Abstract

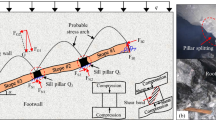

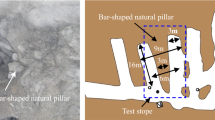

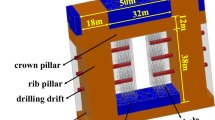

To solve the problems of high ore resources loss and natural pillar splitting failure in multi-stope mining of gently inclined thin orebody by traditional room-and-pillar method, the overburden stability control technology by replacing natural pillars with pre-stressed expandable pillars (PEP) is developed in this paper. By means of numerical simulation and physical experimental methods, the distribution characteristics of stress, displacement, and failure zone of surrounding rock in multi-stope mining with and without PEP support were studied. The results demonstrate that the PEP supporting effect can improve the stress environment of surrounding rock compared with the unsupported condition, divide the stress reduction zone of the stope roof, and avoid the overburden failure induced by tensile stress penetration in the shallow-buried stope. Moreover, the PEP support can effectively limit the crack propagation depth and damage degree of the surrounding rock. Deriving from the physical test, compared to the unsupported scenario, the vertical deformation of the stope roof is reduced by about 44% on average with the PEP support, thus preventing overburden collapse caused by large deformation. Besides, the greater the mining depth of the stope, the greater the increase in the bearing capacity of the PEP support. Field industrial test shows that the stope and PEP supports are visually safe and stable after mining. The overburden stability control technology with PEP support proposed in this study can offer a key reference for improving ore resource recovery in multi-stope mining of gently inclined orebody.

Similar content being viewed by others

References

Ghasemi, E.; Shahriar, K.: A new coal pillars design method in order to enhance safety of the retreat mining in room and pillar mines. Saf. Sci. 50, 579–585 (2012). https://doi.org/10.1016/j.ssci.2011.11.005

Napa-García, G.F.; Câmara, T.R.; Navarro Torres, V.F.: Optimization of room-and-pillar dimensions using automated numerical models. Int. J. Min. Sci. Technol. 29, 797–801 (2019). https://doi.org/10.1016/j.ijmst.2019.02.003

Esterhuizen, G.S.; Dolinar, D.R.; Ellenberger, J.L.: Pillar strength in underground stone mines in the United States. Int. J. Rock Mech. Min. Sci. 48, 42–50 (2011). https://doi.org/10.1016/j.ijrmms.2010.06.003

Li, C.; Xu, J.; Wang, Z.; Qin, S.: Domino instability effect of surrounding rock-coal pillars in a room-and-pillar gob. Int. J. Min. Sci. Technol. 23, 913–918 (2013). https://doi.org/10.1016/j.ijmst.2013.11.006

Zhang, C.; Zhao, Y.; Han, P.; Bai, Q.: Coal pillar failure analysis and instability evaluation methods: a short review and prospect. Eng. Fail. Anal. 138, 106344 (2022). https://doi.org/10.1016/j.engfailanal.2022.106344

Zhou, Z.; Zang, H.; Cao, W.; Du, X.; Chen, L.; Ke, C.: Risk assessment for the cascading failure of underground pillar sections considering interaction between pillars. Int. J. Rock Mech. Min. Sci. 124, 104142 (2019). https://doi.org/10.1016/j.ijrmms.2019.104142

Xie, P.; Luo, Y.; Wu, Y.; Gao, X.; Luo, S.; Zeng, Y.: Roof deformation associated with mining of two panels in steeply dipping coal seam using subsurface subsidence prediction model and physical simulation experiment. Min. Metall. Explor. 37, 581–591 (2020). https://doi.org/10.1007/s42461-019-00156-x

Yu, Y.; Chen, S.; Deng, K.; Fan, H.: Long-term stability evaluation and pillar design criterion for room-and-pillar mines. Energies 10, 1644 (2017). https://doi.org/10.3390/en10101644

Guo, W.; Xu, F.: Numerical simulation of overburden and surface movements for Wongawilli strip pillar mining. Int. J. Min. Sci. Technol. 26, 71–76 (2016). https://doi.org/10.1016/j.ijmst.2015.11.013

Li, X.; Qiu, J.; Zhao, Y.; Chen, Z.; Li, D.: Instantaneous and long-term deformation characteristics of deep room-pillar system induced by pillar recovery. Trans. Nonferrous Met. Soc. China. 30, 2775–2791 (2020). https://doi.org/10.1016/S1003-6326(20)65420-6

