Abstract

This work focuses on the design of an effective treatment process for slaughterhouse waste management. Four different treatment sequences were proposed, based on aerobic and anaerobic technologies, as well as thermal and centrifugation pre-treatments. Biochemical methane potential tests were carried out to assess the viability in terms of biodegradability and biogas production of the anaerobic digestion units, which involved different substrates for each proposed process (raw slaughterhouse wastewater, thermal pre-treated slaughterhouse activated sludge, supernatant of thermal pre-treated slaughterhouse sludge, and co-digestion mixture of slaughterhouse wastewater and supernatant of thermal pre-treated slaughterhouse sludge). The obtained results showed that thermal pre-treatment is not effective by itself. However, if it is followed by centrifugation, organic matter removal is importantly improved. In addition, removal efficiency reached 76.0% when employing a co-digestion mixture. Kinetic analyses showed that the specific constant rate of the mixture was 1.5 times higher than with the sole supernatant. Afterwards, the co-digestion mixture was employed as a substrate for an anaerobic sequencing batch reactor working under a semi-continuous operational mode. The influence of organic load rate (OLR) on organic matter removal and biogas production was studied. The best operational OLR range was 1.16–2.16 kg/m3•d, achieving 87.8% of chemical oxygen demand removal and 0.23 LCH4/Ldigester·d of methane production rate. A faster organic load rate than 2.88 kg/m3•d led to bioreactor destabilisation. The obtained results were competitive against published studies that employed different anaerobic technologies and made progress towards the industrial implementation of effective technology in slaughterhouse facilities.

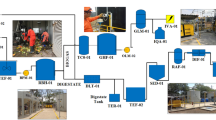

Graphical abstract

Similar content being viewed by others

Abbreviations

- AD:

-

Anaerobic digestion

- ACoD:

-

Anaerobic co-digestion

- AS:

-

Active sludge

- AnSBR:

-

Anaerobic sequencing batch reactor

- COD:

-

Chemical oxygen demand (kg/m3)

- CODs:

-

Soluble chemical oxygen demand (kg/m3)

- CODt:

-

Total chemical oxygen demand (kg/m3)

- HRT:

-

Hydraulic retention time (d)

- K:

-

Specific constant rate from the modified Gompertz model (NLCH4/kgSV0·d)

- SWW:

-

Slaughterhouse wastewater

- TS:

-

Total solids (kg/m3)

- TSS:

-

Thermal pre-treated slaughterhouse sludge

- STSS:

-

Supernatant of thermal pre-treated slaughterhouse sludge

- VFA:

-

Volatile fatty acids

- VS:

-

Volatile solids (kg/m3)

- XCH4:

-

Percentage of methane in the biogas (%)

- YCH4MAX:

-

Maximum methane yield from the modified Gompertz model (NLCH4/kgSV0)

- λ:

-

Lag-phase parameter from the modified Gompertz model (d

- CH4:

-

Relating to methane

- COD:

-

Relating to chemical oxygen demand

- Exp:

-

Relating to experimental data

- Digester:

-

Relating to the operating volume

- Removal:

-

Relating to degradation of organic matter

- VS:

-

Relating to volatile solids

- VS0:

-

Relating to initial volatile solids

References

Bustillo-Lecompte CF, Mehrvar M (2015) Slaughterhouse wastewater characteristics, treatment, and management in the meat processing industry: a review on trends and advances. J Environ Manage 161:287–302

Moukazis I, Pellera FM, Gidarakos E (2018) Slaughterhouse by-products treatment using anaerobic digestion. Waste Manage 71:652–662

Eurostat (2019) European Commission, http://ec.europa.eu/eurostat. Accessed 05/05/2021

Amuda OS, Alade A (2006) Coagulation/flocculation process in the treatment of abattoir wastewater. Desalination 196(1–3):22–31

Aziz A, Basheer F, Sengar A, Khan SU, Farooqi IH (2019) Biological wastewater treatment (anaerobic-aerobic) technologies for safe discharge of treated slaughterhouse and meat processing wastewater. Sci Tota Environ 686:681–708

Eurostat (2018) European Commission, http://ec.europa.eu/eurostat. Accessed 05/05/2021

Salehiyoun AR, Di Maria F, Sharifi M, Norouzi O, Zilouei H, Aghbashlo M (2020) Anaerobic co-digestion of sewage sludge and slaughterhouse waste in existing wastewater digesters. Renew Energy 145:2503–2509

Ortner M, Leitzinger K, Skupien S, Bochmann G, Fuchs W (2014) Efficient anaerobic mono-digestion of N-rich slaughterhouse waste: influence of ammonia, temperature and trace elements. Bioresour Technol 174:222–232

Shende AD, Pophali GR (2020) Anaerobic treatment of slaughterhouse wastewater: a review. Environ Sci Pollut Res 28(1):35–55

Siddiqui YA, Uddin MN, Mofijur M, Fattah IMR, Ong HC, Lam SS, Kumar PS, Ahmed SF (2021) Theoretical calculation of biogas production and greenhouse gas emission reduction potential of livestock, poultry and slaughterhouse waste in Bangladesh. J Environ Chem Eng 9(3):105204

