Abstract

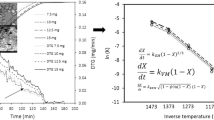

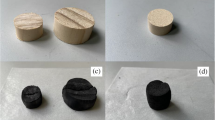

Chars of different particle sizes (150–250, 500–600 μm) from two different biomass species (spruce and coconut shell) were gasified under entrained flow condition in the presence of CO2 at different temperatures (800, 900 and 1000 °C). The concentration of CO2 was also varied between 5 and 20 % to determine its effect. It was found that significant improvement in gasification efficiency is possible by lowering the particle size below 0.5 mm. This finding was attributed to the spruce char as it showed the highest (≈50 %) conversion for the lowest particle size. It was also revealed that less reactive chars (coconut shell) were insensitive to the particle size and temperature variation for CO2 as a gasifying agent. Generally, pyrolysis process dominates the conversion process during raw biomass gasification. No tar component was observed during gasification at 1000 °C. As a whole, this study provides useful insight about the entrained flow gasification process of biomass chars with CO2.

Similar content being viewed by others

References

Bell DA, Towler BF, Maohong F (2011) Coal gasification and its applications. doi:10.1016/B978-0-8155-2049-8.10015-4

Zhou J, Chen Q, Zhao H, Cao X, Mei Q, Luo Z, Cen K (2009) Biomass-oxygen gasification in a high-temperature entrained-flow gasifier. Biotechnol Adv 27:606–611. doi:10.1016/j.biotechadv.2009.04.011

Zhang Y, Kajitani S, Ashizawa M, Oki Y (2010) Tar destruction and coke formation during rapid pyrolysis and gasification of biomass in a drop-tube furnace. Fuel 89:302–309. doi:10.1016/j.fuel.2009.08.045

Zhao Y, Sun S, Zhou H, Sun R, Tian H, Luan J, Qian J (2010) Experimental study on sawdust air gasification in an entrained-flow reactor. Fuel Process Technol 91:910–914. doi:10.1016/j.fuproc.2010.01.012

Zhao Y, Sun S, Tian H, Qian J, Su F, Ling F (2009) Characteristics of rice husk gasification in an entrained flow reactor. Bioresour Technol 100:6040–6044. doi:10.1016/j.biortech.2009.06.030

Hernández JJ, Aranda G, Barba J, Mendoza JM (2012) Effect of steam content in the air–steam flow on biomass entrained flow gasification. Fuel Process Technol 99:43–55. doi:10.1016/j.fuproc.2012.01.030

Hernández JJ, Aranda-Almansa G, Serrano C (2010) Co-gasification of biomass wastes and coal–coke blends in an entrained flow gasifier: an experimental study. Energy Fuel 24:2479–2488. doi:10.1021/ef901585f

Lapuerta M, Hernández JJ, Pazo A, López J (2008) Gasification and co-gasification of biomass wastes: effect of the biomass origin and the gasifier operating conditions. Fuel Process Technol 89:828–837. doi:10.1016/j.fuproc.2008.02.001

Qin K, Jensen PA, Lin W, Jensen AD (2012) Biomass gasification behavior in an entrained flow reactor: gas product distribution and soot formation. Energy Fuel 26:5992–6002

Qin K, Lin W, Jensen PA, Wu H, Jensen AD (2013) Characterization of residual particulates from biomass entrained flow gasification. Energy Fuel 27:262–270

Qin K, Lin W, Jensen PA, Jensen AD (2012) High-temperature entrained flow gasification of biomass. Fuel 93:589–600. doi:10.1016/j.fuel.2011.10.063

Hernández JJ, Aranda-Almansa G, Bula A (2010) Gasification of biomass wastes in an entrained flow gasifier: effect of the particle size and the residence time. Fuel Process Technol 91:681–692. doi:10.1016/j.fuproc.2010.01.018

Kajitani S, Suzuki N, Ashizawa M, Hara S (2006) CO2 gasification rate analysis of coal char in entrained flow coal gasifier. Fuel 85:163–169. doi:10.1016/j.fuel.2005.07.024

