Abstract

A novel consolidated bioprocess was designed for processing of Parthenium hysterophorus biomass based on ultrasound-assisted deep eutectic solvent (DES) pretreatment followed by in situ enzymatic saccharification and fermentation of sugars to ethanol-biofuel. Among various DESs examined, choline chloride/sorbitol (CCS, molar ratio 1:5) pretreated P. hysterophorus biomass yielded maximum sugar (148.54 mg/g biomass) upon enzymatic saccharification. Furthermore, combined ultrasonic irradiation and CCS pretreatment resulted in substantially enhanced sugar yield as compared with either of the standalone pretreatment. A central composite design was employed for the optimization of combined ultrasound and choline chloride/sorbitol pretreatment that further aided in achieving increased reducing sugar yield (25.72%). The pretreated biomass was examined by X-ray diffraction (XRD), Fourier-transform infrared spectroscopy (FT-IR), scanning electron microscopy (SEM) and proton nuclear magnetic resonance (1H-NMR) analysis to elucidate the functional mechanisms of combinative pretreatment. Understanding of pretreatment mechanisms may help custom designing of novel strategies for the efficient refining of biomass.

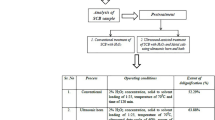

Graphical abstract

Similar content being viewed by others

References

Lin W, Xing S, Jin Y, Lu X, Huang C, Yong Q (2020) Insight into understanding the performance of deep eutectic solvent pretreatment on improving enzymatic digestibility of bamboo residues. Bioresour Technol 306:123163. https://doi.org/10.1016/j.biortech.2020.123163

Toor M, Kumar SS, Malyan SK, Bishnoi NR, Mathimani T, Rajendran K, Pugazhendhi A (2020) An overview on bioethanol production from lignocellulosic feedstocks. Chemosphere 242:125080. https://doi.org/10.1016/j.chemosphere.2019.125080

Sharma V, Nargotra P, Bajaj BK (2019) Ultrasound and surfactant assisted ionic liquid pretreatment of sugarcane bagasse for enhancing saccharification using enzymes from an ionic liquid tolerant Aspergillus assiutensis VS34. Bioresour Technol 285:121319. https://doi.org/10.1016/j.biortech.2019.121319

Pandiyan K, Singh A, Singh S, Saxena AK, Nain L (2019) Technological interventions for utilization of crop residues and weedy biomass for second generation bio-ethanol production. Renew Energy 132:723–741. https://doi.org/10.1016/j.renene.2018.08.049

Nargotra P, Sharma V, Gupta M, Kour S, Bajaj BK (2018) Application of ionic liquid and alkali pretreatment for enhancing saccharification of sunflower stalk biomass for potential biofuel-ethanol production. Bioresour Technol 267:560–568. https://doi.org/10.1016/j.biortech.2018.07.070

Borah AJ, Agarwal M, Goyal A, Moholkar VS (2019) Physical insights of ultrasound-assisted ethanol production from composite feedstock of invasive weeds. Ultrason Sonochem 51:378–385. https://doi.org/10.1016/j.ultsonch.2018.07.046

Nargotra P, Sharma V, Bajaj BK (2019) Consolidated bioprocessing of surfactant-assisted ionic liquid-pretreated Parthenium hysterophorus L. biomass for bioethanol production. Bioresour Technol 289:121611. https://doi.org/10.1016/j.biortech.2019.121611

Saini A, Aggarwal NK (2019) Saccharification of Parthenium hysterophorus biomass using cellulase from Streptomyces sp. NAA2. Ann Microbiol 69:685–694. https://doi.org/10.1007/s13213-019-01459-6

Vaid S, Bhat N, Nargotra P, Bajaj BK (2018) Combinatorial application of ammonium carbonate and sulphuric acid pretreatment to achieve enhanced sugar yield from pine needle biomass for potential biofuel–ethanol production. Energy Ecol Environ 3:126–135. https://doi.org/10.1007/s40974-018-0083-1

Tian D, Guo Y, Hu J, Yang G, Zhang J, Luo L, Shen F (2020) Acidic deep eutectic solvents pretreatment for selective lignocellulosic biomass fractionation with enhanced cellulose reactivity. Int J Biol Macromol 142:288–297. https://doi.org/10.1016/j.ijbiomac.2019.09.100

