Abstract

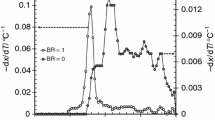

Co-pyrolysis of lignocellulosic biomass and coal is considered as an effective way to reduce the carbon footprint. Bamboo is being a potential source of bioenergy particularly in the North East States of India; the thermal performance and synergetic behaviour of co-pyrolysis of bamboo with high ash Indian coal are investigated at various heating rates in a thermogravimetric analyser. Three different blend samples (25% bamboo with 75% coal, 50% bamboo with 50% coal and 75% bamboo with 25% coal) are used. The kinetic parameters are determined using three isoconversional methods: Friedman, Ozawa-Flynn-Wall and Kissinger–Akahira–Sunose. Average activation energy for all three blend samples is found in the range of 121–253 kJ/mol. Co-pyrolysis of all three blend samples have revealed some synergistic effect. However, the blend containing 25% of bamboo has shown the highest synergetic effect in terms of thermodynamic parameters.

Similar content being viewed by others

Data availability

NA.

References

Panwar NL, Gajera B, Jain S, Salvi BL (2020) Thermogravimetric studies on co-pyrolysis of raw/torrefied biomass and coal blends. Waste Manag Res. https://doi.org/10.1177/0734242X19896624

Konwar K, Nath HP, Bhuyan N, Saikia BK, Borah RC, Kalita AC, Saikia N (2019) Effect of biomass addition on the devolatilization kinetics, mechanisms and thermodynamics of a northeast Indian low rank sub-bituminous coal. Fuel 256:115926. https://doi.org/10.1016/j.fuel.2019.115926

Pattanayak S, Hauchhum L, Loha C, Sailo L (2021) Feasibility study of biomass gasification for power generation in Northeast India. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-021-01419-8

Zhao C, Guo Y, Yan J, Sun J, Li W, Lu P (2019) Enhanced CO2 sorption capacity of amine-tethered fly ash residues derived from co-firing of coal and biomass blends. Appl Energy 242:453–461. https://doi.org/10.1016/j.apenergy.2019.03.143

Quan C, Gao N (2016) Copyrolysis of biomass and coal: a review of effects of copyrolysis parameters, product properties, and synergistic mechanisms, Biomed Res. Int. 2016:1–11. https://doi.org/10.1155/2016/6197867

Yao X, Zhou H, Xu K, Chen S, Ge J, Xu Q (2020) Systematic study on ash transformation behaviour and thermal kinetic characteristics during co-firing of biomass with high ratios of bituminous coal. Renew Energy 147:1453–1468. https://doi.org/10.1016/j.renene.2019.09.103

Deng S, Lu X, Tan H, Wang X, Xiong X (2020) Effects of a combination of biomass addition and atmosphere on combustion characteristics and kinetics of oily sludge. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-020-00697-y

Yousaf B, Liu G, Abbas Q, Wang R, Ubaid Ali M, Ullah H, Liu R, Zhou C (2017) Systematic investigation on combustion characteristics and emission-reduction mechanism of potentially toxic elements in biomass- and biochar-coal co-combustion systems. Appl. Energy. 208:142–157. https://doi.org/10.1016/j.apenergy.2017.10.059

Cordero T, Rodríguez-Mirasol J, Pastrana J, Rodríguez JJ (2004) Improved solid fuels from co-pyrolysis of a high-sulphur content coal and different lignocellulosic wastes. Fuel 83:1585–1590. https://doi.org/10.1016/j.fuel.2004.02.013

Saha GR, Das T, Handique P, Kalita D, Saikia BK (2018) Copyrolysis of low-grade Indian coal and waste plastics: future prospects of waste plastic as a source of fuel. Energy Fuels. 32:2421–2431. https://doi.org/10.1021/acs.energyfuels.7b03298

Ye B, Zhang R, Cao J, Lei K, Liu D (2020) The study of co-combustion characteristics of coal and microalgae by single particle combustion and TGA methods. J Energy Inst 93:508–517. https://doi.org/10.1016/j.joei.2019.07.001

Farrow ST, Sun C, Liu H, Le Manquais K, Snape CE (2020) Comparative study of the inherent combustion reactivity of sawdust chars produced by TGA and in the drop tube furnace. Fuel Process Technol 201:106361. https://doi.org/10.1016/j.fuproc.2020.106361

Mosqueda A, Wei J, Medrano K, Gonzales H, Ding L, Yu G, Yoshikawa K (2019) Co-gasification reactivity and synergy of banana residue hydrochar and anthracite coal blends. Appl Energy 250:92–97. https://doi.org/10.1016/j.apenergy.2019.05.008

Kim JH, Jeong TY, Yu J, Jeon CH (2019) Influence of biomass pretreatment on co-combustion characteristics with coal and biomass blends. J Mech Sci Technol 33:2493–2501. https://doi.org/10.1007/s12206-019-0446-3

Thibanyane N, Agachi P, Danha G (2019) Effects of biomass/coal copyrolysis parameters on the product yield: a review. Procedia Manuf 35:477–487. https://doi.org/10.1016/j.promfg.2019.07.007

