Abstract

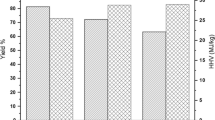

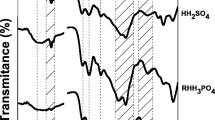

Hydrothermal carbonization (HTC) of biomass is a promising technology for generating value-added products. To reduce expenditure of pure water, reed stalk (RS) was hydrothermally treated under dilute black liquor condition. The physicochemical and combustion properties of RS hydrochars were investigated. The results showed that the coalification degree of hydrochar was improved significantly with increasing of hydrothermal temperature and residence time. The upgrading of coalification degree was attributed to the increment of C content and the reduction of the O, H contents of hydrochar under the reactions of dehydration and decarboxylation. With increasing the coalification degree of hydrochar, the HHV and the energy densification of hydrochar increased. And the energy recovery rate of hydrochar decreased due to the reduction of mass yield. The thermogravimetric results revealed that the mean combustion reactivity of hydrochar at the stage of volatile matter combustion was found to decrease with increasing the coalification degree of hydrochar. The relative sensitivities of mean combustion reactivities to heating rate were also associated with the coalification degree of hydrochar. The research showed that the RS could be transformed into value-added fuel by HTC under dilute black liquor condition. It provides an alternative method to reduce expenditure of HTC process water.

Similar content being viewed by others

References

Fang J, Zhan L, Ok YS, Gao B (2018) Minireview of potential applications of hydrochar derived from hydrothermal carbonization of biomass. J Ind Eng Chem 57:15–21. https://doi.org/10.1016/j.jiec.2017.08.026

Funke A, Ziegler F (2010) Hydrothermal carbonization of biomass: a summary and discussion of chemical mechanisms for process engineering. Biofuels Bioprod Biorefining 4:160–177. https://doi.org/10.1002/bbb.198

Román S, Libra J, Berge N et al (2018) Hydrothermal carbonization: modeling, final properties design and applications: a review. Energies 11:216. https://doi.org/10.3390/en11010216

Titirici M-M, White RJ, Falco C, Sevilla M (2012) Black perspectives for a green future: hydrothermal carbons for environment protection and energy storage. Energy Environ Sci 5:6796–6822. https://doi.org/10.1039/C2EE21166A

Wang T, Zhai Y, Zhu Y et al (2018) A review of the hydrothermal carbonization of biomass waste for hydrochar formation: process conditions, fundamentals, and physicochemical properties. Renew Sustain Energy Rev 90:223–247. https://doi.org/10.1016/j.rser.2018.03.071

Köchermann J, Görsch K, Wirth B et al (2018) Hydrothermal carbonization: temperature influence on hydrochar and aqueous phase composition during process water recirculation. J Environ Chem Eng 6:5481–5487. https://doi.org/10.1016/j.jece.2018.07.053

Wang F, Wang J, Gu C et al (2019) Effects of process water recirculation on solid and liquid products from hydrothermal carbonization of Laminaria. Bioresour Technol 292:121996. https://doi.org/10.1016/j.biortech.2019.121996

Zhou Y, Shi W, Engler N, Nelles M (2021) High-value utilization of kitchen waste derived hydrochar in energy storage regulated by circulating process water. Energy Convers Manag 229:113737. https://doi.org/10.1016/j.enconman.2020.113737

Wang R, Jin Q, Ye X et al (2020) Effect of process wastewater recycling on the chemical evolution and formation mechanism of hydrochar from herbaceous biomass during hydrothermal carbonization. J Clean Prod 277:123281. https://doi.org/10.1016/j.jclepro.2020.123281

Kang S, Li X, Fan J, Chang J (2012) Solid fuel production by hydrothermal carbonization of black liquor. Bioresour Technol 110:715–718. https://doi.org/10.1016/j.biortech.2012.01.093

Zhao Y, Tian Y, Zhou H, Tian Y (2020) Hydrothermal conversion of black liquor to phenolics and hydrochar: characterization, application and comparison with lignin. Fuel 280:118651. https://doi.org/10.1016/j.fuel.2020.118651

Zhang Y, Zahid I, Danial A et al (2021) Hydrothermal carbonization of miscanthus: processing, properties, and synergistic co-combustion with lignite. Energy 225:120200. https://doi.org/10.1016/j.energy.2021.120200

