Abstract

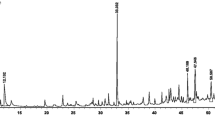

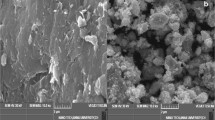

In this study, Manilkara zapota seed oil was used for biodiesel production. The free fatty acid content of the oil was determined as 5.91 mg KOH/g and hence a two-step acid-base transesterification reaction was followed to convert M. zapota seed oil into biodiesel. The performance variables such as reaction temperature, alcohol to oil ratio, experimental duration, and catalyst weight were optimized using Taguchi orthogonal array. The study revealed a 40°C reaction temperature, 6:1 alcohol-to-oil ratio, 150 min experimental duration, and 1 wt.% NaOH catalyst that were optimal performance variables to obtain maximum conversion efficiency of 97.08%. Among the four performance variables, the alcohol-to-oil ratio was found to be the most effective variable with 84.36% of the contribution. The synthesized Manilkara zapota methyl ester (MZME) procured from seed oil with optimized performance variables matches with the standards of ASME D 6751.

Similar content being viewed by others

Abbreviations

- MZSO:

-

Manilkara zapota seed oil

- MZME:

-

Manilkara zapota methyl ester

- OA:

-

orthogonal array

- RBF:

-

round bottom flask

- A.V:

-

acid value

- FFA:

-

free fatty acid

- DOE:

-

design of experiment

- ANOVA:

-

analysis of variance

- S/N ratio:

-

signal to noise ratio

References

RavikumarJayabal (2020) Combined effect of oxygenated additives, injection timing and EGR on combustion, performance and emission characteristics of a CRDi diesel engine powered by sapota biodiesel/diesel blends. Fuel 268:117254. https://doi.org/10.1016/j.fuel.2020.118121

Jayabal R, Thangavelu L, Velu C (2019) Experimental investigation on the effect of ignition enhancers in the blends of sapota biodiesel/diesel blends on a CRDi engine. Energy Fuel 33:12431–12440

Budhwani AAA, Maqbool A, Hussain T, Syed MN (2019) Production of biodiesel by enzymatic transesterification of non-edible Salvadora persica (Pilu) oil and crude coconut oil in a solvent-free system. Bioresour Bioprocess 6(1):41

Samir Naje A, Yuvarajan D, abed Al-Ridah Z, Sandeep H, Nagarajan A (2020) Ignition study of neat biodiesel in dual fueled research engine. Fuel 281:118673. https://doi.org/10.1016/j.fuel.2020.118673

Devarajan Y, Nagappan B, Mageshwaran G, Sunil Kumar M, Durairaj RB (2020d) Feasibility study of employing diverse antioxidants as an additive in research diesel engine running with diesel-biodiesel blends. Fuel 277:118161. https://doi.org/10.1016/j.fuel.2020.118161

Bhanu Teja N, Devarajan Y, Mishra R et al (2021) Detailed analysis on sterculia foetida kernel oil as renewable fuel in compression ignition engine. Biomass Conv Bioref. https://doi.org/10.1007/s13399-021-01328-w

Dwivedi G, Sharma MP (2015) Application of Box–Behnken design in optimization of biodiesel yield from Pongamia oil and its stability analysis. Fuel. 145:256–262

Devarajan Y, Nagappan BK, Munuswamy DB (2017) Performance and emissions analysis on diesel engine fuelled with cashew nut shell biodiesel and pentanol blends. Korean J Chem Eng 34(4):1021–1026

Hemanandh J, Devarajan Y, Mishra R et al (2021) Experimental investigation on slaughter, fish waste and poultry excrete oil as fuel blends in diesel engine. Biomass Conv Bioref. https://doi.org/10.1007/s13399-021-01293-4

Gopinath S, Devan PK (2020) Optimization and prediction of reaction parameters of plastic Pyrolysis oil production using Taguchi Method. Iran J Chem Chem Eng Article:39(2)

Kumar RS, Sivakumar S, Joshuva A, Deenadayalan G, Vishnuvardhan R (2019) Data set on optimization of ethyl ester production from sapota seed oil. Data Brief 25:104388. https://doi.org/10.1016/j.dib.2019.104388

