Abstract

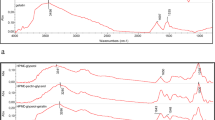

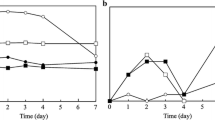

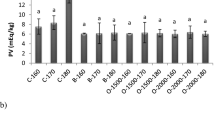

Functional, oxygen-scavenging low-density polyethylene (PE) films were fabricated for developing a fish cake package and modified by incorporating sodium carbonate (SC) and coated with 10–20% pyrogallic acid (PA). The effect of oxygen scavenging films on the storage stability of fresh fish cake was studied. The oxygen scavenging analysis, microbial analysis, and tests for pH, texture profile, thiobarbituric acid reactive substances (TBARS) for fish cakes were performed during 30 days of storage at 5 and 25 °C. The initial oxygen concentration (%) in the headspace of the absorption cell (20.90%) decreased to 18.26% and 9.46% for the film containing 20% PA and to 18.64% and 14.77% for the film containing 10% PA after 8 days of storage at 5 and 25 °C, respectively. The pure PE-coated fish experienced the greatest pH change (3.45), while the PE/SC/PA-20% film showed the lowest (4.01) until the storage end. Samples packaged in PE/SC/PA-20% were firmer than the control. At the end of storage, the TBARS value in the modified PE/SC/PA-20% sample showed the lowest value of 26.32 and 33.38 mg MDA/kg at 5 and 25 °C. The film-coated with 20% PA effectively maintained the quality of a fish cake during 30 days of storage. The microbiological load in the PE/SC/PA-20% was less than 7 log CFU/g, which is permissible according to international standards. The results proved that the developed oxygen scavenging films could be attributed to the positive effects on the quality loss of oxygen-sensitive fish cake products.

Similar content being viewed by others

References

Gaikwad KK, Singh S, Lee YS (2018) Oxygen scavenging films in food packaging. Environ Chem Lett 16:523–538

Gibis D, Rieblinger K (2011) Oxygen scavenging films for food application. Procedia Food Sci 1:229–234

Bolumar T, LaPeña D, Skibsted LH, Orlien V (2016) Rosemary and oxygen scavenger in active packaging for prevention of high-pressure induced lipid oxidation in pork patties. Food Packag Shelf Life 7:26–33

Singh S, Gaikwad KK, Lee YS (2019) Development and application of a pyrogallic acid-based oxygen scavenging packaging system for shelf life extension of peeled garlic. Sci Hortic (Amsterdam) 256:108548

Tanwar R, Gupta V, Kumar P et al (2021) Development and characterization of PVA-starch incorporated with coconut shell extract and sepiolite clay as an antioxidant film for active food packaging applications. Int J Biol Macromol 185:451–461. https://doi.org/10.1016/J.IJBIOMAC.2021.06.179

Kumar P, Tanwar R, Gupta V et al (2021) Pineapple peel extract incorporated poly (vinyl alcohol)-corn starch film for active food packaging: preparation, characterization and antioxidant activity. Int J Biol Macromol 187:223–231

Singh AK, Ramakanth D, Kumar A, et al (2021) Active packaging technologies for clean label food products: a review. J Food Meas Charact 1–11

Gaikwad KK, Singh S, Negi YS, Lee YS (2020) The effect of trans-polyisoprene/LDPE based active films on oxidative stability in roasted peanuts. J Food Meas Charact 14:1857–1864

Lee J, Chang Y, Lee E et al (2018) Ascorbic acid-based oxygen scavenger in active food packaging system for raw meatloaf. J Food Sci 83:682–688

Laufer G, Kirkland C, Cain AA, Grunlan JC (2013) Oxygen barrier of multilayer thin films comprised of polysaccharides and clay. Carbohydr Polym 95:299–302

Cruz RS, Camilloto GP, dos Santos Pires AC (2012) Oxygen scavengers: an approach on food preservation. Struct Funct food Eng 2:21–42

Dey A, Neogi S (2019) Oxygen scavengers for food packaging applications: a review. Trends Food Sci Technol 90:26–34

Ozdemir M, Floros JD (2004) Active food packaging technologies. Crit Rev Food Sci Nutr 44:185–193

Ozturk Sarikaya SB (2015) Acethylcholinesterase inhibitory potential and antioxidant properties of pyrogallol. J Enzyme Inhib Med Chem 30:761–766

Zou G-S, Li S-J, Zheng S et al (2018) Lemon-peel extract ameliorates rheumatoid arthritis by reducing xanthine oxidase and inflammatory cytokine levels. J Taiwan Inst Chem Eng 93:54–62

Fager EP, Reynolds AH (1929) Absorption of oxygen by alkaline tannates. Ind Eng Chem 21:357–359

Han Y, Wang L (2017) Sodium alginate/carboxymethyl cellulose films containing pyrogallic acid: physical and antibacterial properties. J Sci Food Agric 97:1295–1301

Marrez DA, Abdelhamid AE, Darwesh OM (2019) Eco-friendly cellulose acetate green synthesized silver nano-composite as antibacterial packaging system for food safety. Food Packag Shelf Life 20:100302

Gaikwad KK, Lee YS (2016) Novel natural phenolic compound-based oxygen scavenging system for active packaging applications. J Food Meas Charact 10:533–538

