Abstract

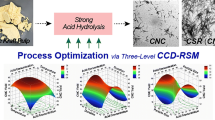

The present study aims to develop a statistical model utilizing the response surface methodology (RSM) to investigate the performance of oxalic acid-choline chloride deep eutectic solvent (OA-ChCl DES) in hydrolyzing amorphous domain of the bleached rice straw pulp (BP), while liberating the oxalic acid-choline chloride DES cellulose nanocrystal (OA-ChCl DES CNC). The process parameters, including temperature, reaction time, and BP to OA-ChCl DES mass ratio, were optimized through the RSM coupled with the face-centered central composite design (FCCCD). The mathematical models were generated, while the analysis of variance (ANOVA) was conducted to determine the most significant factors influencing the response which was measured in terms of yield. The findings revealed that the OA-ChCl DES CNC yield as high as 55.08% was attained under the acidic DES hydrolysis conditions of 79.5 °C, 4 h, and 1:12.64 mass ratio. This regression model enables researchers to predict the OA-ChCl DES CNC yield with respect to the influencing parameters as well as providing an insight for further scale-up process.

Similar content being viewed by others

References

Luque R, Herrero-Davila L, Campelo JM, Clark JH, Hidalgo JM, Luna D, Marinas JM, Romero AA (2008) Biofuels: a technological perspective. Energ Environ Sci 1:542–564. https://doi.org/10.1039/b807094f

Lee HV, Hamid SBA, Zain SK (2014) Conversion of lignocellulosic biomass to nanocellulose: structure and chemical process. Sci World J 2014:1–20. https://doi.org/10.1155/2014/631013

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994. https://doi.org/10.1039/c0cs00108b

Shak KPY, Pang YL, Mah SK (2018) Nanocellulose: recent advances and its prospects in environmental remediation. Beilstein J Nanotech 9:2479–2498. https://doi.org/10.3762/bjnano.9.232

Beck-Candanedo S, Roman M, Gray DG (2005) Effect of reaction conditions on the properties and behavior of wood cellulose nanocrystal suspensions. Biomacromol 6:1048–1054. https://doi.org/10.1021/bm049300p

Camarero Espinosa S, Kuhnt T, Foster EJ, Weder C (2013) Isolation of thermally stable cellulose nanocrystals by phosphoric acid hydrolysis. Biomacromol 14:1223–1230. https://doi.org/10.1021/bm400219u

Du H, Liu W, Zhang M, Si C, Zhang X, Li B (2019) Cellulose nanocrystals and cellulose nanofibrils based hydrogels for biomedical applications. Carbohyd Polym 209:130–144. https://doi.org/10.1016/j.carbpol.2019.01.020

Jordan JH, Easson MW, Condon BD (2020) Cellulose hydrolysis using ionic liquids and inorganic acids under dilute conditions: morphological comparison of nanocellulose. RSC Adv 10:39413–39424. https://doi.org/10.1039/D0RA05976E

Sirviö JA, Visanko M, Liimatainen H (2016) Acidic deep eutectic solvents as hydrolytic media for cellulose nanocrystal production. Biomacromol 17:3025–3032. https://doi.org/10.1021/acs.biomac.6b00910

Abbott AP, Capper G, Davies DL, Rasheed RK, Tambyrajah V (2003) Novel solvent properties of choline chloride/urea mixtures. Chem Commun 70–71. https://doi.org/10.1039/b210714g

Gunny AAN, Arbain D, Nashef EM, Jamal P (2015) Applicability evaluation of deep eutectic solvents-cellulase system for lignocellulose hydrolysis. Bioresource Technol 181:297–302. https://doi.org/10.1016/j.biortech.2015.01.057

Mbous YP, Hayyan M, Hayyan A, Wong WF, Hashim MA, Looi CY (2017) Applications of deep eutectic solvents in biotechnology and bioengineering-promises and challenges. Biotechnol Adv 35:105–134. https://doi.org/10.1016/j.biotechadv.2016.11.006

