Abstract

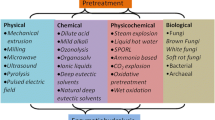

The conversion of lignocellulosic biomass into bioethanol remains a challenging process due to the recalcitrant structure of lignocellulose. The presence of the sturdy lignin protective sheath, complex structure, and partial crystallinity of cellulose often reduces the enzymatic susceptibility of lignocellulosic biomass. Therefore, pretreatment is aimed to increase accessibility by improving the physicochemical properties and composition of lignocellulosic biomass. It is the first and the most critical step that needs to be carefully selected and designed to overcome the constraints and improve the overall efficiency of bioethanol production. In recent years, ball milling has been applied as an emerging technique to produce bioethanol from lignocellulosic biomass efficiently and in an environment-friendly manner. Furthermore, ball milling technique coupled with chemical and physicochemical pretreatments has been shown to facilitate lignin removal, reduce cellulose crystallinity, and increase the specific surface area which ultimately improves the digestibility of lignocellulosic biomass. Over the last decade, several reports have been published on the application of ball milling to intensify the pretreatment process. However, a compiled report showing the progress of the technology in bioethanol processing is absent. In this review, a critical analysis and evaluation of published works on ball milling and ball milling–assisted chemical/physicochemical pretreatments are presented. It also addresses the synergistic effects of combining ball milling and chemical/physicochemical treatments to bring desirable characteristics of lignocellulosic biomass that will eventually improve hydrolysis yield and reduce chemical and energy consumption in bioethanol production.

Similar content being viewed by others

Data availability

All relevant data are included in the paper.

Change history

11 October 2021

A Correction to this paper has been published: https://doi.org/10.1007/s13399-021-02018-3

References

Singh KJ, Sooch SS (2004) Comparative study of economics of different models of family size biogas plants for state of Punjab, India. Energy Convers Manag 45:1329–1341

Muktham R, Bhargava SK, Bankupalli S, Ball AS (2016) A review on 1st and 2nd generation bioethanol production-recent progress. J Sustain Bioenergy Syst 6:72–92

Virgínio e Silva JO, Almeida MF, da Conceição Alvim-Ferraz M, Dias JM, (2018) Integrated production of biodiesel and bioethanol from sweet potato. Renew Energy 124:114–120

Roberto IC, Castro RCA, Silva JPA, Mussatto SI (2020) Ethanol production from high solid loading of rice straw by simultaneous saccharification and fermentation in a non-conventional reactor. Energies 13:2090

Ciliberti C, Biundo A, Albergo R et al (2020) Syngas derived from lignocellulosic biomass gasification as an alternative resource for innovative bioprocesses. Processes 8:1–38

Raja AS, Arasu AV (2015) Exhaust gas treatment for reducing cold start emissions of a motorcycle engine fuelled with gasoline-ethanol blends. J Energy South Africa 26:84–93

Micic V, Jotanovic M (2015) Bioethanol as fuel for internal combustion engines. Zast Mater 56:403–408

Morales M, Quintero J, Conejeros R, Aroca G (2015) Life cycle assessment of lignocellulosic bioethanol : environmental impacts and energy balance. Renew Sustain Energy Rev 42:1349–1361

Ruth D, Janssen R (2007) Bio fuel technology handbook, In WIP Renewable Energies, German, München

Satari B, Karimi K, Kumar R (2019) Cellulose solvent-based pretreatment for enhanced second-generation biofuel production: a review. Sustain Energy Fuels 3:11–62

Robak K, Balcerek M (2018) Review of second generation bioethanol production from residual biomass. Food Technol Biotechnol 56:174–187

Rezania S, Oryani B, Cho J et al (2020) Different pretreatment technologies of lignocellulosic biomass for bioethanol production : an overview. Energy 199:117457

Sindhu R, Binod P, Pandey A (2016) Biological pretreatment of lignocellulosic biomass-an overview. Bioresour Technol 199:76–82

Mo Y, Kim H, Sang B et al (2018) Effects of water content on ball milling pretreatment and the enzymatic digestibility of corn stover. Water-Energy Nexus 1:61–65

