Abstract

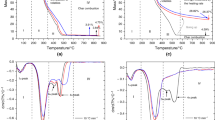

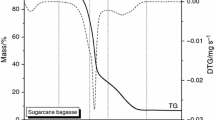

The combustion behavior, chemical kinetics, and thermodynamic parameters of Poinciana cover and Poinciana seeds were investigated using TGA at different heating rates in the air atmosphere. Kinetic characteristic parameters were estimated by adopting five traditional and parallel kinetic models besides the DTA technique. Functional group properties using FTIR were presented and discussed. The physicochemical characteristics of these materials assured their bioenergy potential for conversion into valuable, sustainable, and renewable energy resources. The activation energy values calculated from DTA measurements for Poinciana cover and seeds were found to be in good agreement with the kinetic data obtained by parallel methods using TGA data. The significant variations of the values of the pre-exponential factor of the Poinciana cover confirm the presence of a complex multi-step reaction during its combustion. DTG profiles of the Poinciana cover showed one sharp peak with a high mass loss rate value in a short time required high energy and resulted in high activation energy values. Also, the high ash content of this material resisted the oxygen diffusion and delayed the ignition which in turn played a key role in raising the activation energy values. The higher volatile content of Poinciana seeds and its high IR absorbance helped in lowering the activation energy values obtained from various models. Advanced ignition and delayed burnout give the Poinciana seeds superiority over Poinciana cover as a new alternative source of energy. The Gibbs free energy (ΔG) values of Poinciana seed material are higher than those of Poinciana cover either for the total conversion process of the volatiles and char conversion. This result reflects the bioenergy potential of Poinciana seeds through oxidation. The resulted high entropy change (\(\Delta S\)) values for the poinciana cover material ensure that this material is far from its thermodynamic equilibrium and its reactivity is high.

Similar content being viewed by others

Abbreviations

- \({\alpha }_{cal}\) :

-

The conversion value calculated from the regression equation

- \({\alpha }_{exp,i}\) :

-

Experimental fractional conversion corresponding to the temperature \((T_{i})\)

- \({\alpha }_{model,i}\) :

-

The conversion value calculated from the model at temperature \(T_{i}\)

- \({\left({~}^{dm}\!\left/ \!\!{~}_{dt}\right.\right)}_{ av}\) :

-

Average mass loss rate under oxidative atmosphere at temperatures ranged from \(T_{ig}\) to \(T_{bo}\), \(\%/min\)

- \({\left({~}^{dm}\!\left/ \!\!{~}_{dt}\right.\right)}_{ peak}\) :

-

Maximum combustion rate, \(\%/min\)

- \({\left({~}^{dm}\!\left/ \!\!{~}_{dt}\right.\right)}_{DTG, peak}\) :

-

Maximum rate of mass loss, \(\%/min\)

- \({\Delta T}_{0.5}\) :

-

Temperature range of \(({(dm/dt)}_{DTG,peak}/{(dm/dt)}_{peak})=0.5\), °C

- \({\Delta t}_{0.5}\) :

-

Time range \(({(dm/dt)}_{DTG,peak}/{(dm/dt)}_{peak})=0.5\) , \(min\)

- \({{\alpha }}_{\text{vol}}\) :

-

Volatiles conversion fraction, %

- \({{\alpha }}_{ch}\) :

-

Char conversion fraction, %

- \({C}_{si}\) :

-

Combustion stability index, \(\%/min\;^\circ C^2\)

- \({D}_{bo}\) :

-

Burnout index, \(\%/min^4\)

- \({D}_{i}\) :

-

Ignition index, \(\%/min^3\)

- E :

-

Activation energy \((kJ/mole)\)

- \({E}_{ch}\) :

-

Char activation energy, kJ/mole

- \({E}_{dir}\) :

-

Direct activation energy of the decomposition reaction, kJ /mole

- \({E}_{fit}\) :

-

Activation energy of the decomposition reaction obtained from the fitting method, kJ /mole

- \({E}_{vol}\) :

-

Volatiles activation energy, kJ/mole

- \({H}_{f}\) :

-

Combustion intensity \(^\circ C\)

- \({K}_{B}\) :

-

Boltzmann constant, \(1.381\times10^{-23}\;J/K\)

- \({P}_{g}\) :