Douard L, Bras J, Encinas T, Belgacem MN (2021) Natural acidic deep eutectic solvent to obtain cellulose nanocrystals using the design of experience approach. Carbohyd Polym 252:117136. https://doi.org/10.1016/j.carbpol.2020.117136

Liu Y, Guo B, Xia Q, Meng J, Chen W, Liu S, Wang Q, Liu Y, Li J, Yu H (2017) Efficient cleavage of strong hydrogen bonds in cotton by deep eutectic solvents and facile fabrication of cellulose nanocrystals in high yields. ACS Sustain Chem Eng 5:7623–7631. https://doi.org/10.1021/acssuschemeng.7b00954

Ling Z, Edwards JV, Guo Z, Prevost NT, Nam S, Wu Q, French AD, Xu F (2019) Structural variations of cotton cellulose nanocrystals from deep eutectic solvent treatment: micro and nano scale. Cellulose 26:861–876. https://doi.org/10.1007/s10570-018-2092-9

Lim WL, Gunny AAN, Kasim FH, AlNashef IM, Arbain D (2019) Alkaline deep eutectic solvent: a novel green solvent for lignocellulose pulping. Cellulose 26:4085–4098. https://doi.org/10.1007/s10570-019-02346-8

Lim WL, Gunny AAN, Kasim FH, Gopinath SCB, Kamaludin NHI (2021) Cellulose nanocrystals from bleached rice straw pulp: acidic deep eutectic solvent versus sulphuric acid hydrolyses. Cellulose 1–17. https://doi.org/10.1007/s10570-021-03914-7

Karim MZ, Chowdhury ZZ, Hamid SBA, Ali ME (2014) Statistical optimization for acid hydrolysis of microcrystalline cellulose and its physiochemical characterization by using metal ion catalyst. Materials 7:6982–6999. https://doi.org/10.3390/ma7106982

Czitrom V (1999) One-factor-at-a-time versus designed experiments. Am Stat 53:126–131. https://doi.org/10.1080/00031305.1999.10474445

DiNardo A, Brar HS, Subramanian J, Singh A (2019) Optimization of microwave-assisted extraction parameters and characterization of phenolic compounds in Yellow European Plums. Can J Chem Eng 97:256–267. https://doi.org/10.1002/cjce.23237

Liu Y, Luo X, Lan Z, Tang J, Zhao P, Kan H (2018) Ultrasonic-assisted extraction and antioxidant capacities of flavonoids from Camellia fascicularis leaves. CyTA - J Food 16:105–112. https://doi.org/10.1080/19476337.2017.1343867

Chen X, Yu J, Zhang Z, Lu C (2011) Study on structure and thermal stability properties of cellulose fibers from rice straw. Carbohyd Polym 85:245–250. https://doi.org/10.1016/j.carbpol.2011.02.022

Chen YW, Lee HV, Abd Hamid SB (2017) Investigation of optimal conditions for production of highly crystalline nanocellulose with increased yield via novel Cr(III)-catalyzed hydrolysis: response surface methodology. Carbohyd Polym 178:57–68. https://doi.org/10.1016/j.carbpol.2017.09.029

Dufresne A (2019) Nanocellulose processing properties and potential applications. Curr For Rep 5:76–89. https://doi.org/10.1007/s40725-019-00088-1

Song W, Deng Y, Zhu H (2016) Research on wheat straw pulping with ionic liquid 1-ethyl-3-methylimidazole bromide. Kemija u Industriji / J Chem Chem Eng 65:579–585. https://doi.org/10.15255/KUI.2016.032

Kaith BS, Sharma R, Kalia S, Bhatti MS (2014) Response surface methodology and optimized synthesis of guar gum-based hydrogels with enhanced swelling capacity. RSC Adv 4:40339–40344. https://doi.org/10.1039/c4ra05300a

Uyanık GK, Güler N (2013) A study on multiple linear regression analysis. Procd Soc Behv 106:234–240. https://doi.org/10.1016/j.sbspro.2013.12.027

