Abstract

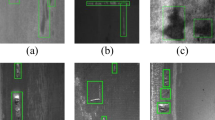

Timely defect detection plays a positive role in preventing the evaluation of steel derivative damage. As a state-of-the-art image recognition technology, pixel-level segmentation technology can obtain the pixel distribution and generate the shape of the objects accurately, which provides a potential detection method for steel surface defects. Therefore, this paper employed the well-known pixel-level segmentation CNN (DeepLab_v3+) to detect three defect categories (inclusions, patches and scratches) on the steel surface, and the ‘regionprops’ function was used to quantify the defect features (length, average width, maximum width, area and ratio). The results show that ResNet50, as the backbone network of DeepLab_v3+, has the highest detection precision for steel surface defects, and its accuracy is more competitive than that of other algorithms (FCN, SegNet, U-Net and PAG-Net). The proposed quantitative method also achieved encouraging results (the average relative error (ARE) of the evaluation indicator, 10%, 18%, 17%, 23% and 23%, respectively), and the precision was higher than that of the other methods. This demonstrated that the proposed method can greatly benefit steel surface defect detection and evaluation of defect levels.

Similar content being viewed by others

References

Luo, Q.; Fang, X.; Liu, L.; Yang, C.; Sun, Y.: Automated visual defect detection for flat steel surface: a survey. IEEE Trans. Instrum. Meas. 69, 626–644 (2020)

Dong, H.; Song, K.; He, Y.; Xu, J.; Meng, Q.: PGA-Net: pyramid feature fusion and global context attention network for automated surface defect detection. IEEE Trans. Ind. Inform. 16, 7448–7458 (2019)

Wang, J.; Li, Q.; Gan, J.; Yu, H.; Yang, X.: Surface defect detection via entity sparsity pursuit with intrinsic priors. IEEE Trans. Ind. Inform. 16, 141–150 (2020)

Shi, T.; Kong, J.; Wang, X.; Liu, Z.; Zheng, G.: Improved Sobel algorithm for defect detection of rail surfaces with enhanced efficiency and accuracy. J. Cent. South Univ. 23, 2867–2875 (2016)

Choi, J.; Kim, C: Unsupervised detection of surface defects: a two-step approach. In: IEEE International Conference on Image Processing, Orlando, FL, USA, pp. 1037–1040 (2012)

Xing, Z.; Jia, H.: Multilevel color image segmentation based on GLCM and improved salp swarm algorithm. IEEE Access 7, 37672–37690 (2019)

Luo, Q.; Fang, X.; Sun, Y.; Liu, L.; Ai, J.; Yang, C.; Simpson, O.: Surface defect classification for hot-rolled steel strips by selectively dominant local binary patterns. IEEE Access 7, 23488–23499 (2019)

Yong-Hao, A.I.; Ke, X.U.: Surface detection of continuous casting slabs based on curvelet transform and kernel locality preserving projections. J. Iron Steel Res. Int. 20, 80–86 (2013)

Kim, J.; Um, S.; Min, D.: Fast 2-D complex Gabor filter with kernel decomposition. IEEE Trans. Image Process. 27, 1731–1822 (2018)

Liu, W.; Yan, Y.: Automated surface defect detection for cold-rolled steel strip based on wavelet anisotropic diffusion method. Int. J. Ind. Syst. Eng. IJISE 17, 224–239 (2014)

Ke, X.U.: Application of hidden Markov tree model to on-line detection of surface defects for steel strips. J. Mech. Eng. 49, 34 (2013)

Liu, K.; Wang, H.; Chen, H.; Qu, E.; Ying, T.; Sun, H.: Steel surface defect detection using a new Haar–Weibull-variance model in unsupervised manner. IEEE Trans. Instrum. Meas. 66, 2585–2596 (2017)

Choi, D.C.; Jeon, Y.J.; Lee, S.J.; Yun, J.P.; Kim, S.W.: Algorithm for detecting seam cracks in steel plates using a Gabor filter combination method. Appl. Opt. 53, 4865–4872 (2014)

Ashour, M.W.; Khalid, F.; Halin, A.A.; Abdullah, L.N.; Darwish, S.H.: Surface defects classification of hot-rolled steel strips using multi-directional shearlet features. Arab. J. Sci. Eng. 44, 2925–2932 (2019)

Ghorai, S.; Mukherjee, A.; Gangadaran, M.; Dutta, P.K.: Automatic defect detection on hot-rolled flat steel products. IEEE Trans. Instrum. Meas. 62, 612–621 (2013)

