Abstract

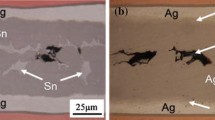

Power semiconductors require a large bonding area for die attachment. For this purpose, transient liquid phase bonding (TLPB) was applied using fabricated interlayers, namely Sn–3Cu and Sn–10Cu, to study the intermetallic compound (IMC) formation, and the results were compared with those obtained with a pure-Sn interlayer. The Sn–3Cu and Sn–10Cu interlayers exhibited primary IMC fraction of 0.06 and 0.24, respectively, before the TLPB. For a Cu/interlayer/Cu sandwich structure, the TLPB was applied at 250 °C over various time periods (1–4 h). A reduction in the bonding time was more significant for a Sn–10Cu interlayer with a larger amount of primary IMCs than for the Sn–3Cu interlayer. The time exponent of the IMC fraction with respect to the bonding time was approximately 0.3 for all interlayers. This implies that the IMC growth mechanism is governed by a liquid channel or wet grain boundary diffusion. The nearly constant fraction and increasing size of the primary IMCs produced during the TLPB indicate that the primary IMCs coalesced during this process. The primary IMCs preferentially coalesced with the interface IMCs produced during the TLPB when they had the same crystalline orientation.

Graphic Abstract

Similar content being viewed by others

References

Drevin-Bazin, A., Lacroix, F., Barbot, J.F.: SiC die attach for high-temperature applications. J. Electron. Mater. 43, 695–701 (2014)

Traeger, R.K., Lysne, P.C., Trans, I.E.E.E.: High temperature electronics application in well logging. Nucl. Sci. 35, 852–854 (1988)

Son, J.H., Kim, M.K., Yu, D.Y., Ko, Y.H., Yoon, J.W., Lee, C.W., Park, Y.B., Bang, J.H.: Thermal aging characteristics of Sn-xSb solder for automotive power module. J. Weld. Join. 35, 38–47 (2017)

Hong, W.S., Oh, C.M.: Degradation behavior of solder joint and implementation technology for lead-free automotive electronics. J. Korean Weld. Join. Soc. 31, 22–30 (2013)

Zhang, H., Minter, J., Lee, N.C.: A brief review on high-temperature, Pb-free die-attach materials. J. Electron. Mater. 48, 201–210 (2019)

Kim, M.S., Oh, C.M., Hong, W.S.: Presureless silver sintering property of SiC device and ZTA AMB substrate for power module. J. Weld. Join. 37, 15–20 (2019)

Yoon, S.W., Glover, M.D., Shiozaki, K.: Nickel–tin transient liquid phase bonding toward high-temperature operational power electronics in electrified vehicles. IEEE Trans. Power Electron. 28, 2448–2456 (2013)

Ishizaki, T., Miura, D., Kuno, A., Nagao, R., Aoki, S., Sohima, Y., Kino, T., Usui, M., Yamada, Y.: Power cycle reliability of Cu nanoparticle joints with mismatched coefficients of thermal expansion. Microelectron. Reliab. 64, 287–293 (2016)

Zhao, N., Zhong, Y., Huang, M.L., Ma, H.T., Dong, W.: Growth kinetics of Cu6Sn5 intermetallic compound at liquid-solid interfaces in Cu/Sn/Cu interconnects under temperature gradient. Sci. Rep. 5, 1–12 (2015)

Feng, J., Hang, C., Tian, Y., Liu, B., Wang, C.: Growth kinetics of Cu6Sn5 intermetallic compound in Cu-liquid Sn interfacial reaction enhanced by electric current. Sci. Rep. 8, 1–10 (2018)

Liu, J.H., Zhoa, H.U., Li, Z.L., Song, X.G., Dong, J.H., Zhoa, Y.X., Feng, J.C.: Study on the microstructure and mechanical properties of Cu–Sn intermetallic joints rapidly formed by ultrasonic-assisted transient liquid phase soldering. J. Alloys Compd. 692, 552–557 (2017)

Hu, T., Chen, H., Li, M.: Die attach materials with high remelting temperatures created by bonding Cu@Sn microparticles at lower temperatures. Mater. Des. 108, 383–390 (2016)

El-Daly, A.A., Hammad, A.E.: Development of high strength Sn–0.7 Cu solders with the addition of small amount of Ag and In. J. Alloys Compd. 509, 8554–8560 (2011)

Kurz, W., Fisher, D.J.: Fundamentals of Solidification, pp. 85–88. Trans Tech Publications, Zurich (1986)

Cook, G.O., Sorensen, C.D.: Overview of transient liquid phase and partial transient liquid phase bonding. J. Mater. Sci. 46, 5305–5323 (2011)

Bosco, N.S., Zok, F.W.: Critical interlayer thickness for transient liquid phase bonding in the Cu–Sn system. Acta Mater. 52, 2965–2972 (2004)

Chiu, W.L., Liu, C.M., Haung, Y.S., Chen, C.: Formation of plate-like channels in Cu6Sn5 and Cu3Sn intermetallic compounds during transient liquid reaction of Cu/Sn/Cu structures. Mater. Lett. 164, 5–8 (2016)

Park, M.S., Gibbons, S.L., Arróyave, R.: Prediction of processing maps for transient liquid phase diffusion bonding of Cu/Sn/Cu joints in microelectronics packaging. Microelectron. Reliab. 54, 1401–1411 (2014)

Gagliano, R.A., Fine, M.E.: Thickening kinetics of interfacial Cu6Sn5 and Cu3Sn layers during reaction of liquid tin with solid copper. J. Electron. Mater. 32, 1441–1447 (2003)

Kou, S.: Welding Metallurgy, p. 149. Wiley-Interscience, Hoboken (2003)

Ghosh, G.: Dissolution and interfacial reactions of thin-film Ti/Ni/Ag metallizations in solder joints. Acta Mater. 49, 2609–2624 (2001)

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) Grant Funded by the Korea government (MSIT) through GCRC-SOP (No. 2011-0030013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sohn, S., Moon, B., Lee, J. et al. Interlayer Material Design Reducing Transient Liquid Phase Bonding Time. Electron. Mater. Lett. 16, 106–114 (2020). https://doi.org/10.1007/s13391-019-00191-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-019-00191-2