Ghadimi, M.; Shahriar, K.; Jalalifar, H.: Study of fully grouted rock bolt in tabas coal mine using numerical and instrumentation methods. Arab. J. Sci. Eng. 41, 2305–2313 (2016). https://doi.org/10.1007/s13369-015-1935-z

Waclawik, P.; Snuparek, R.; Kukutsch, R.: Rock bolting at the room and pillar method at great depths. Procedia Eng. 191, 575–582 (2017). https://doi.org/10.1016/j.proeng.2017.05.220

Barczak, T.M.: An overview of standing roof support practices and developments in the United States. In: Proceedings of the Third South African Rock Engineering Symposium, Johannesburg, Republic of South Africa: J. S. Afr. Inst. Min. Metall., pp. 301–334 (2005)

Cao, S.; Xue, G.; Yilmaz, E.; Yin, Z.; Yang, F.: Utilizing concrete pillars as an environmental mining practice in underground mines. J. Clean. Prod. 278, 123433 (2021). https://doi.org/10.1016/j.jclepro.2020.123433

Skrzypkowski, K.: Decreasing mining losses for the room and pillar method by replacing the inter-room pillars by the construction of wooden cribs filled with waste rocks. Energies 13, 3564 (2020). https://doi.org/10.3390/en13143564

Kang, H.; Lv, H.; Zhang, X.; Gao, F.; Wu, Z.; Wang, Z.: Evaluation of the ground response of a pre-driven longwall recovery room supported by concrete cribs. Rock Mech. Rock Eng. 49, 1025–1040 (2016). https://doi.org/10.1007/s00603-015-0782-2

Meng, F.; Wen, Z.; Shen, B.; Jiang, Y.; Shi, S.; Zhao, R.: Applicability of yielding-resisting sand column and three-dimensional coordination support in stopes. Materials 12, 2635 (2019). https://doi.org/10.3390/ma12162635

Mesgari, S.; Akbarnezhad, A.; Xiao, J.Z.: Recycled geopolymer aggregates as coarse aggregates for Portland cement concrete and geopolymer concrete: effects on mechanical properties. Constr. Build. Mater. 236, 117571 (2020). https://doi.org/10.1016/j.conbuildmat.2019.117571

Cao, S.; Zheng, D.; Yilmaz, E.; Yin, Z.; Xue, G.; Yang, F.: Strength development and microstructure characteristics of artificial concrete pillar considering fiber type and content effects. Constr. Build. Mater. 256, 119408 (2020). https://doi.org/10.1016/j.conbuildmat.2020.119408

Barczak, T.M.; Tadolini, S.C.: Pumpable roof supports: an evolution in longwall roof support technology. Trans. Soc. Min. Metall. Explor. 324, 19–31 (2008)

Batchler, T.: Analysis of the design and performance characteristics of pumpable roof supports. Int. J. Min. Sci. Technol. 27, 91–99 (2017). https://doi.org/10.1016/j.ijmst.2016.10.003

Zhao, H.; Ren, T.; Remennikov, A.: Standing support incorporating FRP and high water-content material for underground space. Tunn. Undergr. Space Technol. 110, 103809 (2021). https://doi.org/10.1016/j.tust.2020.103809

Zhao, H.; Ren, T.; Remennikov, A.: A hybrid tubular standing support for underground mines: compressive behaviour. Int. J. Min. Sci. Technol. 31, 215–224 (2021). https://doi.org/10.1016/j.ijmst.2020.11.004

Li, K.; Li, Y.; Jing, H.: Evaluation of the active support and yielding bearing properties of artificial pillars supporting a stope roof using 3DEC numerical simulation. Adv. Civ. Eng. 2019, e5934360 (2019). https://doi.org/10.1155/2019/5934360

Barczak, T.M.; Tadolini, S.C.; McKelvey, P.: Hydraulic prestressing units: an innovation in roof support technology. In: Proceedings of 23rd International Conference on Ground Control in Mining, Coal International, Morgantown, WV, pp. 286–294 (2004)

Li, Y.; Li, K.; Feng, X.; Cai, M.: Development and evaluation of artificial expandable pillars for hard rock mining. Int. J. Rock Mech. Min. Sci. 110, 68–75 (2018). https://doi.org/10.1016/j.ijrmms.2018.07.014