Zhang Z, Zhu Z, Shen B, Liu L (2019) Insights into biochar and hydrochar production and applications: a review. Energy 171:581–598. https://doi.org/10.1016/j.energy.2019.01.035

Zheng X, Chen W, Ying Z et al (2020) Structure–reactivity correlations in pyrolysis and gasification of sewage sludge derived hydrochar: effect of hydrothermal carbonization. Energy Fuels 34:1965–1976. https://doi.org/10.1021/acs.energyfuels.9b04275

Mendoza Martinez CL, Sermyagina E, Saari J et al (2021) Hydrothermal carbonization of lignocellulosic agro-forest based biomass residues. Biomass Bioenergy 147:106004. https://doi.org/10.1016/j.biombioe.2021.106004

Chen X, Ma X, Peng X et al (2018) Conversion of sweet potato waste to solid fuel via hydrothermal carbonization. Bioresour Technol 249:900–907. https://doi.org/10.1016/j.biortech.2017.10.096

Kannan S, Gariepy Y, Raghavan GSV (2017) Optimization and characterization of hydrochar derived from shrimp waste. Energy Fuels 31:4068–4077. https://doi.org/10.1021/acs.energyfuels.7b00093

Liu H, Chen Y, Yang H et al (2020) Hydrothermal treatment of high ash microalgae: focusing on the physicochemical and combustion properties of hydrochars. Energy Fuels 34:1929–1939. https://doi.org/10.1021/acs.energyfuels.9b04093

Lang Q, Luo H, Li Y et al (2019) Thermal behavior of hydrochar from co-hydrothermal carbonization of swine manure and sawdust: effect of process water recirculation. Sustain Energy Fuels 3:2329–2336. https://doi.org/10.1039/C9SE00332K

Sharma HB, Dubey BK (2020) Binderless fuel pellets from hydrothermal carbonization of municipal yard waste: effect of severity factor on the hydrochar pellets properties. J Clean Prod 277:124295. https://doi.org/10.1016/j.jclepro.2020.124295

Zhu X, Liu Y, Qian F et al (2015) Role of hydrochar properties on the porosity of hydrochar-based porous carbon for their sustainable application. ACS Sustain Chem Eng 3:833–840. https://doi.org/10.1021/acssuschemeng.5b00153

Bargmann I, Rillig MC, Kruse A et al (2014) Initial and subsequent effects of hydrochar amendment on germination and nitrogen uptake of spring barley. J Plant Nutr Soil Sci 177:68–74. https://doi.org/10.1002/jpln.201300160

Islam MdA, Kabir G, Asif M, Hameed BH (2015) Combustion kinetics of hydrochar produced from hydrothermal carbonisation of Karanj (Pongamia pinnata) fruit hulls via thermogravimetric analysis. Bioresour Technol 194:14–20. https://doi.org/10.1016/j.biortech.2015.06.094

Santos Santana M, Pereira Alves R, da Silva Borges WM et al (2020) Hydrochar production from defective coffee beans by hydrothermal carbonization. Bioresour Technol 300:122653. https://doi.org/10.1016/j.biortech.2019.122653

Saqib NU, Baroutian S, Sarmah AK (2018) Physicochemical, structural and combustion characterization of food waste hydrochar obtained by hydrothermal carbonization. Bioresour Technol 266:357–363. https://doi.org/10.1016/j.biortech.2018.06.112

Liu F, Yu R, Ji X, Guo M (2018) Hydrothermal carbonization of holocellulose into hydrochar: Structural, chemical characteristics, and combustion behavior. Bioresour Technol 263:508–516. https://doi.org/10.1016/j.biortech.2018.05.019

Hantoro R, Septyaningrum E, Siswanto BB, Izdiharrudin MF (2020) Hydrochar production through the HTC process: case study of municipal solid waste samples in East Java, Indonesia. Solid Fuel Chem 54:418–426. https://doi.org/10.3103/S036152192006004X

Dong X, Guo S, Wang H et al (2019) Physicochemical characteristics and FTIR-derived structural parameters of hydrochar produced by hydrothermal carbonisation of pea pod (Pisum sativum Linn.) waste. Biomass Convers Biorefinery 9:531–540. https://doi.org/10.1007/s13399-018-0363-1

