Abstract

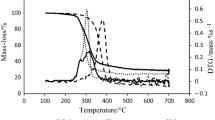

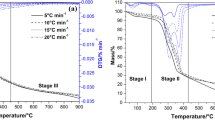

The aim of this study was to investigate the effects of synthetic polymers during co-pyrolysis. To this end, a non-edible lignocellulosic biomass, walnut shells, and three synthetic polymers that were obtained from a recycling plant (PET, PS and PVC) were co-pyrolyzed in pairs using a thermogravimetric analysis (TGA) device coupled online with a mass spectrometer (MS) and an FT-IR spectrometer. The simultaneous usage of the combined techniques allowed collection of information about the pyrolysis and co-pyrolysis processes, as well as identification of the gases that evolved. During dynamic experiments, different heating rates were used and the characteristic temperatures, kinetic parameters, and evolved gases of co-pyrolysis of each pair of the materials were compared to those obtained from the pyrolysis of the individual materials. In order to calculate the activation energy and elucidate the reaction chemistry, four models which use iso-conversional approaches, namely Friedman, Kissinger–Akahira–Sunose, Starink, and Flynn–Wall–Ozawa, were applied to the TGA data and the same trends of results were observed in all models. The activation energy values of the pyrolysis and co-pyrolysis showed fluctuations related to the conversion points which indicated the complex nature of the samples, or interactions occurred during the process. Moreover, PET, PS, and PVC blending resulted in synergy with the biomass depending on the nature of the polymer, and volatile products including methyl, water, methoxy, carbon dioxide, water, benzene, acetaldehyde, styrene, and hydrochloric acid were monitored to obtain their evolution profiles related to decomposition range.

Similar content being viewed by others

References

Burra K, Gupta A (2018) Kinetics of synergistic effects in co-pyrolysis of biomass with plastic wastes. Appl Energy 220:408–418

Honus S, Kumagai S, Molnár V, Fedorko G, Yoshioka T (2018) Pyrolysis gases produced from individual and mixed PE, PP, PS, PVC, and PET—part II: fuel characteristics. Fuel 221:361–373

Kothari R, Tyagi V, Pathak A (2010) Waste-to-energy: a way from renewable energy sources to sustainable development. Renew Sust Energ Rev 14(9):3164–3170

Ucar S, Karagöz S, Karayildirim T, Yanik J (2002) Conversion of polymers to fuels in a refinery stream. Polym Degrad Stab 75(1):161–171

Sinha R, Kumar S, Singh R (2013) Production of biofuel and biochar by thermal pyrolysis of linseed seed. Biomass Convers Biorefinery 3(4):327–335

Azizi K, Moraveji MK, Najafabadi HA (2017) A review on bio-fuel production from microalgal biomass by using pyrolysis method. Renew Sust Energ Rev

Li F, Srivatsa SC, Batchelor W, Bhattacharya S (2017) A study on growth and pyrolysis characteristics of microalgae using thermogravimetric analysis-infrared spectroscopy and synchrotron Fourier transform infrared spectroscopy. Bioresour Technol 229:1–10

Pütün AE, Apaydın E, Pütün E (2004) Rice straw as a bio-oil source via pyrolysis and steam pyrolysis. Energy 29(12–15):2171–2180

Kumagai S, Fujita K, Kameda T, Yoshioka T (2016) Interactions of beech wood–polyethylene mixtures during co-pyrolysis. J Anal Appl Pyrolysis 122:531–540

Chen L, Yu Z, Fang S, Dai M, Ma X (2018) Co-pyrolysis kinetics and behaviors of kitchen waste and chlorella vulgaris using thermogravimetric analyzer and fixed bed reactor. Energy Convers Manag 165:45–52

Fabbri D, Torri C, Spokas KA (2012) Analytical pyrolysis of synthetic chars derived from biomass with potential agronomic application (biochar). Relationships with impacts on microbial carbon dioxide production. J Anal Appl Pyrolysis 93:77–84

Chintala V (2018) Production, upgradation and utilization of solar assisted pyrolysis fuels from biomass—a technical review. Renew Sust Energ Rev 90:120–130

Wang Y, Wu Q, Dai L, Zeng Z, Liu Y, Ruan R, Fu G, Yu Z, Jiang L (2018) Co-pyrolysis of wet torrefied bamboo sawdust and soapstock. J Anal Appl Pyrolysis 132:211–216

Lehto J, Oasmaa A, Solantausta Y, Kytö M, Chiaramonti D (2014) Review of fuel oil quality and combustion of fast pyrolysis bio-oils from lignocellulosic biomass. Appl Energy 116:178–190

Gooty AT, Li D, Briens C, Berruti F (2014) Fractional condensation of bio-oil vapors produced from birch bark pyrolysis. Sep Purif Technol 124:81–88

Lu Q, Li W-Z, Zhu X-F (2009) Overview of fuel properties of biomass fast pyrolysis oils. Energy Convers Manag 50(5):1376–1383