Salleh RM, Ying TL, Mousavi L (2016) Development of fruit bar using Sapodilla (Manilkara zapota L.). J Food Process Preserv 41(2):e12806. https://doi.org/10.1111/jfpp.12806

Kaur, S., Boora, R. S., & Singh, D. (2020). Propagation studies in Sapodilla [Manilkara zapota (L.) P. Royen]: a review. Agric Rev, (Of). https://doi.org/10.18805/ag.r-2010

Sathish Kumar R, Sureshkumar K, Velraj R (2015) Optimization of biodiesel production from Manilkara zapota (L.) seed oil using Taguchi method. Fuel 140:90–96. https://doi.org/10.1016/j.fuel.2014.09.103

Solís-Fuentes JA, Ayala-Tirado RC, Fernández-Suárez AD, Durán-de-Bazúa MC (2015) Mamey sapote seed oil (Pouteria sapota). Potential, composition, fractionation and thermal behavior. Grasas Aceites 66(1):e056. https://doi.org/10.3989/gya.0691141

Appavu P (2018) Effect of injection timing on performance and emission characteristics of palm biodiesel and diesel blends. Journal of Oil Palm Research. https://doi.org/10.21894/jopr.2018.0057

Dewangan A, Yadav AK, Mallick A, Pal A, Singh S (2019) Comparative study of Manilkara zapota and Karanja based biodiesel properties and its effect on diesel engine characteristics. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 1–11. https://doi.org/10.1080/15567036.2019.1661551

Devaraj A, Yuvarajan D, Vinoth Kanna I (2018) Study on the outcome of a cetane improver on the emission characteristics of a diesel engine. International Journal of Ambient Energy :1–4. https://doi.org/10.1080/01430750.2018.1492452

Kılıç M, Uzun BB, Pütün E, Pütün AE (2013) Optimization of biodiesel production from castor oil using factorial design. Fuel Process Technol 111:105–110

Yuvarajan D, Venkata Ramanan M, Christopher Selvam D (2016) Performance analysis on mustard oil methyl ester as a potential alternative fuel. Indian Journal of Science and Technology 9(37). https://doi.org/10.17485/ijst/2016/v9i37/101982

Singh P, Chauhan SR (2017) Feasibility of a new non-edible feedstock in diesel engine: investigation of performance, emission and combustion characteristics. J Mech Sci Technol 31(4):1979–1986

Karabas H (2013) Biodiesel production from crude acorn (Quercus frainetto L.) kernel oil: an optimization process using the Taguchi method. Renew Energy 53:384–388

Karnwal A, Kumar N, Hasan MM, Chaudhary R, Siddiquee AN, Khan ZA (2010) Production of biodiesel from thumba oil: optimization of process parameters. Iran J Energy Environ 1(4):352–358

Onukwuli DO, Emembolu LN, Ude CN, Aliozo SO, Menkiti MC (2017) Optimization of biodiesel production from refined cotton seed oil and its characterization. Egypt J Pet 26(1):103–110

Priyadarshi D, Paul KK (2019) Optimisation of biodiesel production using Taguchi model. Waste Biomass Valorization 10(6):1547–1559

Kumar N, Mohapatra SK, Ragit SS, Kundu K, Karmakar R (2017) Optimization of safflower oil transesterification using the Taguchi approach. Pet Sci 14(4):798–805

Saravanakumar A, Avinash A, Saravanakumar R (2016) Optimization of biodiesel production from Pungamia oil by Taguchi’s technique. Energ Source Part A 38(17):2524–2529

Singh G, Mohapatra SK, Ragit SS, Kundu K (2018) Optimization of biodiesel production from grape seed oil using Taguchi's orthogonal array. Energ Source Part A 40(18):2144–2153

Devarajan Y, Venkata Ramanan M (2016) Investigation on effect of magnetite nanofluid on performance and emission patterns of methyl esters of bio diesel. J Environ Eng Landsc Manag 24(2):90–96. https://doi.org/10.3846/16486897.2016.1142447

Yesilyurt MK, Cesur C (2020) Biodiesel synthesis from Styrax officinalis L. seed oil as a novel and potential non-edible feedstock: a parametric optimization study through the Taguchi technique. Fuel. 265:117025

Singh G, Mohapatra SK, Ragit SS, Kundu K (2018) Optimization of biodiesel production from grape seed oil using Taguchi's orthogonal array. Energ Source Part A 40(18):2144–2153. https://doi.org/10.1080/15567036.2018.1495778