Gaikwad KK, Singh S, Lee YS (2017) A pyrogallol-coated modified LDPE film as an oxygen scavenging film for active packaging materials. Prog Org Coatings 111:186–195

Miltz J, Perry M (2005) Evaluation of the performance of iron-based oxygen scavengers, with comments on their optimal applications. Packag Technol Sci An Int J 18:21–27

Tango CN, Khan I, Park YS, Oh DH (2016) Growth of Staphylococcus aureus in cooked ready-to-eat ground fish as affected by inoculum size and potassium sorbate as food preservative. LWT-Food Sci Technol 71:400–408

Cho Y, Cho K, Shin C, et al An agricultural expert cloud for a smart farm. Springer

Kuswandi B (2020) Active and intelligent packaging, safety, and quality controls. Fresh-cut fruits Veg 243–294

Supawong S, Thawornchinsombut S, Park JW (2018) Controlling lipid oxidation and volatile compounds in frozen fried fish cake prepared with rice bran hydrolysate. J Aquat Food Prod Technol 27:885–899

Chemists A (2000) Approved methods of the AACC. Assoc

Kim S-J, Min SC, Shin H-J et al (2013) Evaluation of the antioxidant activities and nutritional properties of ten edible plant extracts and their application to fresh ground beef. Meat Sci 93:715–722

Papastergiadis A, Mubiru E, Van Langenhove H, De Meulenaer B (2012) Malondialdehyde measurement in oxidized foods: evaluation of the spectrophotometric thiobarbituric acid reactive substances (TBARS) test in various foods. J Agric Food Chem 60:9589–9594

Administration USF and D (1995) Bacteriological analytical manual

Cruz RS, Camilloto GP, dos Santos Pires AC (2012) Oxygen scavengers: an approach on food preservation. Struct Funct food Eng 2:

Gaikwad KK, Lee YS (2017) Effect of storage conditions on the absorption kinetics of non-metallic oxygen scavenger suitable for moist food packaging. J Food Meas Charact 11:965–971

Langowski HC, Wanner T (2005) Organic oxygen scavenger/indicator. EP1952140B1 (WO 2007/059901 A1)

Gaikwad KK, Singh S, Lee YS (2017) A new pyrogallol coated oxygen scavenging film and their effect on oxidative stability of soybean oil under different storage conditions. Food Sci Biotechnol 26:1535–1543

Pan L, Zhang M, Lu L et al (2020) A polyethylene base moisture activating oxygen scavenging film co-extruded with tea polyphenols-β-cyclodextrin inclusion complex. Materials (Basel) 13:3857

Ahn BJ, Gaikwad KK, Lee YS (2016) Characterization and properties of LDPE film with gallic‐acid‐based oxygen scavenging system useful as a functional packaging material. J Appl Polym Sci 133:

Chirife J, Favetto GJ (1992) Some physico-chemical basis of food preservation by combined methods. Food Res Int 25:389–396

Kilincceker O, Dogan IS, Kucukoner E (2009) Effect of edible coatings on the quality of frozen fish fillets. LWT-Food Sci Technol 42:868–873

Raja WH, Kumar S, Bhat ZF, Kumar P (2014) Effect of ambient storage on the quality characteristics of aerobically packaged fish curls incorporated with different flours. Springerplus 3:1–10

Gómez-Estaca J, López-de-Dicastillo C, Hernández-Muñoz P et al (2014) Advances in antioxidant active food packaging. Trends Food Sci Technol 35:42–51

Azlin-Hasim S, Cruz-Romero MC, Morris MA et al (2015) Effects of a combination of antimicrobial silver low density polyethylene nanocomposite films and modified atmosphere packaging on the shelf life of chicken breast fillets. Food Packag Shelf Life 4:26–35

Panea B, Ripoll G, González J et al (2014) Effect of nanocomposite packaging containing different proportions of ZnO and Ag on chicken breast meat quality. J Food Eng 123:104–112

Administration F and D (2013) Revised guidelines for the assessment of microbiological quality of processed foods. Food Drug Administartion Phillipines 1–11

Oladimeji OH, Igboasoiyi AC (2014) Isolation, characterization and antimicrobial analysis of ethyl gallate and pyrogallol from Acalypha wilkesiana var. lace-acalypha (Muell & Arg.). African J Pharmacol Ther 3:

Uemura Y, Shimasaki T, Teramoto N, Shibata M (2016) Thermal and mechanical properties of bio-based polymer networks by thiol-ene photopolymerizations of gallic acid and pyrogallol derivatives. J Polym Res 23:1–10

Acknowledgements

K K Gaikwad thanks the graduate school, Yonsei University Seoul, Korea for providing financial support to carry out this research work during his academic program.

Author information

Authors and Affiliations

Contributions

Kirtiraj K. Gaikwad: experiment design, acquisition of data, analysis and interpretation of data, original manuscript drafting and writing. Ram Kumar Deshmukh: experimental validation, original manuscript reviewing. Youn Suk Lee: conception and design, manuscript revising and editing, supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gaikwad, K.K., Deshmukh, R.K. & Lee, Y.S. Natural phenolic compound coated oxygen scavenging active polyolefin film for preserving quality of fish cake. Biomass Conv. Bioref. 14, 5627–5636 (2024). https://doi.org/10.1007/s13399-022-02678-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02678-9