Abstract

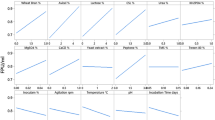

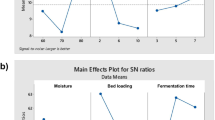

Economical and higher production of cellulase-free xylanase(s) is needed for their wider application in paper and pulp industries. For enzyme production at industrial scale, the growth medium contributes up to 40% of the total production cost. The large quantity of xylan-rich corn cob biomass generated worldwide from corn-processing industries can be used as a cheaper substrate for the production of xylanase. In the present study, the optimization of the production of xylanase by Aspergillus niger DX-23 was studied under solid-state fermentation (SSF) using the Plackett-Burman design (PBD) and response surface methodology (RSM). Among eleven factors investigated (each at two levels) in PBD, corn cob powder, KH2PO4, yeast extract, Tween 20, FeSO4.7H2O, MgSO4.7H2O, CoCl2, MnSO4.H2O and ZnSO4∙H2O significantly (p < 0.05) influenced the production of xylanase by A. niger DX-23. Subsequently, RSM involving central composite design (CCD) was adopted to determine the optimum levels of corn cob powder, NaNO3 and KH2PO4 and FeSO4. According to ANOVA for xylanase production, for CCD-I although the quadratic model developed was significant (p = 0.026465), the model also showed significant lack-of-fit (p = 0.004056) and low predicted R2. Hence, CCD-II which included two variables, i.e. corn cob powder and NaNO3, was carried out. For CCD-II, the quadratic model developed was significant (p = 0.007753), lack-of-fit value was non-significant (p = 0.677031) and the predicted R2 was 0.51. Based on CCD-II, the optimum levels of corn cob powder and NaNO3 in the medium were found to be 150.0 g/l and 5.1 g/l, respectively. To confirm the accuracy of the model, when xylanase production by A. niger DX-23 was studied in an optimized medium under SSF conditions, the xylanase yield reached 306.12 ± 7.4 U/g after 10 days of growth which agreed fairly well with the predicted value (290.15 U/g). Hence, the quadratic model created could be considered to be accurate and reliable for predicting the production of xylanase by A. niger DX-23 under SSF. Moreover, when the effect of pH and inoculum concentration on xylanase production was investigated, in an optimized medium, the maximum production of xylanase was obtained at pH 5.0 and at an inoculum level of 5.0 × 106 spores/ml. When the time course of the fermentation was followed, A. niger DX-23 produced maximum xylanase (496.9 ± 3.0 U/g) after 6 days of fermentation.

Similar content being viewed by others

References

Polizeli MLTM, Rizzatti ACS, Monti R, Terenzi HF, Jorge JA, Amorim DS (2005) Xylanases from fungi: properties and industrial applications. Appl Microbiol Biotechnol 67:577–591

Qinnghe C, Xiaoyu Y, Tiangui N, Cheng J, Qiugang M (2004) The screening of culture condition and properties of xylanase by white-rot fungus Pleurotusostreatus. Proc Biochem 39:1561–1566

Bajaj BK, Sharma M, Sharma S (2011) Alkali stable endo-β-1,4-xylanase production from a newly isolated alkalitolerant Penicillium sp. SS1 using agro-residues. 3 Biotech 1:83–90

Chapla D, Divecha J, Madamwar D, Shah A (2010) Utilization of agro-industrial waste for xylanase production by Aspergillus foetidus MTCC 4898 under solid state fermentation and its application in saccharification. Biochem. Eng. J 49:361–369

Souissi N, Ellouz-Triki Y, Bougatef A, Blibech M, Nasri M (2008) Preparation and use of media for protease producing bacterial strains based on by-products from Cuttlefish (Sepia officinalis) and wastewaters from marine-products processing factories. Microbiol Res 163:473–480

Betini JHA, Michelin M, Peixoto-Nogueira SC, Jorge JA, Terenzi HF, Polizeli MLTM (2009) Xylanases from Aspergillus niger, Aspergillus niveus and Aspergillus ochraceus produced under solid-state fermentation and their application in cellulose pulp bleaching. Bioprocess Biosyst Eng 32:819–824

Amore A, Giacobbe S, Faraco V (2013) Regulation of cellulase and hemicellulase gene expression in fungi. Curr Genomics 14:230–249

Haltrich D, Nidetzky B, Kulbe KD, Steiner W, Zupancic S (1996) Production of fungal xylanases. Bioresour. Technol 58:137–161

