Food Sci Technol 92:548–555. https://doi.org/10.1016/j.lwt.2018.03.012

Sander A (2007) Thin-layer drying of porous materials: selection of the appropriate mathematical model and relationships between thin-layer models parameters. Chem Eng Process Process Intensif 46:1324–1331. https://doi.org/10.1016/j.cep.2006.11.001

Ghanem N, Mihoubi D, Bonazzi C et al (2020) Drying characteristics of lemon by-product (Citrus limon. v. lunari): effects of drying modes on quality attributes kinetics’. Waste Biomass Valori 11:303–322. https://doi.org/10.1007/S12649-018-0381-Z

Bozkir H, Tekgül Y, Erten E (2021) Effects of tray drying, vacuum infrared drying, and vacuum microwave drying techniques on quality characteristics and aroma profile of orange peels. J Food Process Eng 44:e13611. https://doi.org/10.1111/jfpe.13611

Deng L, Mujumdar A, Yang W et al (2020) Hot air impingement drying kinetics and quality attributes of orange peel. J Food Process Preserv 44:e14294. https://doi.org/10.1111/jfpp.14294

AOAC (2000) Official methods of analysis of AOAC International: current through March 2000 supplement. Association of Official Analysis Chemists International. https://doi.org/10.3109/15563657608988149

Dibagar N, Kowalski S, Chayjan R, Figiel A (2020) Accelerated convective drying of sunflower seeds by high-power ultrasound: experimental assessment and optimization approach. Food Bioprod Process 123:42–59. https://doi.org/10.1016/j.fbp.2020.05.014

Abou-Arab A, Mahmoud M, Abu-Salem F (2016) Bioactive compounds content of citrus peel as affected by drying processes. Int J Nutr Food Eng 10:240–243

Singleton V, Orthofer R, Lamuela-Raventós R (1999) Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol 299:152–178. https://doi.org/10.1016/S0076-6879(99)99017-1

Zhishen J, Mengcheng T, Jianming W (1999) The determination of flavonoid contents in mulberry and their scavenging effects on superoxide radicals. Food Chem 64:555–559. https://doi.org/10.1016/S0308-8146(98)00102-2

Brand-Williams W, Cuvelier M, Berset C (1995) Use of a free radical method to evaluate antioxidant activity. LWT - Food Sci Technol 28:25–30. https://doi.org/10.1016/S0023-6438(95)80008-5

Wang Y, Chuang Y, Hsu H (2008) The flavonoid, carotenoid and pectin content in peels of citrus cultivated in Taiwan. Food Chem 106:277–284. https://doi.org/10.1016/j.foodchem.2007.05.086

Chandra A, Kumar S, Tarafdar A, Nema PK (2021) Ultrasonic and osmotic pretreatments followed by convective and vacuum drying of papaya slices. J Sci Food Agric 101:2264–2272. https://doi.org/10.1002/JSFA.10847

Wang K, Li M, Wang Y et al (2021) Effects of extraction methods on the structural characteristics and functional properties of dietary fiber extracted from kiwifruit (Actinidia deliciosa). Food Hydrocoll 110:106162

Goswami D, Gupta RK, Mridula D et al (2015) Barnyard millet based muffins: physical, textural and sensory properties. LWT - Food Sci Technol 64:374–380. https://doi.org/10.1016/j.lwt.2015.05.060

Xu M, Tian G, Zhao C et al (2017) Infrared drying as a quick preparation method for dried tangerine peel. Int J Anal Chem 2017:6254793. https://doi.org/10.1155/2017/6254793

Zhang X, Zhong C, Mujumdar A et al (2019) Cold plasma pretreatment enhances drying kinetics and quality attributes of chili pepper (Capsicum annuum L.). J Food Eng 241:51–57. https://doi.org/10.1016/j.jfoodeng.2018.08.002

Wankhade P, Sapkal R, Sapkal V (2013) Drying characteristics of okra slices on drying in hot air dryer. Procedia Eng 51:371–374. https://doi.org/10.1016/j.proeng.2013.01.051

Goyal R, Kingsly A, Manikantan M (2006) Thin-layer drying kinetics of raw mango slices. Biosyst Eng 95:43–49. https://doi.org/10.1016/j.biosystemseng.2006.05.001

Li H, Xie L, Ma Y et al (2019) Effects of drying methods on drying characteristics, physicochemical properties and antioxidant capacity of okra. LWT - Food Sci Technol 101:630–638. https://doi.org/10.1016/j.lwt.2018.11.076

Niamnuy C, Nachaisin M, Laohavanich J, Devahastin S (2011) Evaluation of bioactive compounds and bioactivities of soybean dried by different methods and conditions. Food Chem 129:899–906. https://doi.org/10.1016/j.foodchem.2011.05.042

Łechtańska J, Szadzińska J, Kowalski S (2015) Microwave-and infrared-assisted convective drying of green pepper: quality and energy considerations. Chem Eng Process Process Intensif 98:155–164. https://doi.org/10.1016/j.cep.2015.10.001

Rafiq S, Singh B, Gat Y (2019) Effect of different drying techniques on chemical composition, color and antioxidant properties of kinnow (Citrus reticulata) peel. J Food Sci Technol 56:2458–2466. https://doi.org/10.1007/S13197-019-03722-9

