Abstract

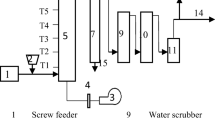

A number of significant parameters such as gasification temperature, dimensions of gasifier, nature of feedstock, position of the components, particle size of feedstock, inlet air temperature, equivalence ratio, and type of gasifier highly influence the yield and characteristics of producer gas (PG). However, structural design of the air nozzle and temperature of the inlet air have received significant attention in enhancing the composition of producer gas and its gasification efficiency. In this study, species transport model of the numerical simulation had been selected to analyze the performance parameters of a gasifier for the air nozzle’s angle and inlet air temperature from 0 to 60° and 27 to 627 °C, respectively. Rice husk was used as the feedstock. For the accuracy of simulation, the results were compared with an experimental study. The combustible gas composition, higher heating value of PG was analyzed in both numerical and experimental studies; furthermore, the prevailing temperature inside the gasifier was also keenly observed and recorded. Among the various nozzle positions, the composition of CO, H2, and CH4 in the producer gas was better at 45° nozzle inclination with 627 °C inlet air temperature; moreover, the composition of the gaseous compounds in the PG were found as 19 to 23%, 13 to 15%, and 2 to 3% respectively. For the above-mentioned conditions of nozzle inclination and inlet air temperature, the calorific value of producer gas was in the range of 4–6 MJ/Nm3. The temperature distribution in the combustion, reduction, pyrolysis, and drying zones was in the range of 1000–1200 °C, 600–700 °C, 300–420 °C, and 200–300 °C, respectively.

Similar content being viewed by others

Data availability

The dataset generated during this work are not publicly available; however, they are available upon reasonable request to the corresponding author.

References

Ahamed TS, Anto S, Mathimani T, Brindhadevi K, Pugazhendhi A (2021) Upgrading of bio-oil from thermochemical conversion of various biomass–Mechanism, challenges and opportunities. Fuel 287:119329. https://doi.org/10.1016/j.fuel.2020.119329

Mahima J, Sundaresh RK, Gopinath KP, Rajan PS, Arun J, Kim SH, Pugazhendhi A (2021) Effect of algae (Scenedesmus obliquus) biomass pre-treatment on bio-oil production in hydrothermal liquefaction (HTL): biochar and aqueous phase utilization studies. Sci Total Environ 778:146262. https://doi.org/10.1016/j.scitotenv.2021.146262

Hiloidhari M, Das D, Baruah DC (2014) Bioenergy potential from crop residue biomass in India. Renew Sust Energ Rev 32:504–512. https://doi.org/10.1016/j.rser.2014.01.025

Singh J, Singh S, Mohapatra SK (2020) Production of syngas from agricultural residue as a renewable fuel and its sustainable use in dual-fuel compression ignition engine to investigate performance, emission, and noise characteristics. Energy Sources 42:41–55. https://doi.org/10.1080/15567036.2019.1587053

Pugazhendhi A, Nagappan S, Bhosale R, Tsai PC, Natarajan S, Devendran S, Al Haj L, Ponnusamy VK, Kumar G (2020) Various potential techniques to reduce the water footprint of microalgal biomass production for biofuel—a review Sci Total Environ 142218.https://doi.org/10.1016/j.scitotenv.2020.142218

Kumar A, Jones DD, Hanna MA (2009) Thermochemical biomass gasification: a review of the current status of the technology. Energies 2(3):556–581. https://doi.org/10.3390/en20300556

Dernbecher A, Dieguez-Alonso A, Ortwein A, Tabet F (2019) Review on modelling approaches based on computational fluid dynamics for biomass combustion systems. Biomass Convers Biorefin 9:129–182. https://doi.org/10.1007/s13399-019-00370-z

Augustine A, Singh CJ, Sekhar JS (2021) Spent tea waste as a biomass for co-gasification enhances the performance of semi-industrial gasifier working on groundnut shell. Biomass Bioenerg 145:105964. https://doi.org/10.1016/j.biombioe.2021.105964

Suksuwan W, Wae-hayee M, Mel M (2018) Development of mini pilot fluidized bed gasifier for industrial approach: preliminary study based on continuous operation. Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 45(1):35–43