Chandel AK, Chandrashekhar G, Radhika K, Ravinder R, Ravindra P (2011) Bioconversion of pentose sugars into ethanol: a review and future directions. Biotechnol Mol Biol Rev 6:8–20

Desai D, Iyer B (2016) Biodeinking of old newspaper pulp using a cellulase-free xylanase preparation of Aspergillus niger DX-23. Biocatal Agri Biotechnol 5:78–85

Desai D, Iyer B (2017) Utilization of corn cob waste for cellulase-free xylanase production by Aspergillus niger DX-23: medium optimization and strain Improvement. Waste Biomass Valor 8:103–113

Virupakshi S, Babu KG, Gaikwad SR, Naik GR (2005) Production of a xylanolytic enzyme by a thermoalkaliphilic Bacillus sp. JB-99 in solid state fermentation. Process Biochem 40:431–435

Uday USP, Choudhury P, Bandyopadhyay TK, Bhunia B (2016) Classification, mode of action and production strategy of xylanase and its application for biofuel production from water hyacinth. Int. J. Biol. Macromol 82:1041–1054

Pandey A, Selvakumar P, Soccol CR, Nigam P (1999) Solid state fermentation for the production of industrial enzymes. Curr Science 77:149–162

Sabu A, Pandey A, Daud MJ, Szakacs G (2005) Tamarind seed powder and palm kernel cake: two novel agro residues for the production of tannase under solid state fermentation by Aspergillus niger ATCC 16620. Bioresour Technol 96:1223–1228

Shah AR, Datta M (2005) Xylanase production under solid-state fermentation and its characterization by an isolated strain of Aspergillus foetidus in India. World J. Microbiol Biotechnol 21:233–243

Prasertsan P, Kunghae A, Maneesri J, Oi S (1997) Optimization for xylanase and cellulase production from Aspergillus niger ATTC 6275 in palm oil mill wastes and its application. World J Microbiol Biotechnol 13:555–559

Bhunia B, Dey A (2012) Statistical approach for optimization of physiochemical requirements on alkaline protease production from Bacillus licheniformis NCIM. 2012:2042–2013. https://doi.org/10.1155/2012/905804

Mandels M, Weber J (1969) The production of cellulases. Adv Chem Ser 95:391–412

Sanghvi GV, Koyani RD, Rajput KS (2010) Thermostable xylanase production and partial purification by solid-state fermentation using agricultural waste wheat straw. Mycology 1:106–112

Torres JMO, dela Cruz TEE (2013) Production of xylanases by mangrove fungi from the Philippines and their application in enzymatic pretreatment of recycled paper pulps. World J Microbiol Biotechnol 29:645–655

Oliveira LA, Porto AL, Tambourgi EB (2006) Production of xylanase and protease by Penicillium janthinellum CRC 87 M-115 from different agricultural wastes. Bioresour. Technol. 97:862–867

Howard RL, Abotsi E, Van Rensburg EJ, Howard S (2003) Lignocellulose biotechnology: issues of bioconversion and enzyme production. Afr J Biotechnol 2:602–619

Kumar R, Wyman CE (2009) Effect of xylanase supplementation of cellulase on digestion of corn stover solids prepared by leading pretreatment technologies. Bioresour. Technol 100:4203–4213

Su Y, Zhang X, Hou Z, Zhu X, Guo X, Ling P (2011) Improvement of xylanase production by thermophilic fungus Thermomyceslanuginosus SDYKY-1 using response surface methodology. New Biotechnol 28:40–46

Kanagasabai V, Thangavelu V (2013) Response surface methodological optimization of the medium components for production of xylanase under SSF by Aspergillus fumigatus. J Adv Sci Res 4:13–20

Liu C, Sun ZT, Du JH, Wang J (2008) Response surface optimization of fermentation conditions for producing xylanase by Aspergillus niger SL- 05. J Ind Microbiol Biotechnol 35:703–711

Xu QH, Wang YP, Qin MH, Fu YJ, Li ZQ, Zhang FS, Li JH (2011) Fiber surface characterization of old newsprint pulp deinked by combining hemicellulase with laccase-mediator system. Bioresour Technol 102:6536–6540

Cui F, Zhao L (2012) Optimization of xylanase production from Penicillium sp. WX-Z1 by a two-step statistical strategy: Plackett-Burman and Box-Behnken experimental design. Int. J. Mol Sci 13:10630–10646

Li Y, Liu Z, Cui F, Liu Z, Zhao H (2007) Application of Plackett–Burman experimental design and Doehlert design to evaluate nutritional requirements for xylanase production by Alternaria mali ND-16. Appl Microbiol Biotechnol 77:285–291

