Abstract

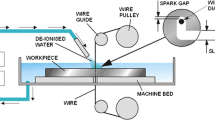

In this research, a novel attempt has been made using silane-treated wheat husk–derived biosilica water dielectric on machining Ti-6Al-4 V titanium alloy. The main aim of this investigation was to improve the machining behavior of Ti-6Al-4 V titanium alloy in electro discharge process using biosilica-activated deionized water dielectric. The biosilica particles had been prepared using thermo-chemical process from wheat husk ash biomass. The dielectric fluid was prepared using simple mixing process and ultrasonically stirred. The microdrilling process was done using a computerized EDM machine with recommended process variables. According to the study, the addition of biosilica particle of significant volume increased the material removal rate and tool’s life. The surface roughness also seemed lesser for biosilica-assisted nanofluid of significant volume. These machining characteristics that improved micro-EDM process could be used to machine high harder defense, automobile, and structural metallic material with high dimensional and functional quality.

Similar content being viewed by others

References

Jain S, Parashar V (2021) Critical review on the impact of EDM process on biomedical materials. Mater Manuf Processes 36(15):1701–1724

Amin, A.K.M.N., Alam, S.T., Islam, M., Amin, M.A., Bashar, M., 2020. An experimental investigation of high-speed end milling of Ti-6Al-4V alloy. Proceedings on International Conference on Mechanical, Industrial and Energy Engineering. Khulna, Bangladesh, December 19–21.

Alam ST, Ahmed M, Khan MA (2021) High-speed end milling of Ti-6l-4V with RSM-GA based optimization and tool wear investigation. J Prod Syst Manuf Sci 2(2):17–33

Phipon, Ruben, IshwerShivakoti, and Ashis Sharma. Sustainable processing of Inconel 718 super alloy in electrical discharge machining process. World J Eng (2020)

Pramanik A, Basak AK, Littlefair G, Debnath S, Prakash C, Singh MeinamAnnebushan, Marla Deepak, Singh Ramesh Kumar (2020) Methods and variables in electrical discharge machining of titanium alloy–a review. Heliyon 6(12):e05554

Priyadarshini M, Behera A, Swain B, Patel S (2020) Multi-objective optimization of EDM process for titanium alloy. Mater Today: Proc 33:5526–5529

Agarwal Neeraj, Shrivastava Nitin, Pradhan MK (2020) Optimization of relative wear ratio during EDM of titanium alloy using advanced techniques. SN Appl Sci 2(1):1–9

Rouniyar Arun Kumar, Shandilya Pragya (2021) Optimization of process parameters in magnetic field assisted powder mixed EDM of aluminium 6061 alloy. Proc Inst Mech Eng, Part C: J Mech Eng Sci 235(16):2998–3014

Bui Viet D, Mwangi James W, Meinshausen Ann-Kathrin, Mueller Andreas J, Bertrand Jessica, Schubert Andreas (2020) Antibacterial coating of Ti-6Al-4V surfaces using silver nano-powder mixed electrical discharge machining. Surf Coat Technol 383:125254

Huu P-N (2020) Multi-objective optimization in titanium powder mixed electrical discharge machining process parameters for die steels. Alex Eng J 59(6):4063–4079

George, Jees, Ravi Chandan, R. Manu, and Jose Mathew. Experimental Investigation of Silicon Powder Mixed EDM Using Graphene and CNT Nano Particle Coated Electrodes. Silicon (2020): 1–17.

Kumar Amit, Mandal Amitava, Dixit Amit Rai, Mandal Deepak Kumar (2020) Quantitative analysis of bubble size and electrodes gap at different dielectric conditions in powder mixed EDM process. Int J Adv Manuf Technol 107(7):3065–3075

Tran T-H, Nguyen M-C, Luu A-T, Le T-Q, Trung-Tuyen Vu, Tran N-G, Do T-T, Ngoc-Pi Vu (2020) Electrical discharge machining with SiC powder-mixed dielectric: an effective application in the machining process of hardened 90CrSi steel. Machines 8(3):36

Wang X, Yi S, Guo H, Li C, Ding S (2020) Erosion characteristics of electrical discharge machining using graphene powder in deionized water as dielectric. Int J Adv Manuf Technol 108(1):357–368

Kiran, P., Shalini Mohanty, and Alok Kumar Das. Surface modification through sustainable micro-EDM process using powder mixed bio-dielectrics. Materials and Manufacturing Processes (2021): 1–12.

