Abstract

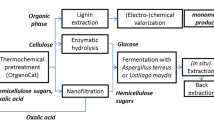

In this work, an organosolv process using beech wood as the feedstock, a mixture of water and methanol (50 vol%) as the solvent and aluminium chloride as the catalyst is designed. Different to other organosolv processes, the formation of the high value-added product furfural occurs already in the cooking stage with a quite high yield (40 mol% based on a lab scale literature process). Different to furfural producing processes, the cellulose remains in the solid phase in high quantity (93 wt% of the initial based on a lab scale literature process). The plant is designed in the way that 99.7 wt% of methanol is recovered. Another specification is the isolation of 95 wt% furfural with a purity of more than 99.5 wt%. After consecutive conversion of cellulose, the minimum sugar selling price of glucose as a dilute solution is calculated as 329 $/t depending strongly on the furfural yield as well as the application of lignin and the corresponding selling price.

Similar content being viewed by others

References

IEA. IEA bioenergy Task 42 on biorefineries (2007) Co-production of fuels, chemicals, power and materials from biomass. In: Minutes of the third Task meeting, Copenhagen, Denmark, 25–26

Bozell JJ, Petersen GR (2010) Technology development for the production of biobased products from biorefinery carbohydrates—the US Department of Energy’s “Top 10” revisited. Green Chem 12:539–554

Brownlee HJ, Miner CS (1923) Process of manufacturing furfural. UK Patent 203691-A

Nimlos MR, Qian X, Davis M, Himmel ME, Johnson DK (2006) Energetics of xylose decomposition as determined using quantum mechanics modeling. J Phys Chem A 110:11824–11838

Zeitsch KJ (2000) The chemistry and technology of furfural and its many byproducts, 1st edn. Elsevier, Amsterdam, pp 43–61

Cai CM, Zhang T, Kumar R, Wyman CE (2014) Integrated furfural production as a renewable fuel and chemical platform from lignocellulosic biomass. J Chem Technol Biotechnol 89:2–10

Alonso-Fagundez N, Granados ML, Mariscal R, Ojeda M (2012) Selective conversion of furfural to maleic anhydride and furan with VO(x)/Al(2)O(3) catalysts. ChemSusChem 5:1984–1990

Lecomte J, Finiels A, Geneste P, Moreau C (1998) Selective hydroxymethylation of furfuryl alcohol with aqueous formaldehyde in the presence of dealuminated mordernites. Appl Catal A 168:235–241

Hayes DJ, Fitzpatrick S, Hayes MHB, Ross JRH (2006) The biofine process—production of levulinic acid, furfural, and formic acid from lignocellulosic feedstocks. In: Kamm B, Gruber PR, Kamm M (eds) Biorefineries-industrial processes and products. Status quo and future directions, 1st edn. Wiley, Weinheim, pp 139–164

Van-Putten RJ, Van der Waal JC, De Jong E, Rasrendra CB, Heeres HJ, De Vries JG (2013) Hydroxymethylfurfural a versatile platform chemical made from renewable resources. Chem Rev 113:1499–1597

Frainier LJ, Fineberg H (1981) Preparation of furfuryl alcohol from furfural. US Patent 4302397

Timokhin BV, Baransky VA, Eliseeva GD (1999) Levulinic acid in organic synthesis. Russ Chem Rev 68:73–84

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686

Zheng Y, Pan Z, Zhang R (2009) Overview of biomass pretreatment for cellulosic ethanol production. Int J Agric Biol Eng 2:51–68

Tao L, Tan ECD, Aden A, Elander RT (2014) Techno-economic analysis and life-cycle assessment of lignocellulosic biomass to sugars using various pretreatment technologies. In: Sun J, Ding SY, Peterson JD (eds) Biological conversion of biomass for fuels and chemicals: exploration from natural utilization systems, 1st edn. RSC Publishing, Cambridge, pp 358–380

Mussatto SI, Dragone G, Guimaraes PMR, Paulo J, Silva A, Carneiro LM, Roberto IC, Vicente A, Domingues L, Teixeira JA (2010) Technological trends, global market, and challenges of bio-ethanol production. Biotechnol Adv 28:817–830