Oveisi E, Sokhansanj S, Lau A, Lim J, Bi X, Preto F, Mui C (2018) Characterization of recycled wood chips, syngas yield, and tar formation in an industrial updraft gasifier. Environments 5(7):84. https://doi.org/10.3390/environments5070084

Larsson A, Seemann M, Neves D, Thunman H (2013) Evaluation of performance of industrial-scale dual fluidized bed gasifiers using the chalmers 2–4-MWth gasifier. Energ Fuel 27(11):6665–6680. https://doi.org/10.1021/ef400981j

Monteiro E, Ismail TM, Ramos A, Abd El-Salam M, Brito PS, Rouboa A (2017) Assessment of the miscanthus gasification in a semi-industrial gasifier using a CFD model. Appl Therm Eng 123:448–457. https://doi.org/10.1016/j.applthermaleng.2017.05.128

Putro FA, Waluyo J, Pranolo SH (2020) The developed performance evaluation method of an industrial scale updraft woody and woody-like biomass gasifier using a thermodynamic approach. AIP Conf Proc 2296(1)020063. https://doi.org/10.1063/5.0030337

Azzone E, Morini M, Pinelli M (2012) Development of an equilibrium model for the simulation of thermochemical gasification and application to agricultural residues. Renew Energ 46:248–254. https://doi.org/10.1016/j.renene.2012.03.017

Ahmed II, Nipattummakul N, Gupta AK (2011) Characteristics of syngas from co-gasification of polyethylene and woodchips. Appl Energy 88(1):165–174. https://doi.org/10.1016/j.apenergy.2010.07.007

Zhou J, Chen Q, Zhao H, Cao X, Mei Q, Luo Z, Cen K (2009) Biomass–oxygen gasification in a high-temperature entrained-flow gasifier. Biotechnol Adv 5(27):606–611. https://doi.org/10.1016/j.biotechadv.2009.04.011

Mansaray KG, Ghaly AE (1998) Agglomeration characteristics of silica sand-rice husk ash mixtures at elevated temperatures. Energy Sources 20(7):631–652. https://doi.org/10.1080/00908319808970083

Nhuchhen DR, Salam PA (2012) Experimental study on two-stage air supply downdraft gasifier and dual fuel engine system. Biomass Convers Biorefin 2(2):159–168. https://doi.org/10.1007/s13399-012-0041-7

Lucas C, Szewczyk D, Blasiak W, Mochida S (2004) High-temperature air and steam gasification of densified biofuels. Biomass Bioenergy 27:563–575. https://doi.org/10.1016/j.biombioe.2003.08.015

Yang W, Ponzio A, Lucas C, Blasiak W (2006) Performance analysis of a fixed-bed biomass gasifier using high-temperature air. Fuel Process Technol 87(3):235–245. https://doi.org/10.1016/j.fuproc.2005.08.004

Murugan PC, Joseph Sekhar S (2017) Numerical simulation of imbert biomass gasifier to select the feedstock available in remote areas. Environ Prog Sustain Energy 36(3):708–716. https://doi.org/10.1002/ep.12485

Susastriawan AA, Saptoadi H, Purnomo, (2020) Utilization of rice husk–sawdust as blending feedstock of small-scale downdraft gasifier. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 42(6):700–708. https://doi.org/10.1080/15567036.2019.1600620

Awais M, Li W, Munir A, Omar MM, Ajmal M (2020) Experimental investigation of downdraft biomass gasifier fed by sugarcane bagasse and coconut shells Biomass Convers Biorefin 1–16. https://doi.org/10.1007/s13399-020-00690-5

Murugan PC, Sekhar SJ (2021) Investigation on the yield of producer gas from tamarind shell (Tamarindus Indica) as feedstock in an Imbert type biomass gasifier. Fuel 292:120310. https://doi.org/10.1016/j.fuel.2021.120310

Gunasekaran AP, Chockalingam MP, Padmavathy SR, Santhappan JS2021)Numerical and experimental investigation on the thermochemical gasification potential of Cocoa pod husk (Theobroma Cacoa) in an open-core gasifier. Clean Technol Environ Policy 1–3. https://doi.org/10.1007/s10098-021-02051-w

