Abstract

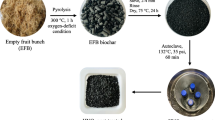

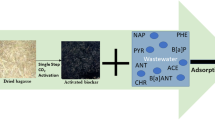

Porous biochar was prepared from agricultural and forestry wastes to remove Cr(VI) in sewage, which solved the problem of water pollution and realized the reuse of wastes. Herein, in this work, the bagasse pith residues after alkali pre-extraction have been used as the raw material for preparing porous biochars (BPR-BC), which could be further used for efficiently purifying the simulated Cr(VI) wastewater. The results showed that the as-prepared biochars had an ultra-high specific surface area of 2745.7 m3/g and Cr(VI) removal capacity of 185.07 mg/g. The kinetic and isotherms studies were best described by pseudo-second-order model and Langmuir adsorption isotherm model, respectively. The thermodynamic studies showed that the adsorption process was endothermic and spontaneous. Furthermore, based on the concept of “waste to waste,” the Cr-contained waste adsorbent by doping Cu has been converted into a bagasse pith residues biochar supported Copper-Chromium catalyst (Cu-CrOx/BPR-BC) for further hydrogenation of furfural. The catalytic experimental result showed that the furfural 1 can be selectively converted into furfuryl alcohol (FOL) and difurfuryl ether (DEF) catalyzed by the prepared Cu-CrOx/BPR-BC catalyst, provided a new idea for the further utilization of Cr(VI) containing adsorbents.

Similar content being viewed by others

Abbreviations

- BPR-BC:

-

Bagasse pith residues biochar

- FAL:

-

Furfural

- FOL:

-

Furfuryl alcohol

- DFE:

-

Difurfuryl ether

- BP:

-

Bagasse pith

- η:

-

Removal efficiency

- q:

-

Adsorption capacity

- Co :

-

Initial Cr(VI) concentration (mg/L)

- Ce :

-

The equilibrium concentration of Cr(VI) in the solution (mg/L)

- SSA:

-

Specific surface area

- qe :

-

The amounts of Cr(VI) adsorbed on BPR-BC (mg/g) at equilibrium state

- k1 :

-

The rate constants of pseudo-first-order (L/min)

- k2 :

-

The rate constants of pseudo-second-order (g/(mg·min))

- qt :

-

The amounts of Cr(VI) adsorbed on BPR-BC (mg/g) at time t

- t:

-

Time (min)

- α:

-

The initial rate of adsorption (mg/(g·min))

- β:

-

Is the constant of desorption (g/mg) in any one experiment

- ki :

-

The rate constants of intra-particle diffusion (mg/(g·min0.5))

- I:

-

Show the effect degree of the boundary layer around the BPR-BC adsorbent during adsorption

- Qm :

-

Maximum amount of Cr(VI) adsorbed on BPR-BC (mg/g) as monolayer coverage

- KF :

-

Freundlich constant (mg/g)

- b:

-

Represents a Langmuir constant related to free adsorption energy (L/mg)

- RL :

-

An essential factor of the Langmuir isotherm is the separation factor

- R2 :

-

Correlation coefficient

- ΔG°:

-

Standard Gibbs free energy (J mol−1) of Cr(VI) adsorption

- ΔH°:

-

Standard enthalpy (kJ mol−1) of Cr(VI) adsorption

- ΔS°:

-

Standard entropy (J mol−1 K−1) of Cr(VI) adsorption

- Kc :

-

Equilibrium constant (L/mol)

- R:

-

8.314 J/mol.K, the universal gas constant

- T:

-

Adsorption temperature (K)

- FA:

-

Furoic acid

- DFE:

-

Diferferal ether

References

Jia P, Lan XC, Li XD, Wang TF (2019) Highly selective hydrogenation of furfural to cyclopentanone over a NiFe bimetallic catalyst in a methanol/water solution with a solvent effect. ACS Sustain Chem Eng 7:15221–15229. https://doi.org/10.1021/acssuschemeng.9b02112

Kleinert M, Barth T (2008) Towards a lignincellulosic biorefinery: direct one-step conversion of lignin to hydrogen-enriched biofuel. Energy Fuels 22:1371–1379. https://doi.org/10.1021/ef700631w

Sun Y, Cheng JY (2002) Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresource Technol 83:1–11. https://doi.org/10.1016/s0960-8524(01)00212-7