Hamawand I, Baillie C, Hamawand I, Baillie C (2015) Anaerobic digestion and biogas potential: simulation of lab and industrial-scale processes. Energies 8:454–474

Mata-Alvarez J, Dosta J, Romero-Güiza MS, Fonoll X, Peces M, Astals SA (2014) Critical review on anaerobic co-digestion achievements between 2010 and 2013. Renew Sust Energ Rev 36:412–427

Siddique MNI, Wahid ZA (2018) Achievements and perspectives of anaerobic co-digestion: A review. J Clean Prod 194(1):359–371

Wang S, Hawkins GL, Kiepper BH, Das KC (2018) Treatment of slaughterhouse blood waste using pilot scale two-stage anaerobic digesters for biogas production. Renew Energy 126:552–562

Angelidaki I, Alves M, Bolzonella D, Borzacconi L, Campos JL, Guwy AJ, Kalyuzhnyi S, Jenicek P, van Lier JB (2009) Defining the biomethane potential (BMP) of solid organic wastes and energy crops: a proposed protocol for batch assays. Water Sci Technol 59(5):927–934

Pagés-Díaz J, Pereda-Reyes I, Taherzadeh MJ, Sárvári-Horváth I, Lundin M (2014) Anaerobic co-digestion of solid slaughterhouse wastes with agro-residues: synergistic and antagonistic interactions determined in batch digestion assays. Chem Eng J 245:89–98

Pitk P, Kaparaju P, Palatsi J, Affes R, Vilu R (2013) Co-digestion of sewage sludge and sterilized solid slaughterhouse waste: methane production efficiency and process limitations. Bioresour Technol 134:227–232

Rodriguez-Abalde A, Fernandez B, Silvestre G, Flotats X (2011) Effects of thermal pre-treatments on solid slaughterhouse waste methane potential. Waste Manag 31:1488–1493

Mpofu AB, Oyekola OO, Welz PJ (2019) Co-digestion of tannery waste activated sludge with slaughterhouse sludge to improve organic biodegradability and biomethane generation. Process Saf Environ Prot 131:235–245

Pagés-Díaz J, Pereda-Reyes I, Sanz JL, Lundin M, Taherzadeh MJ, Horváth IS (2018) A comparison of process performance during the anaerobic mono-and co-digestion of slaughterhouse waste through different operational modes. J Environ Sci 64:149–156

Awais M, Alvarado-Morales M, Tsapekos P, Gulfraz M, Angelidaki I (2016) Methane production and kinetic modeling for co-digestion of manure with lignocellulosic residues. Energy Fuels 30:10516–10523

Caballero P, Agabo-Garcia C, Solera R, Parrado J, Pérez M (2020) Eco-energetic management of activated sludge derived from slaughterhouse wastewater treatment: pre-treatments for enhancing biogas production under anaerobic conditions. Sustain Energy Fuels 4:5072–5079

Lonagath R, Senophiyah-Mary J (2020) Critical review on the necessity of bioelectricity generation from slaughterhouse industry waste and wastewater using different anaerobic digestion reactors. Renew Sust Energ Rev 134:110360

Borja R, Banks CJ, Wang Z (1995) Effect of organic loading rate on anaerobic treatment of slaughterhouse wastewater in a fluidised-bed reactor. Bioresour Technol 52:157–162

Adou KE, Alle OA, Kouakou AR, Adouby K, Drogui P, Tyagi RD (2020) Anaerobic mono-digestion of wastewater from the main slaughterhouse in Yamoussoukro (Côte d’Ivoire): evaluation of biogas potential and removal of organic pollution. J Environ Chem Eng 8(6):103770

Cuetos MJ, Gómez X, Otero M, Morán A (2008) Anaerobic digestion of solid slaughterhouse waste (SHW) at laboratory scale: influence of co-digestion with the organic fraction of municipal solid waste (OFMSW). Biochem Eng J 40:99–106

Marcos A, Al-Kassir A, Mohamad AA, Cuadros F, López-Rodríguez F (2010) Combustible gas production (methane) and biodegradation of solid and liquid mixtures of meat industry wastes. Appl Energy 87:1729–1735

Marcos A, Al-Kassir A, López F, Cuadros F, Brito P (2012) Environmental treatment of slaughterhouse wastes in a continuously stirred anaerobic reactor: effect of flow rate variation on biogas production. Fuel Process Technol 103:178–182

Diez V, Camara JM, Ruiz MO, Martinez R, Ramos C (2021) A novel jet-loop anaerobic filter membrane bioreactor treating raw slaughterhouse wastewater: Biological and filtration processes. Chem Eng J 408:127288

Jensen PD, Yap SD, Boyle-Gotla A, Janoschka J, Carney C, Pidou M, Batstone DJ (2015) Anaerobic membrane bioreactors enable high rate treatment of slaughterhouse wastewater. Biochem Eng J 97:132–141

León-Becerril E, García-Camacho JE, Del Real-Olvera J, López-López A (2016) Performance of an upflow anaerobic filter in the treatment of cold meat industry wastewater. Process Saf Environ Prot 102:385–391

