Abstract

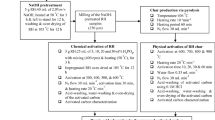

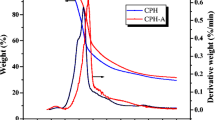

Utilization of cocoa pod husk (CPH) for the preparation of high-surface-area activated carbon (AC) by using low-pollution potassium hydroxide (KOH) as an activating agent was studied in this work. The thermochemical results of CPH, including the proximate analysis, calorific value, organic and mineral component analyses, showed that the biomass should be a great precursor based on its large percentage of volatile matter and less amount of fixed carbon. A series of activation experiments were conducted to produce activated carbons from dries CPH at different temperatures (i.e., 400, 500, 600, 700, and 800 °C) held for 30 min. To evaluate the potential for adsorbent in removing environmental pollutants, the resulting activated carbons were subject to the analyses of chemical and physical properties, including elemental analysis, true density, surface area/pore volume, and surface morphology by scanning electron microscope (SEM). Based on the pore properties, activation temperature at around 800 °C seemed to be the optimal condition for producing highly microporous AC, where its BET surface area (> 1800 m2/g) and total pore volume (about 0.95 cm3/g) largely increased compared with that of the AC produced at 400 °C (ca. 6.0 m2/g). Based on the adsorption kinetic performance tests, it showed that it is feasible to use the resulting AC as an effectively low-cost adsorbent for the removal of organic compound (e.g., dye) from aqueous solution in comparison with commercial AC.

Similar content being viewed by others

References

Vriesmann LC, Teofilo RF, Petkowicz CLO (2012) Extraction and characterization of pectin from cacao pod husks (Theobroma cacao L.) with citric acid. LWT–Food Sci Technol 49:108–116

Vriesmann LC, Amboni RDMC, Petkowicz CLO (2011) Cacao pod husks (Theobroma cacao L.): composition and hot-water-soluble pectins. Ind Crop Prod 34:1173–1181

Donkoh A, Atuahene CC, Wilson BN, Adomako D (1991) Chemical composition of cocoa pod husk and its effect on growth and food efficiency in broiler chicks. Anim Feed Sci Technol 35:161–169

Osei SA, Atuahene CC, Heathcote D, Frimpong EB, Adomako D (1991) Cocoa pod and husk meal as a feed ingredient in layer diets. Anim Feed Sci Technol 35:283–288

Alawa JP, Umunna NN (1993) Alternative feed formulation in the developing countries: prospects for utilization of agro-industrial by-products. J Anim Prod Res 13:63–98

Ridzwan BH, Fadzli MK, Rozali MBO, Chin DTF, Ibrahim BM, Faridnordin BI (1993) Evaluation of cocoa-pod husks on performance of rabbits. Anim Feed Sci Technol 40:267–272

Taiwo OE, Osinowo FAO (2001) Evaluation of various agro-wastes for traditional black soap production. Bioresour Technol 79:95–97

Moyin-Jesu EI (2007) Use of plant residues for improving soil fertility, pod nutrients, root growth and pod weight of okra (Abelmoschus esculentum L). Bioresour Technol 98:2057–2064

Oddoye EOK, Rhule SWA, Agyente-Badu K, Anchirinah V, Owusu Ansah F (2010) Fresh cocoa pod husk as an ingredient in the diets of growing pigs. Sci Res Essay 5:1141–1144

Ashade OO, Osineye OM (2013) Effect of replacing maize with cocoa pod husk in the nutrition of Oreochromis niloticus. J Fish Aquat Sci 8:73–79

Martinez R, Torres P, Meneses MA, Figueroa JG, Perez-Alvarez JA, Viuda-Martos M (2012) Chemical, technological and in vitro antioxidant properties of cocoa (Theobroma cacao) co-products. Food Res Int 49:39–45

Oddoye EOK, Agyente-Badu CK, Gyedu-Akoto E (2013) Cocoa and its by-products: identification and utilization. In: Watson RR, Preedy VR, Zibadi S (eds) Chocolate in health and nutrition. Springer, New York, pp 23–37

Betiku E, Etim AO, Pereao O, Ojumu TV (2017) Two-step conversion neem (Azadirachta indica) seed oil into fatty methyl esters using a heterogeneous biomass-based catalyst: an example of cocoa pod husk. Energy Fuel 31:6182–6193

Chan SY, Choo WS (2013) Effect of extraction conditions on the yield and chemical properties of pectin from cocoa husks. Food Chem 41:3752–3758

Priyangini F, Walde SG, Ramalingam C (2018) Extraction optimization of pectin from cocoa pod husks (Theobroma cacao L.) with ascorbic acid using response surface methodology. Carbohydr Polym 202:497–503

Khanahmadi S, Yusof F, Ong HC, Amid A, Shah H (2016) Cocoa pod husk: a new source of CLEA-lipase for preparation of low-cost biodiesel: an optimized process. J Biotechnol 231:95–105