Hassan SS, Williams GA, Jaiswal AK (2018) Emerging technologies for the pretreatment of lignocellulosic biomass. Bioresour Technol 262:310–318

Tu W-CC, Hallett JP (2019) Recent advances in the pretreatment of lignocellulosic biomass. Curr Opin Green Sustain Chem 20:11–17

Harmsen P, Lips S, Bakker R (2013) Pretreatment of lignocellulose for biotechnological production of lactic acid-research review. Wageningen UR Food and Biobased Research, Wageningen, The Netherlands

Barakat A, Mayer-laigle C, Solhy A et al (2014) Mechanical pretreatments of lignocellulosic biomass : towards facile and environmentally sound technologies for biofuels production. RSC Adv 4:48109–48127

Luo J, Fang Z, Smith RL (2014) Ultrasound-enhanced conversion of biomass to biofuels. Prog Energy Combust Sci 41:56–93

Ranjan A, Singh S, Malani RS, Moholkar VS (2016) Ultrasound-assisted bioalcohol synthesis: review and analysis. RSC Adv 6:65541–65562

Laghari SM (2014) Microwave individual and combined pre-treatments on lignocellulosic biomasses. IOSR J Eng 4:14–28

Agu OS, Tabil LG, Meda V et al (2019) Pretreatment of crop residues by application of microwave heating and alkaline solution for biofuel processing: a review. Renew Resour Biorefineries. IntechOpen

Lempiäinen H, Lappalainen K, Haverinen J, et al (2020) The effect of mechanocatalytic pretreatment on the structure and depolymerization of willow. Catalysts 10:255

Ayeni AO, Adeeyo OA, Oresegun OM, Oladimeji TE (2015) Compositional analysis of lignocellulosic materials: evaluation of an economically viable method suitable for woody and non-woody biomass. Am J Eng Res 4:14–19

Nair RB, Lennartsson PR, Taherzadeh MJ (2017) Bioethanol production from agricultural and municipal wastes. In: Current developments in biotechnology and bioengineering: Solid Waste Management. Elsevier B.V., pp 157–190

Cheng JJ, Timilsina GR (2011) Status and barriers of advanced biofuel technologies: a review. Renew Energy 36:3541–3549

Kang Q, Appels L, Tan T, Dewil R (2014) Bioethanol from lignocellulosic biomass: current findings determine research priorities. Sci World J 2014:1–13

Kim SJ, Um BH, Im DJ et al (2018) Combined ball milling and ethanol organosolv pretreatment to improve the enzymatic digestibility of three types of herbaceous biomass. Energies 11:2457

Qu T, Zhang X, Gu X et al (2017) Ball milling for biomass fractionation and pretreatment with aqueous hydroxide solutions. ACS Sustain Chem Eng 5:7733–7742

Ravindran R, Jaiswal S, Abu-Ghannam N, Jaiswal AK (2018) A comparative analysis of pretreatment strategies on the properties and hydrolysis of brewers’ spent grain. Bioresour Technol 248:272–279

Baruah J, Nath BK, Sharma R et al (2018) Recent trends in the pretreatment of lignocellulosic biomass for value-added products. Front Energy Res 6:1–19

Kumar SS (2017) Recent updates on different methods of pretreatment of lignocellulosic feedstocks: a review. Bioresour Bioprocess 4:7

Lomovsky O, Bychkov A, Lomovsky I (2016) Mechanical pretreatment. In: Biomass fractionation technologies for a lignocellulosic feedstock based biorefinery. Elsevier Inc., pp 23–55

Kim HJ, Chang JH, Jeong B-Y, Lee JH (2013) Comparison of milling modes as a pretreatment method for cellulosic biofuel production. J Clean Energy Technol 1:45–48

Sharma HK, Xu C, Qin W (2019) Biological pretreatment of lignocellulosic biomass for biofuels and bioproducts: an overview. Waste and Biomass Valorization 10:235–251

Zhu D, Zhang P, Xie C et al (2017) Biodegradation of alkaline lignin by Bacillus ligniniphilus L1. Biotechnol Biofuels 10:1–14