Li, K.; Li, Y.; Wang, Z.; Xu, S.; Xiong, Z.: Research on the enlargement of stope span based on the pre-stressed expandable pillar support technology. Rock Mech. Rock Eng. 54, 4663–4675 (2021). https://doi.org/10.1007/s00603-021-02514-y

Li, K.; Jiang, K.; Li, Y.; Wang, X.; Liu, K.; Xu, S.: Determination of the load bearing capacity of pre-stressed expandable props for ground support in underground mines. Int. J. Min. Sci. Technol. (2023). https://doi.org/10.1016/j.ijmst.2023.05.003

Ye, Q.; Wang, G.; Jia, Z.; Zheng, C.; Wang, W.: Similarity simulation of mining-crack-evolution characteristics of overburden strata in deep coal mining with large dip. J. Pet. Sci. Eng. 165, 477–487 (2018). https://doi.org/10.1016/j.petrol.2018.02.044

Zhao, P.; Zhuo, R.; Li, S.; Shu, C.M.; Jia, Y.; Lin, H.; Chang, Z.; Ho, C.H.; Laiwang, B.; Xiao, P.: Fractal characteristics of methane migration channels in inclined coal seams. Energy 225, 25 (2021). https://doi.org/10.1016/j.energy.2021.120127

Wang, T.; Chen, C.; Xia, K.; Shao, Y.; Liu, X.; Yang, K.: Ground movement in the hanging wall of underground iron mines with steeply dipping discontinuities: a case study. Arab. J. Sci. Eng. (2023). https://doi.org/10.1007/s13369-023-07820-x

Li, Y.; Xiong, Z.; Li, K.; Yu, P.; Ding, Y.; Li, Z.: Stress evolution and failure characteristics of overburden during multi-stope mining for a gently inclined thin orebody. Min. Metall. Explor. 40, 637–653 (2023). https://doi.org/10.1007/s42461-023-00746-w

Suorineni, F.T.; Mgumbwa, J.; Kaiser, P.K.; Thibodeau, D.: Mining of orebodies under shear loading Part 2—failure modes and mechanisms. Min. Technol. 123, 240–249 (2014). https://doi.org/10.1179/1743286314y.0000000072

Rashed, G.; Slaker, B.; Sears, M.M.; Murphy, M.M.: A parametric study for the effect of dip on stone mine pillar stability using a simplified model geometry. Min. Metall. Explor. 38, 967–977 (2021). https://doi.org/10.1007/s42461-021-00394-y

Çakır, Ö.; Coskun, N.: Theoretical issues with Rayleigh surface waves and geoelectrical method used for the inversion of near surface geophysical structure. J. Hum. Earth Future 2, 183–199 (2021). https://doi.org/10.28991/HEF-2021-02-03-01

Kien, D.V.; Anh, D.N.: Numerical simulation of the stability of rock mass around large underground cavern. Civ. Eng. J. 8, 81–91 (2022). https://doi.org/10.28991/CEJ-2022-08-01-06

Itasca Consulting Group Inc.: UDEC: Universal Distinct Element Code, Version 6.0. Itasca, Minneapolis (2014)

Gao, F.Q.; Stead, D.: The application of a modified Voronoi logic to brittle fracture modelling at the laboratory and field scale. Int. J. Rock Mech. Min. Sci. 68, 1–14 (2014). https://doi.org/10.1016/j.ijrmms.2014.02.003

Van Heerden, W.: In situ complete stress-strain characteristics of large coal specimens. J. South. Afr. Inst. Min. Metall. 75, 207–217 (1975)

Huang, H.; Shen, J.; Chen, Q.; Karakus, M.: Estimation of REV for fractured rock masses based on Geological Strength Index. Int. J. Rock Mech. Min. Sci. 126, 104179 (2020). https://doi.org/10.1016/j.ijrmms.2019.104179

Zhou, Z.; Sun, J.; Lai, Y.; Wei, C.; Hou, J.; Bai, S.; Huang, X.; Liu, H.; Xiong, K.; Cheng, S.: Study on size effect of jointed rock mass and influencing factors of the REV size based on the SRM method. Tunn. Undergr. Space Technol. 127, 104613 (2022). https://doi.org/10.1016/j.tust.2022.104613

Yang, S.-Q.; Chen, M.; Jing, H.-W.; Chen, K.-F.; Meng, B.: A case study on large deformation failure mechanism of deep soft rock roadway in Xin’An coal mine, China. Eng. Geol. 217, 89–101 (2017). https://doi.org/10.1016/j.enggeo.2016.12.012