Murugan PC, Sekhar SJ (2017) Species-Transport CFD model for the gasification of rice husk (Oryza Sativa) using downdraft gasifier. Comput Electron Agric 139:33–40. https://doi.org/10.1016/j.compag.2017.05.004

Jayah TH, Aye L, Fuller RJ, Stewart DF (2003) Computer simulation of a downdraft wood gasifier for tea drying. Biomass Bioenergy 25(4):459–469. https://doi.org/10.1016/S0961-9534(03)00037-0

Prasertcharoensuk P, Hernandez DA, Bull SJ, Phan AN (2018) Optimisation of a throat downdraft gasifier for hydrogen production. Biomass Bioenergy 116:216–226. https://doi.org/10.1016/j.biombioe.2018.06.019

Olayanju TM, Dairo OU, Sobukola OP, Odebiyi O, Dahunsi SO (2020) Development of small-scale downdraft gasifiers for biomass gasification. Earth Environ Sci 445. https://doi.org/10.1088/1755-1315/445/1/012056

Sia SQ, Wang WC (2020) Numerical simulations of fluidized bed fast pyrolysis of biomass through computational fluid dynamics. Renew Energy. https://doi.org/10.1016/j.renene.2020.03.134

Murugan PC, Sekhar SJ (2017c) Numerical studies to predict the impact of air nozzle position and inclination on the performance of downdraft gratifier. J Appl Fluid Mech 10(3):947–955. https://doi.org/10.18869/acadpub.jafm.73.238.26446

Puig-Arnavat M, Bruno JC, Coronas A (2010) Review and analysis of biomass gasification models. Renew Sustain Energy Rev 14(9):2841–2851. https://doi.org/10.1016/j.rser.2010.07.030

Singh RI, Brink A, Hupa M (2013) CFD modeling to study fluidized bed combustion and gasification. Appl Therm Eng 52(2):585–614. https://doi.org/10.1016/j.applthermaleng.2012.12.017

Tinaut FV, Melgar A, Perez JF, Horrillo A (2008) Effect of biomass particle size and air superficial velocity on the gasification process in a downdraft fixed bed gasifier. An experimental and modelling study. Fuel Process Technol 89(11):1076–1089. https://doi.org/10.1016/j.fuproc.2008.04.010

Fletcher DF, Haynes BS, Christo FC, Joseph SD (2000) A CFD based combustion model of an entrained flow biomass gasifier. Appl Math Model 24(3):165–182. https://doi.org/10.1016/S0307-904X(99)00025-6

Sharma AK (2008) Equilibrium and kinetic modeling of char reduction reactions in a downdraft biomass gasifier: A comparison. Sol Energy 82(10):918–928. https://doi.org/10.1016/j.solener.2008.03.004

Babu BV, Sheth PN (2006) Modeling and simulation of reduction zone of downdraft biomass gasifier: effect of char reactivity factor. Energy Convers Manag 47(15–16):2602–2611. https://doi.org/10.1016/j.enconman.2005.10.032

Gerun L, Paraschiv M, Vijeu R, Bellettre J, Tazerout M, Gøbel B, Henriksen U (2008) Numerical investigation of the partial oxidation in a two-stage downdraft gasifier. Fuel 87(7):1383–1393. https://doi.org/10.1016/j.fuel.2007.07.009

Gao N, Li A (2008) Modeling and simulation of combined pyrolysis and reduction zone for a downdraft biomass gasifier. Energy Convers Manag 49(12):3483–3490. https://doi.org/10.1016/j.enconman.2008.08.002

Ngamsidhiphongsa N, Ponpesh P, Shotipruk A, Arpornwichanop A (2020) Analysis of the Imbert downdraft gasifier using a species-transport CFD model including tar-cracking reactions. Energy Convers Manag 213:112808. https://doi.org/10.1016/j.enconman.2020.112808

Demirbas A (2004) Combustion characteristics of different biomass fuels. Prog Energy Combust Sci 30(2):219–230. https://doi.org/10.1016/j.pecs.2003.10.004

Ramirez JJ, Martinez JD, Petro SL (2007) Basic design of a fluidized bed gasifier for rice husk on a pilot scale. Lat Am Appl Res 37(4):299–306

