Abstract

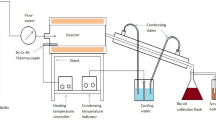

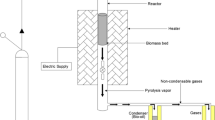

This study evaluates the potentiality of coir pith, an agro-industry by-product, as a low-cost feed-stock for the production of bio-fuels and other value-added chemicals. Thermogravimetric analysis was done to evaluate kinetics, thermodynamic, and mechanistic models of coir pith pyrolysis process. Optimal pyrolysis condition was fixed by using response surface methodology (RSM) in combination with central composite design (CCD). Pyrolysis experiments were carried out by using a miniature fixed-bed reactor at the temperature range of 200–400 °C with the heating rates and nitrogen flow rate ranges of 20–40 °C/min and 70–200 ml/min, respectively. As suggested by the Design expert software, maximum yield of bio-oil (29.31%) can be obtained at temperature of 349.14 °C, heating rate of 21.58 °C/min, and nitrogen flow rate of 196.61 ml/min, which was very much similar to the experimental yield (29.02 ± 0.05%). The bio-oil obtained at this condition was characterized by elemental analysis and different spectroscopic and chromatographic techniques including 1H-NMR, FTIR, and GC-MS. The calorific value of bio-oil was found to be 28.38 MJ/kg. Characterization of bio-oil obtained at the optimum process condition indicates that produced bio-oil is a combination of aliphatic as well as aromatic hydrocarbons which can be represented by the empirical formula of CH1.80 N0.04 O0.35. This investigation also revealed that the kinetic and thermodynamic analyses can correctly predict the possible pyrolysis temperature range for coir pith pyrolysis. The results obtained from the present investigation therefore suggest the suitability of coir pith as a potential feedstock for the conversion of energy and value added chemicals.

Similar content being viewed by others

References

White JE, Catallo WJ, Legendre BL (2011) Biomass pyrolysis kinetics: a comparative critical review with relevant agricultural residue case studies. J Anal Appl Pyrolysis 91(1):1–33

Nagarajan R, Manickam TS, Lothandaraman GV, Ramasamy K, Palaniswamy GV (1985) Manurial value of coir pith. Madras Agric J (B) 72:533–535

Harathi PB, Radha R, Gayathri M (2016) Efficacy of Pleurotus Sajor Caju as an excellent potting medium for garden plants. Int J Pharm Bio Sci 7((1) (B)):103–107

Kunchikannan LKNV, Mande SP, Kishore VVN, Jain KL (2007) Coir pith: a potential agro residue for anaerobic digestion. Energy Source A, Recov Util Environ Effects 29:293–301

Ross PR, Paramanandham J, Thenmozhil P, Abbiramy KS, Muthulingam M (2012) Determination of physico-chemical properties of coir pith in relation to particle size suitable for potting medium. IJEST 2(2):45–47

Reddy N (2019) Sustainable applications of coir and other coconut by-products. Springer International Publishing. https://doi.org/10.1007/978-3-030-21055-7

Ramadhas AS, Jayaraj S, Muraleedharan C (2008) Dual fuel mode operation in diesel engines using renewable fuels: rubber seed oil and coir-pith producer gas. Renew Energy 33(9):2077–2083

Sheeba KN, Babu JSC, Jaisankar S (2013) Steam gasification characteristics of coir pith in a circulating fluidized bed gasifier. Energy Source A, Recov Util Environ Effects 35:110–121

Ramadhas AS, Jayaraj S, Muraleedharan C (2006) Power generation using coir-pith and wood derived producer gas in diesel engines. Fuel Process Technol 87:849–853

Awasthi A, Dhyani V, Biswas B, Kumar J, Bhaskar T (2019) Production of phenolic compounds using waste coir pith: estimation of kinetic and thermodynamic parameters. Bioresour Technol 274:173–179

Kumar P, Rao R, Chand S, Kumar S, Wasewar KL, Yoo CK (2013) Adsorption of lead from aqueous solution onto coir-pith activated carbon. Desalin Water Treat 51:2529–2535

Bach Q-V, Chen W-H (2017) Pyrolysis characteristics and kinetics of microalgae via thermogravimetric analysis (TGA): a state of art review. Bioresour Technol 246:88–100

Cai J, Xu D, Dong Z, Yu X, Yang Y, Banks SW, Bridgwater AV (2018) Processing thermogravimetric analysis data for isoconversional kinetic analysis of lignocellulosic biomass pyrolysis: case study of corn stalk. Renew Sust Energ Rev 82:2705–2715

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N (2011) ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520:1–19

Wang S, Dai G, Yang H, Luo Z (2017) Lignocellulosic biomass pyrolysis mechanism: a state-of-art review. Prog. Energy Combust Sci 62:33–86

Angın D, Tiryaki AE (2016) Application of response surface methodology and artificial neural network on pyrolysis of safflower seed press cake. Energy Source A, Recovery Util Environ Effects 38(8):1055–1061