-

Partial pressure of the reactive gas, Pa

- \({R}_{M}\) :

-

Reactivity, \(\%/min\;^\circ C\)

- S :

-

Comprehensive combustion index \((\%/{min}^2\;^\circ C^3)\) ,

- \({S}_{c, o}\) :

-

Initial specific surface area of raw material, \(cm^2/gm\)

- \({S}_{c}\) :

-

Specific surface area of the produced char, \(cm^2/gm\)

- T o :

-

Initial temperature, °C

- \({T}_{bo}\) :

-

Burnout temperature, °C

- \({T}_{ig}\) :

-

Ignition temperature, ℃

- \({T}_{in}\) :

-

Temperature of the beginning of the phase transition process, K

- \({T}_{peak}\) :

-

Temperature corresponding to the maximum rate of mass loss, ℃

- \({c}_{ch}\) :

-

Mass fraction of char in the biomass material, %

- \({c}_{vol}\) :

-

Mass fraction of volatiles in the biomass material, %

- \({k}_{o, ch}\) :

-

Char frequency factor, min−1

- \({k}_{o, vol}\) :

-

Volatiles frequency factor, min−1

- \({k}_{o}\) :

-

Frequency factor, min−1

- \({max \alpha }_{exp,i}\) :

-

Highest absolute value of experimental fractional conversion

- \({m}_{f}\) :

-

Final mass of any zone, mg

- \({m}_{i}\) :

-

Initial mass of any zone, mg

- \({m}_{v}\) :

-

Instantaneous mass of volatiles at any time (t), mg

- \({m}_{v}\) :

-

Mass of volatiles at a time (t), mg

- \({m}_{vf}\) :

-

Final mass of volatile zone, mg

- \({m}_{vi}\) :

-

Initial mass of volatile zone, mg

- t :

-

Time corresponding to conversion \((min)\)

- \({t}_{0.9}\) :

-

Time for 90% conversion of the combustible substances, \(min\)

- \({t}_{bo}\) :

-

Time corresponding to the burnout temperature, \(min\)

- \({t}_{ig}\) :

-

Time corresponding to the ignition temperature, \(min\)

- \({t}_{peak}\) :

-

Time corresponding to the maximum combustion rate, \(min\)

- \({\alpha }_{model,i}\) :

-

Conversion value calculated from the model at temperature \((T_i)\)

- \(\Delta G\) :

-

Gibbs free energy, \((kJ/mole)\)

- \(\Delta H\) :

-

Enthalpy change, \((kJ/mole)\)

- \(\Delta S\) :

-

Entropy change, \((kJ/mole)\;K\)

- \(h\) :

-

Plank constant, \(6.626\times10^{-34}\;J.s\)

- S :

-

Comprehensive combustion index, \(\%/{min}^2\;^\circ C^3\)

- τ:

-

Duration time of the transition process, \(min\)

- \(E\) :

-

Activation energy, kJ/mole

- \(M\) :

-

Moisture content, %

- \(N\) :

-

Number of data points

- \(R\) :

-

Universal gas constant, \(8.314J/mole\;K\)

- \(T\) :

-

Reaction temperature, K

- \(f\)(\({\alpha }\)):

-

The change in the physical and chemical characteristics of the fuel sample during the conversion process

- \(k\) :

-

The apparent reaction rate, min−1

- P g :

-

Partial pressure of gas, Pa

- \(p\left(x\right)\) :

-

Reaction model function

- \(t\) :

-

Time corresponding to conversion,\(min\)

- DRPM:

-

Double random pore model

- DVM:

-

Double parallel volumetric model

- MVRPM:

-

Mixed volumetric random pore model

- RPM:

-

Random pore model

- RSS:

-

Residual sum of squares

- TGA:

-

Thermal gravimetric analysis

- VM:

-

Volumetric model

- GM:

-

Grain model

- α :

-

Degree of conversion, %

- β :

-

Heating rate, °C/min

- \(\psi\) :

-

Structural parameter

References

Ceylan S, Topcu Y, Ceylan Z (2014) Thermal behaviour and kinetics of alga Polysiphonia elongata biomass during pyrolysis. Bioresour Technol 171:193–198

Shen Y, Li X, Yao Z et al (2019) CO2 gasification of woody biomass: experimental study from a lab-scale reactor to a small-scale autothermal gasifier. Energy 170:497–506

