Abstract

The pursuit of an effective exit hole closure method for preparing high-quality welds has gained significant attention in the research community, driven by the potential of friction stir welding in space and aircraft manufacturing. Many techniques have been developed for avoiding the defect, but no effective solution has yet been observed. In this study, the potential of induction heating was investigated as an alternative method to repair exit holes. The present work aims to find an optimal set of induction heating parameters to effectively fuse a billet of similar volume to an exit hole. A numerical investigation was conducted by developing a two-dimensional (2D) axis-symmetric coupled electromagnetic-thermal model to analyze the effect of induction heating process parameters on the thermal behavior of AA1100 aluminum alloy. Process parameters such as coil geometry, stand-off distance, current and excitation frequency were varied, and the optimal parameters were identified based on temperature distribution, heating rate, thermal stress and phase change in the material. A pancake coil geometry, stand-off distance of 2 mm, current density of 1000 A and frequency of 100 kHz were the optimal set of parameters chosen from the numerical analysis for the effective repair of exit hole. A preliminary experimental investigation was conducted by employing the chosen process parameters and a powder-flux mixture in place of the billet. The observations reveal the possibility of achieving a sound joint under solid-state sintering condition. The use of fine powder-flux mixture at high temperatures facilitated solid-state diffusion resulting in a defect-free interface. The proposed system can be an alternative to the existing processes used for repair with an advantage to act as an in situ repair technique without compromising the original weld properties in the vicinity of the defect. The findings of this study have significant implications for space and aircraft manufacturing, where the use of friction stir welding is prevalent and exit hole defects are a challenge.

Similar content being viewed by others

Abbreviations

- \({J}_{\mathrm{e}}\) :

-

Induced eddy current density, Am−2

- \({\varepsilon }_{0}\) :

-

Permittivity of free space, C2 N−1 m−2

- \({\varepsilon }_{r}\) :

-

Relative electric permittivity

- \({\mu }_{0}\) :

-

Permeability of free space, T m A−1

- \({\mu }_{r}\) :

-

Relative magnetic permeability

- \(\varepsilon\) :

-

Electric permittivity, C2 N−1 m−2

- \(\mu\) :

-

Magnetic permeability, T m A−1

- \(\rho\) :

-

Resistivity of object, Ω m

- \(\sigma\) :

-

Coefficient of electrical conductivity, S m−1

- A :

-

Magnetic vector potential, Wb m−1

- B :

-

Magnetic flux density, T

- C p :

-

Heat capacity, Jkg−1 k−1

- D :

-

Electric flux density, C m−2

- E :

-

Electric flux intensity, N C−1

- H :

-

Magnetic field intensity, A m−1

- J :

-

Current density, A m−2

- k :

-

Thermal conductivity, W m−1 K−1

- L :

-

Latent heat, KJ Kg−1

- n :

-

Normal direction

- Q :

-

Heat produced by eddy currents, Wm−3

- T :

-

Temperature, K

- t :

-

Time, s

- T amb :

-

Ambient temperature, K

References

Givi, M.K.B.; Asadi, P.: Advances in Friction Stir Welding and Processing, 1st edn. Woodhead Publishing, UK (2014)

Park, S.; Nam, H.; Park, J., et al.: Superior-tensile property of CoCrFeMnNi alloys achieved using friction-stir welding for cryogenic applications. Mater. Sci. Eng. A 788, 1–10 (2020). https://doi.org/10.1016/j.msea.2020.139547

Thomas, W.M., Nicholas, E.D., Needham, J.C., Murch, M.G., Templesmith, P., Dawes, C.J.: Friction stir butt welding, (1991)

Mishra, R.S.; De, P.S.; Kumar, N.: Friction Stir Welding and Processing: Science and Engineering, 1st edn. Springer International Publishing, Switzerland (2014)

Ramon, J.; Basu, R.; Vander, V.G.; Bolar, G.: A comprehensive study on solidification (hot) cracking in austenitic stainless steel welds from a microstructural approach. Int. J. Press. Vessel Pip. 194, 1–18 (2021). https://doi.org/10.1016/J.IJPVP.2021.104560