Odude VO, Adesina AJ, Oyetunde OO, Adeyemi OO, Ishola NB, Etim AO, Betiku E (2017) Application of agricultural waste-based catalysts to transesterification of esterified palm kernel oil into biodiesel: a case of banana fruit peel versus cocoa pod husk. Waste Biomass Valoriz. https://doi.org/10.1007/s12649-017-0152-2

Okieimen FE, Imanah JE (2006) Studies in the utilization of agricultural waste products as filler in natural rubber compounds. J Appl Polym Sci 100:2561–2564

Bayer IS, Guzman-Puyol S, Heredia-Guerrero JA, Ceseracciu L, Pignatelli F, Ruffilli R, Cingolani R, Athanassiou A (2014) Direct transformation of edible vegetable waste into bioplastics. Macromolecules 47:5135–5143

El-Shekeil YA, Sapuan SM, Algrafi MW (2014) Effect of fiber loading on mechanical and morphological properties of cocoa pod husk fibers reinforced thermoplastic polyurethane composites. Mater Des 64:330–333

Chun KS, Husseinsyah S, Osman H (2015) Utilization of cocoa pod husk as filler in polypropylene biocomposites: effect of maleated polypropylene. J Thermoplast Compos Mater 28:1507–1521

Koay SC, Chan MY, Pang MM, Tshai KY (2018) Influence of filler loading and palm oil-based green coupling agent on torque rheological properties of polypropylene/cocoa pod husk composites. Adv Polym Technol 37:2246–2252

Syamsiro M, Saptoadi H, Tambunan BH, Pambudi NA (2012) A preliminary study on use of cocoa pod husk as a renewable source of energy in Indonesia. Energy Sustain Dev 16:74–77

Mansur D, Tago T, Masuda T, Abimanyu H (2014) Conversion of cocoa pod husks by pyrolysis and catalytic reaction to produce useful chemicals. Biomass Bioenergy 66:275–285

Tsai CH, Tsai WT, Liu SC, Lin YQ (2018) Thermochemical characterization of biochar from cocoa pod husk prepared at low pyrolysis temperature. Biomass Conv Bioref 8:237–243

Adjin-Tetteh M, Asiedu N, Dodoo-Arhin D, Karam A, Amaniampong PN (2018) Thermochemical conversion and characterization of cocoa pod husks a potential agricultural waste from Ghana. Ind Crop Prod 119:304–312

Fiset JJ, Tyagi RD, Blais JF (2002) Cocoa shells as adsorbent for metal recovery from acid effluent. Water Qual Res J Can 37:379–388

Bello OS, Ahmad MA (2011) Adsorptive removal of a synthetic textile dye using cocoa pod husk. Toxicol Environ Chem 93:1298–1308

Njoku VO, Ayuk AA, Oguzie EE, Ejike EN (2012) Biosorption of cd (II) from aqueous solution by cocoa pod husk biomass: equilibrium, kinetic, and thermodynamic studies. Sep Sci Technol 47:753–761

Theivarasu C, Mylsamy S (2012) Adsorption studies of acid blue-92 from aqueous solution by activated carbon obtained from agricultural industrial waste-cocoa (Theobroma cacao) shell. Asian J Chem 24:2187–2190

Pua FL, Sajab MS, Chia CH, Zakaria S, Rahman IA, Salit MS (2013) Alkaline-treated cocoa pod husks as adsorbent for removing methylene blue from aqueous solutions. J Environ Chem Eng 1:460–465

Njoku VO (2014) Biosorption potential of cocoa pod husk for the removal of Zn (II) from aqueous phase. J Environ Chem Eng 2:881–887

Marsh H, Rodriguez-Reinoso F (2006) Activated carbon. Elsevier, Amsterdam

Leite AJB, Sophia AC, Thue PS, dos Reis GS, Dias SLP, Lima EC, Vaghetti JCP, Pavan FA, de Alencar WS (2017) Activated carbon from avocado seeds for the removal of phenolic compounds from aqueous solutions. Desalin Water Treat 71:168–181

Ahmad F, Daud WMAW, Ahmad MA, Radzi R (2011) Using cocoa (Theobroma cacao) shell-based activated carbon to remove 4-nitrophenol from aqueous solution: kinetics and equilibrium studies. Chem Eng J 178:461–467

Ahmad F, Daud WMAW, Ahmad MA, Radzi R (2012) Cocoa (Theobroma cacao) shell-based activated carbons by CO2 activation in removing of cationic dye from aqueous solution: kinetics and equilibrium studies. Chem Eng Res Des 90:1480–1490

Ahmad F, Daud WMAW, Ahmad MA, Radzi R, Azmi AA (2013) The effect of CO2 activation, on porosity and surface functional groups of cocoa (Theobroma cacao) – shell based activated carbon. J Environ Chem Eng 1:378–388

Bello OS, Siang TT, Ahmad MA (2012) Adsorption of remazol brilliant violet-5R reactive dye from aqueous solution by cocoa pod husk-based activated carbon: kinetics, equilibrium and thermodynamic studies. Asia Pac J Chem Eng 7:378–388