Zhao P, Shen Y, Ge S et al (2014) Clean solid biofuel production from high moisture content waste biomass employing hydrothermal treatment. Appl Energy 131:345–367

El-Sayed SA, Mostafa ME (2014) Pyrolysis characteristics and kinetic parameters determination of biomass fuel powders by differential thermal gravimetric analysis (TGA/DTG). Energy Convers Manag 85:165–172

Ceylan S, Topçu Y (2014) Pyrolysis kinetics of hazelnut husk using thermogravimetric analysis. Bioresour Technol 156:182–188

Oladokun O, Ahmad A, Abdullah TAT et al (2016) Multicomponent devolatilization kinetics and thermal conversion of Imperata cylindrica. Appl Therm Eng 105:931–940. https://doi.org/10.1016/J.APPLTHERMALENG.2016.04.165

Zhang Y, Guo Y, Cheng F et al (2015) Investigation of combustion characteristics and kinetics of coal gangue with different feedstock properties by thermogravimetric analysis. Thermochim Acta 614:137–148. https://doi.org/10.1016/j.tca.2015.06.018

Xu C, Hu S, Xiang J et al (2014) Kinetic models comparison for steam gasification of coal / biomass blend chars. Bioresour Technol 171:253–259

Gil MV, Riaza J, Álvarez L et al (2012) Oxy-fuel combustion kinetics and morphology of coal chars obtained in N2 and CO2 atmospheres in an entrained flow reactor. Appl Energy 91:67–74

Gil MV, Riaza J, Álvarez L et al (2012) Kinetic models for the oxy-fuel combustion of coal and coal / biomass blend chars obtained in N2 and CO2 atmospheres. Energy 48:510–518

Wang G, Zhang J, Shao J et al (2015) Investigation of non-isothermal and isothermal gasification process of coal char using different kinetic model. Int J Min Sci Technol 25:15–21

Wang G, Zhang J, Hou X et al (2015) Study on CO2 gasification properties and kinetics of biomass chars and anthracite char. Bioresour Technol 177:66–73

Zhang J, Wang G, Shao J, Zuo H (2014) A modified random pore model for the kinetics of char gasification. BioResources 9:3497–3507

Mafu LD, Neomagus HWJP, Everson RC et al (2018) The carbon dioxide gasification characteristics of biomass char samples and their effect on coal gasification reactivity during co-gasification. Bioresour Technol 258:70–78

Al-Qayim K, Nimmo W, Hughes K, Pourkashanian M (2017) Kinetic parameters of the intrinsic reactivity of woody biomass and coal chars via thermogravimetric analysis. Fuel 210:811–825

Wang GW, Zhang JL, Shao JG et al (2016) Experiments and kinetic modeling for the oxidative decomposition of herbaceous and wooden residues. BioResources 11:4821–4838

Wang G, Zhang J, Shao J, Ren S (2014) Characterisation and model fitting kinetic analysis of coal/biomass co-combustion. Thermochim Acta 591:68–74

Shao J, Zhang J, Wang G et al (2014) Combustion Property and kinetic modeling of pulverized coal based on non-isothermal thermogravimetric analysis. J Iron Steel Res Int 21:1002–1008

Mostafa ME, He L, Xu J et al (2019) Investigating the effect of integrated CO2 and H2O on the reactivity and kinetics of biomass pellets oxy-steam combustion using new double parallel volumetric model (DVM). Energy 179:343–357. https://doi.org/10.1016/j.energy.2019.04.206

El-Sayed SA, Mostafa ME (2020) Thermal pyrolysis and kinetic parameter determination of mango leaves using common and new proposed parallel kinetic models. RSC Adv 10:18160–18179. https://doi.org/10.1039/d0ra00493f

(2020) The British Petroleum Company BP Statistical Review of World Energy Report

Abdelhady S, Shalaby MA, Shaban A (2021) Techno-economic analysis for the optimal design of a national network of agro-energy biomass power plants in Egypt. Energies 14:3063. https://doi.org/10.3390/EN14113063

Röder M, Whittaker C, Thornley P (2015) How certain are greenhouse gas reductions from bioenergy? Life cycle assessment and uncertainty analysis of wood pellet-to-electricity supply chains from forest residues. Biomass Bioenerg 79:50–63

