Abstract

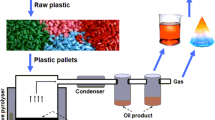

In this work, the direct liquefaction of polypropylene and rendering fat mixtures was performed by using light magnesium oxide (MgO) as catalyst. Polypropylene and rendering fat mixtures were tested in ratio of 10:0, 8:2, 6:4, 4:6, 2:8, and 0:10 (w/w) with 2 g of MgO and 50 g of tetralin as solvent and rendering fat:tetralin ratios of 10:50, 20:40, 30:30, 40:20, 50:10, and 60:10 w/w for the low temperature pyrolysis. Direct liquefaction was tested at 420 °C for 1 h, under nitrogen (1 MPa) in an autoclave. Furthermore, fast pyrolysis was performed to degrade these raw materials to light molecules such as ethylene and propylene. The raw materials and products were analyzed by a combination of several techniques: inductively coupled plasma thermal analyses, infrared spectroscopy, refractive index, elemental analyses (C, H, N, S%), and gas chromatography provided by a flame ionization detector (GC-FID), further analyzed by simulated distillation and refinery gas analysis (RGA).

Similar content being viewed by others

Abbreviations

- RF:

-

Rendering fat

- PP:

-

Polypropylene

References

Schmaltz E, Melvin EC, Diana Z, et al (2020) Plastic pollution solutions: emerging technologies to prevent and collect marine plastic pollution. Environ Int 144. https://doi.org/10.1016/j.envint.2020.106067

Abdel-Shafy HI, Mansour MSM (2018) Solid waste issue: sources, composition, disposal, recycling, and valorization. Egypt J Pet 27:1275–1290. https://doi.org/10.1016/j.ejpe.2018.07.003

Single-use plastics: New EU rules to reduce marine litter. European Commission - Fact Sheet. MEMO/18/3909. Brussels, 28 May (2018). Updated on 11/06/2018 at 11:40. Web page accessed on 7/30/2021: https://ec.europa.eu/commission/presscorner/detail/en/MEMO_18_3909

Martins LS, Silva NGS, Claro AM, et al (2021) Insight on açaí seed biomass economy and waste cooking oil: eco-sorbent castor oil-based. J Environ Manag 293. https://doi.org/10.1016/j.jenvman.2021.112803

Uz VE, Gökalp İ (2020) Sustainable recovery of waste vegetable cooking oil and aged bitumen: Optimized modification for short and long term aging cases. Waste Manage 110:1–9. https://doi.org/10.1016/j.wasman.2020.05.012

Rosson E, Sgarbossa P, Pedrielli F et al (2021) Bioliquids from raw waste animal fats: an alternative renewable energy source. Biomass Convers Biorefin 11:1475–1490. https://doi.org/10.1007/s13399-020-00634-z

Li J, Li W, Wang L, Jin B (2021) Environmental and cost impacts of food waste in university canteen from a life cycle perspective. Energies 14. https://doi.org/10.3390/en14185907

Fernandes F, Matos S, Gaspar D, et al (2021) Boosting the higher heating value of Eucalyptus globulus via thermochemical liquefaction. Sustainability 13. https://doi.org/10.3390/su13073717

Wang Y-Y, Chang C-C, Chang C-Y, et al (2016) Thermal cracking of Jatropha oil with hydrogen to produce bio-fuel oil. Energies 9. https://doi.org/10.3390/en9110910

Shen Y (2020) A review on hydrothermal carbonization of biomass and plastic wastes to energy products. Biomass Bioenergy 134. https://doi.org/10.1016/j.biombioe.2020.105479

Bezergianni S, Dimitriadis A, Kikhtyanin O, Kubička D (2018) Refinery co-processing of renewable feeds. Prog Energy Combust Sci 68:29–64. https://doi.org/10.1016/j.pecs.2018.04.002

Biswas S, Sharma DK (2012) Synergistic co-processing/co-cracking of Jatropha oil, petroleum vacuum residue, and high density polyethylene. J Renew Sustain Energy 4. https://doi.org/10.1063/1.4737924