Zhu Z, Guo D, Jiao Xu, Lin J, Lei J, Bin Xu, Xiaoyu Wu, Wang X (2020) Processing characteristics of micro electrical discharge machining for surface modification of TiNi shape memory alloys using a TiC powder dielectric. Micromachines 11(11):1018

Effect of silane treated wheat husk biosilica (WHB) deionized water dielectric on EDM drilling of Ti-6Al-4 V alloy. https://doi.org/10.1007/s12633-021-01526-1

Terzioğlu Pinar, Yücel Sevil, Öztürk Mehmet (2016) Synthesis of zeolite NaA from a new biosilica source. Waste Biomass Valorization 7(5):1271–1277

Terzioğlu Pınar, Yücel Sevil, Kuş Çiğdem (2019) Review on a novel biosilica source for production of advanced silica-based materials: wheat husk. Asia-Pac J Chem Eng 14(1):e2262

Rajadurai A (2016) Thermo-mechanical characterization of siliconized E-glass fiber/hematite particles reinforced epoxy resin hybrid composite. Appl Surf Sci 384:99–106

Rajadurai A (2017) Inter laminar shear strength behavior of acid, base and silane treated E-glass fibre epoxy resin composites on drilling process. Defence Technol 13(1):40–46

Nguyen H-P, Pham V-D, Ngo N-V (2018) Application of TOPSIS to Taguchi method for multi-characteristic optimization of electrical discharge machining with titanium powder mixed into dielectric fluid. Int J Adv Manuf Technol 98(5):1179–1198

Wang, Chenxue, and Zhang Qiang. (2019) Comparison of micro-EDM characteristics of Inconel 706 between EDM oil and an Al powder-mixed dielectric. Adv Mater Sci Eng 2019.

Luzia, Cezar Augusto Oleinik, Carlos Augusto Henning Laurindo, Paulo César Soares, Ricardo Diego Torres, Luciano Antonio Mendes, and Fred Lacerda Amorim. (2019) Recast layer mechanical properties of tool steel after electrical discharge machining with silicon powder in the dielectric. Int J Adv Manuf Technol 103.

Mohanty, Shalini, Vishnu Kumar, Rashi Tyagi, Shakti Kumar, Brij Bhushan, Alok Kumar Das, and Amit Rai Dixit. Surface alloying using tungsten disulphide powder mixed in dielectric in micro-EDM on Ti6Al4V. In IOP Conference Series: Materials Science and Engineering, vol. 377, no. 1, p. 012040. IOP Publishing, 2018.

Al-Amin Md, Rani Ahmad Majdi Abdul, Aliyu Abdul Azeez Abdu, Razak Muhammad Alhapis Abdul, Hastuty Sri, Bryant Michael G (2020) Powder mixed-EDM for potential biomedical applications: a critical review. Mater Manuf Proc 35(16):1789–1811

Ahmad, Said, Mohd Amri Lajis, ReazulHaq Abdul Haq, Ahmad Mubarak Tajul Arifin, MohdNasrullAbdol Rahman, Ho Fu Haw, and Haslina Abdullah. (2018) Surface roughness and surface topography of Inconel 718 in powder mixed dielectric electrical discharge machining (PMEDM). Int J Integr Eng 10 5

Author information

Authors and Affiliations

Contributions

All have done equal contribution.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sivakumar, K., Sai Prasanna Kumar, J., Loganathan, K. et al. Machining characteristics of silane-treated wheat husk biosilica in deionized water dielectric on EDM drilling of Ti-6Al-4 V alloy. Biomass Conv. Bioref. 14, 199–206 (2024). https://doi.org/10.1007/s13399-022-02308-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02308-4