Abstract

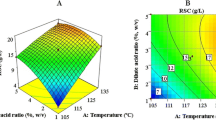

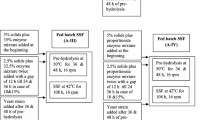

Pyruvate was produced using novel organic macronutrients, pre-treated rice straw and corn steep (CSL) in the media formulation. The results were optimised using response surface methodology and compared using glycerol and jackfruit peel as carbon source. The compromised optimisation of process parameters with rice straw as carbon source reveals significant effects on pyruvate concentration influencing linearly at confidence level at less than 1%. Optimal levels of CSL concentration assisted with incubation time and temperature for glycerol, rice straw, and jackfruit peel resulted in an overall yield of 45.03 g/L, 41.94 g/L, and 40.57 g/L for pyruvate concentration and 0.36 g/L, 0.74 g/L, and 0.87 g/L for reducing sugars, respectively. The purified pyruvate salt extracted from the optimised runs of the three carbon sources was tested using SEM analysis and was found comparable to industrial product.

Similar content being viewed by others

References

Gasmi A, Peana M, Arshad M et al (2021) Krebs cycle: activators, inhibitors and their roles in the modulation of carcinogenesis. Arch Toxicol 95:1161–1178. https://doi.org/10.1007/s00204-021-02974-9

Maleki N, Eiteman MA (2017) Recent progress in the microbial production of pyruvic acid. Fermentation 3:1–17. https://doi.org/10.3390/fermentation3010008

Ghodake GS, Shinde SK, Kadam AA et al (2021) Review on biomass feedstocks, pyrolysis mechanism and physicochemical properties of biochar: state-of-the-art framework to speed up vision of circular bioeconomy. J Clean Prod 297:126645. https://doi.org/10.1016/j.jclepro.2021.126645

Yang D, Tang M, Cai S, et al (2020) Effect of overexpression udha on the production of pyruvate in the E.coli HBUT-P2. In: AIP Conference Proceedings. AIP Publishing LLC, p 20033

Da YY, Liu ZH, Zhu R, Li ZJ (2021) Coutilization of glucose and acetate for the production of pyruvate by engineered Escherichia coli. Biochem Eng J 170:107990. https://doi.org/10.1016/j.bej.2021.107990

Luo Z, Zeng W, Du G et al (2017) A high-throughput screening procedure for enhancing pyruvate production in Candida glabrata by random mutagenesis. Bioprocess Biosyst Eng 40:693–701. https://doi.org/10.1007/s00449-017-1734-x

Rajpurohit H, Eiteman MA (2020) Pretreatment and detoxification of acid-treated wood hydrolysates for pyruvate production by an engineered consortium of Escherichia coli. Appl Biochem Biotechnol 192:243–256. https://doi.org/10.1007/s12010-020-03320-y

Li S, Chen X, Liu L, Chen J (2016) Pyruvate production in Candida glabrata: manipulation and optimization of physiological function. Crit Rev Biotechnol 36:1–10. https://doi.org/10.3109/07388551.2013.811636

Cheng Y-S, Zheng Y, Yu CW et al (2010) Evaluation of high solids alkaline pretreatment of rice straw. Appl Biochem Biotechnol 162:1768–1784. https://doi.org/10.1007/s12010-010-8958-4

Jeya M, Zhang Y-W, Kim I-W, Lee J-K (2009) Enhanced saccharification of alkali-treated rice straw by cellulase from Trametes hirsuta and statistical optimization of hydrolysis conditions by RSM. Bioresour Technol 100:5155–5161. https://doi.org/10.1016/j.biortech.2009.05.040

Soumya B, Gupta PK, Vikas R, Pradeep K (2019) Chemoenzymatic saccharification of Artocarpus heterophyllus Lam.(jackfruit) peel waste and its utilization for bioethanol production. Indian For 145:1204–1209

Ouyang J, Li Z, Li X et al (2009) Enhanced enzymatic conversion and glucose production via two-step enzymatic hydrolysis of corncob residue from xylo-oligosaccharides producer’s waste. BioResources 4:1586–1599. https://doi.org/10.15376/biores.4.4.1586-1599