Singh, V.P.; Patel, S.K.; Ranjan, A.; Kuriachen, B.: Recent research progress in solid state friction-stir welding of aluminium–magnesium alloys: a critical review. J. Mater. Res. Technol. 9, 6217–6256 (2020). https://doi.org/10.1016/j.jmrt.2020.01.008

Kah, P.; Rajan, R.; Martikainen, J.; Suoranta, R.: Investigation of weld defects in friction-stir welding and fusion welding of aluminium alloys. Int. J. Mech. Mater. Eng. 10, 26 (2015). https://doi.org/10.1186/s40712-015-0053-8

Huang, Y.X.; Han, B.; Tian, Y., et al.: New technique of filling friction stir welding. Sci. Technol. Weld. Join. 16, 497–501 (2011). https://doi.org/10.1179/1362171811Y.0000000032

Vilaça, P.; Mendes, J.; Nascimento, F.; Quintino, L.: Application of FSW to join aluminium foil winding coils for electrical transformers. Int. J. Mech. Syst. Eng. (2016). https://doi.org/10.15344/2455-7412/2016/115

Chen, G.; Wang, G.; Shi, Q., et al.: Three-dimensional thermal-mechanical analysis of retractable pin tool friction stir welding process. J. Manuf. Process. 41, 1–9 (2019). https://doi.org/10.1016/j.jmapro.2019.03.022

Han, B.; Huang, Y.; Lv, S., et al.: AA7075 bit for repairing AA2219 keyhole by filling friction stir welding. Mater. Des. 51, 25–33 (2013). https://doi.org/10.1016/j.matdes.2013.03.089

Zhou, L.; Liu, D.; Nakata, K., et al.: New technique of self-refilling friction stir welding to repair keyhole. Sci. Technol. Weld. Join. 17, 649–655 (2012). https://doi.org/10.1179/1362171812Y.0000000058

Zhang, G.F.; Jiao, W.M.; Zhang, J.X.: Filling friction stir weld keyhole using pin free tool and T shaped filler bit. Sci. Technol. Weld. Join. 19, 98–104 (2014). https://doi.org/10.1179/1362171813Y.0000000161

Ji, S.; Meng, X.; Zeng, Y., et al.: New technique for eliminating keyhole by active-passive filling friction stir repairing. Mater. Des. 97, 175–182 (2016). https://doi.org/10.1016/j.matdes.2016.02.088

Vijendra, B.; Sharma, A.: Induction heated tool assisted friction-stir welding (i-FSW): a novel hybrid process for joining of thermoplastics. J. Manuf. Process. 20, 234–244 (2015). https://doi.org/10.1016/j.jmapro.2015.07.005

Kaushik, P.; Kumar Dwivedi, D.: Induction preheating in FSW of Al-Steel combination. Mater. Today. Proc. (2021). https://doi.org/10.1016/j.matpr.2021.01.438

Tran-Ngoc, H.; Khatir, S.; Le-Xuan, T., et al.: Finite element model updating of a multispan bridge with a hybrid metaheuristic search algorithm using experimental data from wireless triaxial sensors. Eng. Comput. 38, 1865–1883 (2022). https://doi.org/10.1007/s00366-021-01307-9

Ling, Y.; Ni, J.; Antonissen, J., et al.: Numerical prediction of microstructure and hardness for low carbon steel wire arc additive manufacturing components. Simul. Model. Pract. Theor. 122, 102664 (2023). https://doi.org/10.1016/j.simpat.2022.102664

Lucia, O.; Maussion, P.; Dede, E.J.; Burdio, J.M.: Induction heating technology and its applications: Past developments, current technology, and future challenges. IEEE Trans. Ind. Electron. 61, 2509–2520 (2014). https://doi.org/10.1109/TIE.2013.2281162