Liu JZ, Weng LP, Zhang QL, Xu H, Ji LN (2003) Optimization of glucose oxidase production by Aspergillus niger in a benchtop bioreactor using response surface methodology. World J Microb Biot 19:317–323. https://doi.org/10.1023/A:1023622925933

Chen X, Du W, Liu D (2008) Response surface optimization of biocatalytic biodiesel production with acid oil. Biochem Eng J 40:423–429. https://doi.org/10.1016/j.bej.2008.01.012

Dahmoune F, Remini H, Dairi S, Aoun O, Moussi K, Bouaoudia-Madi N, Adjeroud N, Kadri N, Lefsih K, Boughani L, Mouni L, Nayak B, Madani K (2015) Ultrasound assisted extraction of phenolic compounds from P. lentiscus L. leaves: comparative study of artificial neural network (ANN) versus degree of experiment for prediction ability of phenolic compounds recovery. Ind Crop Prod 77:251–261. https://doi.org/10.1016/j.indcrop.2015.08.062

Masoumi HRF, Kassim A, Basri M, Abdullah DK (2011) Determining optimum conditions for lipase-catalyzed synthesis of triethanolamine (TEA)-based esterquat cationic surfactant by a Taguchi robust design method. Molecules 16:4672–4680. https://doi.org/10.3390/molecules16064672

Yuan X, Liu J, Zeng G, Shi J, Tong J, Huang G (2008) Optimization of conversion of waste rapeseed oil with high FFA to biodiesel using response surface methodology. Renew Energ 33:1678–1684. https://doi.org/10.1016/j.renene.2007.09.007

Dhandhukia PC, Thakkar VR (2008) Response surface methodology to optimize the nutritional parameters for enhanced production of jasmonic acid by Lasiodiplodia theobromae. J Appl Microbiol 105:636–643. https://doi.org/10.1111/j.1365-2672.2008.03803.x

Beg QK, Sahai V, Gupta R (2003) Statistical media optimization and alkaline protease production from Bacillus mojavensis in a bioreactor. Process Biochem 39:203–209. https://doi.org/10.1016/S0032-9592(03)00064-5

Lee HV, Yunus R, Juan JC, Taufiq-Yap YH (2011) Process optimization design for jatropha-based biodiesel production using response surface methodology. Fuel Process Technol 92:2420–2428. https://doi.org/10.1016/j.fuproc.2011.08.018

Deepak V, Kalishwaralal K, Ramkumarpandian S, Babu SV, Senthilkumar SR, Sangiliyandi G (2008) Optimization of media composition for Nattokinase production by Bacillus subtilis using response surface methodology. Bioresource Technol 99:8170–8174. https://doi.org/10.1016/j.biortech.2008.03.018

Hong B, Chen L, Xue G, Xie Q, Chen F (2014) Optimization of oxalic acid pretreatment of moso bamboo for textile fiber using response surface methodology. Cellulose 21:2157–2166. https://doi.org/10.1007/s10570-014-0227-1

Lu Z, Fan L, Zheng H, Lu Q, Liao Y, Huang B (2013) Preparation, characterization and optimization of nanocellulose whiskers by simultaneously ultrasonic wave and microwave assisted. Bioresource Technol 146:82–88. https://doi.org/10.1016/j.biortech.2013.07.047

Funding

The authors would like to thank the Faculty of Chemical Engineering Technology, Universiti Malaysia Perlis (UniMAP) and Ministry of Education for financing the research under Fundamental Research Grant Scheme FRGS/1/2018/STG01/UNIMAP/03/.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing of interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lim, WL., Gunny, A.A.N., Kasim, F.H. et al. Cellulose nanocrystal production from bleached rice straw pulp by combined alkaline and acidic deep eutectic solvents treatment: optimization by response surface methodology. Biomass Conv. Bioref. 12 (Suppl 1), 25–33 (2022). https://doi.org/10.1007/s13399-021-01654-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01654-z