Abstract

A magnetorheological (MR) damper is effective and economical for miscellaneous applications in automotive, mechanical, civil, and relative fields. A parameter tuning methodology independent of manual trial-and-error has received much technical interest for controlling vibrations. The present work contributes mathematical and Simulink modeling followed by MR damper design and development for vibration optimization of the single degree of freedom system. A Simulink model of an MR damper is performed on the mathematical model for vibration control, and the MR damper’s tuning parameters are experimentally investigated to control the resonance frequency. Theoretical simulated results and its experimental verification show that increasing current raises the force to control the resonance frequency in an MR damper. The present approach provides a concise and improved platform for dynamic vibration absorber in the current potential market and the highly interested control community for the development of the distinctive attributes of the MR Damper.

Similar content being viewed by others

Abbreviations

- A :

-

Parameter to determine the hysteresis loop in the Bouc–Wen model (dimensionless)

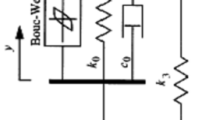

- c 0 :

-

Viscous damping at large velocities, Ns/m

- c 1 :

-

Dashpot used to introduce the nonlinear roll-off observed at low velocities, Ns/m

- c 2 :

-

Damper of the secondary system, Ns/m

- C 0b :

-

Constant that determines Co, Ns/m

- C 1a :

-

Constant that determines C1, Ns/m

- C 1b :

-

Constant that determines C1b, Ns/mV

- F :

-

Frequency of external force, Hz

- f d :

-

Force of damper, N

- \({F}_{o}\) :

-

Amplitude of exciting force due to eccentricity, N

- e :

-

Radial eccentricity of its cam, m

- K o :

-

Preload stiffness, N/m

- K 1 :

-

Primary (supporting) system stiffness, N/m

- K 2 :

-

Secondary (absorber) system stiffness, N/m

- K 3 :

-

Accumulator stiffness, N/m

- m :

-

Mass of eccentricity, kg

- m 1 :

-

Primary mass, kg

- m 2 :

-

Secondary (absorber) mass, kg

- z, \(\dot{z}\) :

-

Variable to depict the history dependence of applied response, Hz

- X :

-

Displacement of the damper piston, m

- \(\dot{y}\) :

-

Velocity of the damper piston, m/s

- N :

-

Wen model (dimensionless)

- x 0 :

-

Initial displacement of spring k1 associated with nominal damper force to accumulator, m

- x 1, x 2 :

-

Displacement of m1 and m2, m

- \({\ddot{x}}_{1},{\ddot{x}}_{2}\) :

-

Acceleration of m1 and m2, m/s2

- Α :

-

Scaling value for Bouc–Wen model, N/m

- α a :

-

Constant that determines α, N/m

- α b :

-

Constant that determines α, N/mV

- γ μ :

-

Parameter that determines the hysteresis loop in the Bouc–Wen model, m−2

- \({\mu }^{{\prime}}\) :

-

Mass ratio (dimensionless)

- \(\dot{u}\) :

-

Constant to govern the first-order filter, s−1

- t :

-

Time, s

- \(\omega\) :

-

Frequency of rotation, rpm

- η :

-

Constant to govern the first-order filter, s−1

- SDOF:

-

Single degree of freedom system

- DVA:

-

Dynamic vibration absorber

- MRDVA:

-

Magnetorheological dynamic vibration absorber

- TVS:

-

Transient voltage suppression

References

Seong, M.S.; Choi, S.B.; Sung, K.G.: Control strategies for vehicle suspension system featuring magnetorheological (MR) damper. Vib. Anal. Control New Trends Dev. (2011). https://doi.org/10.5772/24556

Choi, S.B.; Li, W.; Yu, M.; Du, H.; Fu, J.; Do, P.X.: State of the art of control schemes for smart systems featuring magnetorheological materials. Fac. Eng. Inf. Sci. Pap. Part A 25(4), 1–67 (2016)

Du, H.; Lam, J.; Cheung, K.C.; Li, W.; Zhang, N.: Direct voltage control of magnetorheological damper for vehicle suspensions. Smart Mater. Struct. (2013). https://doi.org/10.1088/0964-1726/22/10/105016

Ahamed, R.; Ferdaus, M.M.; Li, Y.: Advancement in energy harvesting magnetorheological fluid damper: a review. Korea Aust. Rheol. J. 28(4), 355–379 (2016)

Kunadharaju, R.R.; Varma, V.: Vibration control of structures and structural components with magnetorheological fluids. Curr. Sci. 112(3), 499–508 (2017)

Daniel, C.; Hemalatha, G.; Sarala, L.; Tensing, D.; Sundar Manoharan, S.: Seismic mitigation of building frames using magnetorheological damper. Int. J. Eng. Trans. B Appl. 32(11), 1543–1547 (2019)

Naserimojarad, M.M.; Moallem, M.: A comprehensive approach for optimal design of magnetorheological dampers. J. Intell. Mater. Syst. Struct. 29, 3648–3655 (2018)

Desai, R.M.; Jamadar, M.E.H.; Kumar, H.; Joladarashi, S.; Raja Sekaran, S.C.: Design and experimental characterization of a twin-tube MR damper for a passenger van. J. Braz. Soc. Mech. Sci. Eng. 41(8), 1–21 (2019)

Kumbhar, M.B.; Salunkhe, V.G.; Borgaonkar, A.V.; Jagadeesha, T.: Mathematical modelling and experimental evaluation of an air spring-air damper dynamic vibration absorber. J. Vib. Eng. Technol. 9, 781–789 (2021). https://doi.org/10.1007/s42417-020-00263-w