Sugumaran V, Sugumaran V, Prakash S, Arora AK et al (2017) Thermal cracking of potato-peel powder-polypropylene biocomposite and characterization of products—Pyrolysed oils and bio-char. J Anal Appl Pyrol 126:405–414. https://doi.org/10.1016/j.jaap.2017.04.014

Behrendt F, Neubauer Y, Oevermann M et al (2008) Direct liquefaction of biomass. Chem Eng Technol 31:667–677. https://doi.org/10.1002/ceat.200800077

Pinto F, Paradela F, Costa P, Andre R, Rodrigues T, Snape C, Herrador JMH, Fratczak J (2018) The role of solvent and catalysts on co-liquefaction of coal and waste. Chem Eng Trans 70:1735–1740. https://doi.org/10.3303/CET1870290

Miandad R, Barakat MA, Aburiazaiza AS et al (2016) Catalytic pyrolysis of plastic waste: a review. Process Saf Environ Prot 102:822–838. https://doi.org/10.1016/j.psep.2016.06.022

Czajczyńska D, Anguilano L, Ghazal H et al (2017) Potential of pyrolysis processes in the waste management sector. Therm Sci Eng Prog 3:171–197. https://doi.org/10.1016/j.tsep.2017.06.003

Herink T, Belohlav Z, Zamostny P, Doskocil J (2006) Application of hydrocarbon cracking experiments to ethylene unit control and optimization. Pet Chem 46:237–245. https://doi.org/10.1134/S0965544106040037

Murat M, Gholami Z, Šimek J, et al (2021) Rendering fat and heavy Fischer-Tropsch waxes mixtures (0–100%) fast pyrolysis tests for the production of ethylene and propylene. Processes 9. https://doi.org/10.3390/pr9020367

Huo E, Lei H, Liu C, et al (2020) Jet fuel and hydrogen produced from waste plastics catalytic pyrolysis with activated carbon and MgO. Sci Total Environ 727. https://doi.org/10.1016/j.scitotenv.2020.138411

Zhang Y, Zhai X, Gao L et al (2017) Quality of wood-pressed rapeseed oil. J Am Oil Chem Soc 94:767–777. https://doi.org/10.1007/s11746-017-2986-y

Vlachos N, Skopelitis Y, Psaroudaki M et al (2006) Applications of Fourier transform-infrared spectroscopy to edible oils. Anal Chim Acta 573–574:459–465. https://doi.org/10.1016/j.aca.2006.05.034

Catauro M, Piccolella S, Leonelli C (2020) FT-IR Characterization of antimicrobial hybrid materials through sol-gel synthesis. Appl Sci 10. https://doi.org/10.3390/app10031180

Rafati A, Tahvildari K, Nozari M (2018) Production of biodiesel by electrolysis method from waste cooking oil using heterogeneous MgO-NaOH nano catalyst. Energy Sources A: Recovery Util Environ Eff 41:1062–1074. https://doi.org/10.1080/15567036.2018.1539139

Fang J, Zhang L, Sutton D et al (2012) Needleless melt-electrospinning of polypropylene nanofibres. J Nanomater 2012:1–9. https://doi.org/10.1155/2012/382639

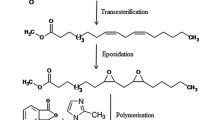

Almazrouei M, Elagroudy S, Janajreh I (2019) Transesterification of waste cooking oil: quality assessment via thermogravimetric analysis. Energy Procedia 158:2070–2076. https://doi.org/10.1016/j.egypro.2019.01.478

Fabiani C, Pisello A, Barbanera M, et al (2019) Assessing the potentiality of animal fat based-bio phase change materials (PCM) for building applications: an innovative multipurpose thermal investigation. Energies 12. https://doi.org/10.3390/en12061111

Al-Maari MA, Ahmad MA, Din ATM, et al (2021) Co-pyrolysis of oil palm empty fruit bunch and oil palm frond with low-density polyethylene and polypropylene for bio-oil production. Arab J Chem 14. https://doi.org/10.1016/j.arabjc.2021.103282

Esmizadeh E, Tzoganakis C, Mekonnen TH (2020) Degradation behavior of polypropylene during reprocessing and its biocomposites: thermal and oxidative degradation kinetics. Polymers 12. https://doi.org/10.3390/polym12081627

