Abstract

The impacts of Co nanoparticles (NPs) on the anaerobic digestion (AD) of cow dung were investigated using kinetic models (modified Gompertze, logistic, and first-order) and experimental measurements. The deviation between the predicted and measured data for biogas yield with modified Gompertze and logistic models were 0.66–2.26% and 1.43–4.19%, respectively. The addition of Co NPs (1–3 mg/L) improved the hydrolysis rate (K) value by 66.66–144% compared with the control. Furthermore, the fertilizer efficiency of effluent with Co NPs was comparable to that of commercial NPK compound fertilizer. The combination of kinetic models and experimental measurements can effectively quantify the impact of Co NPs on AD performance and provide an informed choice for industrial production.

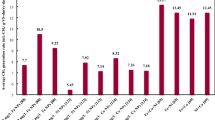

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Abdelsalam E, Samer M, Attia YA, Abdel-Hadi MA, Hassan HE, Badr Y (2016) Comparison of nanoparticles effects on biogas and methane production from anaerobic digestion of cattle dung slurry. Renew Energy 87:592–598. https://doi.org/10.1016/j.renene.2015.10.053

Abdelsalam E, Samer M, Attia YA, Abdel-Hadi MA, Hassan HE, Badr Y (2017a) Effects of Co and Ni nanoparticles on biogas and methane production from anaerobic digestion of slurry. Energy Convers Manag 141:108–119. https://doi.org/10.1016/j.enconman.2016.05.051

Abdelsalam E, Samer M, Attia YA, Abdel-Hadi MA, Hassan HE, Badr Y (2017b) Influence of zero valent iron nanoparticles and magnetic iron oxide nanoparticles on biogas and methane production from anaerobic digestion of manure. Energy 120:842–853. https://doi.org/10.1016/j.energy.2016.11.137

Abdelwahab TAM, Mohanty MK, Sahoo PK Behera D (2021a) Metal nanoparticle mixtures to improve the biogas yield of cattle manure. Biomass Convers Bior 1-12. https://doi.org/10.1007/s13399-021-01286-3

Abdelwahab TAM, Mohanty MK, Sahoo PK Behera D (2021b) Impact of nickel nanoparticles on biogas production from cattle manure. Biomass Convers Bior 1-14. https://doi.org/10.1007/s13399-021-01460-7

Abdelwahab TAM, Mohanty MK, Sahoo PK Behera D (2020b) Impact of iron nanoparticles on biogas production and effluent chemical composition from anaerobic digestion of cattle manure. Biomass Convers Bior. 1-13. https://doi.org/10.1007/s13399-020-00985-7

Abdelwahab TAM, Mohanty MK, Sahoo PK, Behera D (2020a) Application of nanoparticles for biogas production: current status and perspectives. Energ Source Part A 1-13. https://doi.org/10.1080/15567036.2020.1767730

Abdulla HA, Minor EC, Dias RF, Hatcher PG (2010) Changes in the compound classes of dissolved organic matter along an estuarine transect: a study using FTIR and 13C NMR. Geochim Cosmochim Acta 74(13):3815–3838. https://doi.org/10.1016/j.gca.2010.04.006

Ahn HK, Smith MC, Kondrad SL, White JW (2010) Evaluation of biogas production potential by dry anaerobic digestion of switchgrass–animal manure mixtures. Biotechnol Appl Biochem 160(4):965–975. https://doi.org/10.1007/s12010-009-8624-x

Ajay CM, Mohan S, Dinesha P, Rosen MA (2020) Review of impact of nanoparticle additives on anaerobic digestion and methane generation. Fuel 277:118234. https://doi.org/10.1016/j.fuel.2020.118234

Ali A, Mahar RB, Abdelsalam EM, Sherazi STH (2019) Kinetic modeling for bioaugmented anaerobic digestion of the organic fraction of municipal solid waste by using Fe3O4 nanoparticles. Waste Biomass Valori 10(11):3213–3224. https://doi.org/10.1007/s12649-018-0375-x

Amen TW, Eljamal O, Khalil AM, Sugihara Y, Matsunaga N (2018) Methane yield enhancement by the addition of new novel of iron and copper-iron bimetallic nanoparticles. Chem Eng Process 130:253–261. https://doi.org/10.1016/j.cep.2018.06.020