Serapiglia MJ, Mullen CA, Boateng AA, Dien BS, Casler MD (2017) Impact of harvest time and cultivar on conversion of switchgrass to bio-oils via fast pyrolysis. BioEnergy Res 10(2):388–399

Panwar N, Kothari R, Tyagi V (2012) Thermo chemical conversion of biomass—eco friendly energy routes. Renew Sust Energ Rev 16(4):1801–1816

Lorenzetti C, Conti R, Fabbri D, Yanik J (2016) A comparative study on the catalytic effect of H-ZSM5 on upgrading of pyrolysis vapors derived from lignocellulosic and proteinaceous biomass. Fuel 166:446–452

Johansson A-C, Sandström L, Öhrman OG, Jilvero H (2018) Co-pyrolysis of woody biomass and plastic waste in both analytical and pilot scale. J Anal Appl Pyrolysis 134:102–113

Krutof A, Hawboldt K (2018) Upgrading of biomass sourced pyrolysis oil review: focus on co-pyrolysis and vapour upgrading during pyrolysis. Biomass Convers Biorefinery 1–13

Mostafazadeh AK, Solomatnikova O, Drogui P, Tyagi RD (2018) A review of recent research and developments in fast pyrolysis and bio-oil upgrading. Biomass Conversion and Biorefinery 1–35

Santibañez-Aguilar JE, Ponce-Ortega JM, González-Campos JB, Serna-González M, El-Halwagi MM (2013) Optimal planning for the sustainable utilization of municipal solid waste. Waste Manag 33(12):2607–2622

Paradela F, Pinto F, Ramos AM, Gulyurtlu I, Cabrita I (2009) Study of the slow batch pyrolysis of mixtures of plastics, tyres and forestry biomass wastes. J Anal Appl Pyrolysis 85(1–2):392–398

Lu P, Huang Q, Bourtsalas AT, Chi Y, Yan J (2018) Synergistic effects on char and oil produced by the co-pyrolysis of pine wood, polyethylene and polyvinyl chloride. Fuel 230:359–367

Mullen CA, Dorado C, Boateng AA (2018) Catalytic co-pyrolysis of switchgrass and polyethylene over HZSM-5: catalyst deactivation and coke formation. J Anal Appl Pyrolysis 129:195–203

Garba MU, Inalegwu A, Musa U, Aboje AA, Kovo AS, Adeniyi DO (2018) Thermogravimetric characteristic and kinetic of catalytic co-pyrolysis of biomass with low-and high-density polyethylenes. Biomass Convers Biorefinery 8(1):143–150

Moreno AI, Font R, Conesa JA (2017) Combustion of furniture wood waste and solid wood: kinetic study and evolution of pollutants. Fuel 192:169–177

Janković B, Manić N, Stojiljković D, Jovanović V (2018) TSA-MS characterization and kinetic study of the pyrolysis process of various types of biomass based on the Gaussian multi-peak fitting and peak-to-peak approaches. Fuel 234:447–463

Ranzi E, Corbetta M, Manenti F, Pierucci S (2014) Kinetic modeling of the thermal degradation and combustion of biomass. Chem Eng Sci 110:2–12

Pradhan RR, Garnaik PP, Regmi B, Dash B, Dutta A (2017) Pyrolysis kinetics of Sal (Shorea robusta) seeds. Biomass Convers Biorefinery 7(2):237–246

Mukherjee A, Das P, Minu K (2014) Thermogravimetric analysis and kinetic modelling studies of selected agro-residues and biodiesel industry wastes for pyrolytic conversion to bio-oil. Biomass Convers Biorefinery 4(3):259–268

Bahng M-K, Mukarakate C, Robichaud DJ, Nimlos MR (2009) Current technologies for analysis of biomass thermochemical processing: a review. Anal Chim Acta 651(2):117–138

Wang S, Dai G, Yang H, Luo Z (2017) Lignocellulosic biomass pyrolysis mechanism: a state-of-the-art review. Prog Energy Combust Sci 62:33–86

Fang S, Yu Z, Ma X, Lin Y, Chen L, Liao Y (2018) Analysis of catalytic pyrolysis of municipal solid waste and paper sludge using TG-FTIR, Py-GC/MS and DAEM (distributed activation energy model). Energy 143:517–532

Friedman HL (1964) Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. In: Journal of Polymer Science Part C: Polymer Symposia, vol 1. Wiley Online Library, pp 183–195

Kissinger HE (1957) Reaction kinetics in differential thermal analysis. Anal Chem 29(11):1702–1706

Akahira T, Sunose T (1971) Method of determining activation deterioration constant of electrical insulating materials. Res Rep Chiba Inst Technol (Sci Technol) 16:22–31

Flynn JH, Wall LA (1966) General treatment of the thermogravimetry of polymers. J Res Natl Bur Stand 70(6):487–523