Olagbende HO, Aransiola EF, Ogunsina BS et al (2016) Modification of a fixed bed reactor system for pyrolytic conversion of royal poinciana pods into alternative fuels. Int J Renew Energy Res 6:1350–1360

Karmakar B, Samanta S, Halder G (2020) Delonix regia heterogeneous catalyzed two-step biodiesel production from Pongamia pinnata oil using methanol and 2-propanol. J Clean Prod 255:120313. https://doi.org/10.1016/J.JCLEPRO.2020.120313

Lu J-JJ, Chen W-HH (2015) Investigation on the ignition and burnout temperatures of bamboo and sugarcane bagasse by thermogravimetric analysis. Appl Energy 160:49–57. https://doi.org/10.1016/j.apenergy.2015.09.026

El may Y, Jeguirim M, Dorge S et al (2012) Study on the thermal behavior of different date palm residues: characterization and devolatilization kinetics under inert and oxidative atmospheres. Energy 44:702–709

Peng C, Zhai Y, Zhu Y et al (2016) Production of char from sewage sludge employing hydrothermal carbonization: char properties, combustion behavior and thermal characteristics. Fuel 176:110–118

Xinjie L, Singh S, Yang H et al (2021) A thermogravimetric assessment of the tri-combustion process for coal, biomass and polyethylene. Fuel 287:119355. https://doi.org/10.1016/j.fuel.2020.119355

Mureddu M, Dessì F, Orsini A et al (2018) Air- and oxygen-blown characterization of coal and biomass by thermogravimetric analysis. Fuel 212:626–637. https://doi.org/10.1016/J.FUEL.2017.10.005

Wang G, Zhang J, Shao J et al (2016) Experimental and modeling studies on CO2 gasification of biomass chars. Energy 114:143–154

Bhatia SK, Perlmutter DD (1980) A random pore model for fluid-solid reoctions : l. lsothermal. Kinetic Control AIChE J 26:379–386

Gao X, Zhang Y, Li B et al (2016) Determination of the intrinsic reactivities for carbon dioxide gasification of rice husk chars through using random pore model. Bioresour Technol 218:1073–1081

Everson RC, Neomagus HWJP, Kaitano R et al (2008) Properties of high ash coal-char particles derived from inertinite-rich coal: II. Gasification kinetics with carbon dioxide Fuel 87:3403–3408

Boycheva S, Zgureva D, Vassilev V (2013) Kinetic and thermodynamic studies on the thermal behaviour of fly ash from lignite coals. Fuel 108:639–646. https://doi.org/10.1016/j.fuel.2013.02.042

Alves JLF, Da Silva JCG, da Silva Filho VF et al (2019) Bioenergy potential of red macroalgae Gelidium floridanum by pyrolysis: evaluation of kinetic triplet and thermodynamics parameters. Bioresour Technol 291:121892. https://doi.org/10.1016/j.biortech.2019.121892

Edreis EMA, Li X, Atya AHA et al (2020) Kinetics, thermodynamics and synergistic effects analyses of petroleum coke and biomass wastes during H2O co-gasification. Int J Hydrogen Energy 45:24502–24517. https://doi.org/10.1016/j.ijhydene.2020.06.239

(2010) EN 14961–1, Solid biofuels. Fuel specification and classes, Part 1: General requirements

Bhavanam A, Sastry RCC (2015) Kinetic study of solid waste pyrolysis using distributed activation energy model. Bioresour Technol 178:126–131 (Contents)

El-Sayed SA, Khairy M (2015) Effect of heating rate on the chemical kinetics of different biomass pyrolysis materials. Biofuels 6:157–170. https://doi.org/10.1080/17597269.2015.1065590

El-Sayed SA, Mostafa MEME (2015) Kinetic parameters determination of biomass pyrolysis fuels using TGA and DTA techniques. Waste and Biomass Valorization 6:401–415. https://doi.org/10.1007/s12649-015-9354-7

Agar DA, Rudolfsson M, Kalén G et al (2018) A systematic study of ring-die pellet production from forest and agricultural biomass. Fuel Process Technol 180:47–55

Raj T, Kapoor M, Gaur R et al (2015) Physical and chemical characterization of various Indian agriculture residues for biofuels production. Energy Fuels 29:3111–3118. https://doi.org/10.1021/EF5027373