Van Haveren J, Scott EL, Sanders J (2008) Bulk chemicals from biomass. Biofuels Bioprod Bioref 2:41–57

Arato C, Pye EK, Gjennestad G (2005) The lignol approach to biorefining of woody biomass to produce ethanol and chemicals. Appl Biochem Biotechnol 123:871–882

Laure S, Leschinsky M, Fröhling M, Schultmann F, Unkelbach G (2014) Assessment of an organosolv lignocellulose biorefinary concept based on a material flow analysis of a pilot plant. Cellul Chem Technol 48:793–798

Gravitis J, Vedernikov N, Zandersons J, Kokerevics A (2001) Furfural and levoglucosan production from deciduous wood and agricultural wastes. In: Bozell JJ (ed) Chemicals and materials from renewable resources. American Chemical Society, Washington DC, pp 110–122

Vedernikov N, Kampars V, Puke M, Kruma I (2010) Changes in the birch wood lignocellulose composition in the pretreatment process. Sci J Riga TechUniv 22:68–72

Schwiderski M, Kruse A, Grandl R, Dockendorf D (2014) Comparison of the influence of a Lewis acid AlCl3 and a Brønsted acid HCl on the organosolv pulping of beech wood. Green Chem 16:1569–1578

Schwiderski M, Kruse A (2015) Catalytic effect of aluminium chloride on the example of the conversion of sugar model compounds. J Mol Catal A 402:64–70

Fernando EF, Vallejos EM, Area MC (2010) Lignin recovery from spent liquors from the ethanol-water fractionation of sugar cane bagasse. Cellul Chem Technol 44:311–318

Schwiderski M, Kruse A (2015) Aluminiumchlorid-katalysierter organosolv-aufschluss von buchenholz. Chem Ing Tech 87:922–930

AspenTech (2013) Aspen PlusTM V8.2. Software. Aspen Technology, Inc, Massachusetts

Kautto J, Realff MJ, Ragauskas AJ (2013) Design and simulation of an organosolv process for bioethanol production. Biomass Convers Bioref 3:199–212

Kautto J, Realff MJ, Ragauskas AJ, Kässi T (2014) Economic analysis of an organosolv process for bioethanol production. Bioresources 9:6041–6072

Eggeman T, Elander RT (2005) Process and economic analysis of pretreatment technologies. Bioresour Technol 96:2019–2025

Short W, Packey DJ, Holt T (1995) A manual for the economic evaluation and energy efficiency and renewable energy technologies. National Renewable Energy Laboratory technical report NREL/TP-462-5173 Colorado

Fogelholm C-J, Suutela J (1999) Heat and power co-generation. In: Gullichsen J, Fogelholm C-J (eds) Papermaking science and technology, chemical pulping, book 6B, 1st edn. Fapet Oy, Finland, pp 303–337

Demirbas A (2001) Relationships between lignin contents and heating values of biomass. Energy Convers Manage 42:183–188

Pittam DA, Pilcher G (1972) Measurements of heats of combustion by flame calorimetry. Part 8.—methane, ethane, propane, n-butane and 2-methylpropane. J Chem Soc Faraday Trans 1(68):2224–2229

Pan X, Xie D, Yu RW, Lam D, Saddler JN (2007) Pretreatment of lodgepole pine killed by mountain pine beetle using the ethanol organosolv process: fractionation and process optimization. Ind Eng Chem Res 46:2609–2617

Berguson B, Eaton J, Stanton B (2010) “Development of hybrid poplar for commercial production in the United States: the Pacific Northwest and Minnesota experience”, proceedings of the sustainable feedstocks for advanced fuels, sustainable alternative fuel feedstock opportunities, challenges and roadmaps for SIX U.S. regions, chapter 17, soil and water conservation society

ICIS indicative chemical prices. http://www.icis.com/chemicals/channel-info-chemicals-a-z. Accessed 02 July 2015

U.S. Energy Information Administration (2013) Natural gas weekly update. http://www.eia.gov/naturalgas/weekly/archive/2014/06_05/index.cfm. Accessed 15 April 2015

Humbird D, Davis R, Tao L, Kinchin C, Hsu D, Aden A, Schoen P, Lukas J, Olthof B, Worley M, Sexton D, Dudgeon D (2011) Process design and economics for biochemical conversion of lignocellulosic biomass to ethanol. National Renewable Energy Laboratory technical report NREL/TP-5100-47764. Colorado