Mayer-Laigle C, Blanc N, Rajaonarivony RK, Rouau X (2018) Comminution of dry lignocellulosic biomass, a review: part I. From fundamental mechanisms to milling behaviour. Bioengineering 5:41

Jiang L, qun, Zheng A qing, Meng J guang, et al (2019) A comparative investigation of fast pyrolysis with enzymatic hydrolysis for fermentable sugars production from cellulose. Bioresour Technol 274:281–286

Zakaria MR, Hirata S, Hassan MA (2014) Combined pretreatment using alkaline hydrothermal and ball milling to enhance enzymatic hydrolysis of oil palm mesocarp fiber. Bioresour Technol 169:236–243

Karimi K, Taherzadeh MJ (2016) A critical review of analytical methods in pretreatment of lignocelluloses: composition, imaging, and crystallinity. Bioresour Technol 200:1008–1018

da Silva AS, Sobral Teixeira RS, Oliveira R de et al (2013) Sugarcane and woody biomass pretreatments for ethanol production. In: Sustainable degradation of lignocellulosic biomass - techniques, applications and commercialization. InTechOpen

Kim JS, Lee YY, Kim TH (2016) A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour Technol 199:42–48

Da Silva ASA, Inoue H, Endo T et al (2010) Milling pretreatment of sugarcane bagasse and straw for enzymatic hydrolysis and ethanol fermentation. Bioresour Technol 101:7402–7409

Lin Z, Huang H, Zhang H et al (2010) Ball milling pretreatment of corn stover for enhancing the efficiency of enzymatic hydrolysis. Appl Biochem Biotechnol 162:1872–1880

Sipponen MH, Laakso S, Baumberger S (2014) Impact of ball milling on maize (Zea mays L.) stem structural components and on enzymatic hydrolysis of carbohydrates. Ind Crops Prod 61:130–136

Lee JH, Kwon JH, Kim TH, Il CW (2017) Impact of planetary ball mills on corn stover characteristics and enzymatic digestibility depending on grinding ball properties. Bioresour Technol 241:1094–1100

Stolle A (2015) Technical implications of organic syntheses in ball mills. In: Ball milling towards green synthesis: applications, projects, challenges, Edited by Brindaban Ranu and Achim Stolle A. RSC Green Chemistry, pp 241–276

Gorrasi G, Sorrentino A (2015) Mechanical milling as a technology to produce structural and functional bio-nanocomposites. Green Chem 17:2610–2625

Kim HJ, Lee S, Kim J et al (2013) Environmentally friendly pretreatment of plant biomass by planetary and attrition milling. Bioresour Technol 144:50–56

Burmeister CF, Kwade A (2013) Process engineering with planetary ball mills. Chem Soc Rev 42:7660–7667

Abbasi R, Baheti V (2018) Preparation of nanocellulose from jute fiber waste. J Text Eng Fash Technol 4:101–104

Licari A, Monlau F, Solhy A et al (2016) Comparison of various milling modes combined to the enzymatic hydrolysis of lignocellulosic biomass for bioenergy production: glucose yield and energy efficiency. Energy 102:335–342

da Barros R, RO de, Paredes R de S, Endo T, et al (2013) Association of wet disk milling and ozonolysis as pretreatment for enzymatic saccharification of sugarcane bagasse and straw. Bioresour Technol 136:288–294

Zhang H, Zhang P, Ye J et al (2018) Comparison of various pretreatments for ethanol production enhancement from solid residue after rumen fluid digestion of rice straw. Bioresour Technol 247:147–156

Zakaria MR, Fujimoto S, Hirata S, Hassan MA (2014) Ball milling pretreatment of oil palm biomass for enhancing enzymatic hydrolysis. Appl Biochem Biotechnol 173:1778–1789

Jiang J, Wang J, Zhang X, Wolcott M (2016) Evaluation of physical structural features on influencing enzymatic hydrolysis efficiency of micronized wood. RSC Adv 6:103026–103034

Yu Y, Long Y, Wu H (2015) Near-complete recovery of sugar monomers from cellulose and lignocellulosic biomass via a two-step process combining mechanochemical hydrolysis and dilute acid hydrolysis. Energy Fuels 30:1571–1578

