Abstract

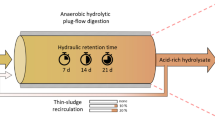

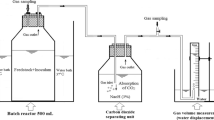

Corn rind is a major agricultural residue which is often problematic for disposal. However, it is a rich lignocellulose source useful for many downstream industrial applications. The technique commonly used in the bioconversion of organic waste is a static two-stage fermentation system; in the first stage, corn rind is converted to simple sugars, and at the second stage, reduced sugars are used to produce commercial products. The stage one is a resource-consuming process as the product removal is not dynamic, and hence, the bioconversion process comes to an equilibrium due to product accumulation. Therefore, a novel concept of continuous multiphase-multistage bioreactor was introduced, in which the sugars formed are continuously removed to enhance the bioconversion efficiency. A lab-scale model with three digestion modules, each with 2000-ml working capacity, is developed for degradation of corn rind to partially optimize the process parameters that eventually improve corn rind degradation. The multiphase in each stage contributes cumulatively in achieving better degradation of corn rind. In the first stage, out of 150-g feed-stock introduced, a total of 2353 mg of free reducing sugar was released on completion of five phases (1st phase; 431 mg, 2nd phase; 690 mg, 3rd phase; 523 mg, 4th phase; 374 mg, 5th phase; 335 mg) which accounts for 44% of the yield potential. The lab-scale prototype showed promising trend of progressive degradation of corn rind that requires further process optimization to achieve maximum productivity. The reducing sugars thus obtained could be used for subsequent bioconversion processes by using suitable microorganisms.

Similar content being viewed by others

Availability of data and material

Data and materials are available.

Code availability

Not applicable

References

Andrade FA, Andrade JO, Andrade CGTJ, Miglioranza E (2014) Accumulation of silicon and arrangement and shapes of silica bodies in corn leaves. Genetics and molecular research : GMR 13:1690–1696

Baptista SL, Cunha JT, Romaní A, Domingues L (2018) Xylitol production from lignocellulosic whole slurry corn cob by engineered industrial Saccharomyces cerevisiae PE-2. Bioresour Technol 267:481–491

Bayrock DP, Michael Ingledew W (2001) Application of multistage continuous fermentation for production of fuel alcohol by very-high-gravity fermentation technology. J Ind Microbiol Biotechnol 27:87–93

Bustos G, R. J. G. G, Vazquez M (2003) Modelling of the hydrolysis of sugar cane bagasse with hydrocholoric acid. Appl Biochem Biotechnol 104:51–68

DE&S (2020) Advance estimates of production of food grains for 2019-20. Directorate of Economics & Statistics, Department of Agriculture, Cooperation and Farmers Welfare, Government of India

Intanoo P, Chaimongkol P, Chavadej S (2016) Hydrogen and methane production from cassava wastewater using two-stage upflow anaerobic sludge blanket reactors (UASB) with an emphasis on maximum hydrogen production. Int J Hydrog Energy 41:6107–6114

Mcghee JE, Julian GS, Detroy RW (1982) Continuous and static fermentation of glucose to ethanol by immobilized Saccharomyces cerevisiae cells of different ages. Appl Environ Microbiol 44(1):19–22

Pérez-Rodríguez N, García-Bernet D, Domínguez JM (2016) Effects of enzymatic hydrolysis and ultrasounds pretreatments on corn cob and vine trimming shoots for biogas production. Bioresour Technol 221:130–138

Sadasivam S, Manickam K (1992) Biochemical methods for agricultural sciences. Wiley Eastern, Coimbatore

Saliu BK, Sani A (2012) Bioethanol potentials of corn cob hydrolysed using cellulases of Aspergillus niger and Penicillium decumbens. EXCLI J 11:468–479

Sasikumar V, Priya V, Shankar C, Sekar S (2014) Isolation and preliminary screening of lignin degrading microbes. Journal of Academia and Industrial Research 3(6):291–294

Tabatabaei M, Rahim RA, Abdullah N, Wright A-DG, Shirai Y, Sakai K, Sulaiman A, Hassan MA (2010) Importance of the methanogenic archaea populations in anaerobic wastewater treatments. Process Biochem 45:1214–1225

Umashankar N, Meghashree H, Benherlal P, Chavan M (2018) Isolation and screening of lignin degrading bacteria from different natural and organic sources. Int J Curr Microbiol App Sci 7(12):609–617

Wu J, Hu J, Zhao S, He M, Hu G, Ge X, Peng N (2018) Single-cell protein and xylitol production by a novel yeast strain Candida intermedia FL023 from lignocellulosic hydrolysates and xylose. Appl Biochem Biotechnol 185:163–178

Funding

This research work was financially supported by the Science and Engineering Research Board, Department of Science and Technology, Government of India, under the Empowerment and Equity Opportunities for Excellence in Science Program, EMEQ.

Author information

Authors and Affiliations

Contributions

All authors have contributed in research as well as publication.

Corresponding author

Ethics declarations

Ethics approval

Not applicable

Consent to participate

Consent from all participating researchers have been obtained.

Consent for publication

Consent from all participating researchers has been obtained for publishing results.

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Umashankar, N., Benherlal, P.S. & Chavan, M. Bioprocessing of corn rind using continuous multiphase-multistage bioreactor for downstream applications. Biomass Conv. Bioref. 13, 953–960 (2023). https://doi.org/10.1007/s13399-021-01341-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01341-z