Abstract

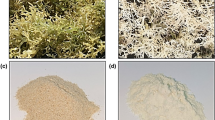

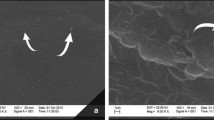

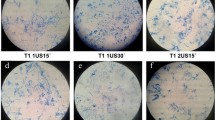

Brewers’ spent grain is an important source of non-starch polysaccharides, such as arabinoxylans. In this paper, a fraction rich in arabinoxylans was extracted from brewers’ spent grain (BSG-AX) by alkaline medium; was characterized by FTIR spectroscopy, scanning electronic microscopy (SEM), and zeta potential; and was used to prepare fourteen thermoplastic films by addition of two plasticizers (glycerol and polypropylene glycol) and a defoamer agent (coconut oil). All films were characterized by FTIR spectroscopy, SEM, and thermogravimetric analysis (TGA). Activation energy (Ea) of the thermal film’s degradation were determined using four models (Broido, Horowitz-Metzger, Coats-Redfern, and Kissigner-Akahira-Sunose), which provide overall kinetic data. Likewise, microbiological analysis of films was performed for assessing their safety. FTIR spectra of BSG-AX films confirm the presence of distinctive functional groups for arabinoxylan, whereas their morphology shows a homogeneous surface structure. Zeta-potential measures suggest that BSG-AX can be considered as a neutral polysaccharide between pH 3 to 10 (values from − 3.44 to − 9.17 mV). Two stages of mass loss were observed in the plasticized films and three for the control (at 113–174 °C, 215–350 °C, and 487–598 °C). The addition of the plasticizer and defoamer agents increases the Ea of the films; namely, the films show greater thermal stability. Besides, the microbiological analysis suggests that the BSG-AX films are safe (absence of total coliforms and 102 CFU g−1 of aerobic mesophylls). In conclusion, plasticized films prepared with BSG-AX have characteristics such as resistance to a wide range of temperatures and can be used as packaging materials.

Similar content being viewed by others

References

Nizamuddin S, Jamal M, Gravina R, Giustozzi F (2020) Recycled plastic as bitumen modifier: the role of recycled linear low-density polyethylene in the modification of physical, chemical and rheological properties of bitumen. J Clean Prod 266:121988. https://doi.org/10.1016/j.jclepro.2020.121988

Sharmila G, Muthukumaran C, Kumar NM, Sivakumar VM, Thirumarimurugan M (2020) Food waste valorization for biopolymer production. In: Varjani S, Pandey A, Gnansounou E, Khanal SK, Raveendran S (eds) Current developments in biotechnology and bioengineering. Resource recovery from wastes. Elsevier, Netherlands, pp 233–249. https://doi.org/10.1016/B978-0-444-64321-6.00012-4

Erum A, Bashir S, Saghir S, Tulain UR, Saleem U, Nasir M, Kanwal F, Hayat MN (2015) Acute toxicity studies of a novel excipient arabinoxylan isolated from Ispaghula (Plantago ovata) husk. Drug Chem Toxicol 38(3):300–305. https://doi.org/10.3109/01480545.2014.956219

Izydorczyk MS, Dexter JE (2008) Barley β-glucans and arabinoxylans: molecular structure, physicochemical properties, and uses in food products–a Review. Food Res Int 41(9):850–868. https://doi.org/10.1016/j.foodres.2008.04.001

Mendis M, Simsek S (2014) Arabinoxylans and human health. Food Hydrocoll 42:239–243. https://doi.org/10.1016/j.foodhyd.2013.07.022

Lynch KM, Steffen EJ, Arendt EK (2016) Brewers’ spent grain: a review with an emphasis on food and health. J Int Brewing 122(4):553–568. https://doi.org/10.1002/jib.363

Mussatto SI (2014) Brewer’s spent grain: a valuable feedstock for industrial applications. J Sci Food Agr 94(7):1264–1275. https://doi.org/10.1002/jsfa.6486

Varma CAK, Kumar KJ (2017) Structural, functional and pH sensitive release characteristics of water-soluble polysaccharide from the seeds of Albizia lebbeck L. Carbohyd Polym 175:502–508. https://doi.org/10.1016/j.carbpol.2017.08.017

