Abstract

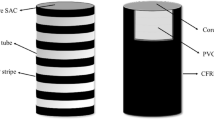

An eco-friendly self-compacting geopolymer concrete made of ground granulated blast furnace slag was used as a confinement material in glass fibre-reinforced polymer columns to test its efficiency relating to load carrying capacity toward axial compression and cyclic lateral loads. Steel reinforcements were incorporated to improve the mechanical performance of the proposed composite specimens. Two significant parameters of the GFRP tubular columns viz., diameter to thickness (D/t ratio) and fibre winding angles were varied to examine their effects through experiments on mechanical, ductility, and rigidity characteristics. Two variations of D/t ratio viz., 30 and 50 and three different variations of fibre orientations viz., 0°, 30°, and 45° were considered for parametric analysis. Irrespective of the parameters considered, all the columns showed a two-segmented axial load-deformation pattern with a gradual increase in load carrying capacity post-yielding stage upon axial compression and closed hysteresis loop upon lateral cyclic loading. Stepping up the D/t ratio from 30 to 50 mm retarded the axial load carrying capacity up to 20% and 50% of that of the lateral load carrying capacity, as well as increasing the ductility of the composite columns. 0° fibre orientation showed significant efficiency of 6.67–46.78% relating to axial and lateral load carrying capacity compared to other orientations. The effect of the difference in 30° and 45° orientations was almost negligible, i.e., less than 10% concerning axial and lateral loading characteristics.

Similar content being viewed by others

References

Rodrigues, F.A.; Joekes, I.: Cement industry: sustainability, challenges and perspectives. Environ. Chem. Lett. 9(2), 151–166 (2011). https://doi.org/10.1007/s10311-010-0302-2

Kajaste, R.; Hurme, M.: Cement industry greenhouse gas emissions–management options and abatement cost. J. Clean. Prod. 112, 4041–4052 (2016). https://doi.org/10.1016/j.jclepro.2015.07.055

Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L.: Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 1(11), 559–573 (2020). https://doi.org/10.1038/s43017-020-0093-3

Christy, C.F.; Tensing, D.: Effect of Class-F fly ash as partial replacement with cement and fine aggregate in mortar (2010). http://nopr.niscpr.res.in/handle/123456789/8614

Bilodeau, A.; Malhotra, V.M.: High-volume fly ash system: concrete solution for sustainable development. Mater. J. 97(1), 41–48 (2000)

Shubbar, A.A.; Al-Shaer, A.; AlKizwini, R.S.; Hashim, K.; Al Hawesah, H.; Sadique, M.: Investigating the influence of cement replacement by high volume of GGBS and PFA on the mechanical performance of cement mortar. In: IOP Conference Series: Materials Science and Engineering, vol. 584, No. 1, p. 012022. IOP Publishing (2019)

Xu, Z.; Gao, J.; Zhao, Y.; Li, S.; Guo, Z.; Luo, X.; Chen, G.: Promoting utilization rate of ground granulated blast furnace slag (GGBS): incorporation of nanosilica to improve the properties of blended cement containing high volume GGBS. J. Clean. Prod. 332, 130096 (2022). https://doi.org/10.1016/j.jclepro.2021.130096

Davidovits, J.: Geopolymers: inorganic polymeric new materials. J. Therm. Anal. Calorim. 37(8), 1633–1656 (1991). https://doi.org/10.1007/bf01912193

Azad, N.M.; Samarakoon, S.S.M.: Utilization of industrial by-products/waste to manufacture geopolymer cement/concrete. Sustainability 13(2), 873 (2021). https://doi.org/10.3390/su13020873

Almutairi, A.L.; Tayeh, B.A.; Adesina, A.; Isleem, H.F.; Zeyad, A.M.: Potential applications of geopolymer concrete in construction: a review. Case Stud. Constr. Mater. 15, e00733 (2021). https://doi.org/10.1016/j.cscm.2021.e00733

Rovnaník, P.: Effect of curing temperature on the development of hard structure of metakaolin-based geopolymer. Constr. Build. Mater. 24(7), 1176–1183 (2010). https://doi.org/10.1016/j.conbuildmat.2009.12.023