Xiang H, Yang J, Feng Z, Hu W, Liang F, Ni L, Gao Q, Liu Z (2019) Investigation of the cofiring process of raw or torrefied bamboo and masson pine by using a cone calorimeter. ACS Omega 4:19246–19254. https://doi.org/10.1021/acsomega.9b02593

Yang Z, Wu Y, Zhang Z, Li H, Li X, Egorov RI, Strizhak PA, Gao X (2019) Recent advances in co-thermochemical conversions of biomass with fossil fuels focusing on the synergistic effects. Renew Sustain Energy Rev 103:384–398. https://doi.org/10.1016/j.rser.2018.12.047

Boukaous N, Abdelouahed L, Chikhi M, Meniai AH, Taouk B (2019) Combustion behaviour of several Mediterranean biomass sources and their blends biomass/char, 2019 10th Int. Renew Energy Congr IREC 2019:1–6. https://doi.org/10.1109/IREC.2019.8754608

Sh L, Jeong TY, Jeon KT, Park KW, Lee BH, Jeon CH (2019) Combustion behaviors of wood pellet fuel and its co-firing with different coals. J Mech Sci Technol 33:4545–4553. https://doi.org/10.1007/s12206-019-0851-7

Chen X, Liu L, Zhang L, Zhao Y, Qiu P (2019) Pyrolysis characteristics and kinetics of coal-biomass blends during co-pyrolysis. Energy Fuels 33:1267–1278. https://doi.org/10.1021/acs.energyfuels.8b03987

Gouws SM, Carrier M, Bunt JR et al (2021) Co-pyrolysis of coal and raw/torrefied biomass: a review on chemistry, kinetics and implementation. Renew Sustain Energy Revi 135:110189

Kang K, Klinghoffer NB, ElGhamrawy I, Berruti F (2021) Thermochemical conversion of agroforestry biomass and solid waste using decentralized and mobile systems for renewable energy and products. Renew Sustain Energy Rev 149:111372

Oladejo J, Adegbite S, Gao X, Liu H, Wu T (2018) Catalytic and non-catalytic synergistic effects and their individual contributions to improved combustion performance of coal/biomass blends. Appl Energy 211:334–345. https://doi.org/10.1016/j.apenergy.2017.11.052

Ly HV, Park JW, Kim S, Hwang HT, Kim J, Woo HC (2020) Catalytic pyrolysis of bamboo in a bubbling fluidized-bed reactor with two different catalysts: HZSM-5 and red mud for upgrading bio-oil. Renew Energy 149:1434–1445

Pattanayak S, Loha C, Hauchhum L, Sailo L (2020) Application of MLP-ANN models for estimating the higher heating value of bamboo biomass. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-020-00685-2

Pattanayak S, Hauchhum L, Loha C, Sailo L (2019) Selection criteria of appropriate bamboo based biomass for thermochemical conversion process. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-019-00421-5

Lin Y, Xiao H, Chen B, Ge Y, He Q, Tao S, Wang W (2020) Thermal behavior and general distributed activation energy model kinetics of lignite–Chinese herb residues blends during co-pyrolysis. Bioresour Technol 304:122991. https://doi.org/10.1016/j.biortech.2020.122991

Li K, Jiang Q, Chen G, Gao L, Peng J, Chen Q, Koppala S, Omran M, Chen J (2021) Kinetics characteristics and microwave reduction behavior of walnut shell-pyrolusite blends. Bioresour Technol 319:124172. https://doi.org/10.1016/j.biortech.2020.124172

Zhao Y, Cao H, Yao C, Li R, Wu Y (2020) Synergistic effects on cellulose and lignite co-pyrolysis and co-liquefaction. Elsevier Ltd. https://doi.org/10.1016/j.biortech.2019.122627

Ndou NR, Bada SO, Falcon RMS, Weiersbye IM (2020) Co-combustion of Searsia lancea and Tamarix usneoides with high ash coal. Fuel 267:117282. https://doi.org/10.1016/j.fuel.2020.117282

Han B, Chen Y, Wu Y, Hua D, Chen Z, Feng W, Yang M, Xie Q (2014) Co-pyrolysis behaviors and kinetics of plastics-biomass blends through thermogravimetric analysis. J Therm Anal Calorim 115:227–235. https://doi.org/10.1007/s10973-013-3228-7

Saeed S, Saleem M, Durrani A (2020) Thermal performance analysis and synergistic effect on co-pyrolysis of coal and sugarcane bagasse blends pretreated by trihexyltetradecylphosphonium chloride. Fuel 278:118240. https://doi.org/10.1016/j.fuel.2020.118240

Khasraw D, Spooner S, Hage H, Meijer K, Li Z (2021) Devolatilisation characteristics of coal and biomass with respect to temperature and heating rate for HIsarna alternative ironmaking process. Fuel 284:119101. https://doi.org/10.1016/j.fuel.2020.119101

Saha D, Sinha A, Pattanayak S, Roy B (2021) Pyrolysis kinetics and thermodynamic parameters of plastic grocery bag based on thermogravimetric data using iso-conversional methods. Int J Environ Sci Technol 2021:1–16. https://doi.org/10.1007/s13762-020-03106-z

