Abstract

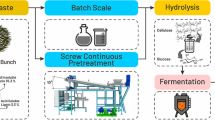

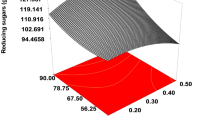

A statistical based study employing response surface method (RSM) was conducted to ascertain the optimum pretreatment conditions using an alkaline wash technique i.e. at different temperature, time and base concentration using Malaysian oil palm empty fruit bunches (EFB) as a model substrate. Strong acid-dilute acid hydrolysis and dietary fibre methods were used in order to determine structural carbohydrates and lignin content of pretreated EFB and analysed using one-way analysis of variance (ANOVA). Based on the RSM model, 17 runs of different pretreatment conditions were carried out. ANOVA analysis on the different techniques yielded an F value of 5.32 leading to the rejection of null hypothesis. As such, both techniques were determined to be statistically different. Response surface model with quadratic function was generated for biomass pretreatment using alkaline wash which has indicated that sodium hydroxide concentration is the most important factor in determining lignin removal, followed by time of reaction. The final lignin content of pretreated biomass shall be 9.04 wt.% which is 62.7% of lignin removal.

Similar content being viewed by others

References

Fernando S, Adhikari S, Chandrapal C, Murali N (2006) Biorefineries: current status, challenges and future direction. Energy Fuel 20:1727–1737

Garcia-Nunez JA, Ramirez-Contreras NE, Rodriguez DT, Silva-Lora E, Frear CS, Stockle C, Garcia-Perez M (2016) Evolution of palm oil mills into bio-refineries: literature review on current and potential use of residual biomass and effluents. Resour Conser Recycling 110:99–114

Esposito D, Antonietti M (2015) Redefining biorefinery: the search for unconventional building blocks. Chem Soc Rev 44:5821–5835

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Methods for lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res 48:3713–3729

Awalludin MF, Sulaiman O, Hashim R, Wan Nadhari WNA (2015) An overview of the oil palm industry in Malaysia and its waste utilization through thermochemical conversion, specifically via liquefaction. Renew Sus Energy Rev 50:1469–1484

Abnisa F, Daud WMAW, Husin W, Sahu JN (2011) Utilization possibilities of palm shell as a source of biomass energy in Malaysia by producing bio-oil in pyrolysis process. Biomass Bioenergy 35:1863–1872

Goh CS, Tan KT, Lee KT (2010) Bio-ethanol from lignocellulose: status, perspective and challenges in Malaysia. Bioresour. Tech. 101:4834–4841

Karim RA, Hussain AS, Zain AM (2014) Production of bioethanol from empty fruit bunches cellulosic biomass and Avicel PH-101 cellulose. Biomass Conv Bioref 4:333–340

Katahira R, Mittal A, McKinney K, Chen X, Tucker MP, Johnson DK, Beckham GT (2016) Base catalysed depolymerisation of biorefinery lignin. ACS Sustainable Chem & Eng 4:1474–1486

Roberts VM, Stein V, Reiner T, Lemonidou A, Li X, Lercher JA (2011) Towards quantitative catalytic lignin depolymerisation. Chem Eur Jour 17:5939–5948

Dabral S, Mottweiler J, Rinesch T, Bolm C (2015) Base-catalysed cleavage of lignin β-O-4 model compounds in dimethyl carbonate. Green Chem 17:4908–4912

Xu C, Arancon RAD, Labidi J, Luque R (2014) Lignin: depolymerisation strategies: towards valuable chemicals and fuels. Chem Soc Rev 43(22):7485–7500

Wang H, Tucker M, Ji Y (2013) Recent development in chemical depolymerisation of lignin: a review. Jour Appl Chem. doi:10.1155/2013/838645

ASTM International, ASTM E1690 Standard method for determination of ethanol extractives in biomass (2016)

Goering HK and PJ Van Soest (1970) Forage fiber analysis (apparatus, reagents, procedures, and some applications). Agricultural Research Service (ARS) Handbook. No. 379. Washington, DC

Van Soest PJ, Robertson JB, Lewis BA (1991) Methods for dietary fiber, neutral detergent fiber, and non-starch polysaccharides in relation to animal nutrition. J Dairy Sci 74:3583–3597

Chaves AV, Waghorn GC, Tavendale MH (2002) A simplified method for lignin measurement in a range of forage species. Proceedings of the New Zealand Grassland Association 64:129–133