Ozawa T (1965) A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn 38(11):1881–1886

Starink M (1996) A new method for the derivation of activation energies from experiments performed at constant heating rate. Thermochim Acta 288(1–2):97–104

Hernando H, Fermoso J, Moreno I, Coronado J, Serrano D, Pizarro P (2017) Thermochemical valorization of camelina straw waste via fast pyrolysis. Biomass Convers Biorefinery 7(3):277–287

Qiu H-W, Zhou Q-C, Geng J (2015) Pyrolytic and kinetic characteristics of Platycodon grandiflorum peel and its cellulose extract. Carbohydr Polym 117:644–649

Christ D, Scherzinger M, Neuling U, Kaltschmitt M (2019) Thermochemical conversion of solid biofuels: processes and techniques. In: Energy from organic materials (biomass) a volume in the encyclopedia of sustainability science and technology, 2nd edn. pp 393–413

Mallick D, Poddar MK, Mahanta P, Moholkar VS (2018) Discernment of synergism in pyrolysis of biomass blends using thermogravimetric analysis. Bioresour Technol 261:294–305

Zhang J, Zhong Z, Zhang B, Xue Z, Guo F, Wang J (2016) Prediction of kinetic parameters of biomass pyrolysis based on the optimal mixture design method. Clean Techn Environ Policy 18(5):1621–1629

Collard F-X, Blin J (2014) A review on pyrolysis of biomass constituents: mechanisms and composition of the products obtained from the conversion of cellulose, hemicelluloses and lignin. Renew Sust Energ Rev 38:594–608

Zabaniotou A, Ioannidou O, Antonakou E, Lappas A (2008) Experimental study of pyrolysis for potential energy, hydrogen and carbon material production from lignocellulosic biomass. Int J Hydrog Energy 33(10):2433–2444

Ashraf A, Sattar H, Munir S (2019) Thermal decomposition study and pyrolysis kinetics of coal and agricultural residues under non-isothermal conditions. Fuel 235:504–514

Meng A, Chen S, Long Y, Zhou H, Zhang Y, Li Q (2015) Pyrolysis and gasification of typical components in wastes with macro-TGA. Waste Manag 46:247–256

Ali I, Bahaitham H, Naebulharam R (2017) A comprehensive kinetics study of coconut shell waste pyrolysis. Bioresour Technol 235:1–11

Ma Y, Wang J, Zhang Y (2018) TG-FTIR study on pyrolysis of Enteromorpha prolifera. Biomass Convers Biorefinery 8(1):151–157

Holland B, Hay J (2002) The thermal degradation of PET and analogous polyesters measured by thermal analysis–Fourier transform infrared spectroscopy. Polymer 43(6):1835–1847

Dimitrov N, Krehula LK, Siročić AP, Hrnjak-Murgić Z (2013) Analysis of recycled PET bottles products by pyrolysis-gas chromatography. Polym Degrad Stab 98(5):972–979

Hurley MJ, Gottuk DT, Hall Jr JR, Harada K, Kuligowski ED, Puchovsky M, Watts JM Jr, Wieczorek CJ (2015) SFPE handbook of fire protection engineering. Springer

Faravelli T, Pinciroli M, Pisano F, Bozzano G, Dente M, Ranzi E (2001) Thermal degradation of polystyrene. J Anal Appl Pyrolysis 60(1):103–121

Czégény Z, Jakab E, Bozi J, Blazsó M (2015) Pyrolysis of wood–PVC mixtures. Formation of chloromethane from lignocellulosic materials in the presence of PVC. J Anal Appl Pyrolysis 113:123–132

Karayildirim T, Yanik J, Yuksel M, Saglam M, Vasile C, Bockhorn H (2006) The effect of some fillers on PVC degradation. J Anal Appl Pyrolysis 75(2):112–119

Czégény Z, Jakab E, Blazsó M (2002) Thermal decomposition of polymer mixtures containing poly (vinyl chloride). Macromol Mater Eng 287(4):277–284

Yu J, Sun L, Ma C, Qiao Y, Yao H (2016) Thermal degradation of PVC: a review. Waste Manag 48:300–314

Mu W, Ben H, Ragauskas A, Deng Y (2013) Lignin pyrolysis components and upgrading—technology review. BioEnergy Res 6(4):1183–1204

Malika A, Jacques N, Fatima B, Mohammed A (2016) Pyrolysis investigation of food wastes by TG-MS-DSC technique. Biomass Convers Biorefinery 6(2):161–172

Funding

This work received BIDEB 2214-A support from TUBİTAK.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Özsin, G., Pütün, A.E. & Pütün, E. Investigating the interactions between lignocellulosic biomass and synthetic polymers during co-pyrolysis by simultaneous thermal and spectroscopic methods. Biomass Conv. Bioref. 9, 593–608 (2019). https://doi.org/10.1007/s13399-019-00390-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-019-00390-9