Jeya M, Thiagarajan S, Gunasekaran P (2005) Improvement of xylanase production in solid-state fermentation by alkali tolerant Aspergillus versicolor MKU3. Lett. Appl. Microbiol 41:175–178

de Oliveira SLR, Maciel TC, Sancho SO, Rodrigues S (2016) Solid-state production of cellulase by Melanoporia sp. CCT 7736: a new strain isolated from coconut shell (Cocos nucifera L.). Bioresour. Bioprocess 3:1

Alberton LR, Vandenberghe LPDS, Assmann R, Fendrich RC, Rodriguéz-León J, Soccol CR (2009) Xylanase production by Streptomyces viridosporus T7A in submerged and solid-state fermentation using agro-industrial residues. Braz. Arch. Biol. Technol 52:171–180

Kapilan R, Arasaratnam V (2011) Paddy husk as support for solid state fermentation to produce xylanase from Bacillus pumilus. Rice Sci 18:36–45

Niawanti H, Putri NP, Rabimardani N, Amalia S, Lusiani CE (2019) Modeling of tannin mass transfer on the Averrhoa bilimbi leaf extraction using Box-Behnken Design. Eurasia J Biosci. 13:2327–2335

Aziz DE, Abdelbary AA, Elassasy AI (2019) Investigating superiority of novel bilosomes over niosomes in the transdermal delivery of diacerein: in vitro characterization, ex vivo permeation and in vivo skin deposition study. J Liposome Res 2(29):73–85

Pandey A (1992) Recent process developments in solid state fermentation. Process Biochem 27:12–17

Ikasari L, Mitchell DA (1994) Protease production by Rhizopus oligosporus in solid state fermentation. Appl Microbiol Biotechnol 10:320–324

Raimbault M, Alazard D (1980) Culture method to study fungal growth in solid fermentation. European J Appl Microbiol Biotechnol 9:199–209

De Souza CGM, Girardo NS, Costa MAF, Peralta RM (1999) Influence of growth conditions on the production of xylanolytic enzymes by Aspergillus flavus. J Basic Microbiol 39:155–160

Narang S, Sahai V, Bisaria VS (2001) Optimization of xylanase production by Melanocarpusalbomyces IIS68 in solid state fermentation using response surface methodology. J Biosci Bioeng 91:425–427

Park Y, Kang S, Lee J, Hong SL, Kim S (2002) Xylanase production in solid state fermentation by Aspergillus niger mutant using statistical experimental designs. Appl Microbiol Biotechnol 58:761–766

Senthilkumar SR, Ashokkumar B, Chandra RK, Gunasekaran P (2005) Optimization of medium composition for alkali-stable xylanase production by Aspergillus fischeri Fxn 1 in solid-state fermentation using central composite rotary design. Bioresour Technol 96:1380–1386

Sonia KG, Chadha BS, Saini HS (2005) Sorghum straw for xylanase hyper-production by Thermomyces lanuginosus (D 2 W 3) under solid-state fermentation. Bioresour Technol 96:1561–1569

Azin M, Moravej R, Zareh D (2007) Production of xylanase by Trichoderma longibrachiatum on a mixture of wheat bran and wheat straw: optimization of culture condition by Taguchi method. Enzyme Microbial Technol 40:801–805

Garai D, Kumar V (2013) Response surface optimization for xylanase with high volumetric productivity by indigenous alkali tolerant Aspergillus candidus under submerged cultivation. 3 Biotech 3:127–136

Masui DC, Zimbardi ALRL, Souza FHM, Guimaraes LHS, Furriel RPM, Jorge JA (2012) Production of a xylose-stimulated β-glucosidase and a cellulase-free thermostable xylanase by the thermophilic fungus Humicola brevis var. thermoidea under solid state fermentation. World J. Microbiol. Biotechnol 28:2689–2701

Xu YX, Li YL, Xu SC, Liu Y, Wang X, Tang JW (2008) Improvement of xylanase production by Aspergillus niger XY-1 using response surface methodology for optimizing the medium composition. J Zhejiang Univ Sci B 9:558–566

Dai XJ, LiU MQ, Jin HX, Jing MY (2011) Optimization of solid-state fermentation of Aspergillus niger JL-15 for xylanase production and xylooligosaccharides preparation. Czech. J. Food Sci 29:557–567

Krishna C (2005) Solid-state fermentation systems—an overview. Crit Rev Biotechnol 25:1–30

Jecu L (2000) Solid state fermentation of agricultural wastes for endoglucanase production. Industrial Crops and Products 11:1–5