Clement CL, Mkhize TY, Prashant R, Brandt-Talbot A, Deenadayalu N, Fennell PS, Hallett JP (2018) Pretreatment of South African sugarcane bagasse using a low-cost protic ionic liquid: a comparison of whole, depithed, fibrous and pith bagasse fractions. Biotechnol Biofuels 11:247. https://doi.org/10.1186/s13068-018-1247-0

Jin F, Enomoto H (2011) Rapid and highly selective conversion of biomass into value-added products in hydrothermal conditions: chemistry of acid/base-catalysed and oxidation reactions. Energy Environ Sci 4:382–397. https://doi.org/10.1039/c004268d

Wang C, Chen X, Qi M, Wu J, Gozaydin G, Yan N, Zhong H, Jin F (2019) Room temperature, near-quantitative conversion of glucose into formic acid. Green Chem 21:6089–6096. https://doi.org/10.1039/c9gc02201e

Gallina G, Cabeza A, Grenman H, Biasi P, Garcia-Serna J, Salmi T (2018) Hemicellulose extraction by hot pressurized water pretreatment at 160 degrees C for 10 different woods: yield and molecular weight. J Supercrit Fluid 133:716–725. https://doi.org/10.1016/j.supflu.2017.10.001

He L, Chen D, Yang S, Peng L, Zhang J, Guan Q, Zhang P (2020) Deep insights into the atmospheric sodium hydroxide-hydrogen peroxide extraction process of hemicellulose in bagasse pith: technical uncertainty, dissolution kinetics behavior, and mechanism. Ind Eng Chem Res 59:10150–10159. https://doi.org/10.1021/acs.iecr.0c01076

He L, Yang S, Chen D, Peng L, Liu Y, Guan Q, Li J (2020) Hemicellulose transportation from different tissues of corn stalk to alkaline hydrogen peroxide solution. Cellulose 27:4255–4269. https://doi.org/10.1007/s10570-020-03088-8

Hu N, Chen D, Guan Q, Peng L, Zhang J, He L, Shi Y (2020) Preparation of hemicellulose-based hydrogels from biomass refining industrial effluent for effective removal of methylene blue dye. Environ Technol 412:1–22. https://doi.org/10.1080/09593330.2020.1795930

Amin AE-EAZ (2020) Bagasse pith-vinasse biochar effects on carbon emission and nutrient release in calcareous sandy soil. J Soil Sci Plant Nutr 20:220–231. https://doi.org/10.1007/s42729-019-00125-9

Luo X, Cai Y, Liu L, Zeng J (2019) Cr(VI) adsorption performance and mechanism of an effective activated carbon prepared from bagasse with a one-step pyrolysis and ZnCl2 activation method. Cellulose 26:4921–4934. https://doi.org/10.1007/s10570-019-02418-9

Guan Q, Gao K, Ning P, Miao R, He L (2020) Value-added utilization of paper sludge: preparing activated carbon for efficient adsorption of Cr(VI) and further hydrogenation of furfural. Sci Total Environ 741.https://doi.org/10.1016/j.scitotenv.2020.140265

Lam KF, Yeung KL, McKay G (2007) Efficient approach for Cd2+ and Ni2+ removal and recovery using mesoporous adsorbent with tunable selectivity. Environ Sci Technol 41:3329–3334. https://doi.org/10.1021/es062370e

Sud D, Mahajan G, Kaur MP (2008) Agricultural waste material as potential adsorbent for sequestering heavy metal ions from aqueous solutions - a review. Bioresource Technol 99:6017–6027. https://doi.org/10.1016/j.biortech.2007.11.064

Bandara T, Xu J, Potter ID, Franks A, Chathurika JBAJ, Tang C (2020) Mechanisms for the removal of Cd(II) and Cu(II) from aqueous solution and mine water by biochars derived from agricultural wastes. Chemosphere 254:126745. https://doi.org/10.1016/j.chemosphere.2020.126745

Liu K, Li F, Cui J, Yang S, Fang L (2020) Simultaneous removal of Cd(II) and As(III) by graphene-like biochar-supported zero-valent iron from irrigation waters under aerobic conditions: synergistic effects and mechanisms. J Hazard Mater 395:122623. https://doi.org/10.1016/j.jhazmat.2020.122623