Gao C, Xiao W, Ji G et al (2017) Regularity and mechanism of wheat straw properties change in ball milling process at cellular scale. Bioresour Technol 241:214–219

Zheng Y, Fu Z, Li D et al (2018) Effects of ball milling processes on the microstructure and rheological properties of microcrystalline cellulose as a sustainable. Materials (Basel) 11:1057

Vaidya AA, Donaldson LA, Newman RH et al (2016) Micromorphological changes and mechanism associated with wet ball milling of Pinus radiata substrate and consequences for saccharification at low enzyme loading. Bioresour Technol 214:132–137

Jamal M, Sujan S, Miah M et al (2011) Ball milling pretreatment of bagasse for ethanol production by enzymatic saccharification and fermentation. Bangladesh J Sci Ind Res 46:353–358

Yu Y, Wu H (2011) Effect of ball milling on the hydrolysis of microcrystalline cellulose in hot-compressed water. AIChE J 57:793–800

Schneider L, Haverinen J, Jaakkola M, Lassi U (2017) Effective saccharification of lignocellulosic barley straw by mechanocatalytical pretreatment using potassium pyrosulfate as a catalyst. Bioresour Technol 234:1–7

Gu YM, Kim H, Sang B-I, Lee JH (2018) Effects of water content on ball milling pretreatment and the enzymatic digestibility of corn stover. Water-Energy Nexus 1:61–65

Schneider L, Haverinen J, Jaakkola M, Lassi U (2017) Pretreatment and fractionation of lignocellulosic barley straw by mechanocatalysis. Chem Eng J 327:898–905

Nemoto S, Ueno T, Watthanaphanit A et al (2017) Crystallinity and surface state of cellulose in wet ball-milling process. J Appl Polym Sci 134:1–7

Kano FS, Souza AG De (2019) Variation of the milling conditions in the obtaining of nanocellulose from the paper sludge. Materia (Rio Janeiro) 24

Yuan X, Liu S, Feng G et al (2016) Effects of ball milling on structural changes and hydrolysis of lignocellulosic biomass in liquid hot-water compressed carbon dioxide. Korean J Chem Eng 33:2134–2141

Zhang Z, Tahir N, Li Y et al (2019) Tailoring of structural and optical parameters of corncobs through ball milling pretreatment. Renew Energy 141:298–304

Chin SX, Chia CH, Zakaria S et al (2015) Ball milling pretreatment and diluted acid hydrolysis of oil palm empty fruit bunch (EFB) fibres for the production of levulinic acid. J Taiwan Inst Chem Eng 52:85–92

Kim SM, Dien BS, Singh V (2016) Promise of combined hydrothermal/chemical and mechanical refining for pretreatment of woody and herbaceous biomass. Biotechnol Biofuels 9:1–15

Zakaria MR, Norrrahim MNF, Hirata S, Hassan MA (2015) Hydrothermal and wet disk milling pretreatment for high conversion of biosugars from oil palm mesocarp fiber. Bioresour Technol 181:263–269

Zhu Z, Macquarrie DJ, Simister R et al (2015) Microwave assisted chemical pretreatment of Miscanthus under different temperature regimes. Sustain Chem Process 3:15

Soontornchaiboon W, Kim SM, Pawongrat R (2016) Effects of alkaline combined with ultrasonic pretreatment and enzymatic hydrolysis of agricultural wastes for high reducing sugar production. Sains Malaysiana 45:955–962

Subhedar PB, Ray P, Gogate PR (2018) Intensification of delignification and subsequent hydrolysis for the fermentable sugar production from lignocellulosic biomass using ultrasonic irradiation. Ultrason Sonochem 40:140–150

Eblaghi M, Niakousari M, Sarshar M, Mesbahi GR (2016) Combining ultrasound with mild alkaline solutions as an effective pretreatment to boost the release of sugar trapped in sugarcane bagasse for bioethanol production. J Food Process Eng 39:273–282

Lee H V, Hamid SBA, Zain SK (2014) Conversion of lignocellulosic biomass to nanocellulose : structure and chemical process. Sci World J 2014:631013

