Abstract

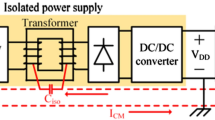

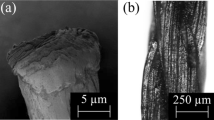

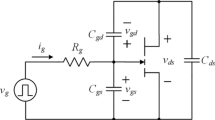

Higher switching frequencies and faster switching speeds in power electronics were realized as a result of using wide bandgap (SiC, GaN) devices. Although having higher dV/dt can be beneficial in power electronics application, insulation reliability of inductors can be affected due to the inductor’s parasitic capacitances’ influence. Parasitic capacitances can change the inductor’s impedance drastically at high switching frequencies. Higher dV/dt across an inductor can cause higher voltage stress and less uniform voltage distribution across its turns. Thus, inductor winding insulation can be at risk in medium or high voltage applications under high dV/dt. A convenient solution is to add filters in the circuit to slow down the switching (reduce the dV/dt) which means some advantages of using wide bandgap devices will be lost. Hence, the approach of utilizing additive manufacturing to fabricate the inductor winding and optimize the parasitics is introduced instead of slowing down the switching. In this approach, the voltage stress is distributed more evenly across the inductor’s winding which reduces the maximum voltage stress across some turns. A 20 kV inductor is developed to showcase the proposed approach. Experimental results show that the peak voltage stress between inductor turns has reduced by over 10\(\%\). Furthermore, the maximum voltage stress difference between inductor turns has reduced 67\(\%\).

Similar content being viewed by others

References

Millan, J.; Godignon, P.; Perpina, X.; Perez-Tomas, A.; Rebollo, J.: A survey of wide bandgap power semiconductor devices. IEEE Trans. Power Electron. 29(5), 2155–2163 (2013)

Alves, L.F.; Gomes, R.C.; Lefranc, P.; Pegado, R.; Jeannin, P.-O., Luciano, B.A., Rocha, F.V.: Sic power devices in power electronics: an overview. In: Brazilian Power Electronics Conference (COBEP). IEEE 2017, pp. 1–8 (2017)

Chen, S.; Liu, A.; He, J.; Bai, S.; Sheng, K.: Design and application of high-voltage sic jfet and its power modules. IEEE J. Emerg. Sel. Top. Power Electron. 4(3), 780–789 (2016)

Attia, Y.; Abdelrahman, A.; Hamouda, M.; Youssef, M.: Sic devices performance overview in ev dc, dc converter: a case study in a nissan leaf. In: IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific). IEEE 2016, pp. 214–219 (2016)

Chen, J.; Du, X.; Luo, Q.; Zhang, X.; Sun, P.; Zhou, L.: A review of switching oscillations of wide bandgap semiconductor devices. IEEE Trans. Power Electron. 35(12), 13182–13199 (2020)

Zhu, S.; Yuan, X.; Mellor, P.: Modelling of high frequency effects of laminated iron-core power inductors and reduction of parasitic capacitance. In: IECON 2017-43rd Annual Conference of the IEEE Industrial Electronics Society. IEEE, pp. 1299–1306 (2017)

Zhang, X.; Li, H.; Brothers, J.A.; Fu, L.; Perales, M.; Wu, J.; Wang, J.: A gate drive with power over fiber-based isolated power supply and comprehensive protection functions for 15-kv sic mosfet. IEEE J. Emerg. Sel. Top. Power Electron. 4(3), 946–955 (2016)

Masdi, H.; Mariun, N.; Mohamed, A.; Wahab, N.I.A.: Study of impulse voltage distribution in transformer windings. In: 2010 IEEE International Conference on Power and Energy. IEEE, 2010, pp. 379–383.

Cremasco, A.; Rothmund, D.; Curti, M.; Lomonova, E.A.: Voltage distribution in the windings of medium-frequency transformers operated with wide bandgap devices. IEEE J. Emerg. Sel. Top. Power Electron. (2021)

Zhao, H.; Shen, Z.; Dalal, D.N.; Jørgensen, A.B.; Wang, X.; Munk-Nielsen, S.; Uhrenfeldt, C.: Parasitic capacitance modeling of inductors without using the floating voltage potential of core. IEEE Trans. Ind. Electron. 69(3), 3214–3222 (2021)

Zhao, H.; Luan, S.; Shen, Z.; Hanson, A.J.; Gao, Y.; Dalal, D.N.; Wang, R.; Zhou, S.; Munk-Nielsen, S.: Rethinking basic assumptions for modeling parasitic capacitance in inductors. IEEE Trans. Power Electron. 37(7), 8281–8289 (2021)

Krings, A.; Paulsson, G.; Sahlen, F.; Holmgren, B.: Experimental investigation of the voltage distribution in form wound windings of large ac machines due to fast transients. In: 2016 XXII International Conference on Electrical Machines (ICEM). IEEE, 2016, pp. 1700–1706.

