Abstract

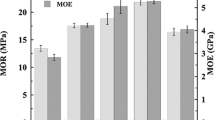

Natural adhesives made from non-fossil resources are expected to grow significantly in the future. This study analyzes the effects of maleic acid (MA) content and particle size class on the physical and mechanical characteristics of sorghum (Sorghum bicolor) biomass particleboard (SBMA-particleboard) as potential materials for table tennis blade. MA content was varied in the range of 5 to 20 wt%, while SBMA-particleboard were manufactured using various particles size class and target densities of 300 mm × 300 mm × 0.6 cm and 600 kg/m3, respectively. The result showed that the physical and mechanical properties of SBMA-particleboard improved with increasing MA content of 15 wt%. Furthermore, the MA content of 15 wt% effectively manufactured SBMA-particleboard, while the powder particle class provided higher dimensional stability and internal bond due to the more extensive contact area. Fourier transform infrared spectroscopy analysis showed the presence of ester linkages, indicating a reaction between the carboxyl groups of MA and the hydroxyl of the sorghum biomass to provide good physical and mechanical properties for SBMA-particleboard as potential materials for table tennis blade.

Similar content being viewed by others

References

Pan Z, Cathcart A, Wang D (2006) Properties of particleboard bond with rice bran and polymeric methylene diphenyl diisocyanate adhesives. Ind Crops Prod 23:40–45. https://doi.org/10.1016/j.indcrop.2005.03.004

Arifin AMT, Hassan MF, Ismail AE et al (2017) Investigation on suitability of natural fibre as replacement material for table tennis blade investigation on suitability of natural fibre as replacement material for table tennis blade. IOP Conf Series: Journal of Physics: Conf Series 914:012015. https://doi.org/10.1088/1742-6596/914/1/012015

Amin MHM, Arifin AMT, Hassan MF, Li H et al (2017) An evaluation of mechanical properties on kenaf natural fiber / polyester composite structures as table tennis blade an evaluation of mechanical properties on kenaf natural fiber / polyester composite structures as table tennis blade. IOP Conf Series: Journal of Physics: Conf Series 914(2017):012015. https://doi.org/10.1088/1742-6596/914/1/012015

Hashim R, Saari N, Sulaiman O et al (2010) Effect of particle geometry on the properties of binderless particleboard manufactured from oil palm trunk. Mater Des 31:4251–4257. https://doi.org/10.1016/j.matdes.2010.04.012

Osarenmwinda JO, Nwachukwu JC (2007) Effect of particle size on some properties of rice husk particleboard. Adv Mater Res 18–19:43–48. https://doi.org/10.4028/www.scientific.net/amr.18-19.43. Accessed 7 Feb 2022

Oliveira SL, Mendes RF, Mendes LM, Freire TP (2016) Particleboard panels made from sugarcane bagasse: Characterization for use in the furniture industry. Mater Res 19:914–922. https://doi.org/10.1590/1980-5373-MR-2015-0211

Soleimani M, Tabil XL, Grewal R, Tabil LG (2017) Carbohydrates as binders in biomass densification for biochemical and thermochemical processes. Fuel 193:134–141. https://doi.org/10.1016/j.fuel.2016.12.053

Santoso M, Widyorini R, Prayitno TA, Sulistyo J (2017) Bonding performance of maltodextrin and citric acid for particleboard made from nipa fronds. J Korean Wood Sci Technol 45:432–443. https://doi.org/10.5658/WOOD.2017.45.4.432

Widyorini R, Umemura K, Septiano A et al (2018) Manufacture and properties of citric acid-bonded composite board made from salacca frond: effects of maltodextrin addition, pressing temperature, and pressing method. BioResources 13:8662–8676

Juliana AH, Paridah MT, Rahim S et al (2012) Properties of particleboard made from kenaf (Hibiscus cannabinus L.) as function of particle geometry. Mater Des 34:406–411. https://doi.org/10.1016/j.matdes.2011.08.019