Dong X, Guo S, Ma M et al (2020) Hydrothermal carbonization of millet stalk and dilute-acid-impregnated millet stalk: combustion behaviors of hydrochars by thermogravimetric analysis and a novel mixed-function fitting method. Fuel 273:117734. https://doi.org/10.1016/j.fuel.2020.117734

Guo S, Dong X, Wu T et al (2015) Characteristic evolution of hydrochar from hydrothermal carbonization of corn stalk. J Anal Appl Pyrolysis 116:1–9. https://doi.org/10.1016/j.jaap.2015.10.015

Weber K, Quicker P (2018) Properties of biochar. Fuel 217:240–261. https://doi.org/10.1016/j.fuel.2017.12.054

Channiwala SA, Parikh PP (2002) A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel 81:1051–1063. https://doi.org/10.1016/S0016-2361(01)00131-4

Güleç F, Riesco LMG, Williams O et al (2021) Hydrothermal conversion of different lignocellulosic biomass feedstocks – effect of the process conditions on hydrochar structures. Fuel 302:121166. https://doi.org/10.1016/j.fuel.2021.121166

Zhuang X, Zhan H, Song Y et al (2019) Insights into the evolution of chemical structures in lignocellulose and non-lignocellulose biowastes during hydrothermal carbonization (HTC). Fuel 236:960–974. https://doi.org/10.1016/j.fuel.2018.09.019

Guo S, Dong X, Wu T, Zhu C (2016) Influence of reaction conditions and feedstock on hydrochar properties. Energy Convers Manag 123:95–103. https://doi.org/10.1016/j.enconman.2016.06.029

Wang G, Zhang J, Lee J-Y et al (2020) Hydrothermal carbonization of maize straw for hydrochar production and its injection for blast furnace. Appl Energy 266:114818. https://doi.org/10.1016/j.apenergy.2020.114818

Zhang D, Wang F, Shen X et al (2018) Comparison study on fuel properties of hydrochars produced from corn stalk and corn stalk digestate. Energy 165:527–536. https://doi.org/10.1016/j.energy.2018.09.174

Zhu Y, Si Y, Wang X et al (2018) Characterization of hydrochar pellets from hydrothermal carbonization of agricultural residues. Energy Fuels 32:11538–11546. https://doi.org/10.1021/acs.energyfuels.8b02484

Zhu G, Yang L, Gao Y et al (2019) Characterization and pelletization of cotton stalk hydrochar from HTC and combustion kinetics of hydrochar pellets by TGA. Fuel 244:479–491. https://doi.org/10.1016/j.fuel.2019.02.039

Cai H-Y, Güell AJ, Chatzakis IN et al (1996) Combustion reactivity and morphological change in coal chars: effect of pyrolysis temperature, heating rate and pressure. Fuel 75:15–24. https://doi.org/10.1016/0016-2361(94)00192-8

Qin K, Thunman H (2015) Diversity of chemical composition and combustion reactivity of various biomass fuels. Fuel 147:161–169. https://doi.org/10.1016/j.fuel.2015.01.047

Zhang X, Li Y, Wang M et al (2020) Effects of hydrothermal carbonization conditions on the combustion and kinetics of wheat straw hydrochar pellets and efficiency improvement analyses. Energy Fuels 34:587–598. https://doi.org/10.1021/acs.energyfuels.9b03754

Acknowledgements

We would like to acknowledge the funding support from the National Natural Science Foundation of China (Grant no. 51206194) and the Practice Innovation Training Program Projects for the Jiangsu College Students, China (Grant no. 202111276025Z).

Funding

National Natural Science Foundation of China,51206194,Shuqing Guo,College Students’ Innovation and Entrepreneurship Training Program of Jiangsu Province,202111276025Z,Chen Cheng

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dong, X., Guo, S., Li, S. et al. Physicochemical characteristics and combustion reactivity of reed stalk hydrochar obtained under dilute black liquor condition. Biomass Conv. Bioref. 14, 955–969 (2024). https://doi.org/10.1007/s13399-022-02394-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02394-4