Pereira RG, Veloso CM, da Silva NM, de Sousa LF, Bonomo RCF, de Souza AO, Souza MOG, Fontan RCI (2014) Preparation of activated carbons from cocoa shells and siriguela seeds using H3PO4 and ZnCl2 as activating agents for BSA and α-lactalbumin adsorption. Fuel Process Technol 126:476–486

Ribas MC, Adebayo MA, Prola LDT, Lima EC, Cataluna R, Feris LA, Puchana-Rosero MJ, Machado FM, Pavan FA, Calvete T (2014) Comparison of a homemade cocoa shell activated carbon with commercial activated carbon for the removal of reactive violet 5 dye from aqueous solutions. Chem Eng J 248:315–326

Saucier G, Adebayo MA, Lima EC, Cataluna R, Thue PS, Prola LDT, Puchana-Rosero MJ, Machado FM, Pavan FA, Dotto GL (2015) Microwave-assisted activated carbon from cocoa shell as adsorbent for removal of sodium diclofenac and nimesulide from aqueous effluents. J Hazard Mater 289:18–27

Tsai WT, Huang PC (2018) Characterization of acid-leaching cocoa pod husk (CPH) and its resulting activated carbon. Biomass Conv Bioref 8:521–528

Plaza-Recobert M, Trautwein G, Perez-Cadenas M, Alcaniz-Monge J (2017) Preparation of binderless activated carbon monoliths from cocoa bean husk. Microporous Mesoporous Mater 243:28–38

Perez-Cadenas M, Plaza-Recobert M, Trautwein G, Alcaniz-Monge J (2018) Development of tailored mesoporosity in carbonized cocoa bean husk. Microporous Mesoporous Mater 256:128–139

Rodriguez MH, Yperman J, Carleer R, Maggen J, Vanderheyden S, Hernandez JF, Calvis AO, Gryglewicz G (2018) Evaluation of activation parameters of activated carbon from coffee and cocoa seed husk rests: carbon yields and Ni(II) adsorption capacity study. Desalin Water Treat 104:175–188

Tsai WT, Chang CY, Wang SY, Chang CF, Chien SF, Sun HF (2001) Preparation of activated carbons from corn cob catalyzed by potassium salts and subsequent gasification with CO2. Bioresour Technol 78:203–208

Titiloye JO, Baker MSA, Odetoye TE (2013) Thermochemical characterisation of agricultural wastes from West Africa. Ind Crop Prod 47:199–203

Tsai WT, Chang CY, Lee SL (1998) A low cost adsorbent from agricultural waste corn cob by zinc chloride activation. Bioresour Technol 64:211–217

Lowell S, Shields JE, Thomas MA, Thommes M (2006) Characterization of porous solids and powders: surface area, pore size and density. Springer, Dordrecht

Smith JM (1981) Chemical engineering kinetics, 3rd edn. McGraw-Hill, New York

Bansal RC, Donnet JB, Stoeckli F (1988) Active carbon. Marcel Dekker, New York

Molina-Sabio M, Rodriguez-Reinoso F (2004) Role of chemical activation in the development of carbon porosity. Colloid Surf A 241:15–25

Olivares-Marin M, Fernandez-Gonzalez C, Macias-Garcia A, Gomez-Serrano V (2006) Preparation of activated carbons from cherry stones by activation with potassium hydroxide. Appl Surf Sci 252:5980–5983

Okman I, Karagoz S, Tay T, Erdem M (2014) Activated carbons from grape seeds by chemical activation with potassium carbonate and potassium hydroxide. Appl Surf Sci 293:138–142

Adinata D, Daud WMAW, Aroua MK (2007) Preparation and characterization of activated carbon from palm shell by chemical activation with K2CO3. Bioresour Technol 98:145–149

Li Z, Gao X, Wu L, Wang K, Kobayashi N (2017) Preparation of activated carbons from poplar wood by chemical activation with KOH. J Porous Mater 24:193–202

Ho YS, Chiang CC, Hsu YC (2001) Sorption kinetics for dye removal from aqueous solution using activated clay. Sep Sci Technol 36:2473–2488

Brady M, McKay G (1995) Characterization of adsorbents. In: McKay G (ed) Use of adsorbents for the removal of pollutants from wastewaters. CRC Press, Boca Raton, pp 39–58

Acknowledgements

The authors express sincere appreciation to the Instrument Centers of National Chung Hsing University and National Pingtung University of Science and Technology for their assistance in elemental analysis and scanning electron microscope (SEM) observation, respectively.

Funding

The authors thank the Pingtung County Government (Taiwan) and Wel-Han Environmental Industrial Co. (Pingtung County Government, Taiwan) for providing financial support for this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tsai, WT., Bai, YC., Lin, YQ. et al. Porous and adsorption properties of activated carbon prepared from cocoa pod husk by chemical activation. Biomass Conv. Bioref. 10, 35–43 (2020). https://doi.org/10.1007/s13399-019-00403-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-019-00403-7