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res 48:3713–3729

Norsyarahah S, Kamarludin C, Jainal MS et al (2014) Mechanical pretreatment of lignocellulosic biomass for biofuel production 625:838–841

Gu YM, Kim S, Sung D et al (2019) Feasibility of continuous pretreatment of corn stover : a comparison of three commercially available continuous pulverizing devices. Energies 12:1422

Barakat A, Chuetor S, Monlau F et al (2014) Eco-friendly dry chemo-mechanical pretreatments of lignocellulosic biomass: impact on energy and yield of the enzymatic hydrolysis. Appl Energy 113:97–105

Yuan Z, Long J, Wang T et al (2015) Process intensification effect of ball milling on the hydrothermal pretreatment for corn straw enzymolysis. Energy Convers Manag 101:481–488

Loustau-cazalet C, Sambusiti C, Buche P et al (2016) Innovative deconstruction of biomass induced by dry chemo-mechanical activation : impact on enzymatic hydrolysis and energy efficiency. ACS Sustain Chem Eng 4:2689–2697

Schneider L, Dong Y, Haverinen J et al (2016) Efficiency of acetic acid and formic acid as a catalyst in catalytical and mechanocatalytical pretreatment of barley straw. Biomass Bioenerg 91:134–142

Shen F, Xiong X, Fu J, et al (2020) Recent advances in mechanochemical production of chemicals and carbon materials from sustainable biomass resources. Renew Sustain Energy Rev 130:109944

Zhang Y, Huang M, Su J et al (2019) Overcoming biomass recalcitrance by synergistic pretreatment of mechanical activation and metal salt for enhancing enzymatic conversion of lignocellulose. Biotechnol Biofuels 12:1–15

Schneider L, Haverinen J, Jaakkola M, Lassi U (2016) Solid acid-catalyzed depolymerization of barley straw driven by ball milling. Bioresour Technol 206:204–210

Inoue H, Yano S, Endo T et al (2008) Combining hot-compressed water and ball milling pretreatments to improve the efficiency of the enzymatic hydrolysis of eucalyptus. Biotechnol Biofuels 1:1–9

Hideno A, Inoue H, Tsukahara K et al (2009) Wet disk milling pretreatment without sulfuric acid for enzymatic hydrolysis of rice straw. Bioresour Technol 100:2706–2711

Kumar R, Wyman CE (2013) Physical and Chemical features of pretreated biomass that influence macro-/micro-accessibility and biological processing. In: Aqueous pretreatment of plant biomass for biological and chemical conversion to fuels and chemicals. pp 281–310

Li L, Zhou W, Wu H et al (2014) Relationship between crystallinity index and enzymatic hydrolysis performance of celluloses separated from aquatic and terrestrial plant materials. BioResources 9:3993–4005

Chen X, Zhang Y, Mei J et al (2019) Ball milling for cellulose depolymerization and alcoholysis to produce methyl levulinate at mild temperature. Fuel Process Technol 188:129–136

Liu H, Chen X, Ji G, et al (2019) Mechanochemical deconstruction of lignocellulosic cell wall polymers with ball-milling. Bioresour Technol 286:121364.

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Auxenfans T, Crônier D, Chabbert B, Paës G (2017) Understanding the structural and chemical changes of plant biomass following steam explosion pretreatment. Biotechnol Biofuels 10:36

Meng X, Pu Y, Yoo CG et al (2017) An in-depth understanding of biomass recalcitrance using natural poplar variants as the feedstock. Chemsuschem 10:139–150

Yu Z, Jameel H, Chang H-MM et al (2012) Evaluation of the factors affecting avicel reactivity using multi-stage enzymatic hydrolysis. Biotechnol Bioeng 109:1131–1139

Xu H, Che X, Ding Y et al (2019) Effect of crystallinity on pretreatment and enzymatic hydrolysis of lignocellulosic biomass based on multivariate analysis. Bioresour Technol 279:271–280

Pihlajaniemi V, Sipponen MH, Liimatainen H et al (2016) Weighing the factors behind enzymatic hydrolyzability of pretreated lignocellulose. Green Chem 18:1295–1305