Marquez-Escalante JA, Rascón-Chu A, Campa-Mada A, Martínez-Robinson KG, Carvajal-Millan E (2019) Influence of carboxymethylation on the gelling capacity, rheological properties, and antioxidant activity of feruloylated arabinoxylans from different sources. J Appl Polym Sci 137(5):48325. https://doi.org/10.1002/app.48325

Niño-Medina G, Carvajal-Millán E, Lizardi J, Rascon-Chu A, Marquez-Escalante JA, Gardea A, Martinez-Lopez AL, Guerrero V (2009) Maize processing waste water arabinoxylans: Gelling capability and cross-linking content. Food Chem 115(4):1286–1290. https://doi.org/10.1016/j.foodchem.2009.01.046

Pérez-Flores JG, Contreras-López E, Castañeda-Ovando A, Pérez-Moreno F, Aguilar-Arteaga K, Álvarez-Romero GA, Téllez-Jurado A (2019) Physicochemical characterization of an arabinoxylan-rich fraction from brewers’ spent grain and its application as a release matrix for caffeine. Food Res Int 116:1020–1030. https://doi.org/10.1016/j.foodres.2018.09.041

Yilmaz-Turan S, Jiménez-Quero A, Menzel C, de Carvalho DM, Lindström ME, Sevastyanova O, Moriana R, Vilaplana F (2020) Bio-based films from wheat bran feruloylated arabinoxylan: effect of extraction technique, acetylation and feruloylation. Carbohyd Polym 250:116916. https://doi.org/10.1016/j.carbpol.2020.116916

Höije A, Gröndahl M, Tømmeraas K, Gatenholm P (2005) Isolation and characterization of physicochemical and material properties of arabinoxylans from barley husks. Carbohyd Polym 61(3):266–275. https://doi.org/10.1016/j.carbpol.2005.02.009

Mostafavi FS, Zaeim D (2020) Agar-based edible films for food packaging applications — a review. Int J Bio Macromol 159:1165–1179. https://doi.org/10.1016/j.ijbiomac.2020.05.123

Ahmad N, Tayyeb D, Ali I, Alruwaili NK, Ahmad W, Rehman A, Khan AH, Iqbal MS (2020) Development and characterization of hemicellulose-based films for antibacterial wound-dressing application. Polymers 12(3):548. https://doi.org/10.3390/polym12030548

Sriram A, Swaminathan G (2018) Pyrolysis of Musa balbisiana flower petal using thermogravimetric studies. Bioresource Technol 265:236–246. https://doi.org/10.1016/j.biortech.2018.05.043

Balavairavan B, Saravanakumar SS, Manikandan KM (2020) Physicochemical and structural properties of green biofilms from poly (vinyl alcohol)/nano coconut shell filler. J Nat Fibers 29(9):2756–2771. https://doi.org/10.1080/15440478.2020.1723778

Coats AW, Redfern JP (1964) Kinetic parameters from thermogravimetric data. Nature 201:68–69. https://doi.org/10.1038/201068a0

Pourmortazavi SM, Kohsari I, Teimouri MB, Hajimirsadeghi SS (2007) Thermal behaviour kinetic study of dihydroglyoxime and dichloroglyoxime. Mater Lett 61(25):4670–4673. https://doi.org/10.1016/j.matlet.2007.03.041

Robertson JA, I’Anson KJA, Brocklehurst TF, Faulds CB, Waldron KW (2010) Effect of storage conditions on the microbial ecology and biochemical stability of cell wall components in brewers’ spent grain. J Agric Food Chem 58(12):7266–7272. https://doi.org/10.1021/jf1001099

[ICMSF] International Commission for the Microbiological Specifications for Foods (1978) Microorganisms in foods. 1. Their significance and methods of enumeration, 2nd edn. University of Toronto Press, Toronto

Svärd A, Brännvall E, Edlund U (2015) Rapeseed straw as a renewable source of hemicelluloses: Extraction, characterization and film formation. Carbohyd Polym 133:179–186. https://doi.org/10.1016/j.carbpol.2015.07.023