Wang C, Wang X, Jiang X, Li F, Lei Y, Lin Q (2019) The thermal behavior and kinetics of co-combustion between sewage sludge and wheat straw. Fuel Process Technol 189:1–14. https://doi.org/10.1016/j.fuproc.2019.02.024

Mi B, Yang X, Liang F, Zhang T, Hu W, Liu Z (2017) Investigating synergistic interaction of bamboo and torrefied bamboo with coal during cocombustion. Wood Fiber Sci 49:249–259

Vyazovkin S, Burnham AK, Criado JM, Pérez-maqueda LA, Popescu C, Sbirrazzuoli N (2011) Thermochimica Acta ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520:1–19. https://doi.org/10.1016/j.tca.2011.03.034

Shahid A, Ishfaq M, Sajjad M, Malik S, Farooq M, Hui Z, Hassan A, Esam M (2019) Bioresource technology bioenergy potential of the residual microalgal biomass produced in city wastewater assessed through pyrolysis, kinetics and thermodynamics study to design algal biorefinery. Bioresour Technol 289:121701. https://doi.org/10.1016/j.biortech.2019.121701

Vuppaladadiyam AK, Liu H, Zhao M, Soomro AF, Memon MZ, Dupont V (2019) Biotechnology for biofuels thermogravimetric and kinetic analysis to discern synergy during the co-pyrolysis of microalgae and swine manure digestate. Biotechnol Biofuels 12:1–18. https://doi.org/10.1186/s13068-019-1488-6

Dhawan H, Upadhyayula S, Sharma DK (2018) Organo-refining to produce near zero ash coals: determination of elemental concentration in clean coals. Energy Fuels 32(6):6535–6544. https://doi.org/10.1021/acs.energyfuels.8b00549

Tian H, Jiao H, Cai J, Wang J, Yang Y, Bridgwater AV (2020) Co-pyrolysis of Miscanthus Sacchariflorus and coals: a systematic study on the synergies in thermal decomposition, kinetics and vapour phase products. Fuel 262:116603. https://doi.org/10.1016/j.fuel.2019.116603

Africa S, Falcon PR (2016) Combustion and physicochemical properties of raw and thermally treated bamboos

Pérez-Jeldres R, Cornejo P, Flores M, Gordon A, García X (2017) A modeling approach to co-firing biomass/coal blends in pulverized coal utility boilers: synergistic effects and emissions profiles. Energy 120:663–674. https://doi.org/10.1016/j.energy.2016.11.116

El-Sayed S (2019) Thermal decomposition, kinetics and combustion parameters determination for two different sizes of rice husk using TGA. Eng Agric Environ Food 12:460–469. https://doi.org/10.1016/j.eaef.2019.08.002

Wei J, Guo Q, Ding L, Yoshikawa K, Yu G (2017) Synergy mechanism analysis of petroleum coke and municipal solid waste (MSW)-derived hydrochar co-gasification. Appl Energy 206:1354–1363. https://doi.org/10.1016/j.apenergy.2017.10.005

Contreras ML, García-Frutos FJ, Bahillo A (2016) Study of the thermal behaviour of coal/biomass blends during oxy-fuel combustion by thermogravimetric analysis. J Therm Anal Calorim 123:1643–1655. https://doi.org/10.1007/s10973-015-5067-1

Liu Z, Hu W, Jiang Z, Mi B, Fei B (2016) Investigating combustion behaviors of bamboo, torrefied bamboo, coal and their respective blends by thermogravimetric analysis. Renew Energy 87:346–352. https://doi.org/10.1016/j.renene.2015.10.039

Pattanayak S, Hauchhum L, Loha C, Sailo L, Mishra L (2021) Experimental investigation on pyrolysis kinetics, reaction mechanisms and thermodynamic parameters of biomass and tar in N2 atmosphere. Sustain Energy Technol Assess 48:101632. https://doi.org/10.1016/j.seta.2021.101632

Acknowledgements

We are thankful to Advanced Research Centre for Bamboo and Rattan, Aizawl, Mizoram, India, for providing the bamboo samples. We are also grateful to Director, CSIR-CMERI and Director NIT Mizoram for their encouragement and support.

Author information

Authors and Affiliations

Contributions

SP, experimentation, literature review and writing the original draft of the manuscript; LH, expert view and supervision of the manuscript; CL, expert view and supervision of the manuscript; LS, supervision of the manuscript; DS, idea, literature review and writing the original draft of the manuscript. All the authors contributed to the research article and approved the final version.

Corresponding author

Ethics declarations

Ethics approval

NA

Consent to participate

NA

Consent for publication

NA

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Pattanayak, S., Hauchhum, L., Loha, C. et al. Thermal performance and synergetic behaviour of co-pyrolysis of North East Indian bamboo biomass with coal using thermogravimetric analysis. Biomass Conv. Bioref. 13, 11755–11768 (2023). https://doi.org/10.1007/s13399-021-02196-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02196-0