Albidah, A.S.: Effect of partial replacement of geopolymer binder materials on the fresh and mechanical properties: a review. Ceram. Int. 47(11), 14923–14943 (2021). https://doi.org/10.1016/j.ceramint.2021.02.127

Jawahar, J.G.; Mounika, G.: Strength properties of fly ash and GGBS based geopolymer concrete. Asian J. Civ. Eng. 17(1), 127–135 (2016)

El-Hassan, H.; Ismail, N.: Effect of process parameters on the performance of fly ash/GGBS blended geopolymer composites. J. Sustain. Cem. Based Mater. 7(2), 122–140 (2018). https://doi.org/10.1080/21650373.2017.1411296

Sathish Kumar, V.; Ganesan, N.; Indira, P.V.: Engineering properties of hybrid fibre reinforced ternary blend geopolymer concrete. J. Compos. Sci. 5(8), 203 (2021). https://doi.org/10.3390/jcs5080203

Sathish Kumar, V.; Ganesan, N.; Indira, P.V.: Effect of hybrid fibres on the durability characteristics of ternary blend geopolymer concrete. J. Compos. Sci. 5(10), 279 (2021). https://doi.org/10.3390/jcs5100279

Olutoge, F.A.; Quadri, H.A.; Olafusi, O.S.: Investigation of the strength properties of palm kernel shell ash concrete. Eng. Technol. Appl. Sci. Res. 2(6), 315–319 (2012). https://doi.org/10.48084/etasr.238

Bahurudeen, A.; Kanraj, D.; Dev, V.G.; Santhanam, M.: Performance evaluation of sugarcane bagasse ash blended cement in concrete. Cem. Concr. Compos. 59, 77–88 (2015). https://doi.org/10.1016/j.cemconcomp.2015.03.004

Singh, B.: Rice husk ash. In: Waste and Supplementary Cementitious Materials in Concrete, pp. 417–460. Woodhead Publishing (2018). https://doi.org/10.1016/B978-0-08-102156-9.00013-4

He, J.; Kawasaki, S.; Achal, V.: The utilization of agricultural waste as agro-cement in concrete: a review. Sustainability 12(17), 6971 (2020). https://doi.org/10.3390/su12176971

Bank, L.C.: Composites for Construction: Structural Design with FRP Materials. John Wiley & Sons (2006)

Hollaway, L.C.: A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr. Build. Mater. 24(12), 2419–2445 (2010). https://doi.org/10.1016/j.conbuildmat.2010.04.062

Campione, G.: Influence of FRP wrapping techniques on the compressive behavior of concrete prisms. Cem. Concr. Compos. 28(5), 497–505 (2006). https://doi.org/10.1016/j.cemconcomp.2006.01.002

Sasmal, S.; Ramanjaneyulu, K.; Novák, B.; Srinivas, V.; Kumar, K.S.; Korkowski, C.; Iyer, N.R.: Seismic retrofitting of nonductile beam-column sub-assemblage using FRP wrapping and steel plate jacketing. Constr. Build. Mater. 25(1), 175–182 (2011). https://doi.org/10.1016/j.conbuildmat.2010.06.041

Xiao, Y.: Applications of FRP composites in concrete columns. Adv. Struct. Eng. 7(4), 335–343 (2004). https://doi.org/10.1260/1369433041653552

Ye, Y.Y.; Zeng, J.J.; Li, P.L.: A state-of-the-art review of FRP-confined steel-reinforced concrete (FCSRC) structural members. Polymers 14(4), 677 (2022). https://doi.org/10.3390/polym14040677

Ozbakkaloglu, T.: Compressive behavior of concrete-filled FRP tube columns: assessment of critical column parameters. Eng. Struct. 51, 188–199 (2013). https://doi.org/10.1016/j.engstruct.2013.01.017

Zhu, Z.; Ahmad, I.; Mirmiran, A.: Seismic performance of concrete-filled FRP tube columns for bridge substructure. J. Bridg. Eng. 11(3), 359–370 (2006)