APHA (1995) Standard methods for examination of water and wastewater. American Public Health Association APHA, Washington, DC

APHA (2005) Standard methods for examination of water and wastewater, 21st edn. APHA, Washington, DC

Bayr S, Pakarinen O, Korppoo A, Liuksia S, Väisänen A, Kaparaju P, Rintala J (2012) Effect of additives on process stability of mesophilic anaerobic monodigestion of pig slaughterhouse waste. Bioresour Technol 120:106–113. https://doi.org/10.1016/j.biortech.2012.06.009

Bedoić R, Špehar A, Puljko J, Čuček L, Ćosić B, Pukšec T, Duić N (2020) Opportunities and challenges: experimental and kinetic analysis of anaerobic co-digestion of food waste and rendering industry streams for biogas production. Renew Sustain Energy Rev 130:109951. https://doi.org/10.1016/j.rser.2020.109951

Boer JL, Mulrooney SB, Hausinger RP (2014) Nickel-dependent metalloenzymes. Arch Biochem Biophys 544:142–152. https://doi.org/10.1016/j.abb.2013.09.002

Chen Y, Cheng JJ, Creamer KS (2008) Inhibition of anaerobic digestion process: a review. Bioresour Technol 99(10):4044–4064. https://doi.org/10.1016/j.biortech.2007.01.057

Chowdhury T, Chowdhury H, Hossain N, Ahmed A, Hossen MS, Chowdhury P, Thirugnanasambandam M and Saidur R (2020) Latest advancements on livestock waste management and biogas production: Bangladesh’s perspective. J Clean Prod 122818. https://doi.org/10.1016/j.jclepro.2020.122818

Deepanraj B, Sivasubramanian V, Jayaraj S (2017) Effect of substrate pretreatment on biogas production through anaerobic digestion of food waste. Int J Hydrog Energy 42(42):26522–26528. https://doi.org/10.1016/j.ijhydene.2017.06.178

Demirel B, Scherer P (2011) Trace element requirements of agricultural biogas digesters during biological conversion of renewable biomass to methane. Biomass Bioenergy 35(3):992–998. https://doi.org/10.1016/j.biombioe.2010.12.022

Donoso-Bravo A, Pérez-Elvira SI, Fdz-Polanco F (2010) Application of simplified models for anaerobic biodegradability tests. Evaluation of pre-treatment processes. Chem Eng J 160(2):607–614. https://doi.org/10.1016/j.cej.2010.03.082

Facchin V, Cavinato C, Fatone F, Pavan P, Cecchi F, Bolzonella D (2013) Effect of trace element supplementation on the mesophilic anaerobic digestion of foodwaste in batch trials: the influence of inoculum origin. Biochem Eng J 70:71–77. https://doi.org/10.1016/j.bej.2012.10.004

Feng XM, Karlsson A, Svensson BH, Bertilsson S (2010) Impact of trace element addition on biogas production from food industrial waste–linking process to microbial communities. FEMS Microbiol Ecol 74(1):226–240. https://doi.org/10.1111/j.1574-6941.2010.00932.x

Gamage IH, Jonker A, Zhang X, Yu P (2014) Non-destructive analysis of the conformational differences among feedstock sources and their corresponding co-products from bioethanol production with molecular spectroscopy. Spectrochim Acta A Mol Biomol Spectrosc 118:407–421. https://doi.org/10.1016/j.saa.2013.08.095

Ghosh P, Kumar M, Kapoor R, Kumar SS, Singh L, Vijay V, Vijay VK, Kumar V, Thakur IS (2020) Enhanced biogas production from municipal solid waste via co-digestion with sewage sludge and metabolic pathway analysis. Bioresour Technol 296:122275. https://doi.org/10.1016/j.biortech.2019.122275

Hassanein A, Lansing S, Tikekar R (2019) Impact of metal nanoparticles on biogas production from poultry litter. Bioresour Technol 275:200–206. https://doi.org/10.1016/j.biortech.2018.12.048