Kusumah SS, Massijaya SY, Prasetyo KW, et al (2020) Surface modification of eco-friendly particleboard made from sorghum bagasse and citric acid sucrose adhesive. IOP Conf Ser Mater Sci Eng 935:012054. https://doi.org/10.1088/1757-899X/935/1/012054

[FAS] Foreign Agricultural Service (2020) World agricultural production. United States Dep Agric 1–34. Accessed 3 November 2021

Pabendon MB, Sarungallo R, Mas’ud S (2012) Prospect of the using of stem juice, bagasse, and grain of sweet sorghum as raw material for bioethanol production. Penelit Pertan Tanam Pangan 31:180–187. https://doi.org/10.21082/jpptp.v31n3.2012.p/25p

Iswanto AH (2014) Effect of resin type, pressing temperature and time on particleboard properties made from sorghum bagasse. Agric For Fish 3:62. https://doi.org/10.11648/j.aff.20140302.12

Khazaeian A, Ashori A, Dizaj MY (2015) Suitability of sorghum stalk fibers for production of particleboard. Carbohydr Polym 120:15–21. https://doi.org/10.1016/j.carbpol.2014.12.001

Chaturvedi R, Pappu A (2016) Performance of formaldehyde resins and cement bonded particleboards and understanding its properties for further advancement. Int J Waste Resour 6:1–8. https://doi.org/10.4172/2252-5211.1000215

Zhang J, Song F, Tao J, et al (2018) Research progress on formaldehyde emission of wood-based panel. Int J Polym Sci 2018: 9349721. https://doi.org/10.1155/2018/9349721

Ferdosian F, Pan Z, Gao G, Zhao B (2017) Bio-based adhesives and evaluation for wood composites application. Polymers (Basel) 9 (70): 1-29. https://doi.org/10.3390/polym9020070

Salem MZM, Böhm M (2013) Understanding of formaldehyde emissions from solid wood: An overview. BioResources 8:4775–4790. https://doi.org/10.15376/biores.8.3.4775-4790

IARC Working Group on the Evaluation of Carcinogenic Risks to Humans (2012) Chemical agents and related occupations. IARC Monogr Eval Carcinog Risks Hum 100:9–562

Réh R, Igaz R, Krišt’ák L, et al (2019) Functionality of beech bark in adhesive mixtures used in plywood and its effect on the stability associated with material systems. Materials (Basel) 12: 1298. https://doi.org/10.3390/ma12081298

Mao A, Hassan EB, Kim MG (2013) Investigation of low mole ratio UF and UMF resins aimed at lowering the formaldehyde emission potential of wood composite boards. BioResources 8:2453–2469. https://doi.org/10.15376/biores.8.2.2453-2469

Barry A, Corneau D (2006) Effectiveness of barriers to minimize VOC emissions including formaldehyde. For Prod J 56:38–42

Lubis MAR, Park BD (2020) Enhancing the performance of low molar ratio urea–formaldehyde resin adhesives via in-situ modification with intercalated nanoclay. J Adhes 00:1–20. https://doi.org/10.1080/00218464.2020.1753515

Yadav SM, Lubis MAR, Wibowo ES, Park BD (2020) Effects of nanoclay modification with transition metal ion on the performance of urea–formaldehyde resin adhesives. Polym Bull. https://doi.org/10.1007/s00289-020-03214-3

He Z (2017) Bio-based Wood Adhesives. In Bio-based Wood Adhesives. https://doi.org/10.1201/9781315369242

Ghaffar SH, Fan M (2014) Lignin in straw and its applications as an adhesive. Int J Adhes Adhes 48:92–101. https://doi.org/10.1016/j.ijadhadh.2013.09.001

Mati-Baouche N, Elchinger PH, De Baynast H et al (2014) Chitosan as an adhesive. Eur Polym J 60:198–213. https://doi.org/10.1016/j.eurpolymj.2014.09.008

Norstrom E, Fogelstrom L, Nordqvist P et al (2015) Xylan - A green binder for wood adhesives. Eur Polym J 67:483–493. https://doi.org/10.1016/j.eurpolymj.2015.02.021

Umemura K, Kawai S (2015) Development of wood-based materials bonded with citric acid. For Prod J 65:38–42. https://doi.org/10.13073/FPJ-D-14-00036