Chen F, Zhang M, Ma L, Ren J, Ma P, Li B, Wu N, Song Z, Huang L (2020) Nitrogen and sulfur codoped micro-mesoporous carbon sheets derived from natural biomass for synergistic removal of chromium(VI): adsorption behavior and computing mechanism. Sci Total Environ 730:138930. https://doi.org/10.1016/j.scitotenv.2020.138930

Ma HF, Yang JJ, Gao X, Liu ZB, Liu XX, Xu ZG (2019) Removal of chromium (VI) from water by porous carbon derived from corn straw: influencing factors, regeneration and mechanism. J Hazard Mater 369:550–560. https://doi.org/10.1016/j.jhazmat.2019.02.063

Zhang Y, Li M, Li JC, Yang YY, Liu X (2019) Surface modified leaves with high efficiency for the removal of aqueous Cr (VI). Appl Surf Sci 484:189–196. https://doi.org/10.1016/j.apsusc.2019.04.088

Bastami TR, Entezari MH (2012) Activated carbon from carrot dross combined with magnetite nanoparticles for the efficient removal of p-nitrophenol from aqueous solution. Chem Eng J 210:510–519. https://doi.org/10.1016/j.cej.2012.08.011

Yan K, Chen A (2013) Efficient hydrogenation of biomass-derived furfural and levulinic acid on the facilely synthesized noble-metal-free Cu-Cr catalyst. Energy 58:357–363. https://doi.org/10.1016/j.energy.2013.05.035

Ludlow DK (2006) Activated carbon adsorption by Roop Chand Bansal and Meenakshi Goyal. J Am Chem Soc 128:10630–10630

Martins AC, Pezoti O, Cazetta AL, Bedin KC, Yamazaki DAS, Bandoch GFG, Asefa T, Visentainer JV, Almeida VC (2015) Removal of tetracycline by NaOH-activated carbon produced from macadamia nut shells: kinetic and equilibrium studies. Chem Eng J 260:291–299. https://doi.org/10.1016/j.cej.2014.09.017

Inagaki M, Tascón JMD (2006) Activated carbon surfaces in environmental remediation. Interface Sci Techno 7:49–105

Feng J, Liu Y, Zhang L, Zhu J, Chen J, Xu H, Yang H, Yan W (2020) Effects of calcination temperature on organic functional groups of TiO2 and the adsorption performance of the TiO2 for methylene blue. Sep Sci Technol 55:672–683. https://doi.org/10.1080/01496395.2019.1574822

Kumar A, Jena HM (2017) Adsorption of Cr(VI) from aqueous solution by prepared high surface area activated carbon from Fox nutshell by chemical activation with H3PO4. J Environ Chem Eng 5:2032–2041. https://doi.org/10.1016/j.jece.2017.03.035

Li C, Pan G, Wang X, Qiang X, Qiang T (2020) The effects of non-metallic organic tanning agents on the microbial community structure in wastewater. J Clean Prod 279:123553. https://doi.org/10.1016/j.jclepro.2020.123553

Vasilenko TA, Lamakina MP, Brusnitsyna OM (2018) The purification of electroplating industry effluents with agricultural waste. Solid State Phenom 284:814–821. https://doi.org/10.4028/www.scientific.net/SSP.284.814

Xia D, Tan F, Zhang C, Jiang X, Chen Z, Li H, Zheng Y, Li Q, Wang Y (2016) ZnCl2-activated biochar from biogas residue facilitates aqueous As(III) removal. Appl Surf Sci 377:361–369. https://doi.org/10.1016/j.apsusc.2016.03.109

Budimirovic D, Velickovic ZS, Djokic VR, Milosauljevic M, Markovski J, Levic S, Marinkovic AD (2017) Efficient As(V) removal by alpha-FeOOH and alpha-FeOOH/alpha-MnO2 embedded PEG-6-arm functionalized multiwall carbon nanotubes. Chem Eng Res Des 119:75–86. https://doi.org/10.1016/j.cherd.2017.01.010

Dutta DP, Venugopalan R, Chopade S (2017) Manipulating carbon nanotubes for efficient removal of both cationic and anionic dyes from wastewater. Chemistryselect 2:3878–3888. https://doi.org/10.1002/slct.201700135

Pérez-Candela M, Martin-Martinez J, Torregrosa R (1995) Chromium(VI) removal with activated carbons. Water Res 29:2174–2180. https://doi.org/10.1016/0043-1354(95)00035-J

