Abstract

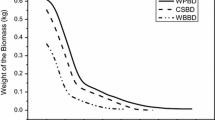

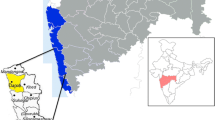

About 67% of the Indian population uses the simple traditional cook stoves using wood, coal, etc., as the primary fuel sources. These traditional cook stoves have thermal efficiency hardly (10–15%) with in-efficient utilization of scared natural resources. These lead to excessive smoke emission coupled with indoor air pollution. Community cooking in hostels of academic institutions of Northeast India is done by firewood, charcoal, or coal in a very inefficient way during the insufficient supply of non-renewable liquefied petroleum gas. Therefore, the present work directs design and performance testing of an efficient community biomass fired cook stove (four burners). The overall dimensions of the improved stove were (1650 mm × 1500 mm × 650 mm). Delonix regia (Gulmohar) was considered as a fuel for the cook stove. The stoichiometric air requirement was estimated as 6.06 kg against per kilogram of feedstock. The firepower of the improved cook stove was estimated as 86.54 kW under the stoichiometric combustion condition. Overall fuel combustion rate of the burner was 19.23 kg h−1 woody biomass. Maximum thermal efficiency at 20% excess air was 40%, and the burning rate of the fuel in the improved cook stove was computed as 0.0718 kg/min. The specific wood consumption was estimated as 0.20 kg/kg of water boiled at the maximum thermal efficiency point.

Similar content being viewed by others

Data availability

All the data generated or analysed during this experimental study are included in this article. Therefore, the average data available from the experimental study performance evaluation of improved cook stove has been presented in the graphical form (no additional simulation data is available/not applicable).

Abbreviations

- A:

-

Flow area (m2)

- AFR:

-

Air fuel ratio

- ASTM:

-

American Society for Testing and Materials

- Cl :

-

Loss coefficient

- CP :

-

Specific heat (kJ kg−1K)

- FCR:

-

Fuel consumption rate

- Cw :

-

Specific heat of water (kJ kg−1K)

- EAR:

-

Excess air ratio

- FCR:

-

Fuel consumption rate

- F:

-

Burning rate of fuel (kg min−1)

- H:

-

Height of chimney from center of fuel inlet

- H:

-

Enthalpy (kJ)

- hC :

-

Cold enthalpy

- hH :

-

Hot enthalpy

- HT:

-

Heat transfer

- LHV:

-

Lower heating value (MJ kg−1)

- Lv :

-

Latent heat of vaporization of water (kJ kg−1)

- \(\dot{m}\) :

-

Mass flow rate

- \({m}^{"}\) :

-

Mass loss coefficient

- M:

-

Molecular weight

- O:

-

Oxygen

- mA :

-

Mass of air (kg)

- PHU:

-

Percentage heat utilization

- \(\dot{Q}\) :

-

Heat addition (W)

- P:

-

Pressure (bar)

- R:

-

Universal gas constant

- SWC:

-

Specific wood consumption

- T:

-

Temperature (°C)

- \(\dot{V}\) :

-

Volume flow rate (m3 s−1)

- X:

-

Moisture percentage

- ρ:

-

Density (kg m−3)

- η:

-

Efficiency

- \({\eta }_{TE}\) :

-

Thermal efficiency

- \({\eta }_{Comb}\) :

-

Combustion efficiency

- \(\varnothing\) :

-

Equivalence ratio

- Da:

-

Dry air

- amb:

-

Ambient

- e:

-

Evaporated

- i:

-

Initial

- f:

-

Final

References

Block B, India announces improved cook stove, http://www.worldwatch.org/node/6328; Accessed: 25/06/2020.

Saldiva PHN, Miraglia SGEK (2004) Health effects of cook stove emissions. Energ Sustain Dev 8(3):13–19

Bruce N, Perez-Padilla R, Albalak R (2000) Indoor air pollution in developing countries: a major environmental and public health challenge. Bull World Health Organization 78:1078–1092

Smith KR, Mehta S (2003) The burden of disease from indoor air pollution in developing countries: comparison of estimates. Int J Hygiene Environ Health 206:279–289

Karanja A, Gasparatos G (2019) Adoption, and impact of clean bioenergy cook stoves in Kenya. Renew Sustain Energy Rev 102:285–306

Armendariz CA, Edwards RD, Johnson M, Zuk M, Rojas L, Jiménez RD (2008) Reduction in personal exposures to particulate matter and carbon monoxide as a result of the installation of a Patsari improved cook stove in Michoacan Mexico. Indoor Air 18(2):93–105

Johnson M, Edwards RD, Frenk CA, Masera O (2007) In-field greenhouse gas emissions from cook-stoves in rural Mexican households. Atmos Environ 42(6):1206–1222

Garcia-Frapolli E, Schilmann A, Berrueta VM, Riojas-Rodríguez H, Edwards RD, Johnson M (2012) Beyond fuelwood savings: valuing the economic benefits of introducing improved biomass cook-stoves in the Purepecha region of Mexico. Ecol Econ 69(12):2598–2605

Raju SP (1957) Smokeless kitchens for the millions, 2nd edn. The Christian Literature Society, Madras

IIT Delhi, TERI, 2010 New Delhi, New initiative for development and deployment of improved cook-stoves: recommended action plan, Final report. Ministry of New and Renewable Energy Government of India, (http://www.inspirenetwork.org/mnre/doc/Final_Report_Cookstove.doc) (accessed: 25/06/2020).

