Abstract

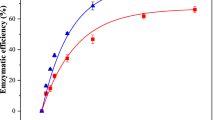

Concentrated protic ionic liquid (PIL) without dilution has increased saccharification efficiency due to the solubilization of hemicellulose and lignin compounds. However, concentrated PILs are not cost-effective, highly viscous, and toxic to microorganisms. The present study evaluates the effect of PILs on the solubilization of hemicellulose and lignin present in coconut coir and pith. PILs including pyridinium hydrogen sulfate [PyH][HSO4] and triethylammonium hydrogen sulfate [TEA][HSO4] were considered in this study. The sugars and lignin were partially hydrolyzed during the PIL pretreatment of coir and pith. However, the degree of biomass solubilization varied for different types of biomass and PIL. The changes in the biomass after pretreatment were studied through FTIR and XRD analysis. The yield of glucose released from [PyH][HSO4] and [TEA][HSO4] pretreated coir and pith increased 4.12, 4.73 and 7.36, and 6.44, respectively. The results showed that diluted PIL could be used in a biorefinery to increase the glucose yield with almost similar efficiency obtained from concentrated PIL. The recovery and reusability studies showed the recycled PIL could be utilized 3 times. Further application of low concentrations of PIL suggests the possibility of a new process design for a biorefinery to achieve low operating costs.

Graphical abstract

Similar content being viewed by others

References

Kim D (2018) Physico-chemical conversion of lignocellulose: Inhibitor effects and detoxification strategies: A mini review. Molecules 23:309. https://doi.org/10.3390/molecules23020309

Ning P, Yang G, Hu L et al (2021) Recent advances in the valorization of plant biomass. Biotechnol Biofuels 14. https://doi.org/10.1186/s13068-021-01949-3

Sankaran R, Parra Cruz RA, Pakalapati H et al (2020) Recent advances in the pretreatment of microalgal and lignocellulosic biomass: a comprehensive review. Bioresour Technol 298:122476. https://doi.org/10.1016/j.biortech.2019.122476

Binod P, Gnansounou E, Sindhu R, Pandey A (2019) Enzymes for second generation biofuels: Recent developments and future perspectives. Bioresour Technol Reports 5:317–325. https://doi.org/10.1016/j.biteb.2018.06.005

Sun C, Ren H, Sun F et al (2022) Glycerol organosolv pretreatment can unlock lignocellulosic biomass for production of fermentable sugars: present situation and challenges. Bioresour Technol 344, https://doi.org/10.1016/j.biortech.2021.126264

Manfredi AP, Ballesteros I, Sáez F et al (2018) Integral process assessment of sugarcane agricultural crop residues conversion to ethanol. Bioresour Technol 260:241–247. https://doi.org/10.1016/j.biortech.2018.03.114

Arenas-Cárdenas P, López-López A, Moeller-Chávez GE, León-Becerril E (2017) Current pretreatments of lignocellulosic residues in the production of bioethanol. Waste and Biomass Valorization 8:161–181. https://doi.org/10.1007/s12649-016-9559-4

Chaturvedi S, Bhattacharya A, Khare SK (2018) Trends in oil production from oleaginous yeast using biomass: biotechnological potential and constraints. Appl Biochem Microbiol. https://doi.org/10.1134/S000368381804004X

Luo C, Brink DL, Blanch HW (2002) Identification of potential fermentation inhibitors in conversion of hybrid poplar hydrolyzate to ethanol. Biomass Bioenergy 22:125–138. https://doi.org/10.1016/S0961-9534(01)00061-7

Cheah WY, Sankaran R, Show PL et al (2020) Pretreatment methods for lignocellulosic biofuels production: current advances, challenges and future prospects. Biofuel Res J 7:1115–1127. https://doi.org/10.18331/BRJ2020.7.1.4

Chuetor S, Ruiz T, Barakat A et al (2021) Evaluation of rice straw biopowder from alkaline-mechanical pretreatment by hydro-textural approach. Bioresour Technol 323:124619. https://doi.org/10.1016/j.biortech.2020.124619