Panagiotou G, Kekos D, Macris BJ, Christakopoulous P (2003) Production of cellulolytic and xylanolytic enzymes by Fusarium oxysporum grown on corn stover in solid state fermentation. Industrial Crops and Products 18:37–45

Pandya JJ, Gupte A (2012) Production of xylanase under solid-state fermentation by Aspergillus tubingensis JP-1 and its application. Bioprocess Biosyst Eng 35:769–779

Haq I, Tasneem M, Raana K, Khan A, Mukhtar H, Javed M (2004) Optimization of cultural conditions for the production of xylanase by chemically mutated strain of Aspergillus niger GCBCX-20. Int J Agri Biol 6:1115–1118

Thomas L, Parameswaran B, Pandey A (2016) Hydrolysis of pretreated rice straw by an enzyme cocktail comprising acidic xylanase from Aspergillus sp. for bioethanol production. Renewable Energy:98

Castro LPM, Trejo-Aguilar BA, Osorio GA (1997) Thermostable xylanases produced at 37 C and 45 C by a thermotolerant Aspergillus strain. FEMS Microbiol Rev 146:97–102

Pang PK, Darah I, Poppe L, Szakacs G, Ibrahim CO (2006) Xylanase production by a local isolate, Trichoderma spp. FETL c3-2 via solid state fermentation using agricultural wastes as substrates. Malaysian J Microbiol 2:7–14

Simoes MLG, Tauk-Tornisielo SM (2006) Optimization of xylanase biosynthesis by Aspergillus japonicus isolated from a “Caatinga” area in the Brazilian state of Bahia. Afr. J Biotechnol 5:1135

Gawande PV, Kamat MY (1999) Production of Aspergillus xylanase by lignocellulosic waste fermentation and its application. J Appl Microbiol 87:511–519

Alves-Prado HF, Pavezzi FC, Leite RSR, de Oliveira VM, Sette LD, Amore A, Giacobbe S, Faraco V (2013) Regulation of cellulase and hemicellulase gene expression in fungi. Curr genomics 14:230–249

Sudan R, Bajaj BK (2007) Production and biochemical characterization of xylanase from an alkalitolerant novel species Aspergillus niveus RS2. World J Microbiol Biotechnol 23:491–500

Murthy PS, Naidu MM (2012) Production and application of xylanase from Penicillium sp. utilizing coffee by-products. Food Bioproc Technol 5:657–664

Ghanem NB, Yusef HH, Mahrouse HK (2000) Production of Aspergillus terreus xylanase in solid-state cultures: application of the Plackett–Burman experimental design to evaluate nutritional requirements. Bioresource Technology 73:113–121

Kavya V, Padmavathi T (2009) Optimization of growth conditions for xylanase production by Aspergillus niger in solid state fermentation. Polish J. Microbiol 58:125–130

Ajijolakewu AK, Leh CP, Abdullah WN, Lee CK (2017) Optimization of production conditions for xylanase production by newly isolated strain Aspergillus Niger through solid state fermentation of oil palm empty fruit bunches. Biocatal. Agric. Biotechnol. 11:239e247–239e247. https://doi.org/10.1016/j.bcab.2017.07.009

Tai WY, Tan JS, Lim V, Lee CK (2019) Comprehensive studies on optimization of cellulase and xylanase production by a local indigenous fungus strain via solid state fermentation using oil palm frond as substrate. Biotechnol Prog. 35:e2781. https://doi.org/10.1002/btpr.2781

Bagewadi ZK, Mulla SI, Ninnekar HZ (2017) Optimization of endoglucanase production from Trichoderma harzianum strain HZN11 by central composite design under response surface methodology. Biomass Conv Bioref 8:305–316. https://doi.org/10.1007/s13399-017-0285-3

José Lucas de Almeida AF, Souza LO, de Araújo Fernandes AG AG, Oliveira MLF, de Oliveira JR, Franco M (2020) Optimization of the solid-state fermentation conditions and characterization of xylanase produced by Penicillium roqueforti ATCC 10110 using yellow mombin residue (Spondias mombin L.), Chemical Eng. Comm. 207:31–42

Funding

We are thankful to Charotar University of Science and Technology for providing us financial support, laboratory and instrument facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Desai, D.I., Iyer, B.D. Optimization of medium composition for cellulase-free xylanase production by solid-state fermentation on corn cob waste by Aspergillus niger DX-23. Biomass Conv. Bioref. 12, 1153–1165 (2022). https://doi.org/10.1007/s13399-020-00749-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00749-3