Bansal MB, Saini RP, Khatod DK (2013) Development of cooking sector in rural areas in India—a review. Renew sustain Energy Rev 17:44–53

Lombardi F, Colombo L, Colombo E (2017) Design and validation of a cooking stoves thermal performance simulator (Cook-STePS) to simulate water heating procedures in selected condition. Energy 141:1384–1392

Kees M, Feldmann L (2011) The role of donor organizations in promoting energy efficient cook-stoves. Energ Policy 39(11):7595–7599

Chica E, Perez JF (2019) Development and performance evaluation of an improved biomass cook stove for isolated communities from developing countries. Case Studies Therm Eng 14:100435

Stove testing, the partnership for clean indoor air, June 2012. (Available from: http://www.pciaonline.org/testing , Accessed : 25/06/2020)

Panwar NL, Rathore NS (2008) Design and performance evaluation of a 5 kW producer gas stove. Biomass Bioenerg 32:1349–1352

Raman P, Murali J, Sakthivadivel D, Vigneswaran VS (2013) Performance evaluations of three types of forced draft cook stoves using fuel wood and coconut shell. Biomass Bioenerg 49:333–340

Moya R, Tenorio C (2013) Fuelwood characteristics and its relation with extractives and chemical properties of ten fast-growth species in Costa Rica. Biomass Bioenerg 56:14–21

T Paloposki J Saastamoinen K Klobut P Tuomaala 2012 Analysis of wood firing in stoves by the oxygen consumption method and the carbon dioxide generation method https://doi.org/10.1016/j.biombioe.2011.12.041:1-24

Meyer NK (2012) Particulate, black carbon and organic emissions from small-scale residential wood combustion appliances in Switzerland. Biomass Bioenerg 36:31–42

Jerneck A, Olsson L (2013) A smoke-free kitchen: initiating community based co-production for cleaner cooking and cuts in carbon emissions. J Clean Prod 113:208–215

Ravindra K, Kaur-Sidhu M, Mor S, John S (2019) Trend in household energy consumption pattern in India: a case study on the influence of socio-cultural factors for the choice of clean fuel use. J Clean Prod 213:1024–1034

Kausley SB, Pandit AB (2010) Modelling of solid fuel stoves. Fuel 89:782–791

Njenga M, Iiyama M, Jamnadass RH, Helander H, Larsson L (2016) Gasifier as a cleaner cooking system in rural Kenya. J Clean Prod 121:208–217

Sedighi M, Salaraian H (2017) A comprehensive review on technical aspects of biomass cook stoves. Renew Sustain Energy Rev 70:656–665

Kshirsagar MP, Kalamkar VR (2014) A comprehensive review on biomass cook stoves and a systematic approach for modern cook stove design. Renew Sustain Energy Rev 30:580–603

Borpatragohain, R.,Dutta, P.P. 2021 Modelling and performance analysis of improved biomass cook stove. Vol. II: 184–188; Editors: Kakati B., Phukan B.R., Rajbongshi T., Bora D. Tata McGraw Hill, New Delhi.

Barpatragohain, R.,Bharali, N., Dutta, P.P. 2021 Thermal performance evaluation of an improved biomass cook stove for domestic applications. Proceedings of international conference on thermofluids, 579–590; Editors: Revankar S., SenS., Sahu D, Springer, Singapore.

Bardalai, M., Das, B., Dutta, P.P., Mahapatra, S. 2021 Thermal performance study of bamboo and coal co-gasification in a downdraft gasifier. Modeling, simulation and optimization: proceedings of CoMSO 2020, 15–28; Editors: Das, B., Patgiri, R., Bandyopadhaya, S. Balas, V.M., Springer, Singapore.

Dutta P.P., Das, A., Pandey V., Devi, M. 2014 Fuel characteristics of some locally available biomass as a potential gasification feed stock for thermal application. Industrial Eng Chem Res J, 53 (51), 19806–19813 (American Chemical Society).