Pour, A.F.; Gholampour, A.; Zheng, J.; Ozbakkaloglu, T.: Behavior of FRP-confined high-strength concrete under eccentric compression: tests on concrete-filled FRP tube columns. Compos. Struct. 220, 261–272 (2019). https://doi.org/10.1016/j.compstruct.2019.03.031

Guo, Y.C.; Xiao, S.H.; Zeng, J.J.; Su, J.Y.; Li, T.Z.; Xie, Z.H.: Behavior of concrete-filled FRP tube columns internally reinforced with FRP-steel composite bars under axial compression. Constr. Build. Mater. 315, 125714 (2022). https://doi.org/10.1016/j.conbuildmat.2021.125714

Dong, Z.; Han, T.; Zhang, B.; Zhu, H.; Wu, G.; Wei, Y.; Zhang, P.: A review of the research and application progress of new types of concrete-filled FRP tubular members. Constr. Build. Mater. 312, 125353 (2021). https://doi.org/10.1016/j.conbuildmat.2021.125353

Fanggi, B.L.; Ozbakkaloglu, T.: Behavior of hollow and concrete-filled FRP-HSC and FRP-HSC-steel composite columns subjected to concentric compression. Adv. Struct. Eng. 18(5), 715–738 (2015). https://doi.org/10.1260/1369-4332.18.5.715

Cai, J.; Hao, H.; Ozbakkaloglu, T.; Zhang, Y.; Pan, J.: Behavior of geopolymeric recycled aggregate concrete-filled FRP tube (GRACFFT) columns under lateral cyclic loading. Eng. Struct. 222, 111047 (2020). https://doi.org/10.1016/j.engstruct.2020.111047

Mohamed, H.M.; Masmoudi, R.: Axial load capacity of concrete-filled FRP tube columns: experimental versus theoretical predictions. J. Compos. Constr. 14(2), 231–243 (2010). https://doi.org/10.1061/(ASCE)CC.1943-5614.0000066

Huang, L.; Zhang, S.S.; Yu, T.; Peng, K.D.: Circular hybrid double-skin tubular columns with a stiffener-reinforced steel inner tube and a large-rupture-strain FRP outer tube: compressive behavior. Thin-Walled Struct. 155, 106946 (2020). https://doi.org/10.1016/j.tws.2020.106946

Shan, B.; Liu, G.; Li, T.Y.; Liu, F.C.; Liu, Z.; Xiao, Y.: Experimental research on seismic behavior of concrete-filled reactive powder concrete tubular columns. Eng. Struct. 233, 111921 (2021). https://doi.org/10.1016/j.engstruct.2021.111921

Xue, B.; Gong, J.: Study on steel reinforced concrete-filled GFRP tubular column under compression. Thin-Walled Struct. 106, 1–8 (2016). https://doi.org/10.1016/j.tws.2016.04.023

Mohamed, H.M.; Masmoudi, R.: Deflection prediction of steel and FRP-reinforced concrete-filled FRP tube beams. J. Compos. Constr. 15(3), 462–472 (2011). https://doi.org/10.1061/(ASCE)CC.1943-5614.0000172

Wang, W.; Sheikh, M.N.; Hadi, M.N.: Experimental study on FRP tube reinforced concrete columns under different loading conditions. J. Compos. Constr. 20(5), 04016034 (2016). https://doi.org/10.1061/(ASCE)CC.1943-5614.0000690

Ren, F.M.; Liang, Y.W.; Chen, G.M.; Xie, P.; Xiong, M.X.; Wu, D.: FRP-confined steel-reinforced RAC short columns under eccentric compression: a parametric study and a new design calculation model. Compos. Struct. 291, 115597 (2022). https://doi.org/10.1016/j.compstruct.2022.115597

Zheng, J.; Ozbakkaloglu, T.: Sustainable FRP–recycled aggregate concrete–steel composite columns: behavior of circular and square columns under axial compression. Thin-Walled Struct. 120, 60–69 (2017). https://doi.org/10.1016/j.tws.2017.08.011