Song Y, Zhang J, Zhang X, Tan T (2015) The correlation between cellulose allomorphs (I and II) and conversion after removal of hemicellulose and lignin of lignocellulose. Bioresour Technol 193:164–170

Gu B, Wang J, Wolcott MP, Ganjyal GM (2018) Increased sugar yield from pre-milled Douglas- fi r forest residuals with lower energy consumption by using planetary ball milling. Bioresour Technol 251:93–98

Zhu L, O’Dwyer JP, Chang VS et al (2008) Structural features affecting biomass enzymatic digestibility. Bioresour Technol 99:3817–3828

Phanthong P, Guan G, Ma Y et al (2016) Effect of ball milling on the production of nanocellulose using mild acid hydrolysis method. J Taiwan Inst Chem Eng 60:617–622

Ishiguro M, Endo T (2014) Addition of alkali to the hydrothermal – mechanochemical treatment of Eucalyptus enhances its enzymatic saccharification. Bioresour Technol 153:322–326

Kane SN, Mishra A, Dutta AK (2017) Effect of mechanical treatment on properties of zeolites with chabazite structure. J Phys Conf Ser 790:012004

Peng H, Li H, Luo H, Xu J (2013) A novel combined pretreatment of ball milling and microwave irradiation for enhancing enzymatic hydrolysis of microcrystalline cellulose. Bioresour Technol 130:81–87

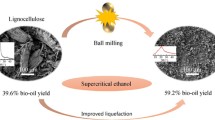

Yang C, Yuan X, Wang X et al (2019) Ball milling promoted direct liquefaction of lignocellulosic biomass in supercritical ethanol. Front Chem Sci Eng 14:605–613

Weiqi W, Shubin W, Liguo L (2013) Combination of liquid hot water pretreatment and wet disk milling to improve the efficiency of the enzymatic hydrolysis of eucalyptus. Bioresour Technol 128:725–730

Lu M, Li J, Han L, Xiao W (2020) High-solids enzymatic hydrolysis of ball-milled corn stover with reduced slurry viscosity and improved sugar yields. Biotechnol Biofuels 13:1–11

Barakat A, Monlau F, Solhy A, Carrere H (2015) Mechanical dissociation and fragmentation of lignocellulosic biomass : effect of initial moisture, biochemical and structural proprieties on energy requirement. Appl Energy 142:240–246

Mayer-Laigle C, Rajaonarivony RK, Blanc N, Rouau X (2018) Comminution of dry lignocellulosic biomass: Part II. technologies, improvement of milling performances, and security issues. Bioengineering 5:50

Barakat A, de Vries H, Rouau X et al (2013) Dry fractionation process as an important step in current and future lignocellulose biorefineries: a review. Bioresour Technol 134:362–373

Kępa K, Chaléat CM, Amiralian N, Batchelor W, Grøndahl L, Martin DJ (2019) Evaluation of properties and specific energy consumption of spinifex-derived lignocellulose fibers produced using different mechanical processes. Cellulose 26:6555–6569

Liu Y, Wang J, Wolcott MP (2016) Assessing the specific energy consumption and physical properties of comminuted Douglas-fir chips for bioconversion. Ind Crops Prod 94:394–400

Acknowledgements

The authors would like to give special thanks to the KU Leuven and Bahir Dar University for providing the necessary resources and support for this review paper.

Funding

The authors would like to acknowledge the Ethiopian Ministry of Science and Higher Education and the German Government for their financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: Reference 113 was incorrect and should have been Kępa K, Chaléat CM, Amiralian N, Batchelor W, Grøndahl L, Martin DJ (2019) Evaluation of properties and specific energy consumption of spinifex-derived lignocellulose fibers produced using different mechanical processes. Cellulose 26:6555–6569.

Rights and permissions

About this article

Cite this article

Sitotaw, Y.W., Habtu, N.G., Gebreyohannes, A.Y. et al. Ball milling as an important pretreatment technique in lignocellulose biorefineries: a review. Biomass Conv. Bioref. 13, 15593–15616 (2023). https://doi.org/10.1007/s13399-021-01800-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01800-7