Ong VZ, Wu TY, Lee CBTL, Cheong NWR, Shak KPY (2019) Sequential ultrasonication and deep eutectic solvent pretreatment to remove lignin and recover xylose from oil palm fronds. Ultrason Sonochem 58:104598. https://doi.org/10.1016/j.ultsonch.2019.05.015

Wang ZK, Li H, Lin XC, Tang L, Chen JJ, Mo JW, Shen XJ (2020) Novel recyclable deep eutectic solvent boost biomass pretreatment for enzymatic hydrolysis. Bioresour Technol 307:123237. https://doi.org/10.1016/j.biortech.2020.123237

Kumar N, Muley PD, Boldor D, Coty GG IV, Lynam JG (2019) Pretreatment of waste biomass in deep eutectic solvents: conductive heating versus microwave heating. Ind Crops Prod 142:111865. https://doi.org/10.1016/j.indcrop.2019.111865

Bundhoo ZM, Mohee R (2018) Ultrasound-assisted biological conversion of biomass and waste materials to biofuels: a review. Ultrason Sonochem 40:298–313. https://doi.org/10.1016/j.ultsonch.2017.07.025

Singh S, Agarwal M, Sarma S, Goyal A, Moholkar VS (2015) Mechanistic insight into ultrasound induced enhancement of simultaneous saccharification and fermentation of Parthenium hysterophorus for ethanol production. Ultrason Sonochem 26:249–256. https://doi.org/10.1016/j.ultsonch.2015.02.011

Hassan SS, Ravindran R, Jaiswal S, Tiwari BK, Williams GA, Jaiswal AK (2020) An evaluation of sonication pretreatment for enhancing saccharification of brewers’ spent grain. Waste Manage 105:240–247. https://doi.org/10.1016/j.wasman.2020.02.012

Zhang Y, Li T, Shen Y, Wang L, Zhang H, Qian H, Qi X (2020) Extrusion followed by ultrasound as a chemical-free pretreatment method to enhance enzymatic hydrolysis of rice hull for fermentable sugars production. Ind Crops Prod 149:112356. https://doi.org/10.1016/j.indcrop.2020.112356

Liu YJ, Li B, Feng Y, Cui Q (2020) Consolidated bio-saccharification: leading lignocellulose bioconversion into the real world. Biotechnol Adv 40:107535. https://doi.org/10.1016/j.biotechadv.2020.107535

Zhang CW, Xia SQ, Ma PS (2016) Facile pretreatment of lignocellulosic biomass using deep eutectic solvents. Bioresour Technol 219:1–5. https://doi.org/10.1016/j.biortech.2016.07.026

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing 20. sugar. Anal Chem 31:426–428

Segal LGJMA, Creely JJ, Martin AE Jr, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Bhagwat S, Girma AD, Kumar A (2016) Statistical optimization of enzymatic saccharification of acid pretreated Parthenium hysterophorus biomass using response surface methodology. Biofuels 7(5):501–509. https://doi.org/10.1080/17597269.2016.1163214

Mamilla JL, Novak U, Grilc M, Likozar B (2019) Natural deep eutectic solvents (DES) for fractionation of waste lignocellulosic biomass and its cascade conversion to value-added bio-based chemicals. Biomass Bioenerg 120:417–425. https://doi.org/10.1016/j.biombioe.2018.12.002

Thi S, Lee KM (2019) Comparison of deep eutectic solvents (DES) on pretreatment of oil palm empty fruit bunch (OPEFB): cellulose digestibility, structural and morphology changes. Bioresour Technol 282:525–529. https://doi.org/10.1016/j.biortech.2019.03.065

Chen Y, Mu T (2019) Application of deep eutectic solvents in biomass pretreatment and conversion. Green Energy Environ 4:95–115. https://doi.org/10.1016/j.gee.2019.01.012

Loow YL, New EK, Yang GH, Ang LY, Foo LYW, Wu TY (2017) Potential use of deep eutectic solvents to facilitate lignocellulosic biomass utilization and conversion. Cellulose 24:3591–3618. https://doi.org/10.1007/s10570-017-1358-y