Retnam, B.; Sivapragash, M.; Pradeep, P.: Effects of fibre orientation on mechanical properties of hybrid bamboo/glass fibre polymer composites. Bull. Mater. Sci. 37(5), 1059–1064 (2014). https://doi.org/10.1007/s12034-014-0045-y

Ahmed, A.A.; Masmoudi, R.: Axial response of concrete-filled FRP tube (CFFT) columns with internal bars. J. Compos. Sci. 2(4), 57 (2018). https://doi.org/10.3390/jcs2040057

Inti, S.; Sharma, M.; Tandon, V.: Ground granulated blast furnace slag (GGBS) and rice husk ash (RHA) uses in the production of geopolymer concrete. In: Geo-Chicago, pp. 621–632 (2016). https://doi.org/10.1061/9780784480137.059

Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S.K.: Geopolymer concrete: a review of some recent developments. Constr. Build. Mater. 85, 78–90 (2015). https://doi.org/10.1016/j.conbuildmat.2015.03.036

ASTM D3039M-08. Standard Test Method for Tensile Properties of Polymer Matrix Composites Materials. West Conshohocken, PA. D3039M-08 (2008)

ASTM D 2290–12. Standard Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe. American Society for Testing and Materials. ASTM International, West Conshohocken, PA, 2006. www.astm.org. (2013)

IS: 16714:2018—Ground granulated blast furnace slag for use of cement, mortar and concrete specification—Bureau of Indian standards, New Delhi

IS: 383–2016. Coarse and Fine Aggregate for Concrete—Specification, Bureau of Indian Standards, New Delhi, India

Arularasi, V.; Thamilselvi, P.; Avudaiappan, S.; Saavedra Flores, E.I.; Amran, M.; Fediuk, R.; Karelina, M.: Rheological behavior and strength characteristics of cement paste and mortar with fly ash and GGBS admixtures. Sustainability 13(17), 9600 (2021). https://doi.org/10.3390/su13179600

EFNARC F. Specification and guidelines for self-compacting concrete. European federation of specialist construction chemicals and concrete system (2002)

Xu, L.; Pan, J.; Chen, J.: Mechanical behavior of ECC and ECC/RC composite columns under reversed cyclic loading. J. Mater. Civ. Eng. 29(9), 04017097 (2017). https://doi.org/10.1061/(ASCE)MT.1943-5533.0001950

Idris, Y.; Ozbakkaloglu, T.: Seismic behavior of high-strength concrete-filled FRP tube columns. J. Compos. Constr. 17(6), 04013013 (2013). https://doi.org/10.1061/(ASCE)CC.1943-5614.0000388

Shao, Y.; Aval, S.; Mirmiran, A.: Fiber-element model for cyclic analysis of concrete-filled fiber reinforced polymer tubes. J. Struct. Eng. 131(2), 292–303 (2005). https://doi.org/10.1061/(ASCE)0733-9445(2005)131:2(292)

Acknowledgements

The authors acknowledged the support by All India Council for Technical Education (AICTE) under Research Promotion Scheme; File No. 8232/RIFD/RPS (POLICY – 1) / 2018-19.

Funding

This work was supported by All India Council for Technical Education (AICTE) under Research Promotion Scheme; File No. 8232/RIFD/RPS (POLICY – 1)/2018–19.

Author information

Authors and Affiliations

Contributions

Conceptualization: VV; Methodology: GP; RJ; Investigation: VV; Writing—original draft preparation: VV; Writing—review and editing: GP, RJ; Funding acquisition: RJ; Resources: GP, RJ; Supervision: GP, RJ.

Corresponding author

Ethics declarations

Conflict of interest

Author Dr. Revathy Jayaseelan received financial support from All India Council for Technical Education (AICTE) under Research Promotion Scheme; File No. 8232/RIFD/RPS (POLICY – 1) / 2018–19.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Veerapandian, V., Pandulu, G. & Jayaseelan, R. Behavior of FRP-Confined Columns with Eco-friendly Concrete Under Combined Axial and Lateral Loading. Arab J Sci Eng 49, 4495–4512 (2024). https://doi.org/10.1007/s13369-023-08146-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-08146-4