Pant M, Omre P, Singh T et al (2020) Screening and formulation of culture conditions for pyruvate production by candida glabrata MCC 1800 from corn steep liquor. Int J Chem Stud 8:1290–1294. https://doi.org/10.22271/chemi.2020.v8.i5r.10480

Anthon GE, Barrett DM (2003) Modified method for the determination of pyruvic acid with dinitrophenylhydrazine in the assessment of onion pungency. J Sci Food Agric 83:1210–1213. https://doi.org/10.1002/jsfa.1525

Singh N, Das MK, Ansari A et al (2021) Biogenic nanosized gold particles: physico-chemical characterization and its anticancer response against breast cancer. Biotechnol Rep 30:e00612. https://doi.org/10.1016/j.btre.2021.e00612

Arora R, Behera S, Sharma NK et al (2020) Bioprospecting saccharification of alkali pretreated paddy straw through statistically designed parameters for biofuel production. Ind Biotechnol 16:375–385. https://doi.org/10.1089/ind.2020.0015

Prasad S, Kumar S, Yadav KK et al (2020) Screening and evaluation of cellulytic fungal strains for saccharification and bioethanol production from rice residue. Energy 190:116422. https://doi.org/10.1016/j.energy.2019.116422

Chen H, Huo W, Wang B et al (2019) L-lactic acid production by simultaneous saccharification and fermentation of dilute ethylediamine pre-treated rice straw. Ind Crops Prod 141:111749. https://doi.org/10.1016/j.indcrop.2019.111749

Valles A, Álvarez-Hornos FJ, Martínez-Soria V et al (2020) Comparison of simultaneous saccharification and fermentation and separate hydrolysis and fermentation processes for butanol production from rice straw. Fuel 282:118831. https://doi.org/10.1016/j.fuel.2020.118831

Dong L, Wu X, Wang Q et al (2020) Evaluation of a novel pretreatment of NaOH/Urea at outdoor cold-winter conditions for enhanced enzymatic conversion and hythane production from rice straw. Sci Total Environ 744:140900. https://doi.org/10.1016/j.scitotenv.2020.140900

Schmatz AA, Salazar-Bryam AM, Contiero J et al (2021) Pseudo-lignin content decreased with hemicellulose and lignin removal, improving cellulose accessibility, and enzymatic digestibility. Bioenergy Res 14:106–121. https://doi.org/10.1007/s12155-020-10187-8

Zhang H, Han L, Dong H (2021) An insight to pretreatment, enzyme adsorption and enzymatic hydrolysis of lignocellulosic biomass: experimental and modeling studies. Renew Sustain Energy Rev 140:110758. https://doi.org/10.1016/j.rser.2021.110758

Kang CK, Jeong SW, Yang JE, Choi YJ (2020) High-yield production of lycopene from corn steep liquor and glycerol using the metabolically engineered Deinococcus radiodurans R1 strain. J Agric Food Chem 68:5147–5153. https://doi.org/10.1021/acs.jafc.0c01024

Zhang J, Jia B (2018) Enhanced butanol production using Clostridium beijerinckii SE-2 from the waste of corn processing. Biomass Bioenergy 115:260–266. https://doi.org/10.1016/j.biombioe.2018.05.012

Acknowledgements

The authors are grateful to TEQIP-III (Technical Education Quality Improvement Programme-Phase III) for the scholarship, and to College of Technology, GBPUAT, Pantnagar for providing necessary facilities to conduct the research work. We are also thankful to NAHEP (National Agricultural Higher Education Project) for the financial support in the patent provisions and associated funds.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The research reported in this manuscript is part of a patent.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Pant, M., Joshi, T., Omre, P.K. et al. Development of novel media formulation using rice straw and corn steep liquor for pyruvate production. Biomass Conv. Bioref. 13, 11621–11629 (2023). https://doi.org/10.1007/s13399-021-02057-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02057-w