Reisinger M, Tirpanalan Ö, Prückler M, Huber F, Kneifel W, Novalin S (2013) Wheat bran biorefinery—a detailed investigation on hydrothermal and enzymatic treatment. Bioresource Technol 144:179–185. https://doi.org/10.1016/j.biortech.2013.06.088

Werner K, Pommer L, Broström M (2014) Thermal decomposition of hemicelluloses. J Anal Appl Pyrol 110:130–137. https://doi.org/10.1016/j.jaap.2014.08.013

Härdelin L, Ström A, Di Maio E, Iannace S, Larsson A (2018) Microcellular foaming of arabinoxylan and PEGylated arabinoxylan with supercritical CO2. Carbohyd Polym 181:442–449. https://doi.org/10.1016/j.carbpol.2017.09.068

Rohman A (2017) Infrared spectroscopy for quantitative analysis and oil parameters of olive oil and virgin coconut oil: A review. Int J Food Prop 20(7):1447–1456. https://doi.org/10.1080/10942912.2016.1213742

Zhang X, Chen T, Lim J, Gu F, Fang F, Cheng L, Campanella OH, Hamaker BR (2019) Acid gelation of soluble laccase-crosslinked corn bran arabinoxylan and possible gel formation mechanism. Food Hydrocoll 92:1–9. https://doi.org/10.1016/j.foodhyd.2019.01.032

Sousa S, Ramos A, Evtuguin DV, Gamelas JA (2016) Xylan and xylan derivatives—their performance in bio-based films and effect of glycerol addition. Ind Crop Prod 94:682–689. https://doi.org/10.1016/j.indcrop.2016.09.031

Egüés I, Stepa AM, Eceiz A, Toriz G, Gatenholm P, Labidi J (2014) Corncob arabinoxylan for new materials. Carbohyd Polym 102:12–20. https://doi.org/10.1016/j.carbpol.2013.11.011

Kaur A, Singh B, Yadav MP, Bhinder S, Singh N (2021) Isolation of arabinoxylan and cellulose-rich arabinoxylan from wheat bran of different varieties and their functionalities. Food Hydrocoll 112:106287. https://doi.org/10.1016/j.foodhyd.2020.106287

Ostolska I, Wiśniewska M (2014) Application of the zeta potential measurements to explanation of colloidal Cr2O3 stability mechanism in the presence of the ionic polyamino acids. Colloid Polym Sci 292:2453–2464. https://doi.org/10.1007/s00396-014-3276-y

Feng H, Li C, Tan CP, Fu X, Zhang B, Huang Q (2017) Physicochemical properties and in vitro bioaccessibility of lutein loaded emulsions stabilized by corn fiber gums. RSC Adv 7(61):38243–38250. https://doi.org/10.1039/C7RA04943A

Pang Z, Deeth H, Sharma R, Bansal N (2015) Effect of addition of gelatin on the rheological and microstructural properties of acid milk protein gels. Food Hydrocoll 43:340–351. https://doi.org/10.1016/j.foodhyd.2014.06.005

Köhnke J, Gierlinger N, Prats-Mateu B, Unterweger C, Solt P, Mahler AK, Schwaiger E, Liebner F, Gindl-Altmutter W (2019) Comparison of four technical lignins as a resource for electrically conductive carbon particles. BioResources 14(1):1091–1109. https://doi.org/10.15376/biores.14.1.1091-1109

Zhao Y, Sun H, Yang B, Fan B, Zhang H, Weng Y (2021) Enhancement of mechanical and barrier property of hemicellulose film via crosslinking with sodium trimetaphosphate. Polymers 13(6):927. https://doi.org/10.3390/polym13060927

Costa MJ, Cerqueira MA, Ruiz HA, Fougnies C, Richel A, Vicente AA, Teixeira JA, Aguedo M (2015) Use of wheat bran arabinoxylans in chitosan-based films: effect on physicochemical properties. Ind Crop Prod 66:305–311. https://doi.org/10.1016/j.indcrop.2015.01.003

Provder T, Kunz B (1996) Application of profilometry and fractal analysis to the characterization of coatings surface roughness. Prog Org Coat 27:219–226. https://doi.org/10.1016/0300-9440(94)00538-9