Basu P (2010) Biomass gasification and pyrolysis: practical design and theory. Elsevier, Oxford, United States

Wincy WB, Edwin M, Sekhar SJ (2020) Energy and exergy evaluation of rice processing mills working with biomass gasifier in parboiling process. Fuel 259:116255. https://doi.org/10.1016/j.fuel.2019.116255

Sharma V, Agarwal VK (2019) Numerical simulation of coal gasification in a circulating fluidized bed gasifier. Brazili Journ of Chem Engg 36(3):1289–1301. https://doi.org/10.1590/0104-6632.20190363s20180423

Pattiya A, Titiloye JO, Bridgwater AV (2009) Fast pyrolysis of agricultural residues from cassava plantation for bio-oil production. Carbon 51:51–59

André RN, Pinto F, Franco C, Dias M, Gulyurtlu I, Matos MA, Cabrita I (2005) Fluidised bed co-gasification of coal and olive oil industry wastes. Fuel 84(12–13):1635–1644. https://doi.org/10.1016/j.fuel.2005.02.018

Doherty W, Reynolds A, Kennedy D (2009) The effect of air preheating in a biomass CFB gasifier using ASPEN Plus simulation. Biomass Bioenergy 33(9):1158–1167. https://doi.org/10.1016/j.biombioe.2009.05.004

Almeida A, Neto P, Pereira I, Ribeiro A, Pilão R (2019) Effect of temperature on the gasification of olive bagasse particles. J Energy Inst 92(1):153–160. https://doi.org/10.1016/j.joei.2017.10.012

Roy MM, Dutta A, Corscadden K (2013) An experimental study of combustion and emissions of biomass pellets in a prototype pellet furnace. Appl Energy 108:298–307. https://doi.org/10.1016/j.apenergy.2013.03.044

Atnaw SM, Kueh SC (2014) Sulaiman SA (2014) Study on tar generated from downdraft gasification of oil palm fronds. Sci World J 497830:1–8. https://doi.org/10.1155/2014/497830

Makwana JP, Pandey J, Mishra G (2019) Improving the properties of producer gas using high temperature gasification of rice husk in a pilot scale fluidized bed gasifier (FBG). Renew Energy 130:943–951. https://doi.org/10.1016/j.renene.2018.07.011

Narvaez I, Orio A, Aznar MP, Corella J (1996) Biomass gasification with air in an atmospheric bubbling fluidized bed. Effect of six operational variables on the quality of the produced raw gas. Ind Eng Chem Res 35(7):2110–2120. https://doi.org/10.1021/ie9507540

Kumar A, Eskridge K, Jones DD, Hanna MA (2009) Steam–air fluidized bed gasification of distillers grains: effects of steam to biomass ratio, equivalence ratio and gasification temperature. Bioresour Technol 100(6):2062–2068. https://doi.org/10.1016/j.biortech.2008.10.011

Gupta AK, Cichonski W (2007) Ultra-high temperature steam gasification of biomass and solid wastes. Environ Eng Sci 24(8):1179–1189. https://doi.org/10.1089/ees.2007.0120

Acknowledgements

The authors would like to acknowledge the Teaching and Non-Teaching faculties of the Department of Automobile Engineering, Kongu Engineering College, Perundurai for providing sufficient facilities to carry out this research work.

Author information

Authors and Affiliations

Contributions

Murugan Paradesi Chockalingam handled conceptualization, methodology, writing original draft. Saji Raveendran Padmavathy was responsible for reviewing and final editing of the manuscript. Sree Nithyanandan was in responsibility of investigation, while Godwin Glivin was in control of result interpretation. Beno Wincy Winsly Roy aided in the analysis and editing of the manuscript. The methodology and data gathering were the responsibility of Joseph Sekhar Santhappan. The final manuscript was read and approved by all the authors.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chockalingam, M.P., Padmavathy, S.R., Nithyanandan, S. et al. Numerical and experimental study on the effect of nozzle position and inlet air temperature in an industrial-type biomass gasifier. Biomass Conv. Bioref. 12, 2291–2303 (2022). https://doi.org/10.1007/s13399-021-01693-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01693-6