Abstract

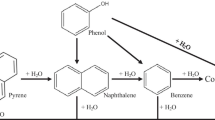

Gasification is a thermo-chemical conversion process used to produce syngas through partial oxidation. Gasification technology provides the opportunity to convert a feedstock into fuel gases or synthetic gases. Raw syngas produced by gasification needs cleaning before being used subsequently. One of the impurities in raw syngas is tar, a group of long-chain sticky hydrocarbons that clog the subsequent devices. One useful way of removing tar is to degrade it thermally into simple fuel gases (e.g., hydrogen, methane). This adds to the heat value of syngas too. In this work, an equilibrium model is reported that simulates the thermal cracking of three representative tars, viz. toluene, benzene and naphthalene, by steam reforming and hydrogenation and estimates the cracking products. Parametric studies have also been carried out to understand the influence of different operating conditions such as temperature and reactant concentrations on the composition of product gas mixture. Reported results may be useful to determine optimum operating conditions in tar cracking systems.

Similar content being viewed by others

References

Higman C, Burgt MVD (2008) Handbook of gasification. Elsevier, USA

Zainal ZA, Ali R, Lean CH, Seetharamu KN (2001) Prediction of performance of a downdraft gasifier using equilibrium modeling for different biomass materials. Energy Convers Manag 42:1499–1515

Jarungthammachote S, Dutta A (2007) A thermodynamic equilibrium model and second law analysis of a downdraft waste gasifier. Energy 32:1660–1669

Melger A, Perez FJ, Laget H, Horillo A (2007) Thermo chemical equilibrium modelling of a gasifying process. Energy Convers Manag 48:59–67

Pengmei LV, Yuan Z, Ma L, Wu C, Chen Y, Zhu J (2007) Hydrogen-rich gas production from biomass air and oxygen/steam gasification in a downdraft gasifier. Renew Energy 32:2173–2185

Roy PC, Datta A, Chakraborty N (2009) Modelling of a downdraft biomass gasifier with finite rate kinetics in the reduction zone. Int J Energy Resour 33:833–851

Yan F, Luo SY, Hu ZQ, Xiao B, Cheng G (2010) Hydrogen-rich gas production by steam gasification of char from biomass fast pyrolysis in a fixed-bed reactor: influence of temperature and steam on hydrogen yield and syngas composition. Bioresour Technol 101:5633–5637

Li C, Suzuki K (2009) Tar property, analysis, reforming mechanism and model for biomass gasification—an overview. Renew Sust Energ Rev 13:594–604

Lopamudra D, Ptasinski JK, Janssen JJ, Frans G (2003) A review of the primary measures for tar elimination in biomass gasification processes. Biomass Bioenergy 24:125–140

Gilbert P, Ryu C, Sharifi V, Swithenbank J (2009) Tar reduction in pyrolysis vapours From biomass over a hot char bed. Bioresour Technol 100:6045–6051

Houben MP, De Lange HC, Van Steenhoven AA (2005) Tar reduction through partial combustion of fuel gas. Fuel 84:817–824

Fagbemi L, Khezami L, Capart R (2001) Pyrolysis products from different biomasses: application to the thermal cracking of tar. Appl Energy 69:293–306

Morf P, Hasler P, Nussbaumer T (2002) Mechanisms and kinetics of homogeneous Secondary reactions of tar from continuous pyrolysis of wood chips. Fuel 81:843–853

Ximena A, Huttinger KJ (1989) Steam gasification of naphthalene as a model reaction of homogeneous gas/gas reactions during coal gasification. Fuel 68:1300–1310

Jess A (1996) Mechanisms and kinetics of thermal reactions of aromatic hydrocarbons from pyrolysis of solid fuels. Fuel 75:144–148

Fourcault A, Marias F, Michon U (2010) Modeling of thermal removal of tars in a high temperature stage fed by a plasma torch. Biomass Bioenergy 34:1363–1374

Pant KK, Kunzrp D (1999) Noncatalytic and catalytic pyrolysis of toluene. Can J Chem Eng 77:150–155

Taralas G, Kontominas MG, Kakatsios X (2003) Modelling the thermal destruction of toluene (C7H8) as tar-related species for fuel gas cleanup. Energy Fuel 17:329–337

Taralas G, Kontominas MG (2005) Numerical modelling of tar species/VOC dissociation for clean and intelligent energy production. Energy Fuel 19:87–93

Jayah TH, Aye L, Fuller RJ, Stewart DF (2003) Computer simulation of a downdraft wood gasifier for tea drying. Biomass Bioenergy 25:459–69

Turns SR (1996) An introduction to combustion concepts and applications. McGraw-Hill, New York

Cances J, Valin S, Castelli P, Thiery S, Dupont C, Petit M (2008) Soot formation during methane reforming at high temperature: experiments and modelling. Chem Eng Trans 16:241–249

Tesner AP, Shurupov VS (1997) Soot formation during pyrolysis of naphthalene, anthracene and pyrene. Combust Sci Technol 126:139–151

Valin S, Cances J, Castelli P, Thiery S, Dufour A, Boissonnet G, Spindler B (2009) Upgrading biomass pyrolysis gas by conversion of methane at high temperature: experiments and modelling. Fuel 88:834–842

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Maiti, R., Ghosh, S. & De, S. Cracking of tar by steam reforming and hydrogenation. Biomass Conv. Bioref. 3, 103–111 (2013). https://doi.org/10.1007/s13399-012-0065-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-012-0065-z