Dague RR (1993) Anaerobic sequencing batch reactor. U.S. Patent 5,185,079. https://patentimages.storage.googleapis.com/e6/d9/2d/3c1360fa67ae16/US5185079.pdf. Accessed 10/05/2021

Pal S, Banat F, Almansoori A, Haija MA (2016) Review of technologies for biotreatment of refinery wastewaters: progress, challenges and future opportunities. Environ Technol Reviews 5(1):12–38

Mahvi AH (2008) Sequencing batch reactor: a promising technology in wastewater treatment. Iran J Environ Health Sci Eng 5(2):79–90

Ndegwa PM, Hamilton DW, Lalman JA, Cumba HJ (2008) Effects of cycle-frequency and temperature on the performance of anaerobic sequencing batch reactors (ASBRs) treating swine waste. Bioresour Technol 99:1972–1980

Kundu P, Debsarkar A, Mukherjee S (2013) Treatment of slaughter house wastewater in a sequencing batch reactor: performance evaluation and biodegradation kinetics. Biotechnol Environ Monit Pollut Abatement 2013:134872

Massé DI, Massé L (2000) Treatment of slaughterhouse wastewater in anaerobic sequencing batch reactors. Can Agr Eng 42(3):131–137

Ágabo-García C, Solera R, Pérez M (2020) First approaches to valorizate fat, oil and grease (FOG) as anaerobic co-substrate with slaughterhouse wastewater: Biomethane potential, settling capacity and microbial dynamics. Chemosphere 259:127474

Ágabo-García, Pérez M, Rodríguez-Morgado B, Parrado J, Solera R (2019) Biomethane production improvement by enzymatic pre-treatments and enhancers of sewage sludge anaerobic digestion. Fuel 255:115713

Ripoll V, Agabo-García C, Perez M, Solera R (2020) Improvement of biomethane potential of sewage sludge anaerobic co-digestion by addition of “sherry-wine” distillery wastewater. J Clean Prod 251:119667

APHA, AWWA, WPCF (2005) Métodos Normalizados. Para análisis de aguas potables y residuales, 1st edn. Díaz de Santos S.A., Spain

Córdoba V, Fernández M, Santalla E (2016) The effect of different inoculums on anaerobic digestion of swine wastewater. J Environ Chem Eng 4:115–122

Yazdani M, Ebrahimi-Nik M, Heidari A, Abbaspour-Fard MH (2019) Improvement of biogas production from slaughterhouse wastewater using biosynthesized iron nanoparticles from water treatment sludge. Renew Energy 135:496–501

Liu CF, Yuan XZ, Zeng GM, Li WW, Li J (2008) Prediction of methane yield at optimum pH for anaerobic digestion of organic fraction of municipal solid waste. Bioresour Technol 99(4):882–888

Yan L, Ye J, Zhang P, Xu D, Wu Y, Liu J, Zhang H, Fang W, Wang B, Zeng G (2018) Hydrogen sulfide formation control and microbial competition in batch anaerobic digestion of slaughterhouse wastewater sludge: effect of initial sludge pH. Biores Technol 259:67–74

Hamilton DW, Steele MT (2014) Operation and performance of a farm-scale anaerobic sequencing batch reactor treating dilute swine manure. Transactions ASABE 57(5):1473–1482

Ma J, Yu L, Frear C, Zhao Q, Li X, Chen S (2013) Kinetics of psychrophilic anaerobic sequencing batch reactor treating flushed dairy manure. Biores Technol 131:6–12

Ndegwa PM, Hamilton DW, Lalman JA, Cumba HJ (2005) Optimization of anaerobic sequencing batch reactors treating dilute swine slurries. Trans ASAE 48(4):1575–1583

Funding

This work was supported by the 2020 European Horizon research and the innovation programme “Water2Return” (grant number 73098).

Author information

Authors and Affiliations

Contributions

Vanessa Ripoll: methodology, validation, formal analysis, data curation, writing (original draft), visualisation. Cristina Agabo-García: validation, formal analysis, data curation, writing (original draft), visualisation. Rosario Solera: conceptualisation; resources; data curation; writing, review and editing; supervision; project administration; funding acquisition. Montserrat Perez: conceptualisation; resources; data curation; writing, review and editing; supervision; project administration; funding acquisition.

Corresponding author

Ethics declarations

Consent to participate

The authors mutually agree with their participation in the present work.

Consent for publication

The paper is an original work of the authors, and all of them mutually agree with its publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Application of circular economy principles in slaughterhouse industries

• Supernatant of treated slaughterhouse sludge as co-substrate of anaerobic digestion

• Biomethane productivity and specific rate were improved by co-digestion

• AnSBR as an effective technology to manage slaughterhouse wastes

• 80% of depuration grade and 0.21 L/g of methane productivity were achieved

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ripoll, V., Agabo-García, C., Solera, R. et al. Anaerobic digestion of slaughterhouse waste in batch and anaerobic sequential batch reactors. Biomass Conv. Bioref. 13, 11457–11468 (2023). https://doi.org/10.1007/s13399-021-02179-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02179-1