Mishra RK, Mohanty K (2018) Pyrolysis kinetics and thermal behavior of waste sawdust biomass using thermogravimetric analysis. Bioresour Technol 251:63–74. https://doi.org/10.1016/J.BIORTECH.2017.12.029

Mlonka-Mędrala A, Magdziarz A, Gajek M et al (2020) Alkali metals association in biomass and their impact on ash melting behaviour. Fuel 261:116421. https://doi.org/10.1016/J.FUEL.2019.116421

Deng L, Zhang T, Che D (2013) Effect of water washing on fuel properties, pyrolysis and combustion characteristics, and ash fusibility of biomass. Fuel Process Technol 106:712–720. https://doi.org/10.1016/J.FUPROC.2012.10.006

Ma C, Weiland F, Hedman H et al (2013) Characterization of reactor ash deposits from pilot-scale pressurized entrained-flow gasification of woody biomass. Energy Fuels 27:6801–6814. https://doi.org/10.1021/EF401591A

Ahmad MS, Mehmood MA, Liu CG et al (2018) Bioenergy potential of Wolffia arrhiza appraised through pyrolysis, kinetics, thermodynamics parameters and TG-FTIR-MS study of the evolved gases. Bioresour Technol 253:297–303. https://doi.org/10.1016/j.biortech.2018.01.033

Viswanath SG, Gupta MC (1996) Estimation of nonisothermal kinetic parameters from a TG curve by the methods of overdetermined system and inflection point. Thermochim Acta 285:259–267. https://doi.org/10.1016/0040-6031(96)02917-6

Ren J, Xie C, Guo X et al (2014) Combustion characteristics of coal gangue under an atmosphere of coal mine methane. Energy Fuels 28:3688–3695. https://doi.org/10.1021/ef500446j

Zhang X, Xu M, Sun R, Sun L (2006) Study on biomass pyrolysis kinetics. J Eng Gas Turbines Power 128:493–496. https://doi.org/10.1115/1.2135816

Huang J, Liu J, Chen J et al (2018) Combustion behaviors of spent mushroom substrate using TG-MS and TG-FTIR: thermal conversion, kinetic, thermodynamic and emission analyses. Bioresour Technol 266:389–397. https://doi.org/10.1016/J.BIORTECH.2018.06.106

Wilson L, Yang W, Blasiak W et al (2011) Thermal characterization of tropical biomass feedstocks. Energy Convers Manag 52:191–198. https://doi.org/10.1016/j.enconman.2010.06.058

Biagini E*, Barontini F, Tognotti L (2006) Devolatilization of biomass fuels and biomass components studied by TG/FTIR technique. Ind Eng Chem Res 45:4486–4493. https://doi.org/10.1021/IE0514049

Avila C, Wu T, Lester E (2014) Estimating the spontaneous combustion potential of coals using thermogravimetric analysis. In: Energy and Fuels. Am Chem Soc 28:1765–1773

Chen J, Liu J, He Y et al (2017) Investigation of co-combustion characteristics of sewage sludge and coffee grounds mixtures using thermogravimetric analysis coupled to artificial neural networks modeling. Bioresour Technol 225:234–245. https://doi.org/10.1016/j.biortech.2016.11.069

Zhang J, Liu J, Evrendilek F et al (2019) Kinetics, thermodynamics, gas evolution and empirical optimization of cattle manure combustion in air and oxy-fuel atmospheres. Appl Therm Eng 149:119–131. https://doi.org/10.1016/j.applthermaleng.2018.12.010

Ge L, Zhang Y, Wang Z et al (2013) Effects of microwave irradiation treatment on physicochemical characteristics of Chinese low-rank coals. Energy Convers Manag 71:84–91. https://doi.org/10.1016/j.enconman.2013.03.021

Wang H, You C (2014) Experimental investigation into the spontaneous ignition behavior of upgraded coal products. In: Energy and Fuels. Am Chem Soc 28:2267–2271

Wang G, Zhang J, Shao J et al (2016) Thermal behavior and kinetic analysis of co-combustion of waste biomass/low rank coal blends. Energy Convers Manag 124:414–426