Sai YW, Lee KM (2019) Enhanced cellulase accessibility using acid-based deep eutectic solvent in pretreatment of empty fruit bunches. Cellulose 26:9517–9528. https://doi.org/10.1007/s10570-019-02770-w

Gao J, Chen C, Lin Y, Zhang L, Ji H, Liu S (2020) Enhanced enzymatic hydrolysis of rice straw via pretreatment with deep eutectic solvents-based microemulsions. Bioresour Technol Reports 10:100404. https://doi.org/10.1016/j.biteb.2020.100404

Wang Z, Hou X, Sun J, Li M, Chen Z, Gao Z (2018) Comparison of ultrasound-assisted ionic liquid and alkaline pretreatment of Eucalyptus for enhancing enzymatic saccharification. Bioresour Technol 254:145–150. https://doi.org/10.1016/j.biortech.2018.01.021

He Z, Wang Z, Zhao Z, Yi S, Mu J, Wang X (2017) Influence of ultrasound pretreatment on wood physiochemical structure. Ultrason Sonochem 34:136–141. https://doi.org/10.1016/j.ultsonch.2016.05.035

Bharadwaja STP, Singh S, Moholkar VS (2015) Design and optimization of a sonohybrid process for bioethanol production from Parthenium hysterophorus. J Taiwan Inst Chem Eng 51:71–78. https://doi.org/10.1016/j.jtice.2015.01.022

Singh S, Sarma S, Agarwal M, Goyal A, Moholkar VS (2015) Ultrasound enhanced ethanol production from Parthenium hysterophorus: a mechanistic investigation. Bioresour Technol 188:287–294. https://doi.org/10.1016/j.biortech.2014.12.038

Singh S, Bharadwaja STP, Yadav PK, Moholkar VS, Goyal A (2014) Mechanistic investigation in ultrasound-assisted (alkaline) delignification of Parthenium hysterophorus biomass. Ind Eng Chem Res 53:14241–14252. https://doi.org/10.1021/ie502339q

Fakayode OA, Aboagarib EAA, Yan D, Li M, Wahia H, Mustapha A, Ma H (2020) Novel two-pot approach ultrasonication and deep eutectic solvent pretreatments for watermelon rind delignification: parametric screening and optimization via response surface methodology. Energy 203:117872. https://doi.org/10.1016/j.energy.2020.117872

Martínez-Patiño JC, Gullón B, Romero I, Ruiz E, Brnčić M, Žlabur JŠ, Castro E (2019) Optimization of ultrasound-assisted extraction of biomass from olive trees using response surface methodology. Ultrason Sonochem 51:487–495. https://doi.org/10.1016/j.ultsonch.2018.05.031

Vaid S, Nargotra P, Bajaj BK (2018) Consolidated bioprocessing for biofuel-ethanol production from pine needle biomass. Environ Prog Sustain Energy 37:546–552. https://doi.org/10.1002/ep.12691

Rojas-Chamorro JA, Romero I, López-Linares JC, Castro E (2020) Brewer’s spent grain as a source of renewable fuel through optimized dilute acid pretreatment. Renew Energy 148:81–90. https://doi.org/10.1016/j.renene.2019.12.030

Loow YL, Wu TY, Yang GH, Ang LY, New EK, Siow LF, Teoh WH (2018) Deep eutectic solvent and inorganic salt pretreatment of lignocellulosic biomass for improving xylose recovery. Bioresour Technol 249:818–825. https://doi.org/10.1016/j.biortech.2017.07.165

Nelson ML, O’Connor RT (1964) Relation of certain infrared bands to cellulose crystallinity and crystal lattice type. Part II. A new infrared ratio for estimation of crystallinity in celluloses I and II. J Appl Polym Sci 8(3):1325–1341. https://doi.org/10.1002/app.1964.070080323

Karimi K, Taherzadeh MJ (2016) A critical review of analytical methods in pretreatment of lignocelluloses: composition, imaging, and crystallinity. Bioresour Technol 200:1008–1018. https://doi.org/10.1016/j.biortech.2015.11.022