Dutta PP, Pandey V, Das AR, Sen S, Baruah DC (2014) Downdraft gasification modelling and experimentation of indigenous biomass for thermal application. Energy Procedia 54:21–36

Dutta PP, Baruah DC (2014) Modeling and experimental studies of black tea using producer gas as fuel. Appl Therm Eng 63:495–502

Dutta PPB, D.C. (2014) Gasification of up rooted tea shrubs for process heat generation in tea manufacturing. Biomass Bioenerg 66:27–38

Dutta PP, Baruah DC (2014) Possibility of biomass gasification in tea manufacturing industries. Int J Renew Energy Technol 5(4):310–322

Susastriawan AAP, Badrawada IGG, Budi DP (2020) An effect of primary air draft and flow rate on thermal performance and CO/CO2 emission of the domestic stove fed with the briquette of coconut shell. Biomass Conversion Bio refinery 10:1099–1104

Kurchania AK, Panwar NL, Pagar SV (2011) Development of domestic biogas stove. Biomass Conversion Bio refinery 1:99–103

Annual book of ASTM Standard 1983 Philadelphia: American Society for Testing of Materials.

Perry R.H, Green D W.1997 Perry’s chemical engineering handbook. New Delhi: McGraw-Hill; 7th Eds.

Baldwin, S. 1987 Biomass cook stoves: engineering design, development, and dissemination, New Jersey.

Agenbroad J, DeFoort M, Kirkpatrick A, Kreutzer C (2011) A simplified model for understanding natural convection driven biomass-cooking stoves—part 1: setup and baseline validation. Energ Sustain Dev 15:160–168

Kumar M, Kumar S, Tyagi SK (2013) Design, development and technological advancement in the biomass cook-stoves: a review. Renew Sustain Energ Review 26:265–285

Tran HC, White RH (1992) Burning rate of solid wood measured in a heat release rate calorimeter. Fire Mater 16(4):197–206

Bureau of Indian Standards 2013 (IS-13152 part-I.

Parker JD, Boggs JH, Blick EF (1969) Introduction to fluid mechanics and heat transfer. Addison Wesley Publ, Reading, MA, USA

Kshirsagar MP, Kalamkar VR (2015) Mathematical tools for predicting thermal performance of natural draft biomass cook-stoves and identification of a new operational parameter. Energy 93:188–201

Basu P (2010) Biomass gasification and pyrolysis practical design. Academic Press, Oxford

JaapKoppejan J, van Loo S (2012) A hand book of biomass combustion and co-firing. Earthscan, London

Phusrimuang J, Wongwuttanasatian T (2016) Improvements on thermal efficiency of a biomass stove for a steaming process in Thailand. Appl Therm Eng 98:196–202

Suresh R, Singh VK, Mallik VK, Datta D, Pal RC (2016) Evaluation of the performance of improved biomass cooking stoves with different solid biomass fuel types. Biomass Bioenerg 96:27–34

Kwofie EW, Ngadi M, Sotocinal S (2017) Energy efficiency and emission assessment of a continuous rice husk stove for rice parboiling. Energy 122:340–349

WHO 2002 The health effects of indoor air pollution exposure in developing countries. In: Bruce N, Perez-Padilla R, Albalak R, editors.

WHO Report 1990 Global environment monitoring system. Air quality in selected urban areas. Geneva: WHO Offset Publication.

Al-Widyan MI, Tashtoush G, Hamasha AM (2006) Combustion and emissions of pulverized olive cake in tube furnace. Energy Convers Manage 47:1588–1596

Approved models of portable improved biomass cook stoves. [Internet]. http://164.100.94.214/sites/default/files/uploads/approved-models-of-portable-improved-biomass-cookstove-manufactures.pdf [Accessed on 27.09.2021].

Ayoub J, Brunet E (1996) Performance of large portable metal wood stoves for community kitchens. Renew Energy 7(1):71–80

Author information

Authors and Affiliations

Contributions

Conceptualization: Partha Pratim Dutta; methodology: Partha Pratim Dutta; formal analysis and investigation: Partha Pratim Dutta, Polash Protim Dutta; writing — original draft preparation: Partha Pratim Dutta; writing — review and editing: Partha Pratim Dutta, Raktimjyoti Borpatragohain, Polash Pratim Dutta; funding acquisition: NIL; resources: Partha Pratim Dutta, Polash Protim Dutta; supervision: Partha Pratim Dutta.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

1. An improved biomass fired cook stove was developed for community cooking.

2. Its thermal performance was evaluated.

3. The minimum and maximum thermal efficiencies were 23 and 40%, respectively.

4. The firepower of the improved cook stove was 86.54 kW.

5. The ranges of indoor CO 2 was (900–650) ppm and CO (5–20) ppm, respectively.

Rights and permissions

About this article

Cite this article

Dutta, P.P., Borpatra Gohain, R. & Dutta, P.P. Performance assessment of an efficient biomass fired cook stove as a standby unit for community cooking. Biomass Conv. Bioref. 13, 11609–11620 (2023). https://doi.org/10.1007/s13399-022-02745-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02745-1