Yi Z, Wang W, Zhang W, Li J (2016) Preparation of tannin-formaldehyde-furfural resin with pretreatment of depolymerization of condensed tannin and ring opening of furfural. J Adhes Sci Technol 30:947–959. https://doi.org/10.1080/01694243.2015.1132576

Zhang H, Liu P, Musa SM et al (2019) Dialdehyde cellulose as a bio-based robust adhesive for wood bonding. ACS Sustain Chem Eng 7:10452–10459. https://doi.org/10.1021/acssuschemeng.9b00801

Kusumah SS, Miyafuji H, Yoshioka K, Kanayama K et al (2016) Utilization of sweet sorghum biomass and citric acid for manufacturing of particleboard I: Effects of pre-drying treatment and citric acid content on the board properties. Ind Crops Prod 84:34–42. https://doi.org/10.1016/j.indcrop.2016.01.042

Widyorini R, Umemura K, Soraya DK et al (2019) Effect of citric acid content and extractives treatment on the manufacturing process and properties of citric acid-bonded Salacca frond particleboard. BioResources 14:4171–4180. https://doi.org/10.15376/biores.14.2.4171-4180

Lee SH, Tahir P, Lum WC et al (2020) A review on citric acid as green modifying agent and binder for wood. Polymers 12:1692. https://doi.org/10.3390/polym12081692

Umemura K, Ueda T, Kawai S (2012) Characterization of wood-based molding bonded with citric acid. J Wood Sci 58:38–45. https://doi.org/10.1007/s10086-011-1214-x

Sutiawan J, Hadi YS, Nawawi DS et al (2021) The properties of particleboard composites made from three sorghum (Sorghum bicolor) accessions using maleic acid adhesive. Chemosphere 290:133163. https://doi.org/10.1016/j.chemosphere.2021.133163

Kusumah SS, Umemura K, Guswenrivo I et al (2017) Utilization of sweet sorghum bagasse and citric acid for manufacturing of particleboard II: influences of pressing temperature and time on particleboard properties. J Wood Sci 63:161–172. https://doi.org/10.1007/s10086-016-1605-0

Kövilein A, Kubisch C, Cai L, Ochsenreither K (2020) Malic acid production from renewables: a review. J Chem Technol Biotechnol 95:513–526. https://doi.org/10.1002/jctb.6269

Sutiawan J, Hermawan D, Kusumah SS et al (2003) Utilization of cassava maltodextrin for eco-friendly adhesive in the manufacturing of sorghum bagasse particleboard. Jurnal Sylva Lestari 8:144–154

Arabi M, Faezipour M, Layeghi M, Enayati AA (2011) Interaction analysis between slenderness ratio and resin content on mechanical properties of particleboard. J For Res 22:461–464. https://doi.org/10.1007/s11676-011-0188-2

Wahyuni Y, Miyamoto T, Hartati H et al (2019) Variation in lignocellulose characteristics of 30 Indonesian sorghum (Sorghum bicolor) accessions. Ind Crops Prod 142:111840. https://doi.org/10.1016/j.indcrop.2019.111840

Parubak BS (2009) The development of oriented strand board with high quality from bamboo. IPB University, Thesis

Sutiawan J, Mardhatillah S, Hermawan D, Syamani FA (2018) Characteristics of particleboard made from mixed waste sengon and sorghum bagasse bonded with citric acid adhesive. J Penelit Has Hutan 38:139–150

JIS (2003) JIS A 5908 2003: Japanese industrial standard for particleboard. Japanese Industrial Standard. Tokyo, Japan

ASTM (1999) D 1037: Standard test methods for evaluating properties of wood-base fiber and particle. American Society for Testing and Materials

Sutiawan J, Hermawan D, Massijaya MY et al (2021) Influence of different hot-pressing conditions on the performance of eco-friendly jabon plywood bonded with citric acid adhesive. Wood Mater Sci Eng 0:1–10. https://doi.org/10.1080/17480272.2021.1884898

