Abstract

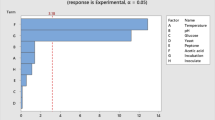

Lignocellulosic raw materials have been widely studied for obtaining bioproducts. Pretreatments for delignification, uncertainties in feedstock composition, long hydrolysis times, and large quantities of expensive enzymes are factors that limit fermentable sugar production. Statistical optimization can help adjust these limiting factors and variables of enzymatic saccharification. This study aimed to optimize conditions for fermentable sugar production using wheat bran, Botrytis ricini URM 5627 endoglucanase, and Box–Behnken experimental design, a response surface methodology. A zymographic assay in polyacrylamide gel was stained with Congo red after hydrolysis. Enzymatic activity measurements indicated enzyme stability at different temperatures (− 20 °C and 6 °C) and periods (up to 120 days). Wheat bran was characterized using Fourier transform infrared spectroscopy (FTIR) before and after enzymatic saccharification. Saccharification time, substrate load, and enzyme load were optimized using the Box–Behnken design. The zymogram demonstrated a single activity band around 39 kDa, the molecular weight of B. ricini URM5627 endoglucanase. Enzyme activity was preserved at 78.78% and 86.08% after storage for 120 days at − 20 °C and 6 °C, respectively. FTIR analyses showed cellulose delignification and loosening after enzymatic action. Maximum production of reducing sugars (116.93 mg g−1) occurred when conditions were maintained at the central point of planning (8 h, 2% substrate load, and 4% enzyme load). The enzyme isolated from B. ricini was stable in solid medium and in stored form, and could saccharify wheat bran without pretreatments. High yield of reducing sugars and proximity between predicted and real values demonstrated effectiveness of statistical optimization in saccharification of lignocellulosic biomass.

Graphical abstract

Similar content being viewed by others

References

Silva TP, de Albuquerque FS, dos Santos CWV, Franco M, Caetano LC, Pereira HJV (2018) Production, purification, characterization and application of a new halotolerant and thermostable endoglucanase of Botrytis ricini URM 5627. Bioresour Technol 270:263–269. https://doi.org/10.1016/j.biortech.2018.09.022

Ferraz JLAA, Souza LO, Soares GA, Coutinho JP, de Oliveira JR, Oliveira EL, Franco M (2018) Enzymatic saccharification of lignocellulosic residues using cellulolytic enzyme extract produced by Penicillium roqueforti ATCC 10110 cultivated on residue of yellow mombin fruit. Bioresour Technol 248:214–220. https://doi.org/10.1016/j.biortech.2017.06.048

Bilal M, Asgher M, Iqbal HMN, Ramzan M (2017) Enhanced bio-ethanol production from old newspapers waste through álcali and enzymatic delignification. Waste Biomass Valor 8:2271–2281. https://doi.org/10.1007/s12649-017-9871-7

Anwar Z, Gulfraz M, Irshad M (2014) Agro-industrial lignocellulosic biomass a key to unlock the future bio-energy: a brief review. J Radiat Res Appl Sci 7:163–173. https://doi.org/10.1016/j.jrras.2014.02.003

Boonsombuti A, Luengnaruemitchai A, Wongkasemjit S (2013) Enhancement of enzymatic hydrolysis of corncob by microwave-assisted alkali pretreatment and its effect in morphology. Cellulose 20:1957–1966. https://doi.org/10.1007/s10570-013-9958-7

Marques GL, Reis NR, Silva TP, Ferreira MLO, Aguiar-Oliveira E, Oliveira JR, Franco M (2017) Production and characterisation of xylanase and endoglucanases produced by Penicillium roqueforti ATCC 10110 through the solid-state fermentation of rice husk residue. Waste Biomass Valor. 9:2061–2069. https://doi.org/10.1007/s12649-017-9994-x

Santos JI, Martín-Sampedro R, Fillat U, Oliva JM, Negro MJ, Ballesteros M, Eugenio M, Ibarra D (2015) Evaluating lignin-rich residues from biochemical ethanol production of wheat straw and olive tree pruning by FTIR and 2D-NMR. International Journal of Polymer Science 2015:1–11. https://doi.org/10.1155/2015/314891

Mood SH, Golfeshan AH, Tabatabaei M, Jouzanib GS, Najafi GH, Gholami M, Ardjmanda M (2013) Lignocellulosic biomass to bioethanol, a comprehensive review with a focus on pretreatment. Renew Sust Energ Rev 27:77–93. https://doi.org/10.1016/j.rser.2013.06.033

Lynd LR, Wyman CE, Gerngross TU (1999) Biocommodity engineering. Biotechnology Program 15:777–793. https://doi.org/10.1021/bp990109e

Gírio FM, Fonseca C, Carvalheiro F, Duarte LC, Marques S, Bogel-Lukasik R (2010) Hemicelluloses for fuel ethanol: a review. Bioresour Technol 101:4775–4800. https://doi.org/10.1016/j.biortech.2010.01.088

Li X, Kim TH, Nghiem NP (2010) Bioethanol production from corn stover using aqueous ammonia pretreatment and two-phase simultaneous saccharification and fermentation (TPSSF). Bioresour Technol 101:5910–5916. https://doi.org/10.1016/j.biortech.2010.03.015

Alvira P, Tomas-Pejo E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis. Bioresour Technol 101:4851–4861. https://doi.org/10.1016/j.biortech.2009.11.093

Singh P, Suman A, Tiwari P, Arya N, Gaur A, Shrivastava AK (2008) Biological pretreatment of sugarcane trash for its conversion to fermentable sugars. World Journal of Microbiology and Biotechnology. https://doi.org/10.1007/s11274-007-9522-4