Kajitani S, Hara S, Matsuda H (2002) Gasification rate analysis of coal char with a pressurized drop tube furnace. Fuel 81:539–546

Tanner J, Kabir KB, Müller M, Bhattacharya S (2015) Low temperature entrained flow pyrolysis and gasification of a Victorian brown coal. Fuel 154:107–113. doi:10.1016/j.fuel.2015.03.069

Yang K, Peng J, Srinivasakannan C, Zhang L, Xia H, Duan X (2010) Preparation of high surface area activated carbon from coconut shells using microwave heating. Bioresour Technol 101:6163–6169. doi:10.1016/j.biortech.2010.03.001

Mahajan OP (1991) CO2 surface area of coals: the 25-year paradox. Carbon N Y 29:735–742

Chen L, Bhattacharya S (2013) Sulfur emission from Victorian brown coal under pyrolysis, oxy-fuel combustion and gasification conditions. Environ Sci Technol 47:1729–1734

Kirtania K, Bhattacharya S (2015) CO2 gasification kinetics of algal and woody char procured under different pyrolysis conditions and heating rates. ACS Sustain Chem Eng 3:365–373. doi:10.1021/sc500777u

Kobayashi H, Howard JBB, Sarofim AFF (1977) Coal devolatilization at high temperatures. Symp Combust 16:411–425. doi:10.1016/S0082-0784(77)80341-X

Umeki K, Kirtania K, Chen L, Bhattacharya S (2012) Fuel particle conversion of pulverized biomass during pyrolysis in an entrained flow reactor. Ind Eng Chem Res 51:13973–13979. doi:10.1021/ie301530j

Kirtania K, Tanner J, Kabir KB, Rajendran S, Bhattacharya S (2014) In situ synchrotron IR study relating temperature and heating rate to surface functional group changes in biomass. Bioresour Technol 151:36–42. doi:10.1016/j.biortech.2013.10.034

Cetin E, Moghtaderi B, Gupta R, Wall TF (2004) Influence of pyrolysis conditions on the structure and gasification reactivity of biomass chars. Fuel 83:2139–2150. doi:10.1016/j.fuel.2004.05.008

Hurt RH, Sarofim AF, Longwell JP (1991) The role of microporous surface area in the gasification of chars from a sub-bituminous coal. Fuel 70:1079–1082. doi:10.1016/0016-2361(91)90263-A

Seo DK, Lee SK, Kang MW, Hwang J, Yu T-U (2010) Gasification reactivity of biomass chars with CO2. Biomass Bioenergy 34:1946–1953. doi:10.1016/j.biombioe.2010.08.008

Di Blasi C (2009) Combustion and gasification rates of lignocellulosic chars. Prog Energy Combust Sci 35:121–140. doi:10.1016/j.pecs.2008.08.001

Van der Drift A, Boerrigter H, Coda B, Cieplik MK, Hemmes K (2004) Entrained flow gasification of biomass—ash behaviour, feeding issues, and system analyses. ECN Biomass, Report No. ECN-C--04-039, pp 21–23

Kirtania K, Joshua J, Kassim MA, Bhattacharya S (2014) Comparison of CO2 and steam gasification reactivity of algal and woody biomass chars. Fuel Process Technol 117:44–52

Acknowledgments

The research work was carried out at the Department of Chemical Engineering, Monash University. The authors like to acknowledge the financial and technical support for this work from Australian Research Council (ARC) LIEF Grant (LE120100141) and Monash Center for Electron Microscopy (MCEM) respectively.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

Supporting information for this work contains scanning electron microscopic images of spruce and coconut shell char. The information is available via the internet at (DOCX 828 kb)

Rights and permissions

About this article

Cite this article

Kirtania, K., Bhattacharya, S. CO2 gasification behavior of biomass chars in an entrained flow reactor. Biomass Conv. Bioref. 6, 49–59 (2016). https://doi.org/10.1007/s13399-015-0174-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-015-0174-6