Prokopovich P, Perni S (2008) An investigation of microbial adhesion to natural and synthetic polysaccharide-based films and its relationship with the surface energy components. J Mater Sci Mater Med 20(1):195–202. https://doi.org/10.1007/s10856-008-3555-6

Flint SH, Brooks JD, Bremer PJ (2000) Properties of the stainless steel substrate, influencing the adhesion of thermo-resistant streptococci. J Food Eng 43(4):235–242. https://doi.org/10.1016/S0260-8774(99)00157-0

Liu J, Meng CG, Yan YH, Shan YN, Kan J, Jin CH (2016) Structure, physical property and antioxidant activity of catechin grafted Tremella fuciformis polysaccharide. Int J Biol Macromol 82:719–724. https://doi.org/10.1016/j.ijbiomac.2015.11.027

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86(12–13):1781–1788. https://doi.org/10.1016/j.fuel.2006.12.013

Alsamad T, Almazrouei M, Hussain MN, Janajreh I (2018) Modeling of thermochemical conversion of glycerol: pyrolysis and H2O and CO2 gasification. Waste Biomass Valori 9(12):2361–2371. https://doi.org/10.1007/s12649-018-0306-x

Song LX, Guo XQ, Du FY, Bai L (2010) Thermal degradation comparison of polypropylene glycol and its complex with β-cyclodextrin. Polym Degrad Stabil 95(4):508–515. https://doi.org/10.1016/j.polymdegradstab.2009.12.025

Bhasney SM, Patwa R, Kumar A, Katiyar V (2017) Plasticizing effect of coconut oil on morphological, mechanical, thermal, rheological, barrier, and optical properties of poly(lactic acid): a promising candidate for food packaging. J Appl Polym Sci 134(41):45390. https://doi.org/10.1002/app.45390

Yan J, Jia X, Feng L, Yadav M, Li X, Yin L (2019) Rheological and emulsifying properties of arabinoxylans from various cereal brans. J Cereal Sci 90:102844. https://doi.org/10.1016/j.jcs.2019.102844

Xu Y, Chen B (2013) Investigation of thermodynamic parameters in the pyrolysis conversion of biomass and manure to biochars using thermogravimetric analysis. Bioresource Technol 146:485–493. https://doi.org/10.1016/j.biortech.2013.07.086

Acknowledgements

Y. J. H. acknowledges CONACyT, Mexico, for their support through a PhD fellowship. C. T. I., K. A. A., L. G. G. O., N. C. C., D. O. R., and A. C. O.; we also thank Sistema Nacional de Investigadores for the stipend received.

Funding

This research was funded by the Consejo Nacional de Ciencia y Tecnología, Mexico (project number CB-2013–220163).

Author information

Authors and Affiliations

Contributions

Conceptualization, A.C.O.; methodology, Y.J.H., C.T.I., E.P.C.O.; investigation, Y.J.H., K.A.A.; analysis of results, L.G.G.O., A.C.O., E.P.C.O.; writing—original draft preparation, A.C.O., D.O.J.; writing—review and editing, L.G.G.O., N.C.C.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Statement of novelty

The inadequate treatment of food industry by-products can cause a negative environmental impact. The brewers’ spent grain (BGS) is the main by-product of the brewing industry, which is obtained in large quantities and is an important source of polysaccharides (mainly arabinoxylans). This by-product was used to recover arabinoxylans (AXs), that can be considered as high-added-value compounds. Additionally, an arabinoxylan-rich fraction from BSG was used to prepare thermoplastic films. These materials were characterized and showed properties that can be favorable for their potential use as coating or packaging material. The ability of AXs to form films has been previously evaluated; however, this work constitutes an advance in the understanding of thermal stability and the effect of plasticizer addition.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jaguey-Hernández, Y., Tapia-Ignacio, C., Aguilar-Arteaga, K. et al. Thermoplastic biofilms obtained from an arabinoxylan-rich fraction from brewers’ spent grain: physicochemical characterization and thermal analysis. Biomass Conv. Bioref. 13, 14035–14047 (2023). https://doi.org/10.1007/s13399-021-02288-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02288-x