Sluiter, A. Ruiz, R., Scarlata, C., Sluiter, J., D. Templeton and D. Crocker (2008) Determination of structural carbohydrates and lignin in biomass. Colorado: National Renewable Energy Laboratory. Laboratory Analytical Procedure. NREL/TP-510-42618

Medina JDC, Woiciechowski A, Filho AZ, Noseda MD, Kaur BS, Soccol CR (2015) Lignin preparation from oil palm empty fruit bunches by sequential acid/alkaline treatment—a biorefinery approach. Bioresour. Tech. 194:172–178

Chiesa S, Gnansounou E (2014) Use of empty fruit bunches from the oil palm for bioethanol production: a thorough comparison between dilute acid and dilute alkali pretreatment. Bioresour Tech 159:355–364

Nieves DC, Karimi K, Horvath IS (2011) Improvement of biogas production from oil palm empty fruit bunches (OPEFB). Ind Crops Prods 34:1097–1101

Isroi, Mofoluwake MI, Ria M, Siti S, Muhammad NC, Claes N, Taherzadeh MJ (2012) Structural changes of oil palm empty fruit bunch (OPEFB) after fungal and phosphoric acid pretreatment. Molecules 17:14995–15012

Abdullah N, Sulaiman F, Gerhauser H (2011) Characterisation of oil palm empty fruit bunches for fuel application. Jour Phy Sci 20:1–24

Financie R, Moniruzzaman M, Uemura Y (2016) Enhanced enzymatic delignification of oil palm biomass with ionic liquid pretreatment. BioChem Eng Jour 110:1–7

Abdul PM, Jahim JM, Harun S, Markom M, Lutpi NA, Hassan O, Balan V, Dale BE, Mohd. Nor MT (2016) Effects of changes in chemical and structural characteristic of ammonia fibre expansion (AFEX) pretreated oil palm empty fruit bunch fibre on enzymatic saccharification and fermentability for biohydrogen. Bioresource Tech 211:200–208

Taherzadeh MI, Karimi K (2008) Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: a review. Intl Jour Mol Sci 9:1621–1651

Mirahmadi K, Kabir MM, Jeihanipour A, Karimi K, Taherzadeh MJ (2010) Alkaline pretreatment of spruce and birch to improve bioethanol and biogas production. Bioresources 5(2):928–938

Myers RH, Montomery DC (2009) Response surface methodology: process and product optimization using designed experiments, 3rd edn. Wiley, New York, pp 317–321

Khuri AI, Mukhopadhyay S (2010) Response surface methodology. WIREs Computational Statistics:128–149

Bas D, Boyaci IH (2007) Modelling and optimization I: usability of response surface methodology. J Food Eng 78(3):836–845

Bezerra MA, Santelli RE, Oliveira EP, Villar LS, Escaleira LA (2008) Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 76:965–977

Whitcomb, P. J., Larntz, K., (1992) The role of pure error on normal probability plots, presented at Transactions of the 46th Annual Quality Congress, Milwaukee

Akhtar J, Teo CL, Lai LW, Hassan N, Idris A, Aziz RA (2015) Factors affecting delignification of oil palm empty fruit bunch by microwave-assisted dilute acid/alkali pretreatment. Bioresources 10(1):588–596

Muryanto, Eka T, Haznan A, Agung. C, Effendi TC, Yanni S (2015) Alkaline delignification of oil palm empty fruit bunch using black liquor from pretreatment. Procedia Chemistry 16:99–105

Hong JY, Kim YS, Oh KK (2013) Fractionation and delignification of empty fruit bunches with low reaction severity for high sugar recovery. Bioresour Technol 146:176–183

Choi, W. I., Park, J. Y., Lee, J. P., Oh, Y. K., Park, Y. C., Kim, J. S., Park, J. M., Kim, C. H., Lee, J. S. (2013) Optimization of NaOH-catalyzed steam pretreatment of empty fruit bunch, Biotechnology for Biofuels, 6 (170)

Hamisan AF, Aziz SA, Kamaruddin K, Md Shah UK, Shahab N, Hassan MA (2009) Delignification of oil palm empty fruit bunch using chemical and microbial pretreatment methods. Int J of Agricultural Research 4(8):250–256

Acknowledgements

The authors would like to acknowledge PETRONAS and PETRONAS Chemical Group Bhd. (PCGB) for funding this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zawawi, A., Gaik, L.P., Sebran, N.H. et al. An optimisation study on biomass delignification process using alkaline wash. Biomass Conv. Bioref. 8, 59–68 (2018). https://doi.org/10.1007/s13399-017-0246-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-017-0246-x