Hayat K, Abbas S, Jia C et al (2011) Comparative study on phenolic compounds and antioxidant activity of feutrell’s early and kinnow peel extracts. J Food Biochem 35:454–471. https://doi.org/10.1111/J.1745-4514.2010.00395.X

Goulas V, Manganaris G (2012) Exploring the phytochemical content and the antioxidant potential of Citrus fruits grown in Cyprus. Food Chem 131:39–47. https://doi.org/10.1016/j.foodchem.2011.08.007

Tangkhawanit E, Meeso N, Siriamornpun S (2022) Changes in bioactive components, biological activities and starch digestibility of soymilk residues as affected by far-infrared radiation combined with hot-air and hot-air. Dry Technol 1–14. https://doi.org/10.1080/07373937.2022.2030351

Hamrouni-Sellami I, Rahali FZ, Rebey IB et al (2013) Total phenolics, flavonoids, and antioxidant activity of sage (Salvia officinalis L.) plants as affected by different drying methods. Food Bioprocess Technol 6:806–817. https://doi.org/10.1007/S11947-012-0877-7

Wanyo P, Siriamornpun S, Meeso N (2011) Improvement of quality and antioxidant properties of dried mulberry leaves with combined far-infrared radiation and air convection in Thai tea process. Food Bioprod Process 89:22–30. https://doi.org/10.1016/j.fbp.2010.03.005

Ozcan MM, Ghafoor K, Al Juhaimi F et al (2021) Influence of drying techniques on bioactive properties, phenolic compounds and fatty acid compositions of dried lemon and orange peel powders. J Food Sci Technol 58:147–158. https://doi.org/10.1007/S13197-020-04524-0

Ghanem Romdhane N, Bonazzi C, Kechaou N, Mihoubi NB (2015) Effect of air-drying temperature on kinetics of quality attributes of lemon (Citrus limon cv. lunari) peels. Dry Technol 33:1581–1589. https://doi.org/10.1080/07373937.2015.1012266

Que F, Mao L, Fang X, Wu T (2008) Comparison of hot air-drying and freeze-drying on the physicochemical properties and antioxidant activities of pumpkin (Cucurbita moschata Duch.) flours. Int J Food Sci Technol 43:1195–1201. https://doi.org/10.1111/j.1365-2621.2007.01590.x

Jeong SM, Kim SY, Kim DR et al (2004) Effect of heat treatment on the antioxidant activity of extracts from citrus peels. J Agric Food Chem 52:3389–3393. https://doi.org/10.1021/JF049899K

Yoo K, Moon B (2016) Comparative carotenoid compositions during maturation and their antioxidative capacities of three citrus varieties. Food Chem 196:544–549. https://doi.org/10.1016/j.foodchem.2015.09.079

Wilson RA, Kadam DM, Chadha S et al (2013) Evaluation of physical and chemical properties of foam-mat dried mango (Mangifera indica) powder during storage. J Food Process Preserv 38:1866–1874. https://doi.org/10.1111/jfpp.12158

Sogi D, Siddiq M, Dolan K (2015) Total phenolics, carotenoids and antioxidant properties of Tommy Atkin mango cubes as affected by drying techniques. LWT - Food Sci Technol 62:564–568. https://doi.org/10.1016/j.lwt.2014.04.015

Ahmed J, Shivhare US, Kaur M (2002) Thermal colour degradation kinetics of mango puree. Int J Food Prop 5:359–366. https://doi.org/10.1081/JFP-120005791

Kammoun Bejar A, Ghanem N, Mihoubi D et al (2011) Effect of infrared drying on drying kinetics, color, total phenols and water and oil holding capacities of orange (Citrus Sinensis) peel and leaves. Int J Food Eng 7. https://doi.org/10.2202/1556-3758.2222/HTML

Dervisoglu M, Yazici F (2006) Note. The effect of citrus fibre on the physical, chemical and sensory properties of ice cream. Food Sci Technol Int 12:159–164. https://doi.org/10.1177/1082013206064005

Marín FR, Soler-Rivas C, Benavente-García O et al (2007) By-products from different citrus processes as a source of customized functional fibres. Food Chem 100:736–741. https://doi.org/10.1016/j.foodchem.2005.04.040

Acknowledgements

The authors are thankful to NIFTEM, Sonipat, India, for the institutional facility.

Funding

This work was supported by Ministry of Food Processing Industries (MOFPI), New Delhi, India (FN Q-11/08/2021- R&D).

Author information

Authors and Affiliations

Contributions

Shweta Suri: conceptualization, visualization, investigation, writing—original draft preparation. Anupama Singh: conceptualization, methodology, supervision, project administration, writing—review and editing. Prabhat K. Nema: conceptualization, methodology, supervision, project administration, writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Drying behavior of kinnow peels in infrared dryer was studied.

• Infrared drying (IRD) retained total phenols, total flavonoids, and total carotenoids.

• IRD of peels at 60°C, 2.0m/s, led to enhancement in DPPH radical scavenging activity and color attributes.

• Page model exhibited the higher R2 values, lower RMSE, and χ2 values at all conditions of IRD temperatures.

• Higher quality kinnow peels were obtained using IRD.

Rights and permissions

About this article

Cite this article

Suri, S., Singh, A. & Nema, P.K. Infrared drying of Kinnow (Citrus reticulata) peel waste: kinetics and quality characterization. Biomass Conv. Bioref. 14, 7579–7590 (2024). https://doi.org/10.1007/s13399-022-02844-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02844-z