Amoah J, Ogura K, Schmetz Q, Kondo A, Ogino C (2019) Co-fermentation of xylose and glucose from ionic liquid pretreated sugar cane bagasse for bioethanol production using engineered xylose assimilating yeast. Biomass Bioenerg 128:105283. https://doi.org/10.1016/j.biombioe.2019.105283

Guo Z, Zhang Q, You T, Ji Z, Zhang X, Qin Y, Xu F (2019) Heteropoly acids enhanced neutral deep eutectic solvent pretreatment for enzymatic hydrolysis and ethanol fermentation of Miscanthus x giganteus under mild conditions. Bioresour Technol 293:122036. https://doi.org/10.1016/j.biortech.2019.122036

Acknowledgements

Authors thankfully acknowledge the Director, School of Biotechnology, University of Jammu, Jammu, for providing necessary laboratory facilities. Professor Raj K. Rampal, Head, Department of Environmental Sciences, and Ms Nishu, Research Scholar, are thanked for kindly helping in lignin analysis in the biomass. SAIF, STIC, Cochin University of Science and Technology, Kerala, India, and SAIF, IIT Madras, Chennai, India, are acknowledged for physicochemical analysis.

Availability of data and material

All datasets used and analyzed in the current study are available from the corresponding author.

Funding

Dr. Bijender Kumar Bajaj gratefully acknowledges the Institute of Advanced Study, Durham University, UK, for providing COFUND International Senior Research Fellowship for a research stay at the Department of Biosciences, Durham University, Durham, UK, and the Commonwealth Scholarship Commission, UK, for providing Commonwealth Fellowship for a research stay at the Institute of Biological, Environmental and Rural Sciences (IBERS), Aberystwyth University, Aberystwyth, UK, and Indo-US Science and Technology Forum (IUSSTF) for a research stay at the Ohio State University, USA. Financial support in the form of Research Projects to Dr. Bijender Kumar Bajaj (B.K.B.) from funding agencies such as the Department of Science and Technology (DST), University Grants Commission (UGC) and Council of Scientific and Industrial Research (CSIR) is gratefully acknowledged. Ms. Parushi Nargotra acknowledges Rashtriya Uchchattar Shiksha Abhiyan (RUSA) for providing a Ph.D. research fellowship. Mr. Vishal Sharma thankfully acknowledges the Department of Science and Technology (Govt. of India) for providing Inspire fellowship for doctoral research. Ms. Surbhi Sharma is thankful to the University of Jammu for providing the University Research Scholarship.

Author information

Authors and Affiliations

Contributions

Dr. Bijender Kumar Bajaj (B.K.B.) conceptualized and designed the research problem. Material preparation, data collection, analysis, investigation and interpretation were performed by Ms. Parushi Nargotra (P.N.) and Mr. Vishal Sharma (V.S.). P.N. wrote the first draft of the manuscript. V.S. and Ms. Surbhi Sharma (S.S.) participated in the editing and preparation of the final manuscript. B.K.B. and Ms. Nisha Kapoor (N.K.) critically reviewed the manuscript for grammatical and scientific errors. B.K.B. submitted the MS. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Code availability

Design-Expert 6.0 Stat-Ease, Inc., Minneapolis, USA

Ethics approval

Not applicable.

Consent for publication

All authors agree to publish this manuscript.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• First report on bioprocessing of P. hysterophorus using deep eutectic solvents, DESs.

• Ultrasound-assisted DES pretreatment enhances the sugar yield and hence the process efficacy.

• A one-pot consolidated process was developed for combined DES and ultrasound pretreatment.

• Molecular mechanism of pretreatment was studied by SEM, FT-IR, XRD and 1H-NMR

• Consolidated one-pot bioprocess for the conversion of biomass to biofuel-ethanol.

Rights and permissions

About this article

Cite this article

Nargotra, P., Sharma, V., Sharma, S. et al. Development of consolidated bioprocess for biofuel-ethanol production from ultrasound-assisted deep eutectic solvent pretreated Parthenium hysterophorus biomass. Biomass Conv. Bioref. 12, 5767–5782 (2022). https://doi.org/10.1007/s13399-020-01017-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-01017-0