IEA (2020) Outlook for biogas and biomethane: prospects for organic growth. Paris: IEA. International. Energy Agency. World energy outlook special report 2019. https://www.iea.org/reports/world-energy-outlook-2019. Accessed 27 Mar 2020

Kiran EU, Trzcinski AP, Liu Y (2015) Enhancing the hydrolysis and methane production potential of mixed food waste by an effective enzymatic pretreatment. Bioresour Technol 183:47–52. https://doi.org/10.1016/j.biortech.2015.02.033

Kothari R, Pandey AK, Kumar S, Tyagi VV, Tyagi SK (2014) Different aspects of dry anaerobic digestion for bio-energy: an overview. Renew Sustain Energy Rev 39:174–195. https://doi.org/10.1016/j.rser.2014.07.011

Liu A, Xu S, Lu C, Peng P, Zhang Y, Feng D, Liu Y (2014) Anaerobic fermentation by aquatic product wastes and other auxiliary materials. Clean Technol Environ Policy 16(2):415–421. https://doi.org/10.1007/s10098-013-0640-4

Madsen M, Holm-Nielsen JB, Esbensen KH (2011) Monitoring of anaerobic digestion processes: a review perspective. Renew Sustain Energy Rev 15(6):3141–3155. https://doi.org/10.1016/j.rser.2011.04.026

Mishra RK, Mohanty K (2018) Pyrolysis kinetics and thermal behavior of waste sawdust biomass using thermogravimetric analysis. Bioresour Technol 251:63–74. https://doi.org/10.1016/j.biortech.2017.12.029

Möller K, Müller T (2012) Effects of anaerobic digestion on digestate nutrient availability and crop growth: a review. Eng Life Sci 12(3):242–257. https://doi.org/10.1002/elsc.201100085

Muyzer G, Stams AJ (2008) The ecology and biotechnology of sulphate-reducing bacteria. Nat Rev Microbiol 6(6):441–454. https://doi.org/10.1038/nrmicro1892

Nguyen D, Visvanathan C, Jacob P, Jegatheesan V (2015) Effects of nano cerium (IV) oxide and zinc oxide particles on biogas production. Int Biodeterior Biodegradation 102:165–171. https://doi.org/10.1016/j.ibiod.2015.02.014

O’Keeffe S, Thrän D (2020) Energy crops in regional biogas systems: an integrative spatial LCA to assess the influence of crop mix and location on cultivation GHG emissions. Sustainability 12(1):237. https://doi.org/10.3390/SU12010237

Qiang H, Lang DL, Li YY (2012) High-solid mesophilic methane fermentation of food waste with an emphasis on Iron, Cobalt, and Nickel requirements. Bioresour Technol 103(1):21–27. https://doi.org/10.1016/j.biortech.2011.09.036

Rawlings JO, Pantula SG, Dickey DA (2001) Applied regression analysis: a research tool. Springer Science & Business Media. https://doi.org/10.1007/b98890

Romero-Güiza MS, Vila J, Mata-Alvarez J, Chimenos JM, Astals S (2016) The role of additives on anaerobic digestion: a review. Renew Sustain Energy Rev 58:1486–1499. https://doi.org/10.1016/j.rser.2015.12.094

Romsaiyud A, Songkasiri W, Nopharatana A, Chaiprasert P (2009) Combination effect of pH and acetate on enzymatic cellulose hydrolysis. J Environ Sci 21(7):965–970. https://doi.org/10.1016/S1001-0742(08)62369-4

Roussel J (2013) Metal behaviour in anaerobic sludge digesters supplemented with trace nutrients (Doctoral dissertation, University of Birmingham)

Sevcu A, El-Temsah YS, Joner EJ, Cernik M (2011) Oxidative stress induced in microorganisms by zero-valent iron nanoparticles. Microbes Environ 26(4):271–281. https://doi.org/10.1264/jsme2.me11126

Suanon F, Sun Q, Li M, Cai X, Zhang Y, Yan Y, Yu CP (2017) Application of nanoscale zero valent iron and iron powder during sludge anaerobic digestion: Impact on methane yield and pharmaceutical and personal care products degradation. J Hazard Mater 321:47–53. https://doi.org/10.1016/j.jhazmat.2016.08.076