Tan HT, Lee KT, Mohamed AR (2011) Pretreatment of lignocellulosic palm biomass using a solvent-ionic liquid [BMIM]Cl for glucose recovery: an optimisation study using response surface methodology. Carbohydr Polym 83:1862–1868. https://doi.org/10.1016/j.carbpol.2010.10.052

Acharya S, Liyanage S, Abidi N et al (2021) Utilization of cellulose to its full potential: a review on cellulose dissolution, regeneration, and applications. Polymers (Basel) 13.https://doi.org/10.3390/polym13244344

Gundupalli MP, Tantayotai P, Anne Sahithi ST et al (2022) Ionic liquid assisted pretreatment to improve cellulose fractionation of lignocellulosic biomass. Ion Liq Technol Environ Sustain:75–99.https://doi.org/10.1016/b978-0-12-824545-3.00006-4

Nurdin M, Abimanyu H, Putriani H et al (2021) Optimization of OPEFB lignocellulose transformation process through ionic liquid [TEA][HSO4] based pretreatment. Sci Rep 11. https://doi.org/10.1038/s41598-021-90891-3

Saher S, Saleem H, Asim AM et al (2018) Pyridinium based ionic liquid: a pretreatment solvent and reaction medium for catalytic conversion of cellulose to total reducing sugars (TRS). J Mol Liq 272:330–336. https://doi.org/10.1016/j.molliq.2018.09.099

Rocha EGA, Pin TC, Rabelo SC, Costa AC (2017) Evaluation of the use of protic ionic liquids on biomass fractionation. Fuel. https://doi.org/10.1016/j.fuel.2017.06.014

Han SY, Park CW, Endo T et al (2020) Extrusion process to enhance the pretreatment effect of ionic liquid for improving enzymatic hydrolysis of lignocellulosic biomass. Wood Sci Technol 54:599–613. https://doi.org/10.1007/s00226-020-01170-9

Li C, Tanjore D, He W et al (2013) Scale-up and evaluation of high solid ionic liquid pretreatment and enzymatic hydrolysis of switchgrass. Biotechnol Biofuels 6. https://doi.org/10.1186/1754-6834-6-154

N, Liu H, Sathitsuksanoh N et al (2013) Production and extraction of sugars from switchgrass hydrolyzed in ionic liquids. Biotechnol Biofuels 6. https://doi.org/10.1186/1754-6834-6-39

Lynam JG, Chow GI, Hyland PL, Coronella CJ (2016) Corn stover pretreatment by ionic liquid and glycerol mixtures with their density, viscosity, and thermogravimetric properties. ACS Sustain Chem Eng 4:3786–3793. https://doi.org/10.1021/acssuschemeng.6b00480

Gschwend FJV, Malaret F, Shinde S et al (2018) Rapid pretreatment of: miscanthus using the low-cost ionic liquid triethylammonium hydrogen sulfate at elevated temperatures. Green Chem 20:3486–3498. https://doi.org/10.1039/c8gc00837j

Mohammadi S, Abbasi M (2015) Design of ionic liquid sulfonic acid pyridinium hydrogen sulfate as an efficient, eco-friendly, and reusable catalyst for one-pot synthesis of highly functionalized tetrahydropyridines. Res Chem Intermed 41:8877–8890. https://doi.org/10.1007/s11164-015-1934-4

George A, Brandt A, Tran K et al (2015) Design of low-cost ionic liquids for lignocellulosic biomass pretreatment. Green Chem. https://doi.org/10.1039/c4gc01208a

Asim AM, Uroos M, Naz S, Muhammad N (2021) Pyridinium protic ionic liquids: effective solvents for delignification of wheat straw. J Mol Liq 325:115013. https://doi.org/10.1016/j.molliq.2020.115013

Gundupalli MP, Bhattacharyya D (2021) Hydrothermal liquefaction of residues of Cocos nucifera (Coir and Pith) using subcritical water: process optimization and product characterization. Energy:121466. https://doi.org/10.1016/j.energy.2021.121466