Sun, S.; Tang, X.; Li, W.; Du, H.; et al.: Advanced vehicle and suspension with variable stiffness and damping MR Damper. IIEE, pp. 444–448 (2017)

Jamadar, M.; Desai, R.M.; Kumar, H.; Joladarashi, S.: Analyzing quarter car model with magneto-rheological (MR) damper using equivalent damping and Magic formula models. Mater. Today Proc. 46, 9944–9949 (2021)

El-Sinawi, A.H.; Alhamaydeh, M.H.; Jhemi, A.A.: Optimal control of magnetorheological fluid dampers for seismic isolation of structures. Math. Probl. Eng. 2013, 1–7 (2013). https://doi.org/10.1155/2013/251935

Ahamed, T.I.; Sundarrajan, R.; Prasaath, G.T.; Raviraj, V.: Implementation of magnetorheological dampers in bumpers of automobiles for reducing impacts during accidents. Procedia Eng. 97, 1220–1226 (2014)

Siginer, D.A.; Letelier, M.F.; Stockle, J.: A new approach to the modeling of magnetorheological dampers and application to resonance control. J. Fluids Eng. ASME 143(091504), 1–8 (2021)

Orecny, M.; Segla, S.; Hunady, R.; Ferkova, Z.: Application of a magnetorheological damper and a dynamic absorber for a suspension of a working machine seat. Procedia Eng. 96, 338–344 (2014)

Parlak, Z.; Engin, T.: Optimal magnetorheological damper configuration using the taguchi experimental design method. J. Mech. Des. Trans. ASME 135(8), 1–9 (2013)

Dutta, S.; Chakraborty, G.: Modeling and characterization of a magnetorheological fluid-based damper and analysis of vibration isolation with the damper operating in passive mode. J. Sound Vib. 353, 96–118 (2015)

Weber, F.; Distl, H.; Fischer, S.; Braun, C.: MR damper controlled vibration absorber for enhanced mitigation of harmonic vibrations. Actuators 5(27), 1–28 (2016)

Christie, M.D.; Sun, S.; Deng, L.; Ning, D.; Du, H.; Zhang, S.; Li, W.: The variable resonance magnetorheological pendulum tuned mass damper: mathematical modelling and seismic experimental studies. J. Intell. Mater. Syst. Struct. 31, 263–276 (2019)

Yuan, R.; Yang, Y.; Chao, Su.; Shaopei, Hu.; Zhang, H.; Cao, E.: Research on vibration reduction control based on reinforcement learning. Hindawi Adv. Civ. Eng. 2021, 1–18 (2021)

Lenggana, B.W.; Ubaidillah, U.; Imaduddin, F.; Choi, S.-B.: Review of magnetorheological damping systems on a seismic building. Syst. Seism. Build. Appl. Sci. 11(9339), 1–28 (2021)

Shiao, Y.; Kuo, W.H.; Nguyen, Q.A.; Lai, C.W.: Development of a variable-damping magnetorheological damper with multiple poles. J. Vibroeng. 17(3), 1071–1078 (2015)

Luong, Q.V.; Jang, D.S.; Hwang, J.H.: Semi-active control for a helicopter with multiple landing gears equipped with magnetorheological dampers. Appl. Sci. MDPI 11(8), 1–18 (2021)

Yang, Bo.; Zhang, Ao.; Bai, Y.; Zhang, K.; Li, He.: Development and simulation of magnetorheological damper for segment erector vibration control. Trans. Can. Soc. Mech. Engineering 43, 237–247 (2019)

Parlak, Z.; Engin, T.; Çallı, I.: Optimal design of MR damper via finite element analyses of fluid dynamic and magnetic field. Mechatronics 22(6), 890–903 (2012). https://doi.org/10.1016/j.mechatronics.2012.05.007

Margolis, D.L.: The response of active and semi-active suspensions to realistic feedback signals. Veh. Syst. Dyn. 11, 267–282 (1982)

Decarlo, R.A.; Zak, S.H.; Matthews, G.P.: Variable structure control of nonlinear multivariable systems: a tutorial. Proc. IEEE 76(3), 212–232 (1988)

Kasemi, B.; Muthalif, A.G.A.; Rashid, M.M.; Fathima, S.: Fuzzy-PID controller for semi-active vibration control using magnetorheological fluid damper. Procedia Eng. 41, 1221–1227 (2012)

Salem, M.H.; Anany, M.N.; EI-habrouk, M.; Rezeka, S.F.: Control of dynamic vibration absorber by magnetorehological damper. Int. Rev. Mech. Eng. (IRME) 7, 81–90 (2013)

Wani, Z.R.; Tantray, M.: Study on integrated response-based adaptive strategies for control and placement optimization of multiple magneto-rheological dampers-controlled structure under seismic excitations. J. Vib. Control 0, 1–15 (2021)

Felix-Herran, L.C.; Mehdib, D.; Ramírez-Mendoza, R.A.; de Rodríguez-Ortiz, J.; Soto, R.: H2 control of a one-quarter semi-active ground vehicle suspension. J. Appl. Res. Technol. 14, 173–183 (2016)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interests or personal relationships.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumbhar, M.B., Desavale, R.G. & Kumbhar, S.G. Dynamic Characterization of MR Fluid-Based Dynamic Vibration Absorber. Arab J Sci Eng 48, 11363–11377 (2023). https://doi.org/10.1007/s13369-022-07410-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07410-3