Hoek, E.; Brown, E.T.: Practical estimates of rock mass strength. Int. J. Rock Mech. Min. Sci. 34, 1165–1186 (1997). https://doi.org/10.1016/S1365-1609(97)80069-X

Hoek, E.; Brown, E.T.: The Hoek–Brown failure criterion and GSI—2018 edition. J. Rock Mech. Geotech. Eng. 11, 445–463 (2019). https://doi.org/10.1016/j.jrmge.2018.08.001

Nariman, N.A.; Hamdia, K.; Ramadan, A.M.; Sadaghian, H.: Optimum design of flexural strength and stiffness for reinforced concrete beams using machine learning. Appl. Sci. 11, 8762 (2021). https://doi.org/10.3390/app11188762

Hassan, S.A.; Shitote, S.M.; Thuo, J.N.; Kiplangat, D.C.: Predictive models to evaluate the interaction effect of soil-tunnel interaction parameters on surface and subsurface settlement. Civ. Eng. J. (2022). https://doi.org/10.28991/CEJ-2022-08-11-05

Özdemir, E.: A new predictive model for uniaxial compressive strength of rock using machine learning method: artificial intelligence-based age-layered population structure genetic programming (ALPS-GP). Arab. J. Sci. Eng. 47, 629–639 (2022). https://doi.org/10.1007/s13369-021-05761-x

Gao, F.; Stead, D.; Coggan, J.: Evaluation of coal longwall caving characteristics using an innovative UDEC Trigon approach. Comput. Geotech. 55, 448–460 (2014). https://doi.org/10.1016/j.compgeo.2013.09.020

Ghabraie, B.; Ren, G.; Zhang, X.; Smith, J.: Physical modelling of subsidence from sequential extraction of partially overlapping longwall panels and study of substrata movement characteristics. Int. J. Coal Geol. 140, 71–83 (2015). https://doi.org/10.1016/j.coal.2015.01.004

Wang, H.; Shi, R.; Deng, D.; Jiang, Y.; Wang, G.; Gong, W.: Characteristic of stress evolution on fault surface and coal bursts mechanism during the extraction of longwall face in Yima mining area, China. J. Struct. Geol. 136, 104071 (2020). https://doi.org/10.1016/j.jsg.2020.104071

Ren, F.; Zhou, Y.; He, R.; Cao, J.; Zou, K.: Similarity model test on the spatiotemporal evolution law of deformation and failure of surrounding rock-induced caving in multi-mined-out areas. Adv. Civ. Eng. 2021, e1224658 (2021). https://doi.org/10.1155/2021/1224658

Cao, J.; Zhang, N.; Wang, S.; Qian, D.; Xie, Z.: Physical model test study on support of super pre-stressed anchor in the mining engineering. Eng. Fail. Anal. 118, 104833 (2020). https://doi.org/10.1016/j.engfailanal.2020.104833

Chi, X.; Yang, K.; Fu, Q.: Analysis of regenerated roof and instability support control countermeasures in a steeply dipping working face. Energy Explor. Exploit. 38, 1082–1098 (2020)

Sherizadeh, T.; Kulatilake, P.H.S.W.: Assessment of roof stability in a room and pillar coal mine in the U.S. using three-dimensional distinct element method. Tunn. Undergr. Space Technol. 59, 24–37 (2016). https://doi.org/10.1016/j.tust.2016.06.005

Wang, T.; Zhao, X.; Hu, W.; Chen, J.; Cheng, L.; Zhao, L.; Zheng, H.: Investigation of mine pressure and deformation due to phosphate ore body excavation based on Hoek-Brown model. J. Unconv. Oil Gas Resour. 15, 158–164 (2016). https://doi.org/10.1016/j.juogr.2016.08.001

Guo, Y.; Miao, Y.: Study on stope stability in continuous mining of long-dip, thin orebody by room-pillar method. Sustainability 14, 9601 (2022). https://doi.org/10.3390/su14159601

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (2022YFC2903801, 2022YFC2903804), and the National Natural Science Foundation of China (52374117, 52004054, 52274115), and the Fundamental Research Funds for the Central Universities (N2224002-27).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xiong, Z., Li, Y., Li, K. et al. Study on Overburden Stability Control by Expandable Pillar Support for Multi-stope Mining in a Gently Inclined Thin Orebody. Arab J Sci Eng 49, 4785–4802 (2024). https://doi.org/10.1007/s13369-023-08214-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-08214-9