Sanroman MA, Lee DJ, Khanal S, Ok YS (2017) Special issue on biochar: production, characterization and applications – beyond soil applications. Bioresour Technol 246:1–1. https://doi.org/10.1016/j.biortech.2017.10.006

Liang H, Sun R, Song B, Sun Q, Peng P, She D (2020) Preparation of nitrogen-doped porous carbon material by a hydrothermal-activation two-step method and its high-efficiency adsorption of Cr(VI). J Hazard Mater 387. https://doi.org/10.1016/j.jhazmat.2019.121987

Okpalugo TIT, Papakonstantinou P, Murphy H, McLaughlin J, Brown NMD (2005) High resolution XPS characterization of chemical functionalised MWCNTs and SWCNTs. Carbon 43:153–161. https://doi.org/10.1016/j.carbon.2004.08.033

Norouzi S, Heidari M, Alipour V, Rahmanian O, Fazlzadeh M, Mohammadi-Moghadam F, Nourmoradi H, Goudarzi B, Dindarloo K (2018) Preparation, characterization and Cr(VI) adsorption evaluation of NaOH-activated carbon produced from Date Press Cake; an agro-industrial waste. Bioresour Technol 258:48–56. https://doi.org/10.1016/j.biortech.2018.02.106

Mika LT, Csefalvay E, Nemeth A (2018) Catalytic conversion of carbohydrates to initial platform chemicals: chemistry and sustainability. Chem Rev 118:505–613. https://doi.org/10.1021/acs.chemrev.7b00395

Yan Y, Bu C, He Q, Zheng Z, Ouyang J (2018) Efficient bioconversion of furfural to furfuryl alcohol by Bacillus coagulans NL01. RSC Adv 8:26720–26727. https://doi.org/10.1039/c8ra05098h

Phitsuwan P, Sakka K, Ratanakhanokchai K (2016) Structural changes and enzymatic response of Napier grass (Pennisetum purpureum) stem induced by alkaline pretreatment. Bioresour Technol 218:247–256. https://doi.org/10.1016/j.biortech.2016.06.089

Cherdchoo W, Nithettham S, Charoenpanich J (2019) Removal of Cr(VI) from synthetic wastewater by adsorption onto coffee ground and mixed waste tea. Chemosphere 221:758–767. https://doi.org/10.1016/j.chemosphere.2019.01.100

Kharrazi SM, Mirghaffari N, Dastgerdi MM, Soleimani M (2020) A novel post-modification of powdered activated carbon prepared from lignocellulosic waste through thermal tension treatment to enhance the porosity and heavy metals adsorption. Powder Technol 366:358–368. https://doi.org/10.1016/j.powtec.2020.01.065

Zhu S, Wang S, Yang X, Tufail S, Chen C, Wang X, Shang J (2020) Green sustainable and highly efficient hematite nanoparticles modified biochar-clay granular composite for Cr(VI) removal and related mechanism. J Clean Prod 276:123009. https://doi.org/10.1016/j.jclepro.2020.123009

Liang M, Ding Y, Zhang Q, Wang D, Li H, Lu L (2020) Removal of aqueous Cr(VI) by magnetic biochar derived from bagasse. Sci Rep 10:21473. https://doi.org/10.1038/s41598-020-78142-3

Hong FM, Juan JY, Xiang G, Zhi BL, Xin XL, Zhao GX (2019) Removal of chromium (VI) from water by porous carbon derived from corn straw: influencing factors, regeneration and mechanism. J Hazard Mater 369:550–560. https://doi.org/10.1016/j.jhazmat.2019.02.063

Zhang Y, Li M, Li J, Yang Y, Liu X (2019) Surface modified leaves with high efficiency for the removal of aqueous Cr (VI). Appl Surf Sci 484:189–196. https://doi.org/10.1016/j.apsusc.2019.04.088

Funding

This work is supported by the National Natural Science Foundationof China (21968014, 22008097), the National Key Research and Development Program of China (Grant No. 2019YFC1805904, 2018YFC1902102, 2018YFC1902105), and the Analysis and Testing Foundation of Kunming University of Science and Technology (No.2019T20170031, 2019M20182208063).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, D., Chen, S., He, L. et al. Preparation of bagasse pith-derived biochar for high-efficiency removal of Cr(VI) and further hydrogenation of furfural. Biomass Conv. Bioref. 14, 1763–1780 (2024). https://doi.org/10.1007/s13399-022-02547-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02547-5