Vohlídal J (2021) Polymer degradation: a short review. Chemistry Teacher International 3:213–220. https://doi.org/10.1515/cti-2020-0015

Zhao Y, Wang W, Jing X, et al (2020) Catalytic cracking of polypropylene by using Fe-SBA-15 synthesized in an acid-free medium for production of light hydrocarbon oils. J Anal Appl Pyrolysis 146. https://doi.org/10.1016/j.jaap.2019.104755

Ouchi T, Yamazaki M, Maeda T, Hotta A (2021) Mechanical property of polypropylene gels associated with that of molten polypropylenes. Gels 7. https://doi.org/10.3390/gels7030099

Xing H, Wan D, Qiu J et al (2014) Combined effects between activating group Z and leaving group R in dithiocarbamates for controlling degradation and branching reactions of polypropylene. Polymer 55:5435–5444. https://doi.org/10.1016/j.polymer.2014.09.005

Nikaido S, Suenobu T, Nakagawa T, Katoh R (2019) Delocalization of positive charge in aromatic liquids studied by subnanosecond near-infrared transient absorption spectroscopy. Chem Phys Lett 731. https://doi.org/10.1016/j.cplett.2019.07.006

Huerta-Angeles G, Brandejsová M, Kulhánek J et al (2016) Linolenic acid grafted hyaluronan: process development, structural characterization, biological assessing, and stability studies. Carbohyd Polym 152:815–824. https://doi.org/10.1016/j.carbpol.2016.07.030

Omidghane M, Bartoli M, Asomaning J et al (2020) Pyrolysis of fatty acids derived from hydrolysis of brown grease with biosolids. Environ Sci Pollut Res 27:26395–26405. https://doi.org/10.1007/s11356-020-09041-3

Yarranton HW, Okafor JC, Ortiz DP, van den Berg FGA (2015) Density and refractive index of petroleum, cuts, and mixtures. Energy Fuels 29:5723–5736. https://doi.org/10.1021/acs.energyfuels.5b01376

Hidalgo-Herrador JM, Frątczak J, Velvarská R, de Paz Carmona H (2020) Oxalic acid-mediated catalytic transfer hydrodeoxygenation of waste cooking oil. Mol Catal 491. https://doi.org/10.1016/j.mcat.2020.110973

Schwach P, Hamilton N, Eichelbaum M et al (2015) Structure sensitivity of the oxidative activation of methane over MgO model catalysts: II. Nature of active sites and reaction mechanism. J Catal 329:574–587. https://doi.org/10.1016/j.jcat.2015.05.008

Maher KD, Bressler DC (2007) Pyrolysis of triglyceride materials for the production of renewable fuels and chemicals. Biores Technol 98:2351–2368. https://doi.org/10.1016/j.biortech.2006.10.025

Acknowledgements

This publication is a result of the project CACTU, Reg. No. CZ.02.1.01/0.0/0.0/17_049/0008397, which has been co-financed by the European Union from the European Regional Development Fund through the Operational Programme Research, Development and Education. The result was achieved using the infrastructure of the project Efficient Use of Energy Resources Using Catalytic Processes (LM2018119) which has been financially supported by MEYS within the targeted support of large infrastructures.

Funding

1) Funder: Ministerstvo Školství, Mládeže a Tělovýchovy. Award number: CZ.02.1.01/0.0/0.0/17_049/0008397. 2) Funder: Ministerstvo Školství, Mládeže a Tělovýchovy (Grant number: LM2018119.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by José Miguel Hidalgo Herrador, Martin Babor, Ritik Tomar, and Zdeněk Tišler. The manuscript was written by José Miguel Hidalgo Herrador and contributions of all authors. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Human and animal rights and informed consent

No animals or humans were used for this research work.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hidalgo Herrador, J.M., Babor, M., Tomar, R. et al. Polypropylene and rendering fat degrading to value-added chemicals by direct liquefaction and fast-pyrolysis. Biomass Conv. Bioref. 14, 1027–1036 (2024). https://doi.org/10.1007/s13399-022-02405-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02405-4