Syaichurrozi I, Sumardiono S (2013) Predicting kinetic model of biogas production and biodegradability organic materials: biogas production from vinasse at variation of COD/N ratio. Bioresour Technol 149:390–397. https://doi.org/10.1016/j.biortech.2013.09.088

Tamburini E, Gaglio M, Castaldelli G, Fano EA (2020) Biogas from agri-food and agricultural waste can appreciate agro-ecosystem services: the case study of Emilia Romagna Region. Sustainability 12(20):8392. https://doi.org/10.3390/su12208392

Thauer RK, Kaster AK, Seedorf H, Buckel W, Hedderich R (2008) Methanogenic archaea: ecologically relevant differences in energy conservation. Nat Rev Microbiol 6(8):579–591. https://doi.org/10.1038/nrmicro1931

Trifunović D, Schuchmann K, Müller V (2016) Ethylene glycol metabolism in the acetogen Acetobacterium woodii. J Bacteriol 198(7):1058–1065. https://doi.org/10.1128/JB.00942-15

Wang QL, Li W, Gao X, Li SJ (2016) Life cycle assessment on biogas production from straw and its sensitivity analysis. Bioresour Technol 201:208–214. https://doi.org/10.1038/srep25857

Wei L, Qin K, Ding J, Xue M, Yang C, Jiang J, Zhao Q (2019) Optimization of the co-digestion of sewage sludge, maize straw and cow manure: microbial responses and effect of fractional organic characteristics. Sci Rep 9(1):1–10. https://doi.org/10.1016/j.chemosphere.2014.08.060

Wong CS, Li WK (1998) A note on the corrected Akaike information criterion for threshold autoregressive models. J Time Ser Anal 19(1):113–124. https://doi.org/10.1111/1467-9892.00080

Yılmaz Ş, Şahan T (2020) Utilization of pumice for improving biogas production from poultry manure by anaerobic digestion: a modeling and process optimization study using response surface methodology. Biomass Bioenergy 138:105601. https://doi.org/10.1016/j.biombioe.2020.105601

Zaidi AA, RuiZhe F, Shi Y, Khan SZ, Mushtaq K (2018) Nanoparticles augmentation on biogas yield from microalgal biomass anaerobic digestion. Int J Hydrog Energy 43(31):14202–14213. https://doi.org/10.1016/j.ijhydene.2018.05.132

Zandvoort MH, Van Hullebusch ED, Fermoso FG, Lens PNL (2006) Trace metals in anaerobic granular sludge reactors: bioavailability and dosing strategies. Eng Life Sci 6(3):293–301. https://doi.org/10.1002/elsc.200620129

Zhang M and Zang L (2019) A review of interspecies electron transfer in anaerobic digestion, In IOP Conference Series: Earth and Environmental Science 310 (4): 042026, IOP Publishing

Zhang W, Wei Q, Wu S, Qi D, Li W, Zuo Z, Dong R (2014) Batch anaerobic co-digestion of pig manure with dewatered sewage sludge under mesophilic conditions. Appl Energy 128:175–183. https://doi.org/10.1016/j.apenergy.2014.04.071

Acknowledgements

The authors gratefully acknowledge the financial support of Indian Council of Agricultural Research (ICAR). We would also like to acknowledge Odisha University of Agriculture & Technology (OUAT). A special thank you to the College of Agricultural Engineering and Technology Biofuel Energy laboratory.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Introduction of Co NPs (1–2 mg/L) can improve biogas production by 6.82–14.81%.

• Three kinetic models (modified Gompertze, logistic, and first-order) are employed to predict biogas yield and hydrolysis rate.

• Predicted data (0.66–2.26%) of modified Gompertze model is closer to measured data than logistic model.

• First-order model fitting proves Co NPs improve the hydrolysis rate (K) value by 66.66–144%.

• The selected kinetic models fit well with the experimental data (R2 > 0.98)

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Abdelwahab, T.A.M., Mohanty, M.K., Sahoo, P.K. et al. Cobalt nanoparticles to enhance anaerobic digestion of cow dung: focusing on kinetic models for biogas yield and effluent utilization. Biomass Conv. Bioref. 13, 11657–11669 (2023). https://doi.org/10.1007/s13399-021-02002-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02002-x