Wang G, Zhang J, Chang W et al (2018) Structural features and gasification reactivity of biomass chars pyrolyzed in different atmospheres at high temperature. Energy 147:25–35

Sy O, DiY S Y et al (2005) Crystalline structure analysis of cellulose treated with sodium hydroxide and carbon dioxide by means of X-ray diffraction and FTIR spectroscopy. Carbohydr Res 340:2376–2391. https://doi.org/10.1016/J.CARRES.2005.08.007

Colom X, Carrillo F, Nogués F, Garriga P (2003) Structural analysis of photodegraded wood by means of FTIR spectroscopy. Polym Degrad Stab 80:543–549. https://doi.org/10.1016/S0141-3910(03)00051-X

Hsu TC, Guo GL, Chen WH, Hwang WS (2010) Effect of dilute acid pretreatment of rice straw on structural properties and enzymatic hydrolysis. Bioresour Technol 101:4907–4913. https://doi.org/10.1016/J.BIORTECH.2009.10.009

Sánchez Orozco R, Balderas Hernández P, Roa Morales G et al (2014) Characterization of lignocellulosic fruit waste as an alternative feedstock for bioethanol production. BioResources 9:1873–1885. https://doi.org/10.15376/BIORES.9.2.1873-1885

Sun XF, Xu F, Sun RC et al (2005) Characteristics of degraded cellulose obtained from steam-exploded wheat straw. Carbohydr Res 340:97–106. https://doi.org/10.1016/J.CARRES.2004.10.022

Mokti N, Azizan A, Shafaei SM et al (2016) Fourier transform infrared spectroscopy interpretation on pretreated Acacia Auriculiformis, Melastoma Malabathricum and Leucaeana Leucocephala. Int J Appl Eng Res 11:10048–10051

Munajad A, Subroto C, Suwarno (2018) Fourier transform infrared (FTIR) spectroscopy analysis of transformer paper in mineral oil-paper composite insulation under accelerated thermal aging. Energies 11:364 11-364. https://doi.org/10.3390/EN11020364

Zhang L, Zou C, Wu D et al (2016) A study of coal chars combustion in O2/H2O mixtures by thermogravimetric analysis. J Therm Anal Calorim 126:995–1005

Alvarez J, Lopez G, Amutio M et al (2019) Evolution of biomass char features and their role in the reactivity during steam gasification in a conical spouted bed reactor. Energy Convers Manag 181:214–222

Fatehi H, Bai X-S (2015) Effect of pore size on the gasification of biomass char. Energy Procedia 75:779–785

Wu Z, Ma C, Jiang Z, Luo Z (2019) Structure evolution and gasification characteristic analysis on co-pyrolysis char from lignocellulosic biomass and two ranks of coal: Effect of wheat straw. Fuel 239:180–190

Qing M, Su S, Wang L et al (2019) Effects of H2O and CO2 on the catalytic oxidation property of V/W/Ti catalysts for SO3 generation. Fuel 237:545–554

Mehmood MA, Ahmad MS, Liu Q et al (2019) Helianthus tuberosus as a promising feedstock for bioenergy and chemicals appraised through pyrolysis, kinetics, and TG-FTIR-MS based study. Energy Convers Manag 194:37–45. https://doi.org/10.1016/j.enconman.2019.04.076

Xiang Y, Xiang Y, Wang L (2016) Thermal decomposition kinetic of hybrid poplar sawdust as biomass to biofuel. J Environ Chem Eng 4:3303–3308. https://doi.org/10.1016/j.jece.2016.07.009

Barbanera M, Cotana F, Di Matteo U (2018) Co-combustion performance and kinetic study of solid digestate with gasification biochar. Renew Energy 121:597–605. https://doi.org/10.1016/j.renene.2018.01.076

Lang Q, Zhang B, Liu Z et al (2019) Co-hydrothermal carbonization of corn stalk and swine manure: combustion behavior of hydrochar by thermogravimetric analysis. Bioresour Technol 271:75–83. https://doi.org/10.1016/j.biortech.2018.09.100

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

EL-Sayed, S.A., Mostafa, M.E. Kinetics, thermodynamics, and combustion characteristics of Poinciana pods using TG/DTG/DTA techniques. Biomass Conv. Bioref. 13, 11583–11607 (2023). https://doi.org/10.1007/s13399-021-02021-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02021-8