Sangian HF, Kristian J, Rahma S et al (2015) Preparation of reducing sugar hydrolyzed from high-lignin coconut coir dust pretreated by the recycled ionic liquid [mmim][dmp] and combination with alkaline. Bull Chem React Eng Catal. https://doi.org/10.9767/bcrec.10.1.7058.8-22

Katinonkul W, Phuriragpitikhon J (2013) Pretreatment of corn husk and coconut husk using ionic liquid to enhance glucose recovery. Bulletin of Applied Sciences 2:26–34

Sluiter A, Hames B, Ruiz RO et al (2008) Determination of structural carbohydrates and lignin in biomass. Laboratory analytical procedure 1617:1–16

Gundupalli MP, Bhattacharyya D (2019) Sequential acid hydrolysis and enzymatic saccharification of coconut coir for recovering reducing sugar: process evaluation and optimization. Bioresour Technol Reports 6:70–80. https://doi.org/10.1016/j.biteb.2019.01.015

Gundupalli MP, Kajiura H, Ishimizu T, Bhattacharyya D (2020) Alkaline hydrolysis of coconut pith: process optimization, enzymatic saccharification, and nitrobenzene oxidation of Kraft lignin. Biomass Convers Biorefinery 1–19. https://doi.org/10.1007/s13399-020-00890-z

Nielsen SS (2010) Determination of moisture content. Food Anal Lab Man:17–27.https://doi.org/10.1007/978-1-4419-1463-7_3

Sluiter A, Ruiz RO, Scarlata C et al (2004) Determination of extractives in biomass. Laboratory analytical procedure (LAP) 1617:1–9

Bano K, Jain A, Sarkar R, Panda TK (2020) Economically viable and efficient catalysts for esterification and cross aldol condensation reactions under mild conditions. ChemistrySelect 5:4470–4477. https://doi.org/10.1002/slct.202000252

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Maillard LC, Maillard LC, Maillard L, Maillard L (1912) Action des acides aminés sur les sucres: formation des mélanoïdines par voie méthodique. Comptes R Acad Sci (Paris) 154:66–68

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Semerci I, Ersan G (2021) Hornbeam pretreatment with protic ionic liquids: cation, particle size, biomass loading and recycling effects. Ind Crops Prod 159. https://doi.org/10.1016/j.indcrop.2020.113021

Brandt-Talbot A, Gschwend FJV, Fennell PS et al (2017) An economically viable ionic liquid for the fractionation of lignocellulosic biomass. Green Chem 19:3078–3102. https://doi.org/10.1039/c7gc00705a

Chen M, Malaret F, Firth AEJ et al (2020) Design of a combined ionosolv-organosolv biomass fractionation process for biofuel production and high value-added lignin valorisation. Green Chem 22:5161–5178. https://doi.org/10.1039/d0gc01143f

Abouelela AR, Al Ghatta A, Verdía P et al (2021) Evaluating the role of water as a cosolvent and an antisolvent in [HSO4]-based protic ionic liquid pretreatment. ACS Sustain Chem Eng 9:10524–10536. https://doi.org/10.1021/acssuschemeng.1c02299

Feng D, Li L, Yang F et al (2011) Separation of ionic liquid [Mmim][DMP] and glucose from enzymatic hydrolysis mixture of cellulose using alumina column chromatography. Appl Microbiol Biotechnol 91:399–405. https://doi.org/10.1007/s00253-011-3263-x

Guadix-Montero S, Sankar M (2018) Review on catalytic cleavage of C-C inter-unit linkages in lignin model compounds: towards lignin depolymerisation. Top Catal 61:183–198. https://doi.org/10.1007/s11244-018-0909-2

Lu Y, Lu Y-C, Hu H-Q et al (2017) Structural characterization of lignin and its degradation products with spectroscopic methods. J Spectrosc 2017:1–15. https://doi.org/10.1155/2017/8951658

Dutta T, Isern NG, Sun J et al (2017) Survey of lignin-structure changes and depolymerization during ionic liquid pretreatment. ACS Sustain Chem Eng. https://doi.org/10.1021/acssuschemeng.7b02123