Rudnev, V.; Loveless, D.; Cook, R.L.: Handbook of Induction Heating, 2nd edn. CRC Press, New York, USA (2017)

Jin, J.-M.: Theory and Computation of Electromagnetic Fields. Wiley, New Jersey (2010)

Heat transfer module. In: COMSOL. https://www.comsol.com/heat-transfer-module. Accessed 11 Sept 2021

Martín, V.; Vázquez, J.; Navarro, C.; Domínguez, J.: Effect of shot peening residual stresses and surface roughness on fretting fatigue strength of Al 7075–T651. Tribol. Int. 142, 106004 (2020). https://doi.org/10.1016/j.triboint.2019.106004

Vu-Huu, T.; Le-Thanh, C.; Nguyen-Xuan, H.; Abdel-Wahab, M.: Polygonal finite element for two-dimensional lid-driven cavity flow. Comput. Mater. Contin. 70(3), 4217–4239 (2022)

Vu-Huu, T.; Phung-Van, P.; Nguyen-Xuan, H.; Abdel Wahab, M.: A polytree-based adaptive polygonal finite element method for topology optimization of fluid-submerged breakwater interaction. Comput. Math. Appl. 76, 1198–1218 (2018). https://doi.org/10.1016/j.camwa.2018.06.008

Shen, H.; Yao, Z.Q.; Shi, Y.J.: Study on temperature field induced in high frequency induction heating. Acta Metall. Sin. 19, 190–196 (2006). https://doi.org/10.1016/S1006-7191(06)60043-4

Kranjc, M.; Zupanic, A.; Miklavcic, D.; Jarm, T.: Numerical analysis and thermographic investigation of induction heating. Int. J. Heat Mass Transf. 53, 3585–3591 (2010). https://doi.org/10.1016/j.ijheatmasstransfer.2010.04.030

Lu, L.; Zhang, S.; Xu, J., et al.: Numerical study of titanium melting by high frequency inductive heating. Int. J. Heat Mass Transf. 108, 2021–2028 (2017). https://doi.org/10.1016/j.ijheatmasstransfer.2017.01.062

Zhu, Y.; Luo, Y.: A simplified heat source model for thick plate bending via high-frequency induction line heating. Ships Offshore Struct. 14, 64–73 (2018). https://doi.org/10.1080/17445302.2018.1475883

Nunes, R.: Properties and selection: nonferrous alloys and special-purpose materials. ASM International, (1990)

Xian-Liang, L.; He, M.; Xiao-Wei, Z., et al.: Analysis of Heat insulation for coil in the electromagnetic induction controlled automated steel-teeming system. Metals 9, 1–12 (2019). https://doi.org/10.3390/met9040434

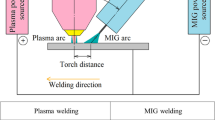

Ikram, A.; Arif, N.; Chung, H.: Design of an induction system for induction assisted alternating current gas metal arc welding. J. Mater. Process. Technol. 231, 162–170 (2016). https://doi.org/10.1016/j.jmatprotec.2015.12.015

Li, Y.; Li, H.; Katgerman, L., et al.: Recent advances in hot tearing during casting of aluminium alloys. Prog. Mater. Sci. 117, 77 (2021). https://doi.org/10.1016/J.PMATSCI.2020.100741

Acknowledgements

The authors would like to acknowledge Department of Science and Technology and Science and Engineering Research Board, Government of India for supporting the research work in terms of financial assistance vide DST-SERB project SRG/2020/000293. The authors also acknowledge the Advanced Joining Laboratory, Department of Mechanical Engineering, National Institute of Technology Silchar, Silchar—788010, Assam, India, for providing the necessary facilities to carry out the research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ramon, J., Pal, M. & Das, B. Investigation of Induction Heating Process for Selective Melting of Aluminum Alloy for the Repair of Exit Hole Defect in Friction Stir Welding Process. Arab J Sci Eng 48, 12291–12311 (2023). https://doi.org/10.1007/s13369-023-07725-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-07725-9