U.S. Energy Information Administration (2013) Electricity wholesale market data. http://www.eia.gov/electricity/wholesale/index.cfm. Accessed 15 April 2015

Tin Win D (2005) Furfural - gold from garbage. AU J T 8:185–190

Watson LJ, Connors CG (2008) Furfural—a value adding opportunity for the Australian sugar industry. Proc Aust Soc Sugar Cane Technol 30:429–436

European Commission, Project of the Intake 2014 Sustainable Energy Services (2014) valorization of low concentration sugar-side stream from dissolving pulp production. http://www.exploreselect.eu/LinkClick.aspx?fileticket=mc5ZSusg5cE%3D&tabid=1421&language=en-GB. Accessed 20 June 2015

Pan X, Gilkes N, Kadla J, Pye K, Saka S, Gregg D, Ehara K, Xie D, Lam D, Saddler J (2006) Bioconversion of hybrid poplar to ethanol and co-products using an organosolv fractionation process: optimization of process yields. Biotechnol Bioeng 94:851–861

Rasrendra CB, Makertihartha IGBN, Adisasmito S, Heeres HJ (2010) Green chemicals from d-glucose: systematic studies on catalytic effects of inorganic salts on the chemo-selectivity and yield in aqueous solutions. Top Catal 53:1241–1247

Schwiderski M, Kruse A, Grandl R, Dockendorf D (2014) Kinetics of the AlCl3 catalyzed xylan hydrolysis during methanosolv pulping of beech wood. RSC Adv 4:45118–45127

Phillips S, Aden A, Jechura J, Dayton D, Eggeman T (2007) Thermochemical ethanol via indirect gasification and mixed alcohol synthesis of lignocellulosic biomass. National Renewable Energy Laboratory technical report NREL/TP-510-41168. Colorado

Gnansounou E, Dauriat A (2010) Techno-economic analysis of lignocellulosic ethanol: a review. Bioresour Technol 101:4980–4991

Huang HJ, Ramaswamy S, Al-Dajani W, Tschirner U, Cairncross RA (2009) Effect of biomass species and plant size on cellulosic ethanol: a comparative process and economic analysis. Biomass Bioenergy 33:234–246

Hu L, Pan H, Zhou Y, Zhang M (2011) Methods to improve lignin’s reactivity as a phenol substitute and as replacement for other phenolic compounds: a brief review. Bioresources 6:3515–3525

Chen MCW (2014) Commercial viability analysis of lignin based carbon fibre. Master thesis, Simon Fraser University

Mao L, Zhang L, Gao N, Li A (2013) Seawater-based furfural production via corncob hydrolysis catalyzed by FeCl3 in acetic acid steam. Green Chem 15:727–737

Zhang L, Yu H (2013) Conversion of xylan and xylose into furfural in biorenewable deep eutectic solvent with trivalent metal chloride added. Bioresources 8:6014–6025

Hallac BB, Sannigrahi P, Pu Y, Ray M, Murphy RJ, Ragauskas AJ (2010) Effect of ethanol organosolv pretreatment on enzymatic hydrolysis of buddleja davidii stem biomass. Ind Eng Chem Res 49:1467–1472

Brosse N, Sannigrahi P, Ragauskas A (2009) Pretreatment of miscanthus x giganteus using the ethanol organosolv process for ethanol production. Ind Eng Chem Res 48:8328–8334

McMillan JD (1993) Xylose fermentation to ethanol: a review. National Renewable Energy Laboratory technical report NREL/TP-421-4944. Colorado

Matsushika A, Inoue H, Kodaki T, Sawayama S (2009) Ethanol production from xylose in engineered saccharomyces cerevisiae strains: current state and perspectives. Appl Microbiol Biotechnol 84:37–53

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 546 kb)

Rights and permissions

About this article

Cite this article

Schwiderski, M., Kruse, A. Process design and economics of an aluminium chloride catalysed organosolv process. Biomass Conv. Bioref. 6, 335–345 (2016). https://doi.org/10.1007/s13399-015-0189-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-015-0189-z