Nakasu PYS, Clarke CJ, Rabelo SC et al (2020) Interplay of acid–base ratio and recycling on the pretreatment performance of the protic ionic liquid monoethanolammonium acetate. ACS Sustain Chem Eng 8:7952–7961. https://doi.org/10.1021/acssuschemeng.0c01311

Banerjee N, Bhatnagar R, Viswanathan L (1981) Inhibition of glycolysis by furfural in Saccharomyces cerevisiae. Eur J Appl Microbiol Biotechnol 11:226–228. https://doi.org/10.1007/BF00505872

Ladeira Ázar RIS, Bordignon-Junior SE, Laufer C et al (2020) Effect of lignin content on cellulolytic saccharification of liquid hot water pretreated sugarcane bagasse. Molecules 25:623. https://doi.org/10.3390/molecules25030623

Sangian HF, Widjaja A (2017) Effect of pretreatment method on structural changes of coconut coir dust. BioResources 12:8030–8046. https://doi.org/10.15376/biores.12.4.8030-8046

Kundu C, Samudrala SP, Kibria MA, Bhattacharya S (2021) One-step peracetic acid pretreatment of hardwood and softwood biomass for platform chemicals production. Sci Rep 11. https://doi.org/10.1038/s41598-021-90667-9

Klinke HB, Thomsen AB, Ahring BK (2004) Inhibition of ethanol-producing yeast and bacteria by degradation products produced during pre-treatment of biomass. Appl Microbiol Biotechnol 66:10–26. https://doi.org/10.1007/s00253-004-1642-2

Gschwend FJV, Chambon CL, Biedka M et al (2019) Quantitative glucose release from softwood after pretreatment with low-cost ionic liquids. Green Chem 21:692–703. https://doi.org/10.1039/C8GC02155D

Fu D, Mazza G (2011) Aqueous ionic liquid pretreatment of straw. Bioresour Technol 102:7008–7011. https://doi.org/10.1016/j.biortech.2011.04.049

Araya-Farias M, Husson E, Saavedra-Torrico J et al (2019) Wheat bran pretreatment by room temperature ionic liquid-water mixture: optimization of process conditions by pls-surface response design. Front Chem 7. https://doi.org/10.3389/fchem.2019.00585

Auxenfans T, Buchoux S, Larcher D et al (2014) Enzymatic saccharification and structural properties of industrial wood sawdust: recycled ionic liquids pretreatments. Energy Convers Manag 88:1094–1103. https://doi.org/10.1016/j.enconman.2014.04.027

Limayem A, Ricke SC (2012) Lignocellulosic biomass for bioethanol production: Current perspectives, potential issues and future prospects. Prog Energy Combust Sci 38:449–467. https://doi.org/10.1016/j.pecs.2012.03.002

Amezcua-Allieri MA, Sánchez Durán T, Aburto J (2017) Study of chemical and enzymatic hydrolysis of cellulosic material to obtain fermentable sugars. J Chem 2017. https://doi.org/10.1155/2017/5680105

Smuga-Kogut M, Kogut T, Markiewicz R, Słowik A (2021) Use of machine learning methods for predicting amount of bioethanol obtained from lignocellulosic biomass with the use of ionic liquids for pretreatment. Energies 14. https://doi.org/10.3390/en14010243

Gundupalli MP, Chuetor S, Cheenkachorn K et al (2021) Interferences of waxes on enzymatic saccharification and ethanol production from lignocellulose biomass. Bioengineering 8. https://doi.org/10.3390/bioengineering8110171

Funding

The Ministry of Human Resource Development (India) and the Department of Science and Technology (India) funded and supported this work under FAST and FIST programs, respectively. Malinee Sriariyanun was supported by King Mongkut’s University of Technology North Bangkok (Contract No. KMUTNB-FF-65–37).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gundupalli, M.P., Bano, K., Panda, T.K. et al. Understanding the effect of low-concentrated protic ionic liquids (PILs) on coconut (Cocos nucifera) residues. Biomass Conv. Bioref. 14, 3275–3291 (2024). https://doi.org/10.1007/s13399-022-02572-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02572-4