Carrier M, Auret L, Bridgwater A, Knoetze JH (2016) Using apparent activation energy as a reactivity criterion for biomass pyrolysis. Energy Fuel 30:7834–7831

Friedman HL (1964) Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci C 6:183–195

Akahira T, Sunose T (1971) Method for determining activation deterioration constant of electrical insulating materials. Res Rep Chiba Inst Technol (Sci Technol) 16:22–31

Flynn JH, Wall LA (1966) General treatment of the thermogravimetry of polymers. J Res Natl Bur Stand A 70:487

Miura K, Maki T (1998) A simple method for estimating f(E) and k0(E) in the distributed activation energy model. Energy Fuel 12:864–869

Choudhury ND, Chutia RS, Bhaskar T, Kataki R (2014) Pyrolysis of jute dust: effect of reaction parameters and analysis of products. J Mater Cycles Waste 16(3):449–459

Chutia RS, Kataki R, Bhaskar T (2013) Thermogravimetric and decomposition kinetic studies of Mesua ferrea L. deoiled cake. Bioresour Technol 139:66–72

Chutia RS, Kataki R, Bhaskar T (2014) Characterization of liquid and solid product from pyrolysis of Pongamia glabra deoiled cake. Bioresour Technol 165:336–342

Saikia R, Baruah B, Kalita D, Pant KK, Gogoi N, Kataki R (2018) Pyrolysis and kinetic analyses of a perennial grass (Saccharum ravannae L.) from north-east India: optimization through response surface methodology and product characterization. Bioresour Technol 253:304–314

Mehmood MA, Ye G, Luo H, Liu C, Malik S, Afzal I, Xu J, Ahmad MS (2017) Pyrolysis and kinetic analyses of camel grass (Cymbopogon schoenanthus) for bioenergy. Bioresour Technol 228:18–24

Akhtar J, Amin NAS (2012) A review on operating parameters for optimum liquid oil yield in biomass pyrolysis. Renew Sust Energ Rev 16:5101–5109

Braga RM, Melo DM, Aquino FM, Freitas JC, Melo MA, Barros JM, Fontes MS (2014) Characterization and comparative study of pyrolysis kinetics of the rice husk and the elephant grass. J Therm Anal Calorim 115(2):1915–1920

Ahmad MS, Mehmood MA, Taqvi ST, Elkamel A, Liu CG, Xu J, Rahimuddin SA, Gull M (2017) Pyrolysis, kinetics analysis, thermodynamics parameters and reaction mechanism of Typha latifolia to evaluate its bioenergy potential. Bioresour Technol 245:491–501

Gogoi M, Konwar K, Bhuyan N, Borah RC, Kalita AC, Nath HP, Saikia N (2018) Assessments of pyrolysis kinetics and mechanisms of biomass residues using thermogravimetry. Bioresour Technol Rep 4:40–49

Ozsin G, Putun AE (2018) Co-pyrolytic behaviors of biomass and polystyrene: kinetics, thermodynamics and evolved gas analysis, Korean J. Chem Eng 35:428–437

Afzal I, Ahmad MS, Malik S, Ibrahim M, Al Ayed OS, Qadir G, Al Doghaither H, Gull M (2018) Thermodynamics and kinetics parameters of Eichhornia crassipes biomass for bioenergy. Protein Pept Lett 25:1–8

Xu Y, Chen B (2013) Investigation of thermodynamic parameters in the pyrolysis conversion of biomass and manure to biochars using thermogravimetric analysis. Bioresour Technol 146:485–493

Onay O (2007) Influence of pyrolysis temperature and heating rate on the production of bio-oil and char from safflower seed by pyrolysis, using a well-swept fixed bed reactor. Fuel Process Technol 88:523–531

Bordoloi N, Narzari R, Chutia RS, Bhaskar T, Kataki R (2015) Pyrolysis of Mesua ferrea and Pongamia glabra seed cover: characterization of bio-oil and its sub-fractions. Bioresour Technol 178:83–89

Lu Q, Yang XL, Zhu XF (2008) Analysis on chemical and physical properties of bio-oil pyrolyzed from rice husk. J Anal Appl Pyrolysis 82:191–198

Das P, Sreelatha T, Ganesh A (2004) Bio-oil from pyrolysis of cashew nut shell-chracterization and related properties. Biomass Bioenergy 27:265–275

Demiral I, Ayan EA (2011) Pyrolysis of grape bagasse: effect of pyrolysis conditions on the product yields and characterization of the product. Bioresour Technol 102:3946–3951

Acknowledgements

The authors would like to offer their sincere thanks to CSIR-NEIST, Jorhat, Assam, for providing analytical facility to conduct TGA. Also, the authors gratefully acknowledges SAIC, Tezpur University, for providing the analyses facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Choudhury, N.D., Bhuyan, N., Bordoloi, N. et al. Production of bio-oil from coir pith via pyrolysis: kinetics, thermodynamics, and optimization using response surface methodology. Biomass Conv. Bioref. 11, 2881–2898 (2021). https://doi.org/10.1007/s13399-020-00630-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00630-3