Liao R, Xu J, Umemura K (2016) Low density sugarcane bagasse particleboard bonded and additive content. BioResources 11:2174–2185

Widyorini R, Umemura K, Putra DR, Prayitno TA et al (2015) Manufacture and properties of citric acid-bonded particleboard made from bamboo materials. Eur J Wood Wood Prod 74:57–65. https://doi.org/10.1007/s00107-015-0967-0

Farrokhpayam SR, Valadbeygi T, Sanei E (2016) Thin particleboard quality: effect of particle size on the properties of the panel. J Indian Acad Wood Sci. https://doi.org/10.1007/s13196-016-0163-9

Nemli G, Ozturk I, Aydin I (2005) Some of the parameters influencing surface roughness of particleboard. Build Environ 40:1337–1340. https://doi.org/10.1016/j.buildenv.2004.12.008

Hiziroglu S, Jarusombuti S, Fueangvivat V (2004) Surface characteristics of wood composites manufactured in Thailand. Build Environ 39:1359–1364. https://doi.org/10.1016/j.buildenv.2004.02.004

Ma Z, Wang J, Li C et al (2019) New sight on the lignin torrefaction pretreatment: relevance between the evolution of chemical structure and the properties of torrefied gaseous, liquid, and solid products. Bioresour Technol 288:121528. https://doi.org/10.1016/j.biortech.2019.121528

Ismayati M, Nakagawa-Izumi A, Kamaluddin NN, Ohi H (2016) Toxicity and feeding deterrent effect of 2-methylanthraquinone from thewood extractives of Tectona grandis on the subterranean termites Coptotermes formosanus and Reticulitermes speratus. Insects 7:63. https://doi.org/10.3390/insects7040063

Ghalibaf M, Doddapaneni TRKC, Alén R (2019) Pyrolytic behavior of lignocellulosic-based polysaccharides. J Therm Anal Calorim 137:121–131. https://doi.org/10.1007/s10973-018-7919-y

Bossa B, Theulé P, Duvernay F et al (2008) Carbamic acid and carbamate formation in NH3:CO2 ices - UV irradiation versus thermal processes. Astron Astrophys 492:719–724. https://doi.org/10.1051/0004-6361:200810536

Saud AS, Maniam GP, Ab. Rahim MH (2021) Introduction of eco-friendly adhesives: source, types, chemistry and characterization. In: Jawaid M, Khan T, Nasir M, Asim M (ed) Eco-friendly adhesives for wood and natural fiber composites. Springer, Malaysia.

Ormondroyd GA (2015) Adhesives for wood composites. Elsevier Ltd.

Cheng X, He X, Xie J et al (2016) Effect of the particle geometry and adhesive mass percentage on the physical and mechanical properties of particleboard made from peanut hull. BioResources 11:7271–7281. https://doi.org/10.15376/biores.11.3.7271-7281

Acknowledgements

The authors are thankful to the PMDSU program IPB University from the Ministry of Research and Higher Education (KEMENRISTEKDIKTI), the National Research and Innovation Agency (BRIN), and the Republic of Indonesia for supporting this work.

Funding

This research was funded by The Ministry of Education, Culture, Research, and Technology (KEMENRISTEKDIKTI) through the PMDSU scheme with the letter No 1/E1/KP. PTNBH/2021.

Author information

Authors and Affiliations

Contributions

Jajang Sutiawan: methodology, data curation, writing-original draft. Dede Hermawan: conceptualization, supervision. Yusuf Sudo Hadi: conceptualization, supervision. Deded Sarip Nawawi: conceptualization, supervision. Imam Busrya Abdillah: validation. Sukma Surya Kusumah: conceptualization, methodology, supervision, validation. Riska Surya Ningrum: methodology. Putri Amanda: methodology. Maya Ismayati: methodology.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sutiawan, J., Hermawan, D., Hadi, Y.S. et al. Properties of sorghum (Sorghum bicolor) biomass particleboard at different maleic acid content and particle size as potential materials for table tennis blade. Biomass Conv. Bioref. 14, 1607–1619 (2024). https://doi.org/10.1007/s13399-022-02525-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02525-x