Cardoso WS, Queiroz PV, Tavares GP, Santos FA, Soares FEF, Kasuya MCM, Queiroz JH (2018) Multi-enzyme complex of white rot fungi in saccharification of lignocellulosic material. Braz. J. Microbiol. https://doi.org/10.1016/j.bjm.2018.05.006

Lopes LS, Veiira N, da Luz JMR, Silva MC, Cardoso WS, Kasuya MCM (2020) Production of fungal enzymes in Macaúba coconut and enzymatic degradation of textile dye. Biocatalysis and Agricultural Biotechnology 26:101651. https://doi.org/10.1016/j.bcab.2020.101651

Sadaf A, Khare SK (2014) Production of Sporotrichum thermophile xylanase by solid state fermentation utilizing deoiled Jatropha curcas seed cake and its application in xylooligosachharide synthesis. Bioresource Technology. https://doi.org/10.1016/j.biortech.2013.11.058

Narra M, Rudakiya DM, Macwan K, Patel N (2020) Black liquor: a potential moistening agent for production of cost-effective hydrolytic enzymes by a newly isolated cellulo-xylano fungal strain Aspergillus tubingensis and its role in higher saccharification efficiency. Bioresour Technol 306:123149. https://doi.org/10.1016/j.biortech.2020.123149

Felina F, Shastri Y (2016) Optimal control of enzymatic hydrolysis of lignocellulosic biomass. Resource-Efficient Technologies. https://doi.org/10.1016/j.reffit.2016.11.0062405-6537

Felina F, Shastri Y (2020) Stochastic optimization of enzymatic hydrolysis of lignocellulosic biomass. Comput Chem Eng. https://doi.org/10.1016/j.compchemeng.2020.1067760098-1

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugars. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Sadana JC, Lachke AH, Patil RV (1984) Endo-(1,4)-β-D-glucanases from Sclerotium rolfsii. Purification, substrate specificity, and mode of action. Carbohydr. Res. https://doi.org/10.1016/0008-6215(84)85206-4

Almeida MN, Falkoski DL, Guimarães VM, Ramos HJO, Visser EM, Maitan-Alfenas GP, de Rezende ST (2013) Characteristics of free endoglucanase and glicosydases multienzyme complex from Fusarium verticillioides. Bioresour Technol. https://doi.org/10.1016/j.biortech.2013.06.021

Chen, G., Du, J., Zhuang, L., Gao P. Purification and properties of endoglucanases from Aspergillus aculeatus SM-L22. (2001)

Jayasekara S, Ratnayake R (2019) Microbial cellulases: an overview and applications. Intechopen. https://doi.org/10.5772/intechopen.84531

Heller MC, Carpenter JF, Randolph TW (1997) Manipulation of lyophilization-induced phase separation: implications for pharmaceutical proteins. Biotechnol Prog 13:590–596

Santos TC, Filho GA, Brito AR, Pires AJV, Bonomo RCF, Franco M (2016) Production and characterization of cellulolytic enzymes by Aspergillus niger and Rhizopus sp. by solid state fermentation of prickly pear. Rev. Caatinga 29:222–233. https://doi.org/10.1590/1983-21252016v29n126rc

Qi G, Huangb D, Jianhui Wanga J, Shena Y, Gao X (2019) Enhanced butanol production from ammonium sulfite pretreated wheat straw by separate hydrolysis and fermentation and simultaneous saccharification and fermentation. Sustain Energy Technol Assess 36:100549. https://doi.org/10.1016/j.seta.2019.100549

Dissanayake N, Thalangamaarachchige VD, Troxell S, Quitevis TL, Abidi N (2018) Substituent effects on cellulose dissolution in imidazolium-based ionic liquids. Cellulose. https://doi.org/10.1007/s10570-018-2055-1

Sawisit S, Jampatesh SS, Jantama K (2018) Optimization of sodium hydroxide pretreatment and enzyme loading for efficient hydrolysis of rice straw to improve succinate production by metabolically engineered Escherichia coli KJ122 under simultaneous saccharification and fermentation. Bioresour Technol 260:348–356. https://doi.org/10.1016/j.biortech.2018.03.107

Wang J, Chioa C, Chen X, Su E, Cao F, Jin Y, Qin W (2019) Efficient saccharification of agave biomass using Aspergillus niger produced low-cost enzyme cocktail with hyperactive pectinase activity. Bioresour Technol 272:26–33. https://doi.org/10.1016/j.biortech.2018.09.069

Adıgüzel AO, Tunçer M (2017) Production and characterization of partially purified thermostable endoxylanase and endoglucanase from novel Actinomadura geliboluensis and the biotechnological applications in the saccharification of lignocellulosic biomass. BioRes. 12(2):2528–2547

Masran R, Zanirun Z, Bahrin EK, Ibrahim MF, Yee PL, Abd-Aziz S (2016) Harnessing the potential of ligninolytic enzymes for lignocellulosic biomass pretreatment. Appl Microbiol Biotechnol 100:5231–5246. https://doi.org/10.1007/s00253-016-7545-1

Acknowledgments

The authors are grateful to the Brazilian Ministry of Education’s Coordination for the Improvement of Higher Education Personnel (CAPES), Brazilian National Council for Scientific and Technological Development (CNPq), and Alagoas State Research Foundation (FAPEAL) for funding this research. The authors also wish to thank the Federal University of Alagoas’ Catalysis Group (GCAR).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Silva, T.P., Ferreira, A.N., de Albuquerque, F.S. et al. Box–Behnken experimental design for the optimization of enzymatic saccharification of wheat bran. Biomass Conv. Bioref. 12, 5597–5604 (2022). https://doi.org/10.1007/s13399-021-01378-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01378-0