Rana VS (2015) Fatty oil and fatty acid composition of Annona squamosa Linn. seed kernels. Int J Fruit Sci 15(1):79–84. https://doi.org/10.1080/15538362.2014.931168

Muqeem M, Sherwani AF, Ahmad M, Khan ZA (2020) Taguchi based grey relational analysis for multi response optimisation of diesel engine performance and emission parameters. J Heavy Veh Syst 27(4):441. https://doi.org/10.1504/ijhvs.2020.109287

Yuvarajan D, Ravikumar J, Babu MD (2016) Simultaneous optimization of smoke and NOxemissions in a stationary diesel engine fuelled with diesel–oxygenate blends using the grey relational analysis in the Taguchi method. Anal Methods 8(32):6222–6230

Vellaiyan S, Amirthagadeswaran KS (2016) Taguchi-Grey relational-based multi-response optimization of the water-in-diesel emulsification process. J Mech Sci Technol 30(3):1399–1404. https://doi.org/10.1007/s12206-016-0247-x

Vellaiyan S, Amirthagadeswaran KS, Sivasamy DB (2018) Taguchi-Grey relation based multi-response optimization of diesel engine operating parameters with water-in-diesel emulsion fuel. Int J Technol 9(1):68. https://doi.org/10.14716/ijtech.v9i1.1374

Dodo RM, Ause T, Dauda ET, Shehu U, Popoola API (2019) Multi-response optimization of transesterification parameters of mahogany seed oil using grey relational analysis in Taguchi method for quenching application. Heliyon 5(8):e02167. https://doi.org/10.1016/j.heliyon.2019.e02167

Sivaiah P, Chakradhar D (2017) Multi-objective optimisation of cryogenic turning process using Taguchi-based grey relational analysis. Int J Mach Mach Mater 19(4):297. https://doi.org/10.1504/ijmmm.2017.08616

Gopal K, Sathiyagnanam AP, Rajesh Kumar B, Damodharan D, Melvin Victor De Poures, Rana D, Saravanan S, Sethuramasamyraja B (2020) “Prediction and optimization of engine characteristics of a DI diesel engine fueled with cyclo-hexanol/diesel blends” Energy Sources, Part A: Recovery, Utilization, and Environmental Effects. 42:2006-2017

Vellaiyan S, Amirthagadeswaran KS (2017) Emission characteristics of water-emulsified diesel fuel at optimized engine operation condition. Pet Sci Technol 35(13):1355–1363. https://doi.org/10.1080/10916466.2017.1330348

Rathinam S, Balan K, Subbiah G, Sajin J, Devarajan Y (2019) Emission study of a diesel engine fueled with higher alcohol-biodiesel blended fuels. International Journal of Green Energy 16(9):667–673. https://doi.org/10.1080/15435075.2019.1617001

Devarajan Y, Munuswamy D, Nagappan B, Subbiah G (2019) Experimental assessment of performance and exhaust emission characteristics of a diesel engine fuelled with Punnai biodiesel/butanol fuel blends. Petroleum Science 16:1471–1478. https://doi.org/10.1007/s12182-019-00361-9

Sivamurugan P, Devarajan Y (2018) Emission analysis of dual fuelled diesel engine. International Journal of Ambient Energy :1–3. https://doi.org/10.1080/01430750.2018.1517696

Choubey G, Devarajan Y, Huang W, Mehar K, Tiwari M, Pandey KM (2019). Recent advances in cavity-based scramjet engine- a brief review. Int J Hydrogen Energy 44(26):13895–13909. https://doi.org/10.1016/j.ijhydene.2019.04.003

Mahalingam A, Devarajan Y, Radhakrishnan S, Vellaiyan S, Nagappan B (2018) Emissions analysis on mahua oil biodiesel and higher alcohol blends in diesel engine. Alexandria Engineering Journal 57(4):2627–2631. https://doi.org/10.1016/j.aej.2017.07.009

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aurtherson, P.B., Suresh Babu Rao, H., Ganesan, S. et al. Production Process Optimization study on the synthesis of Manilkara zapota seed bio-oil and its characterization. Biomass Conv. Bioref. 13, 5005–5013 (2023). https://doi.org/10.1007/s13399-021-01453-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01453-6