He, J.; Chen, H.; Katebi, R.; Weise, N.; Demerdash, N.A.: Mitigation of uneven surge voltage stress on stator windings of induction motors fed by sic-mosfet-based adjustable speed drives. In: IEEE International Electric Machines and Drives Conference (IEMDC). IEEE 2017, pp. 1–7 (2017)

Ju, X.; Cheng, Y.; Yang, M.; Cui, S.; Sun, A.; Liu, X.; He, M.: Voltage stress calculation and measurement for hairpin winding of ev traction machines driven by sic mosfet. IEEE Trans. Ind. Electron. (2021)

Li, X.; Pan, J.; Ke, Z.; Liu, R.; Fan, J.; Zhang, Y.; Hu, B.; Na, R.; Xu, L.; Wang, J.: Optimized dv, dt filter design for sic based modular multilevel converters. In: IEEE Energy Conversion Congress and Exposition (ECCE). IEEE 2020, pp. 2166–2173 (2020)

Zhao, S.; Zhao, X.; Dearien, A.; Wu, Y.; Zhao, Y.; Mantooth, H.A.: An intelligent versatile model-based trajectory-optimized active gate driver for silicon carbide devices. IEEE J. Emerg. Sel. Top. Power Electron. 8(1), 429–441 (2019)

Wang, N.; Cotton, I.; Robertson, J.; Follmann, S.; Evans, K.; Newcombe, D.: Partial discharge control in a power electronic module using high permittivity non-linear dielectrics. IEEE Trans. Dielectr. Electr. Insul. 17(4), 1319–1326 (2010)

Zhang, Z.; Yuan, X.: Applications and future of automated and additive manufacturing for power electronics components and converters. IEEE J. Emerg. Sel. Top. Power Electron. (2021)

Yan, Y.; Ngo, K.D.; Mei, Y.; Lu, G.-Q.: Additive manufacturing of magnetic components for power electronics integration. In: 2016 International Conference on Electronics Packaging (ICEP). IEEE, 2016, pp. 368–371.

Liang, W.; Raymond, L.; Rivas, J.: 3-d-printed air-core inductors for high-frequency power converters. IEEE Trans. Power Electron. 31(1), 52–64 (2015)

Wienhausen, A.H.; Sewergin, A.; Engel, S.P.; De Doncker, R.W.: Highly efficient power inductors for high-frequency wide-bandgap power converters. In: 2017 IEEE 12th International Conference on Power Electronics and Drive Systems (PEDS). IEEE, 2017, pp. 442–447

de Freitas Gutierres, L.F.; Cardoso, G.: Analytical technique for evaluating stray capacitances in multiconductor systems: single-layer air- core inductors. IEEE Trans. Power Electron. 33(7), 6147–6158 (2017)

Tichý, T.; Šefl, O.; Veselý, P.; Cápal, T.: Application possibilities of fused filament fabrication technology for high-voltage and medium- voltage insulation systems. In: 42nd International Spring Seminar on Electronics Technology (ISSE). IEEE 2019, pp. 1–6 (2019)

Li, X.-R.; Guo, J.; Wen-Dong, L.; Zhang, L.-Y.; Wang, C.; Guo, B.-H.; Zhang, G.-J.: Analysis of morphology and electrical insulation of 3d printing parts. In: 2018 IEEE International Conference on High Voltage Engineering and Application (ICHVE). IEEE, 2018, pp. 1–4

Veselý, P.; Horynová, E.; Tichý, T.; Šefl, O.: Study of electrical properties of 3d printed objects. POSTER 2018, 1–4 (2018)

Veselý, P.; Tichý, T.; Šefl, O.; Horynová, E.: Evaluation of dielectric properties of 3d printed objects based on printing resolution. In: IOP Conference Series: Materials Science and Engineering, vol. 461, no. 1. IOP Publishing, 2018, p. 012091

Flowers, P.F.; Reyes, C.; Ye, S.; Kim, M.J.; Wiley, B.J.: 3d printing electronic components and circuits with conductive thermoplastic filament. Addit. Manuf. 18, 156–163 (2017)

Acknowledgements

This work was supported by the Researchers Supporting Project number (RSPD2023R646), King Saud University, Riyadh, Saudi Arabia.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alsaif, F., Wang, J. Effect of High dV/dt on Voltage Stress Across Inductor Turns and Utilization of Additive Manufacturing for Mitigation. Arab J Sci Eng 48, 14439–14447 (2023). https://doi.org/10.1007/s13369-023-07703-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-07703-1