Kang, G.W.; Liu, H.B.: Surface defects inspection of cold rolled strips based on neural network. In: Machine Learning and Cybernetics, 2005. Proceedings of 2005 International Conference on, Guangzhou, China, pp. 5034–5037 (2005)

Zhao, X.Y.; Lai, K.S.; Dai, D.M.: An improved BP algorithm and its application in classification of surface defects of steel plate. J. Iron Steel Res. Int. 14, 52–55 (2007)

Luo, Q.; Fang, X.; Su, J.; Zhou, J.; Zhou, B.; Yang, C.; Liu, L.; Gui, W.; Tian, L.: Automated visual defect classification for flat steel surface: a survey. IEEE Trans. Instrum. Meas. 69, 9329–9349 (2020)

Song, K.; Dong, H.; Yan, Y.: Semi-supervised defect classification of steel surface based on multi-training and generative adversarial network. Opt. Lasers Eng. 122, 294–302 (2019)

Masci, J.; Meier, U.; Fricout, G.; Schmidhuber, J.: Multi-scale pyramidal pooling network for generic steel defect classification. In: The 2013 International Joint Conference on Neural Networks (IJCNN), Dallas, TX, USA, pp. 1–8 (2013)

Cha, Y.J.; Choi, W.; Suh, G.; Mahmoudkhani, S.; Büyükztürk, O.: Autonomous structural visual inspection using region-based deep learning for detecting multiple damage types. Comput. Aided Civ. Infrastruct. Eng. 33, 1–17 (2018)

Li, J.; Su, Z.; Geng, J.; Yin, Y.: Real-time detection of steel strip surface defects based on improved YOLO detection network. IFAC-PapersOnLine 51, 76–81 (2018)

Long, J.; Shelhamer, E.; Darrell, T.: Fully convolutional networks for semantic segmentation. IEEE Trans. Pattern Anal. Mach. Intell. 39, 640–651 (2015)

Yang, F.; Zhang, L.; Yu, S.; Prokhorov, D.; Mei, X.; Ling, H.: Feature pyramid and hierarchical boosting network for pavement crack detection. IEEE Trans. Intell. Transp. Syst. 3, 1525–1535 (2019)

Ren, R.; Hung, T.; TanKay, C.: A generic deep-learning-based approach for automated surface inspection. IEEE Trans. Cybern. 48, 929–940 (2018)

Li, X.; Du, Z.; Huang, Y.; Tan, Z.: A deep translation (GAN) based change detection network for optical and SAR remote sensing images. ISPRS J. Photogramm. Remote Sens. 179, 14–34 (2021)

Liu, K.; Li, A.; Wen, X.; Chen, H.; Yang, P: Steel surface defect detection using GAN and one-class classifier. In: 2019 25th International Conference on Automation and Computing (ICAC) (2019)

Chen, L.C.; Zhu, Y.; Papandreou, G.; Schroff, F.; Adam, H: Encoder–decoder with atrous separable convolution for semantic image segmentation. In: Computer Vision—ECCV, vol. 11211, pp. 833–851 (2018)

Ji, A.; Xue, X.; Wang, Y.; Luo, X.; Xue, W.: An integrated approach to automatic pixel-level crack detection and quantification of asphalt pavement. Autom. Constr. 114, 103176 (2020)

Dais, D.; Bal, İE.; Smyrou, E.; Sarhosis, V.: Automatic crack classification and segmentation on masonry surfaces using convolutional neural networks and transfer learning. Autom. Constr. 125, 103606 (2021)

Song, G.; Song, K.; Yan, Y.: EDRNet: encoder–decoder residual network for salient object detection of strip steel surface defects. IEEE Trans. Instrum. Meas. 69, 9709–9719 (2020)

Acknowledgements

This research was supported by the project (No. 52208309) of the National Natural Science Foundation of China.

Author information

Authors and Affiliations

Contributions

Conceptualization, ST; Data curation, XL and ZL; Formal analysis, JL; Funding acquisition, JL; Investigation, ST and XL; Methodology, ST and ZL; Project administration, ST; Software, ST; Writing – original draft, ST; Writing – review & editing, ZL.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Z., Zeng, Z., Li, J. et al. Automatic Detection and Quantification of Hot-Rolled Steel Surface Defects Using Deep Learning. Arab J Sci Eng 48, 10213–10225 (2023). https://doi.org/10.1007/s13369-022-07567-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07567-x